Method for preparing octenyl succinic acid modified starch and application thereof

A technology of octenyl succinic acid and starch ester, applied in application, food preparation, microsphere preparation and other directions, can solve the problems of easy rupture of starch film, uneven system, slow film forming speed, etc., and achieves favorable dispersion and dissolution. , good safety, the effect of increasing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 Preparation method example

[0042] Materials: The test material is commercially available rice, and the chemical reagents are all analytically pure and obtained from commercial sources.

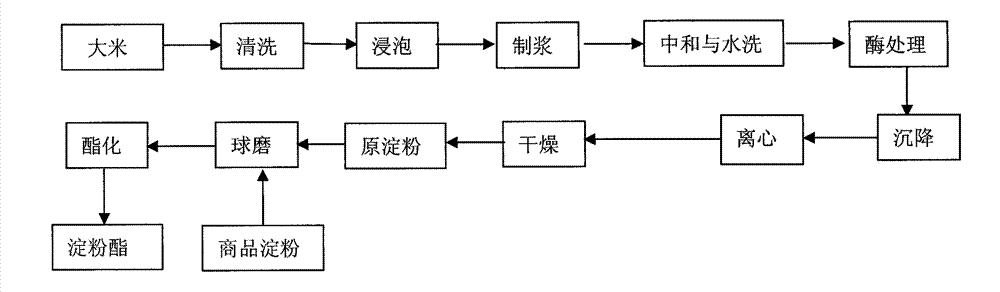

[0043] 1. Extraction process of raw starch

[0044] (1) Cleaning: Weigh 3kg of raw rice and put it into a 10L plastic bucket, add 3-4kg of tap water to clean the raw material three times, drain and set aside;

[0045] (2) soaking: add the rice of the solution soaking step 1) of the NaOH of 0.4% concentration for 24 hours, the weight of this NaOH solution is 3 times of raw material rice weight;

[0046] (3) Pulping: the soaked raw rice with the solution of above-mentioned NaOH is refined together, and the NaOH solution of 0.4% concentration is added while refining, and the weight of the solution of this NaOH is 6 times of the weight of the raw rice, to obtain rice starch slurry;

[0047] (4) Neutralization and washing with water: the rice starch slurry was neutralized t...

Embodiment 2

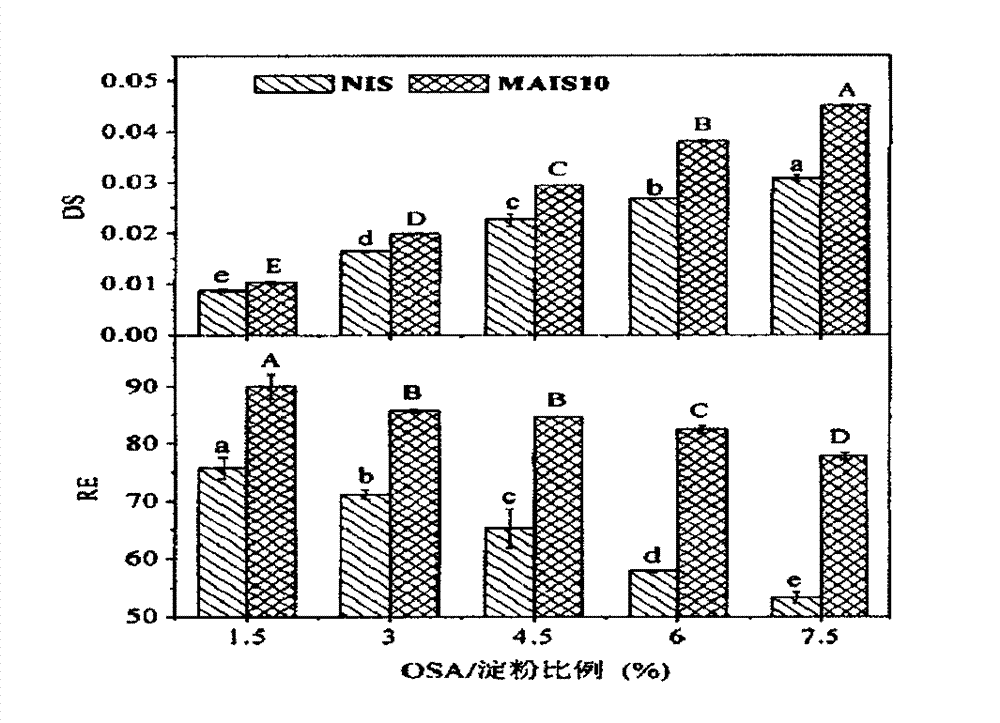

[0076] Example 2 Effect of starch type and mechanical activation mode on octenyl succinic acid starch ester DS

