A method for preparing nano-calcium carbonate from limestone with high magnesium content

A nano calcium carbonate, limestone technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve the problems of high purity requirements of calcium hydroxide slurry, removal of magnesium ions, large amount of ethylene glycol, etc. Achieve the effect of low oil absorption value, increase absorption rate, and increase supersaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

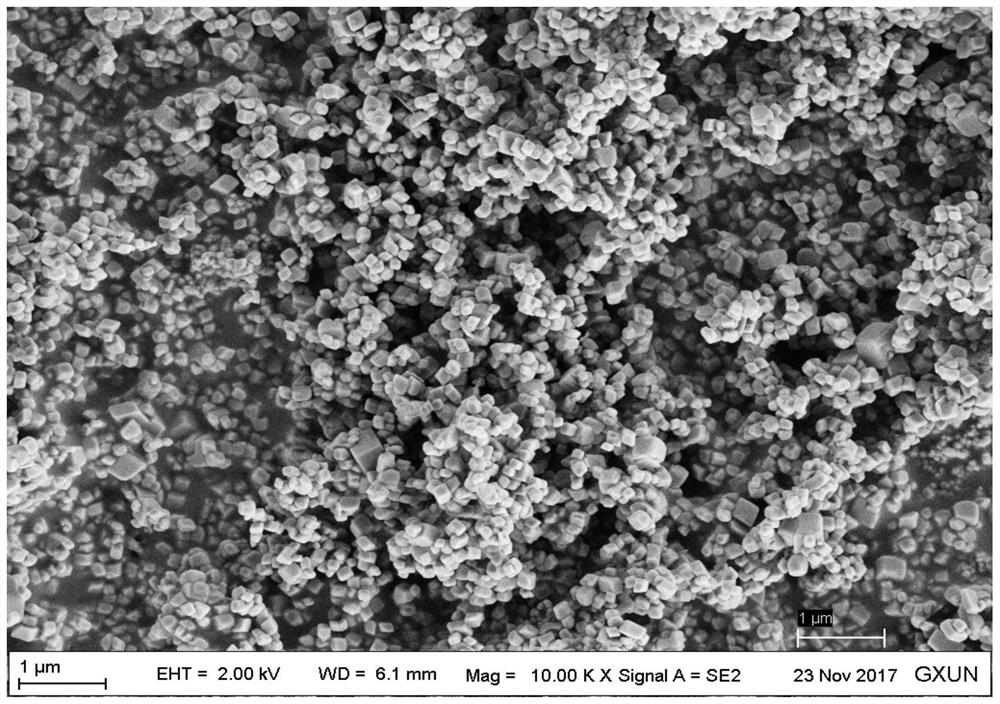

Embodiment 1

[0033] A kind of method that high magnesium content limestone prepares nano-calcium carbonate, comprises the steps:

[0034] (1) High-magnesium limestone (with a magnesium content of 4.05%) is crushed, calcined, digested, sieved and aged to obtain refined milk of lime according to conventional methods;

[0035] (2) Adjust the specific gravity of the refined milk of lime to 1.065, and introduce it into the bubbling carbonation reactor, control the reaction temperature of the milk of lime at 23°C, and feed in a concentration of 33% CO 2The carbonation reaction is carried out with the mixed gas, and sodium hydroxide and sodium polyacrylate are added after carbonization for 50 minutes. The dosages of sodium hydroxide and sodium polyacrylate are respectively 2% and 0.4% of the dry weight of calcium carbonate, and carbonated to pH=7.0, which is At the end point, calcium carbonate cooked pulp is obtained;

[0036] (3) Add 0.7% disodium EDTA to the calcium carbonate cooked pulp, keep...

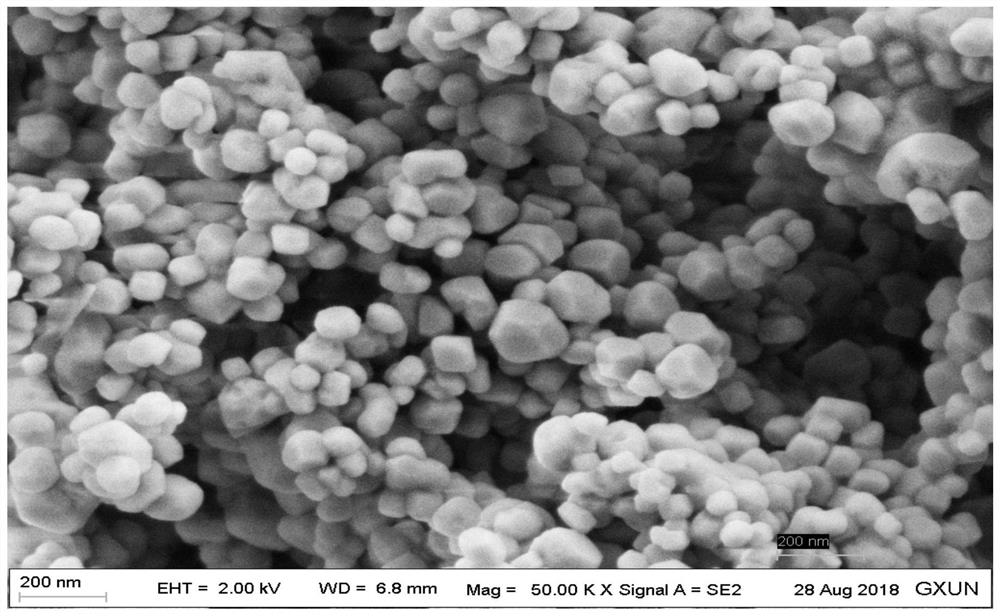

Embodiment 2

[0039] A kind of method that high magnesium content limestone prepares nano-calcium carbonate, comprises the steps:

[0040] (1) High-magnesium limestone (with a magnesium content of 2.16%) is crushed, calcined, digested, sieved and aged to obtain refined milk of lime according to conventional methods;

[0041] (2) Adjust the specific gravity of the refined milk of lime to 1.060, and introduce it into the bubbling carbonation reaction kettle, control the reaction temperature of the milk of lime at 22°C, and feed in a CO2 mixed gas with a concentration of 33% for carbonation reaction, and carbonize for 60 minutes Then add sodium hydroxide and sodium polyacrylate, the dosages of sodium hydroxide and sodium polyacrylate are respectively 1.5% and 0.5% of the dry weight of calcium carbonate, carbonation to pH=7.0 is the end point, and calcium carbonate cooked pulp is obtained;

[0042] (3) Add 0.8% disodium EDTA to the calcium carbonate cooked pulp, keep at a constant temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com