Highly fluorinated nanostructured polymer foams for producing super-repellent surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

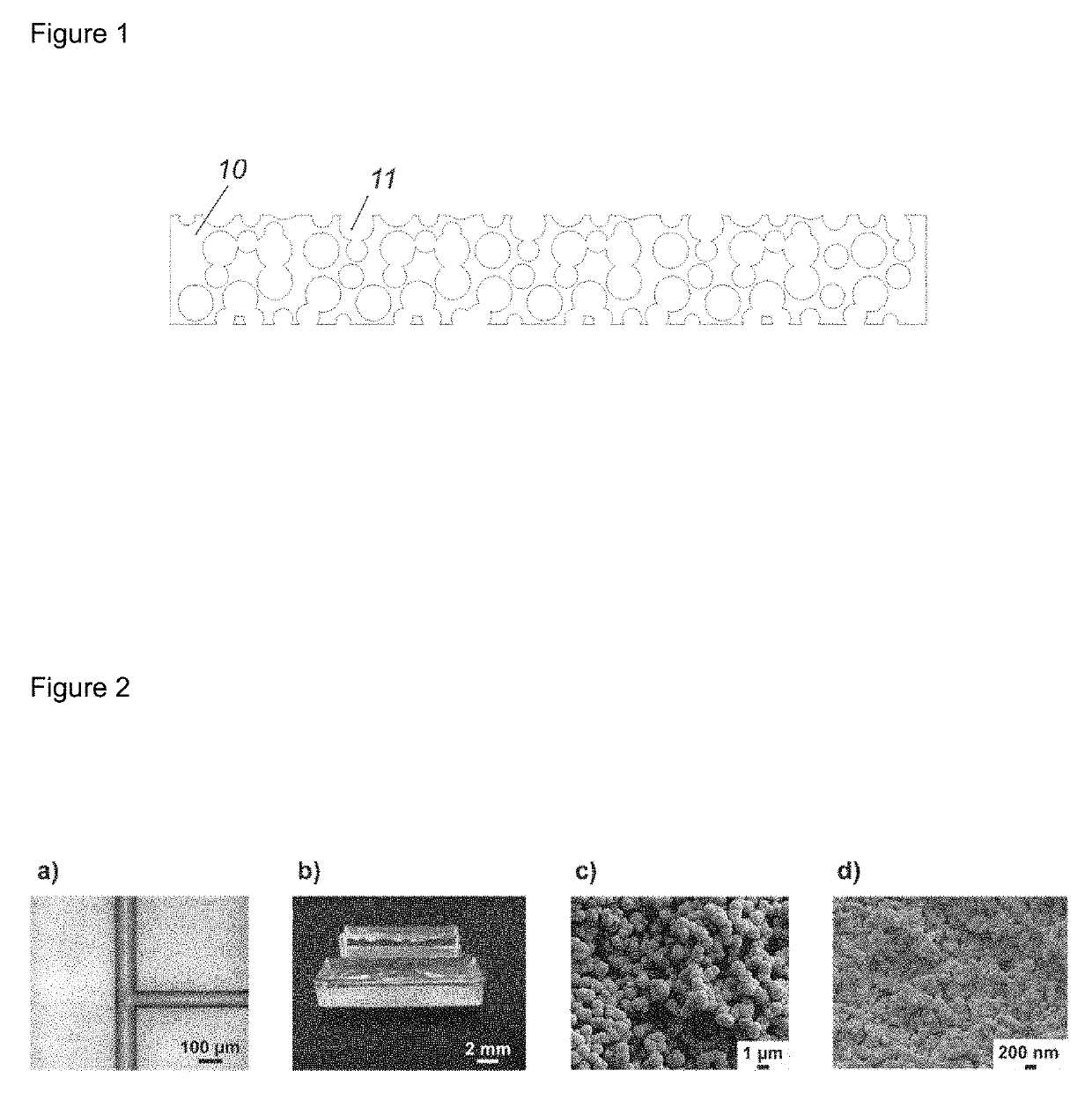

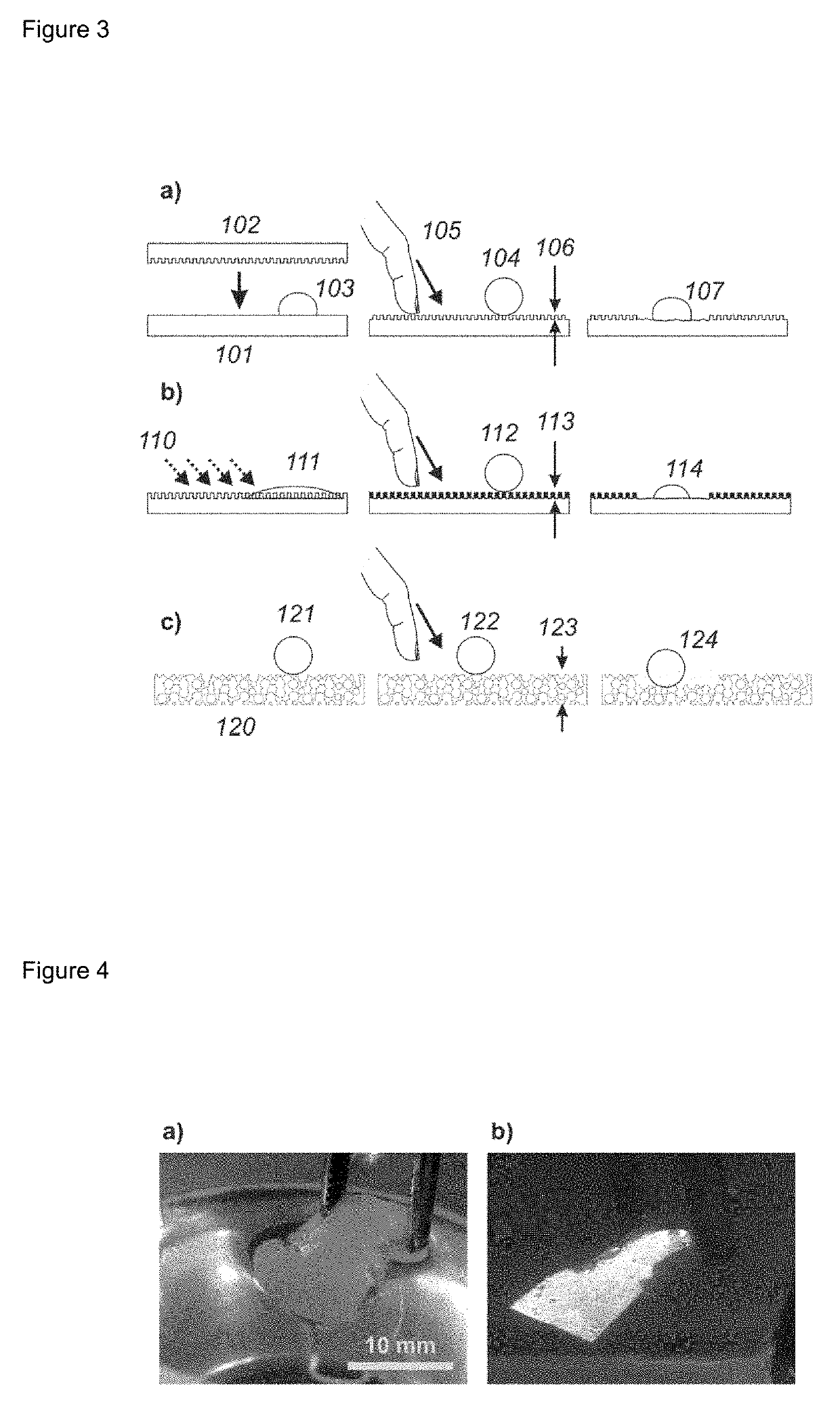

Image

Examples

example 1

[0091]0.214 mmol of a commercially available diacrylate derivative (Fluorolink MD 700) were mixed with 0.243 mmol 1H,1H,2H,2H perfluorooctanol, 0.449 mmol cyclohexanol and 0.006 mmol 2,2-dimethoxy-2-phenylacetophenone. The composition was cured under UV light (370 nm) for a duration of 2 min. The polymer foam obtained in this manner was dipped in isopropanol for 16 hours and then dried in an oven for 80° C. for one hour.

