Flexible ceramic-like tile and production process thereof

A production process and imitation ceramic technology, which is applied in the field of brick decoration materials, can solve the problems of difficult scale industry, poor anti-sticking ability, high material cost, etc., and achieve self-strength enhancement, improved crack resistance, and high anti-pollution performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1: Preparation of flexible imitation ceramic tile (1)

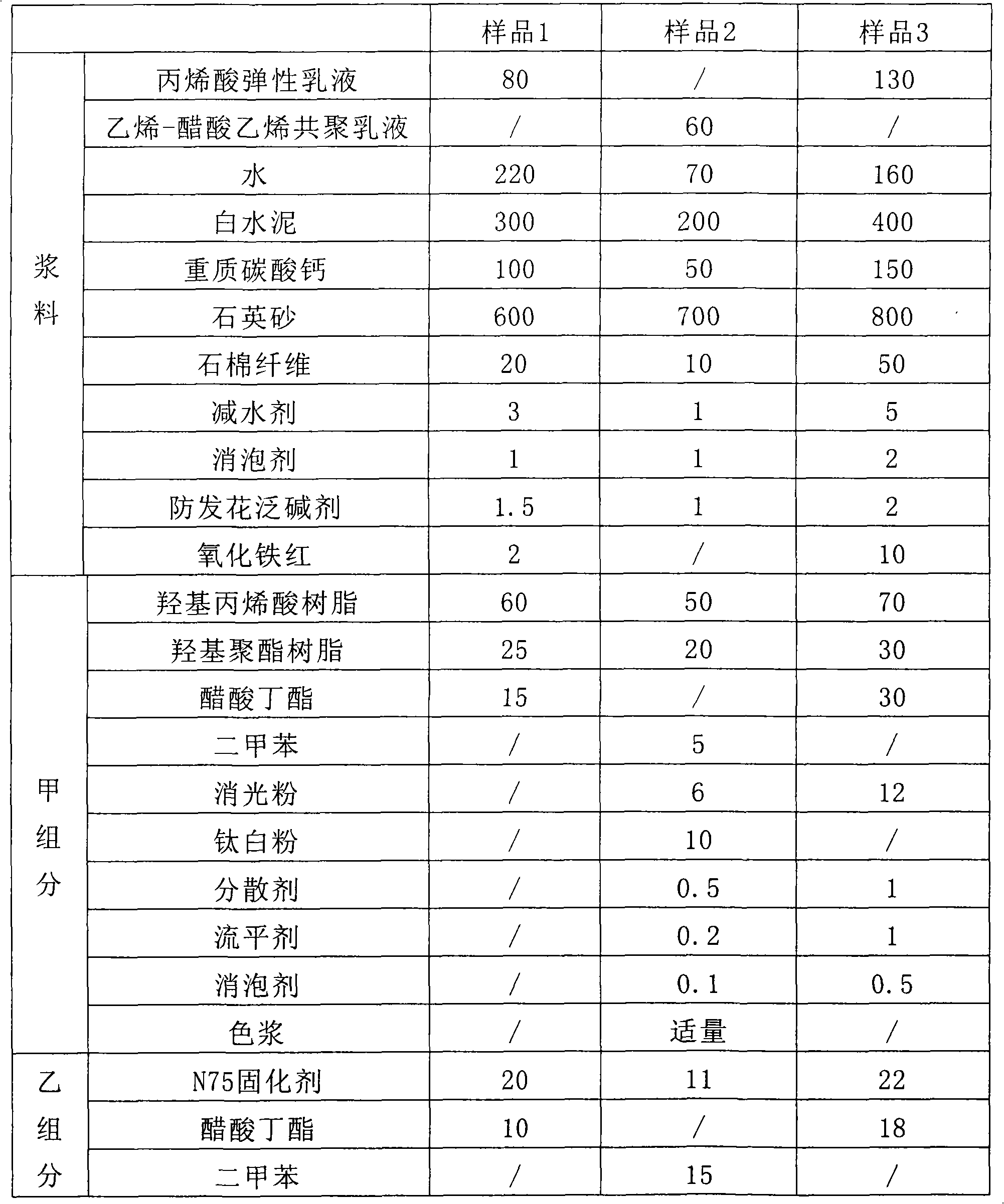

[0081] 1. Raw material

[0082] (1) Slurry

[0083] Acrylic elastic emulsion (National Starch Factory, trade name 604)

[0084] Or ethylene-vinyl acetate copolymer emulsion (Beijing Organic Chemical Factory, trade name BJ-707)

[0085] water

[0086] White cement (P.O.42.5R)

[0087] Ground calcium carbonate (200 mesh)

[0088] Quartz sand (20-120 mesh)

[0090] Water reducer (trade name UNF-5)

[0091] Defoamer (trade name NXZ)

[0092] Anti-blooming Erythrothenic Agent (trade name ERA-100)

[0093] Iron Oxide Red

[0094] (2) The glaze material is a mixture of the following components A and B:

[0095] A component:

[0096] Hydroxy acrylic resin (Tianjin Guofeng trade name 823-60)

[0097] Hydroxy polyester resin (trade name 3043)

[0098] Solvent (butyl acetate or xylene)

[0099] Matting powder (fumed silica)

[0100] Titanium dioxide (U.S. DuPont, R-902)

[0...

