A kind of technological method of tungsten plating on the surface of industrial diamond

A technology of industrial diamond and tungsten plating, applied in metal material coating process, sputtering coating, vacuum evaporation coating and other directions, can solve the problems of high surface tension and difficult bonding between tungsten film and industrial diamond, and achieve stable and reliable quality , the effect of prolonging life and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

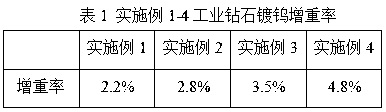

Examples

Embodiment 1

[0021] A process for plating tungsten on the surface of industrial diamonds, comprising the following steps:

[0022] 1) Preparation of adhesive: Mix 24g of PEG-200 and 16g of PEG-600 evenly to obtain 40g of adhesive.

[0023] 2) Preparation of coating powder: mix 367g of white jade corundum, 777g of tungsten powder, 6g of magnesium oxide, 24g of potassium chlorate and 26g of sodium chloride and ball mill for 30 minutes to obtain 1200g of coating powder; the particle size of white jade corundum is W28, the particle size of the magnesium oxide, sodium chloride and potassium chlorate is less than 200 mesh.

[0024] 3) Plating formula mix: first add the adhesive obtained in step 1) to 10,000 carats of industrial diamonds and mix well, then add the coating powder obtained in step 2), and mix thoroughly to obtain the coating formula mix material.

[0025] 4) Evaporation: Put the coating formula mixture obtained in step 3) in the vacuum evaporation chamber, and vacuum the vacuum e...

Embodiment 2

[0028] A process for plating tungsten on the surface of industrial diamonds, comprising the following steps:

[0029] 1) Preparation of adhesive: Mix 30g of PEG-200 and 20g of PEG-600 evenly to obtain 60g of adhesive.

[0030] 2) Preparation of coating powder: mix 366g of white jade corundum, 776g of tungsten powder, 9g of magnesium oxide, 24g of potassium chlorate and 26g of sodium chloride and ball mill for 30 minutes to obtain 1201g of coating powder; the particle size of white jade corundum is W28, the particle size of the magnesium oxide, sodium chloride and potassium chlorate is less than 100 mesh.

[0031] 3) Plating formula mixing: Add the binder obtained in step 1) to 10,000 carats of industrial diamonds and mix well, then add 1000g of coating powder obtained in step 2), and mix well to obtain the coating formula mix.

[0032] 4) Evaporation: Put the coating formula mixture obtained in step 3) in the vacuum evaporation chamber, and vacuum the vacuum evaporation cham...

Embodiment 3

[0035] A process for plating tungsten on the surface of industrial diamonds, comprising the following steps:

[0036] 1) Preparation of adhesive: Mix 49g of PEG-200 and 21g of PEG-600 evenly to obtain 70g of adhesive.

[0037] 2) Preparation of coating powder: mix 491g of white jade corundum, 1404g of tungsten powder, 14g of magnesium oxide, 49g of potassium chlorate and 42g of sodium chloride and ball mill for 30 minutes to obtain 2000g of coating powder; the particle size of white jade corundum is W28, the particle size of the magnesium oxide, sodium chloride and potassium chlorate is less than 200 mesh.

[0038] 3) Plating formula mix: first add the binder obtained in step 1) to 10,000 carats of industrial diamonds and mix well, then add the coating powder obtained in step 2), and mix thoroughly to obtain the coating formula mix material.

[0039] 4) Evaporation: Put the coating formula mixture obtained in step 3) in the vacuum evaporation chamber, and vacuum the vacuum e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com