A kind of process method of cobalt plating on the surface of industrial diamond

A technology of industrial diamonds and process methods, which is applied in metal material coating process, sputtering coating, vacuum evaporation coating, etc., can solve the problem of large interface energy between cobalt film and diamond, so as to reduce the interface energy and expand the scope of application , to avoid the effect of a sharp increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

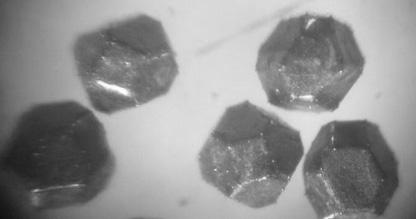

Image

Examples

Embodiment 1

[0028] Cobalt plating on industrial diamond surfaces using the following processes:

[0029] 1) Preparation of river sand: select pure white river sand, wash with water and then carry out particle size screening. The screening method refers to GB / T6406. River sand with particle size; use river sand with a particle size of 80 / 100.

[0030] 2) Preparation of adhesive: The adhesive consisted of 120g of PEG-200 and 80g of PEG-600, and the above-mentioned PEG-200 and PEG-600 were mixed uniformly to obtain 200g of adhesive.

[0031] 3) Preparation of coating powder: 82g of potassium chlorate, 67g of sodium chloride, and 22g of cobalt fluoride were ball-milled with agate balls until all passed through a 100-mesh sieve, and then 560g of cobalt powder and 1269g of river sand prepared in step 1) were added ; Then mix the above components and mill with agate ball for 30 minutes to obtain 2000g of coating powder; the particle size of the cobalt powder is 800 mesh, and the content is ≥99....

Embodiment 2

[0036] Cobalt plating on industrial diamond surfaces using the following processes:

[0037] 1) Preparation of river sand: select pure white river sand, wash with water and then carry out particle size screening. The screening method refers to GB / T6406. River sand with grain size; the grain size of river sand is 80 / 100.

[0038] 2) Preparation of adhesive: The adhesive consisted of 140g of PEG-200 and 60g of PEG-600, and the above-mentioned PEG-200 and PEG-600 were mixed uniformly to obtain 200g of adhesive.

[0039] 3) Preparation of coating powder: 79g of potassium chlorate, 65g of sodium chloride, and 29g of cobalt fluoride were ball-milled with agate balls until all passed through a 100-mesh sieve, and then 609g of cobalt powder and 1219g of river sand prepared in step 1) were added ; Then mix the above components with agate ball mill for 30 minutes to obtain 2001g of coating powder; the particle size of the cobalt powder is 800 mesh, and the content is ≥99.5%.

[0040] ...

Embodiment 3

[0044]Cobalt plating on industrial diamond surfaces using the following processes:

[0045] 1) Preparation of river sand: select pure white river sand, wash with water and then carry out particle size screening. The screening method refers to GB / T6406. River sand with particle size; use river sand with a particle size of 80 / 100.

[0046] 2) Preparation of adhesive: The adhesive consisted of 140g of PEG-200 and 60g of PEG-600, and the above-mentioned PEG-200 and PEG-600 were mixed uniformly to obtain 200g of adhesive.

[0047] 3) Preparation of coating powder: 79g of potassium chlorate, 65g of sodium chloride, and 29g of cobalt fluoride were ball-milled with agate balls until all passed through a 100-mesh sieve, and then 609g of cobalt powder and 1219g of river sand prepared in step 1) were added ; Then mix the above components with agate ball mill for 30 minutes to obtain 2001g of coating powder; the particle size of the cobalt powder is 800 mesh, and the content is ≥99.5%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com