[0077] The octenyl starch succinate prepared by the method of Example 1.

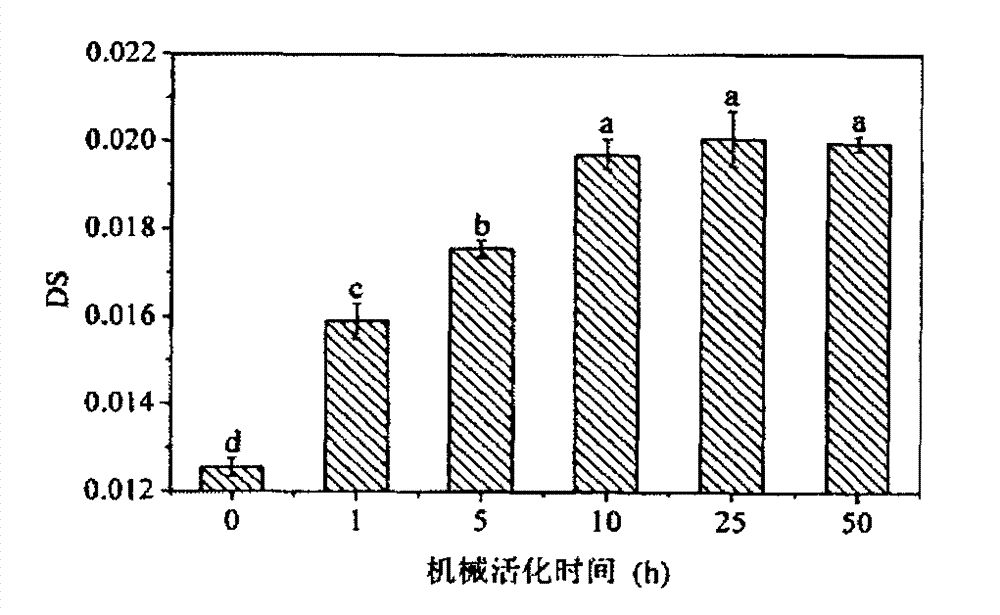

[0078] The DS values of three types of rice starches, such as indica rice starch, japonica rice starch and glutinous rice starch, which were mechanically activated first and then modified by OSA increased significantly with the prolongation of mechanical activation time, but did not change significantly after 10 hours. The DS of natural starch modified by OSA of indica rice starch is the largest, followed by that of japonica rice starch, and the minimum of glutinous rice starch. There was no significant difference, but the DS of indica rice starch was still significantly greater than that of glutinous rice starch. When the mechanical activation time was greater than 5 hours, there was no significant difference between the DS of indica rice starch and japonica rice starch OSA modified under...

Embodiment 3

[0087] The effect of the addition of embodiment 3 alkali on octenyl succinic acid starch ester DS

[0088] The octenyl starch succinate prepared by the method of Example 1.

[0089] No NaCO added 3 , the DS of starch increased from 0.00032 at 0h to 0.00968 at 100h with the extension of mechanical activation time, and the mechanical force caused the esterification reaction between octenyl succinic anhydride and starch. Add NaCO 3 After mechanical activation for 5 hours, the DS of starch can reach 0.01376. With the prolongation of mechanical activation time, DS increased, but the DS difference between mechanical activation 50h and 100h was not significant, see Table 3 for details. Therefore, the simultaneous modification of mechanical activation and OSA can cause OSA esterification without adding alkali, but adding alkaline substances can open the ring of OSA, which can be carried out by esterification.

[0090] Table 3 Effect of alkali addition on starch octenyl succinate D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com