Method for mixing and filling gangue and high-water material

A high-water material and gangue technology, which is applied in the field of mixed filling of gangue and high-water materials, can solve the problems of the impact of surface buildings, the difficulty of gangue connection to the roof, the inability to effectively control the movement of overlying rock in the goaf and the surface subsidence, etc. Strong performance, wide field applicability, and the effect of improving the topping rate and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

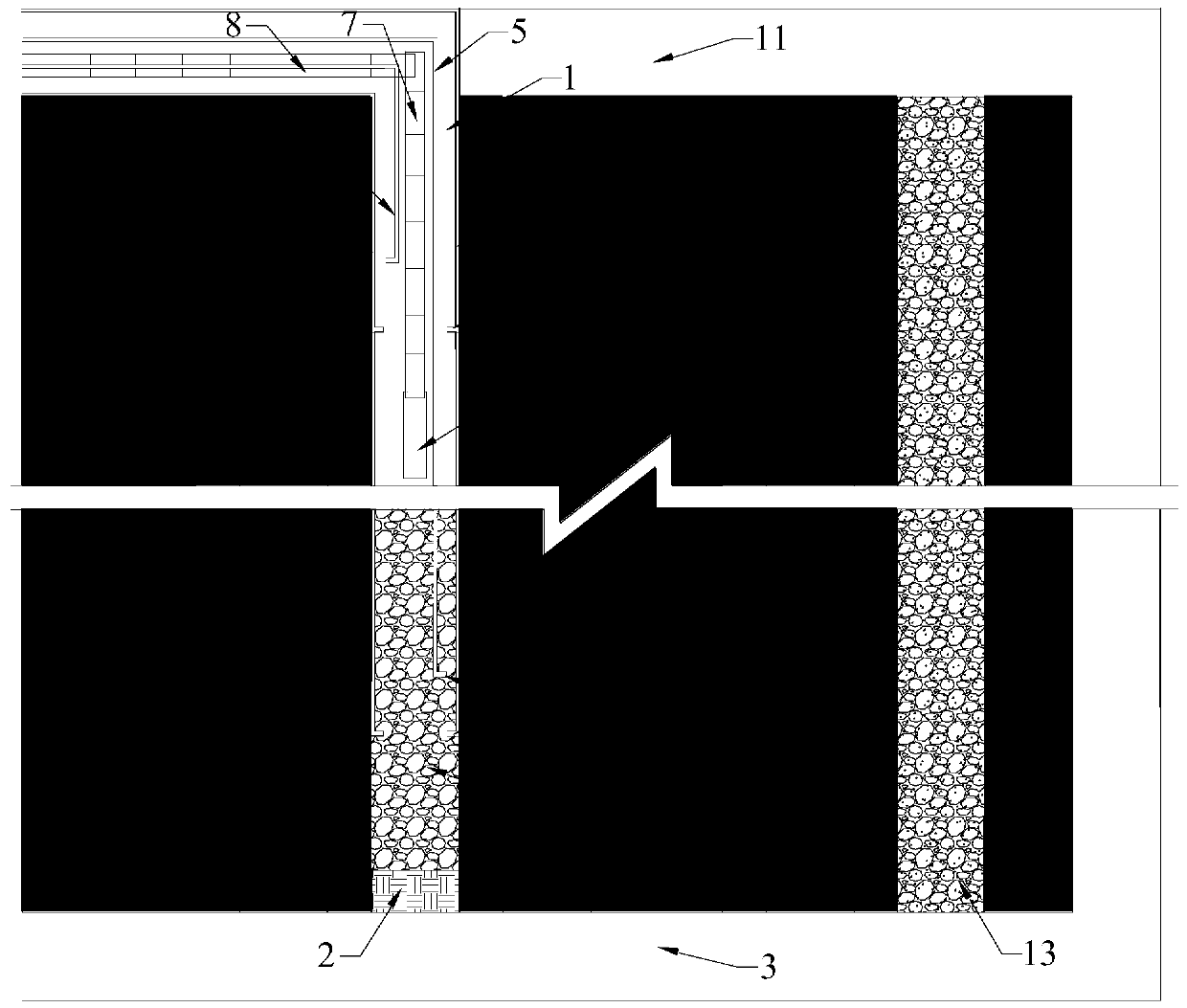

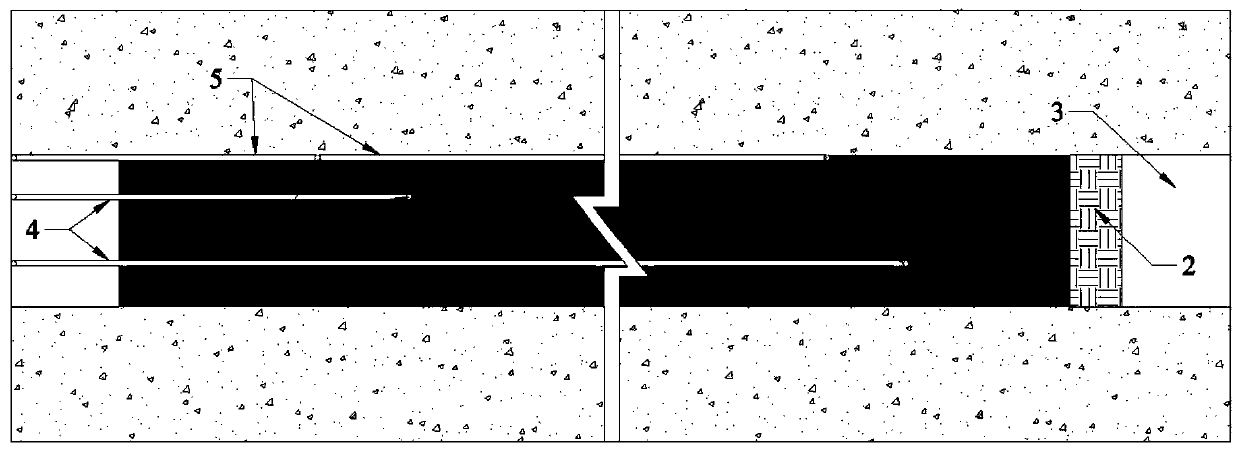

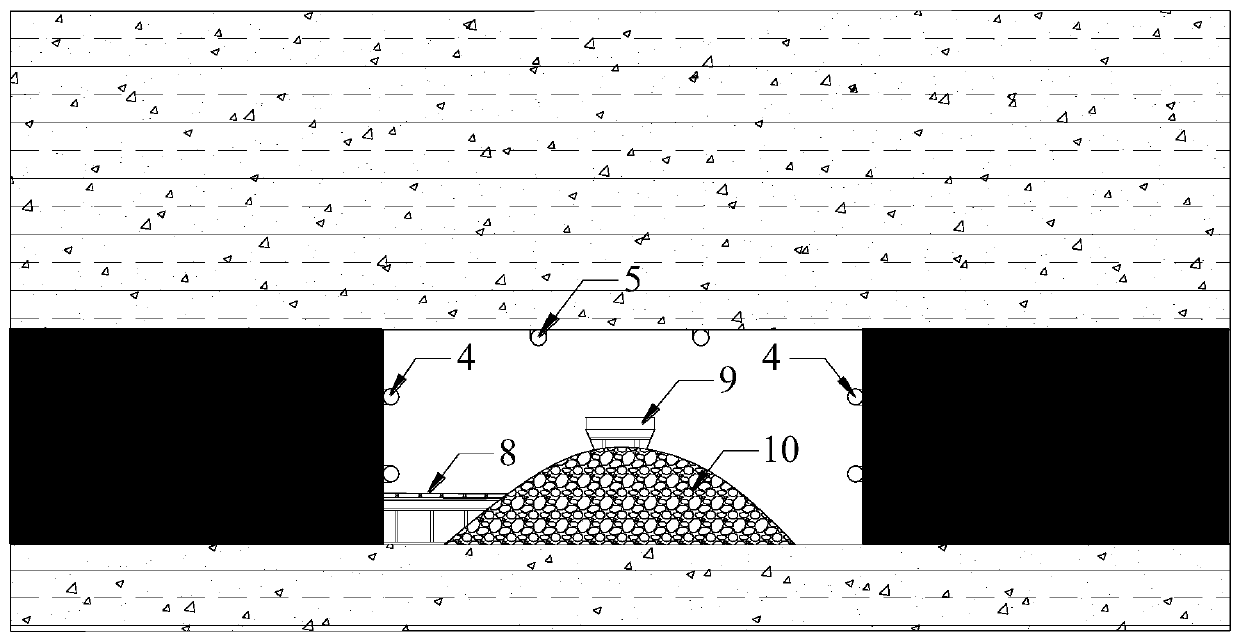

[0029] Such as figure 1 and figure 2 As shown, this method forms a complete set of longwall production system in the coal seam, and then uses roadway mining technology to mine coal to form filling contact roadway 1, and uses the method of filling high-water materials in bags to arrange high The retaining wall 2 is filled with water material, and at the same time, two banks of high-water material filling pipes 4 and the roof high-water material filling pipe 5 are pre-laid on the two sides of the filling connection lane 1 and the roof. The two banks are respectively arranged at 0.3h (h is the mining height) and 0.7h away from the floor. Two sets of high-water material filling pipes 4 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com