Optimizing method of phosphogypsum-based cementitious material to improve filling rate

An optimization method, a technology of phosphogypsum, applied in the fields of analysis of materials, design optimization/simulation, instruments, etc., can solve problems such as the strength of phosphogypsum-based cementitious materials, environmental pollution, poor gelation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Embodiment: The optimization method of this phosphogypsum-based cementitious material is specifically described as follows.

[0045] 1. The activator ratio optimization of early-strength phosphogypsum-based cementitious materials adopts the following steps:

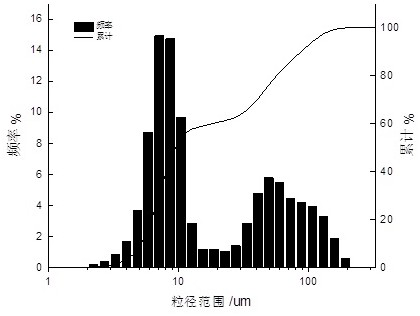

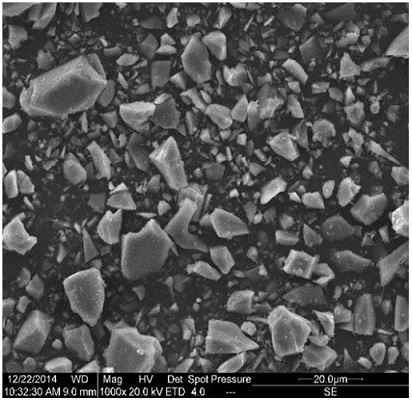

[0046] (1) Dry and grind low-quality phosphogypsum solid waste, and conduct physical and chemical analysis and particle size testing. The results of mineral composition analysis of phosphogypsum are shown in Table 1, and the particle size gradation distribution curve is shown in Table 1. figure 1 , the microscopic surface morphology of phosphogypsum see figure 2 , see the XRD pattern of phosphogypsum image 3 .

[0047] Table 1: Analysis results of mineral composition of phosphogypsum solid waste

[0048]

[0049] (2) Grind and test the particle size of the quicklime activator to obtain the characteristic value of the particle size distribution of quicklime: d 10 =2.17μm, d 30 =4.60μm, d 60 =6.53μm, d 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com