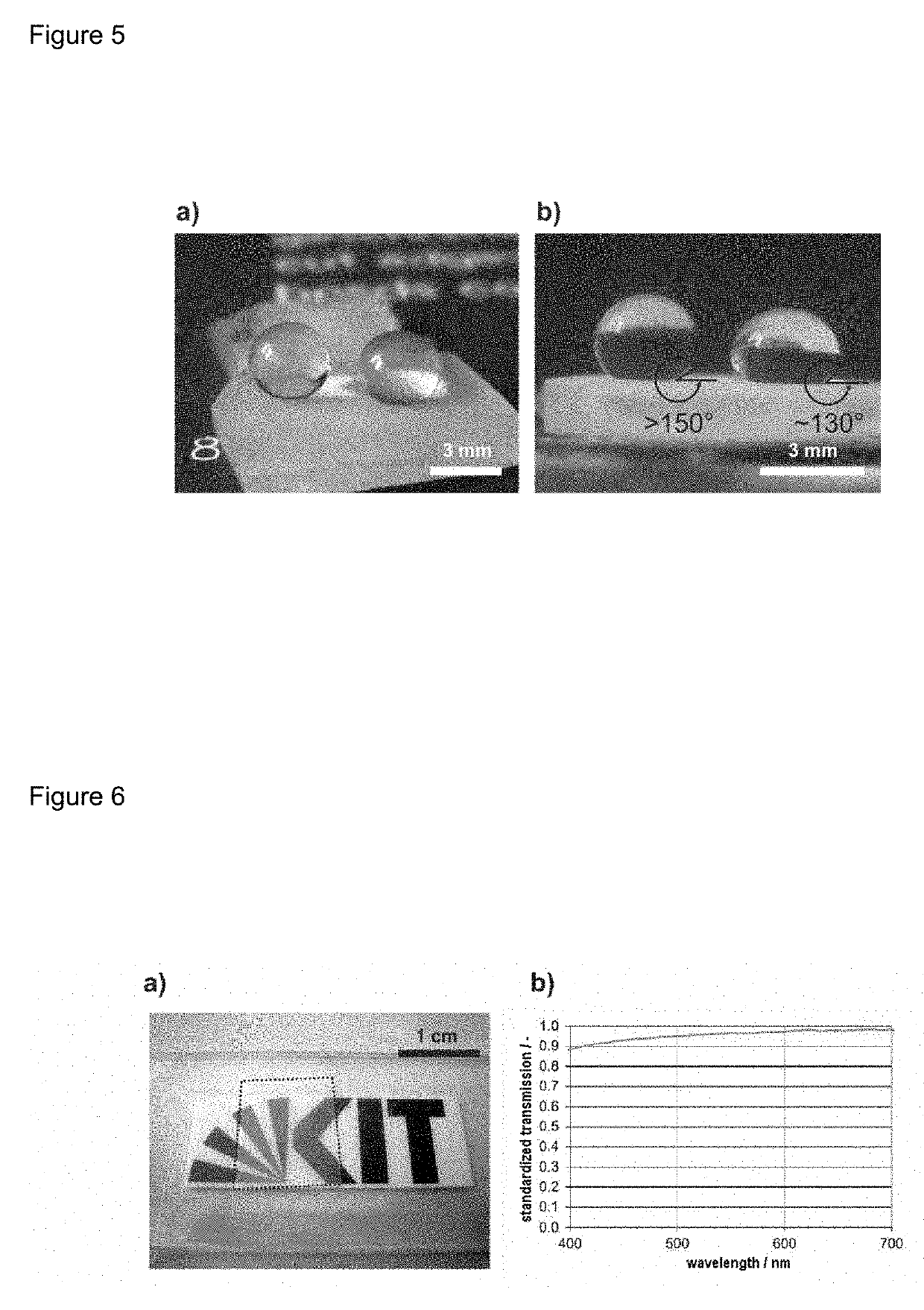

[0092]The polymer foam was super-hydrophobic, transparent with a slight turbidity and had a contact angle of 138° for dimethyl sulfoxide. Furthermore, the polymer foam between 400 and 800 nm had an optical transmission of 58.2% to 91.9% at a thickness of 0.25 mm.

[0093]As a reference, the non-porous form of the polymer foam had a free surface energy of 17.4 mN / m at a density of 1.692 g / mL (+ / −0.112 g / mL, three measurements). In contrast, the porous form of the polymer foam had a free surface energy of 2.939 mN / m at a density of 1.660 g / mL (+ / −0.030 g / mL, three measure...

example 2

[0095]A monomer mixture, consisting of 1.520 mmol of 2,2,3,3,4,4,5,5,6,6,7,7,8,8,8-pentadecafluorooctylmethacrylate and 0.787 mmol of 2,2,3,3,4,4,5,5-octafluorohexyldimethacrylate was mixed with 1.299 mmol of cyclohexanol, 2.049 mmol of 1H,1H,2H,2H-perfluorooctanol, 0.086 mmol of 2,2-dimethoxy-2-phenylacetophenone and 0.681 mmol of acetone. The composition was cured under UV light (220 to 400 nm) for a duration of 5 min. The polymer foam obtained in this manner was dipped in isopropanol for one hour and then dried in an oven at 80° C. for one hour.

[0096]The polymer foam was super-hydrophobic, optically clear and had a contact angle of 102° for dimethyl sulfoxide. Furthermore, the polymer foam between 400 and 800 nm had an optical transmission of 79.9% to 91.4% at a thickness of 0.25 mm.

[0097]As a reference, the non-porous form of the polymer foam had a free surface energy of 17.47 mN / m at a density of 1.654 g / mL (+ / −0.058 g / mL, three measurements). In contrast, the porous form of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com