A method of using a segmented sealing device for strip partial filling and mining

A strip and bar technology, applied in the field of segmented sealing devices, can solve the problems of shortening the coagulation time, complex plugging procedures, and imprecise sealing, etc., so as to improve the coagulation conditions and construction environment, shorten the coagulation time, The effect of reducing filling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

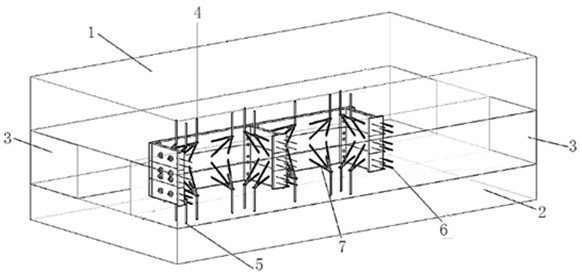

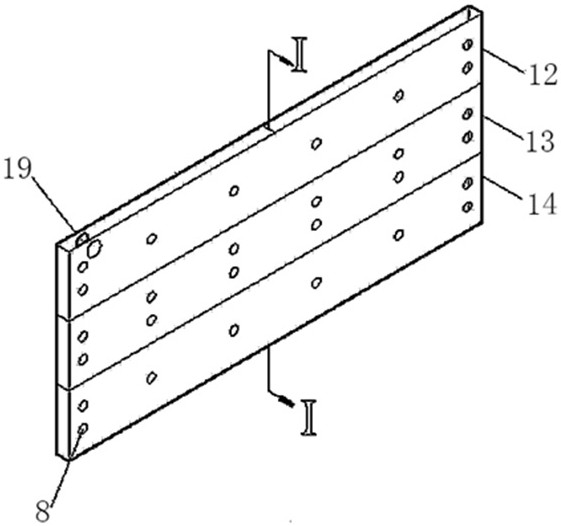

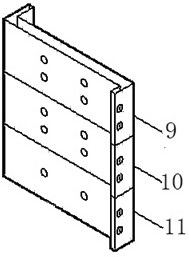

[0031] In conjunction with the accompanying drawings, the comparative invention is further described.

[0032] When filling in the tunnel formed by roof 1, base plate 2 and surrounding rock 3, first determine the position of the lower formwork 11, dig out the groove of the flange plate of the lower formwork 11 on the base plate 2, and place the lower formwork 11 on the side The side is fixed by the side anchor rod 6, and then the middle formwork 10 and the upper formwork 9 are placed and fixed in sequence; the position of the I-shaped formwork is determined according to the length of the side formwork and the position of the fixing bolt hole 8, and the lower I-shaped formwork is excavated on the bottom plate 2. Place the lower I-shaped formwork 17 in the groove of the flange plate of the formwork 17, fix it through the side anchor rod 6, and then place and fix the middle I-shaped formwork 16 and the upper I-shaped formwork 15; determine the end formwork and side formwork And t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com