Optimization method of all-solid-waste cementing material and mixed aggregate filling slurry

A technology of cementitious material and filling slurry, which is applied in the field of filling and mining, can solve the problems of low utilization rate of low-quality solid waste and high cost of filling cementitious materials, so as to improve the top connection rate, reduce the cost of filling and mining, and improve the stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Example 1: An example of optimal design of the proportion of all-solid waste cementitious material and mixed filling slurry prepared by synergistic excitation of steel slag and desulfurized gypsum

[0082] 1. An optimized method for the preparation of all-solid waste cementitious materials by synergistic excitation of steel slag and desulfurized gypsum

[0083] (1) Steel slag-desulfurized gypsum synergistically stimulated preparation of all-solid waste cementitious material cemented filling body strength test

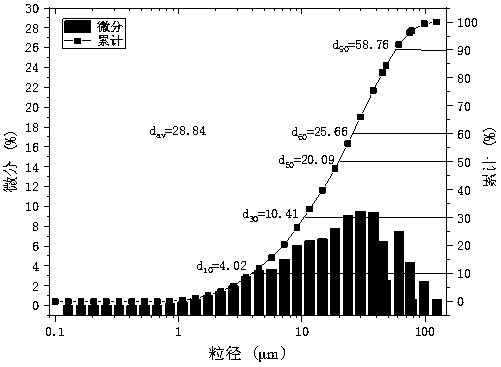

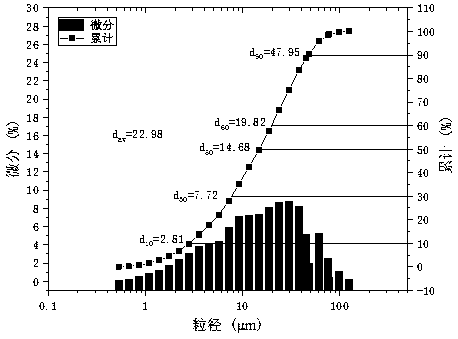

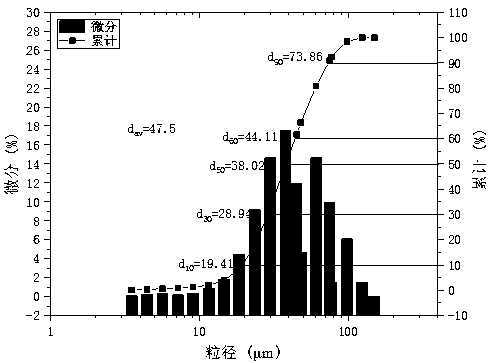

[0084] The solid waste materials are taken from a steel company in the south, and the particle size distribution curve of steel slag fine powder is shown in figure 1 , powder specific surface area 410m 2 / kg; slag powder particle size distribution curve see figure 2 , specific surface area 420m 2 / kg; the particle size distribution of desulfurized gypsum see image 3 , powder specific surface area 405m 2 / kg. The beneficiation tailings are taken from an ir...

Embodiment 2

[0140] Example 2: An example of optimal design of the proportion of all-solid waste cementitious material and mixed filling slurry prepared by synergistic excitation of steel slag-fluorine gypsum

[0141] 1. An optimized method for the preparation of all-solid waste cementitious materials by synergistic excitation of steel slag and fluorine gypsum

[0142] (1) Steel slag-fluorine gypsum synergistic excitation to prepare all-solid waste cementitious material cemented filling body strength test

[0143] The solid waste materials are taken from a steel company in the south, and the particle size distribution curve of steel slag fine powder is shown in figure 1 , the powder specific surface area is 405m 2 / kg; slag powder particle size distribution curve see figure 2 , the powder specific surface area is 425m 2 / kg; fluorine gypsum particle size distribution see Figure 4 , the powder specific surface area is 405m 2 / kg. The beneficiation tailings are taken from an iron min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com