Embodiment 2

[0119] Embodiment 2: Preparation of flexible imitation ceramic tile (two)

[0120] 1. Raw material

[0121] (1) Substrate

[0122] Polyurethane resin (trade name SW-3000)

[0123] water

[0124] DMF

[0125] White cement (P.O.42.5R)

[0126] Ground calcium carbonate (200 mesh)

[0127] Quartz sand (20-120 mesh)

[0128] Wood fiber (polyester non-woven fabric)

[0129] Surfactant (trade name OT-70, DS-80)

[0130] Defoamer (trade name HX-3010)

[0131] Anti-blooming Erythrothenic Agent (trade name ERA-100)

[0132] Iron Oxide Toner

[0133] (2) The glaze material is the same as in Example 1.

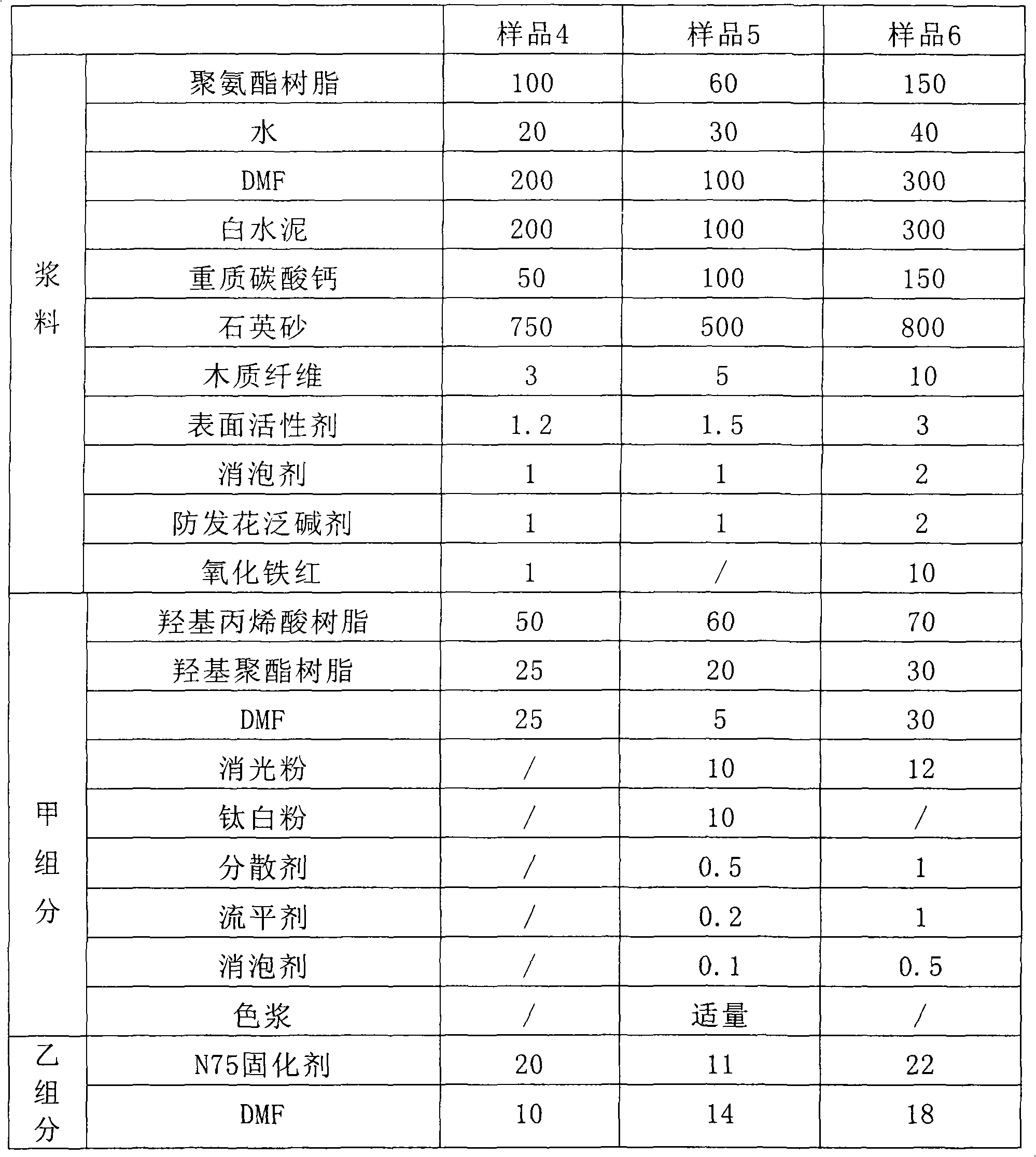

[0134] 2. The ratio of each raw material component, by weight ratio:

[0135] Table 2

[0136]

[0137] 3. Production process of flexible imitation ceramic tiles:

[0138] Step 1: Put all the materials of the substrate slurry into the mixer and stir evenly.

[0139] Step 2: Select a wet process line, scrape the stirred substrate slurry on 45g of polyester non-woven fabri...

Embodiment 3

[0143] Embodiment 3. product performance measurement

[0144] According to the application characteristics of the product of the present invention, the enterprise standard (as shown in Table 3) of the flexible imitation ceramic face brick has been formulated, and the main technical indicators of this standard are based on: JG149-2003 "Expanded Polystyrene Board Thin Plastering Exterior Wall External Thermal Insulation System" ", JG / T24-2000 "Synthetic Resin Emulsion Sand Wall Coating", JG / T26-2002 "National Standard for Inorganic Exterior Architectural Coatings", GB / T4100-2006 "Ceramic Tiles", JC / 547-2005 "Ceramic Wall and Floor Tiles adhesive".

[0145] table 3

[0146] project

[0147] According to this standard, the actual detection indicators of samples 1-6 are shown in Table 4:

[0148] Table 4

[0149] project

[0150] Aging resistance

[0151]The above test results show that the facing tiles of the present invention have the appearance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com