A livestock organic fertilizer processing device

A processing device and organic fertilizer technology, applied in grain processing, mechanical equipment, pipeline systems, etc., can solve problems such as uncertain shape, uncertain water content, uneven sedimentation in pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

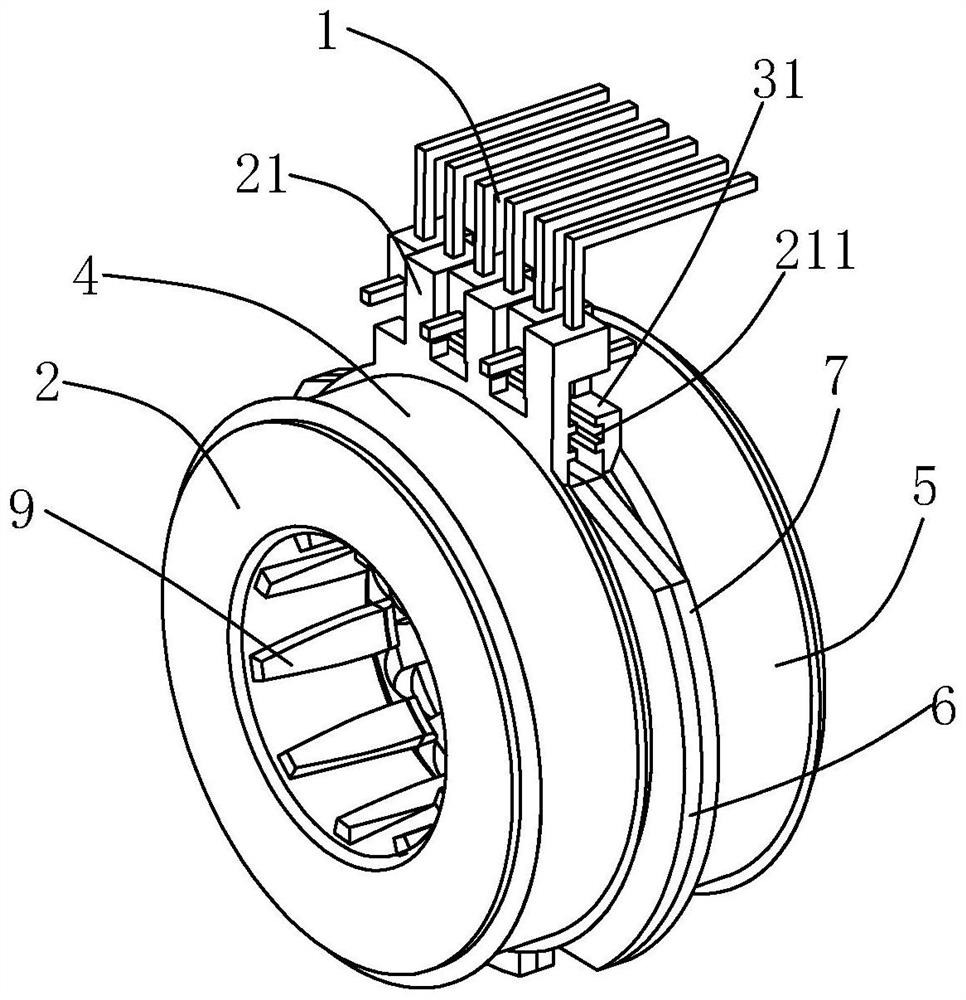

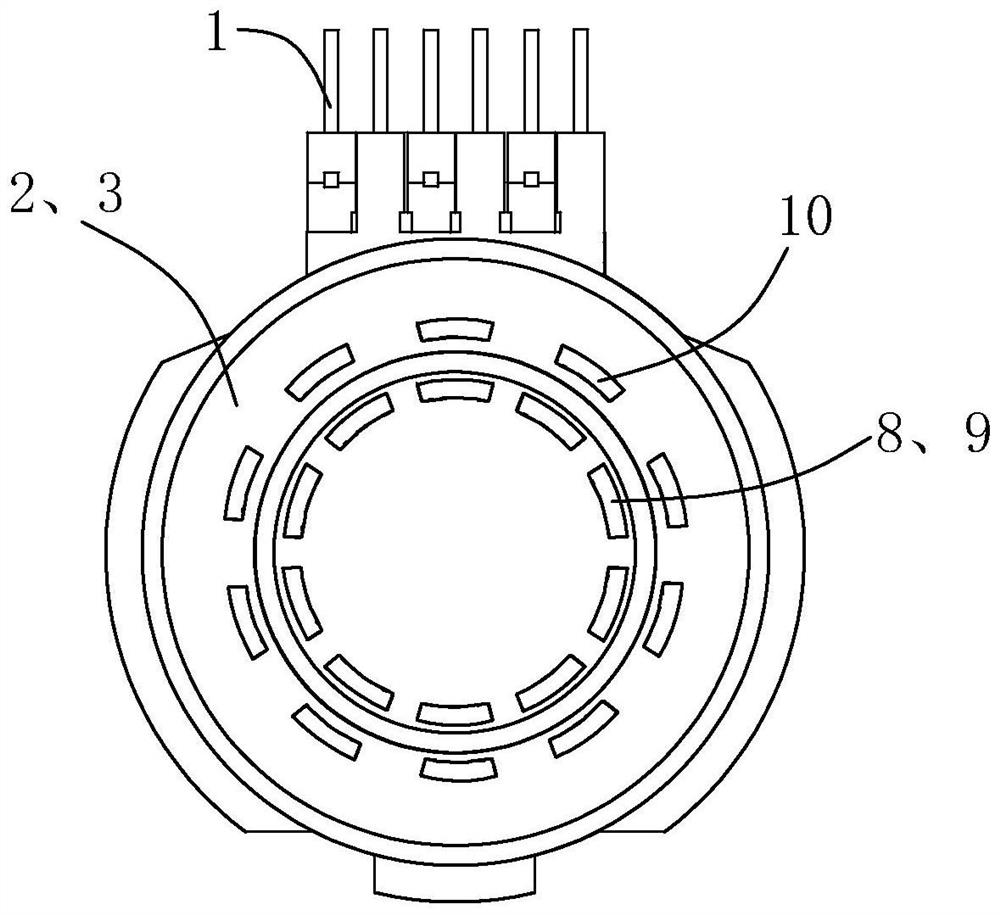

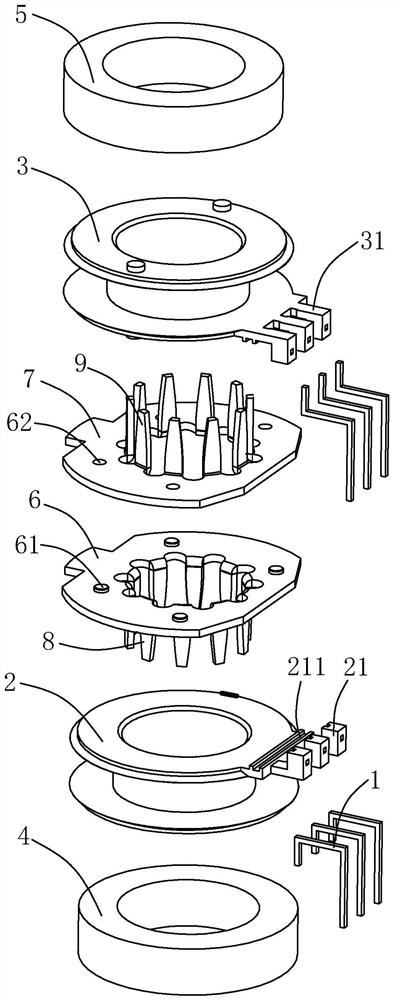

[0028] Embodiment: A livestock organic fertilizer processing device, its main structure includes: line tube group 1, first tube tube 2, first line tube frame 21, card slot 211, second tube tube 3, second line tube frame 31 , the first electromagnetic ring 4, the arc glue block 41, the second electromagnetic ring 5, the first substrate 6, the short axis screw 61, the screw hole 62, the second substrate 7, the first magnetic strip 8, the second magnetic attraction Article 9, permanent magnet block 10, electromagnetic block 11, ninety-degree bending spring tube 12, spring sheath 13, hoop piece 14, is characterized in that: the first tube frame 21 is fixed on one side of the first tube tube 2 , and the cable tube group 1 is inserted into the first tube frame 21; the second tube frame 31 is fixed on one side of the second tube tube 3, and the cable tube group 1 is inserted into the second tube frame 31; Both the first wire pipe frame 21 and the second wire pipe frame 31 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com