Damping device of a mechanical tensioning system for a traction mechanism drive

A technology of shock absorption device and traction mechanism, which is applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve problems such as high cost and increased wear, and achieve the effects of long service life, simple wear and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

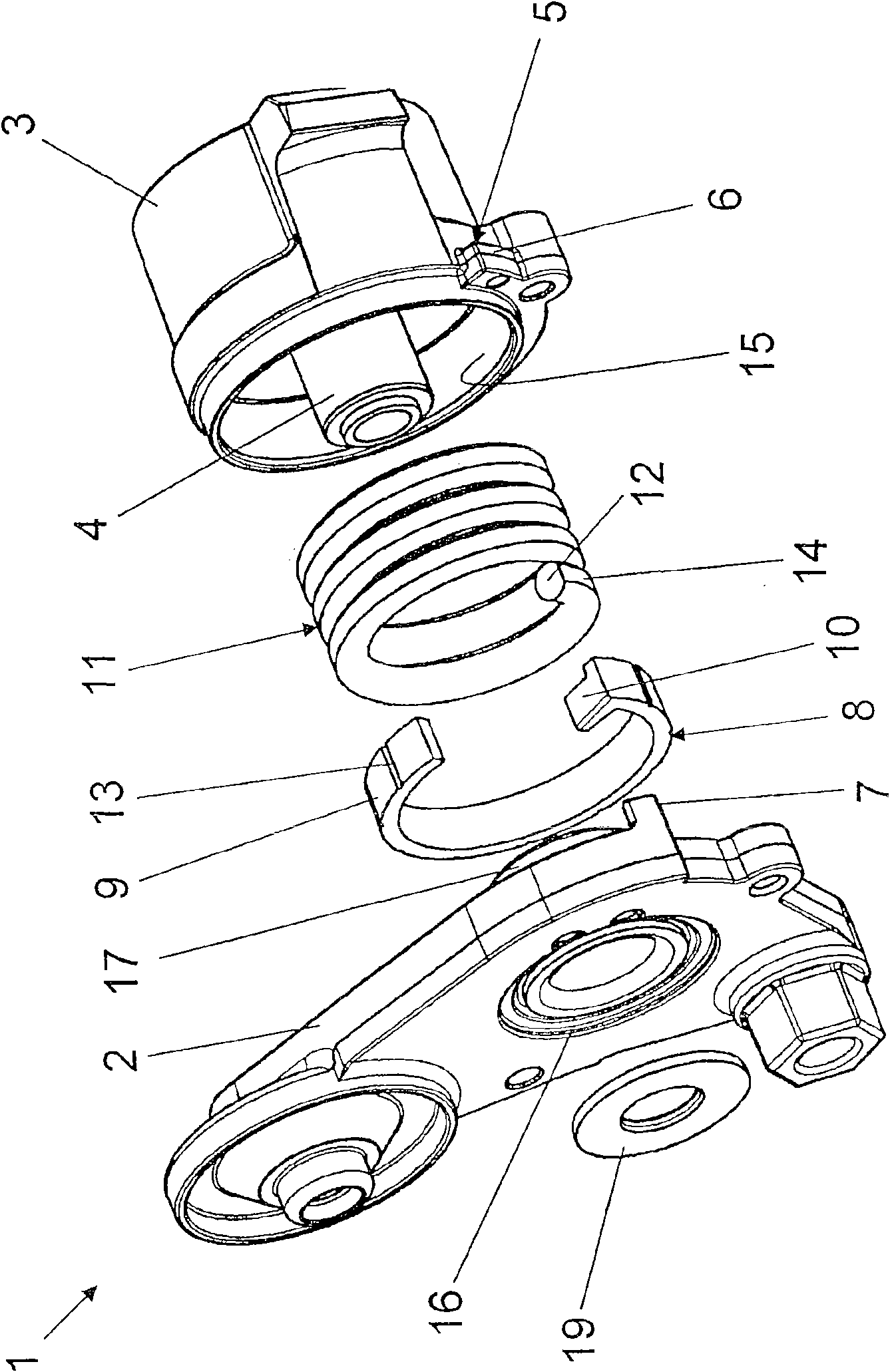

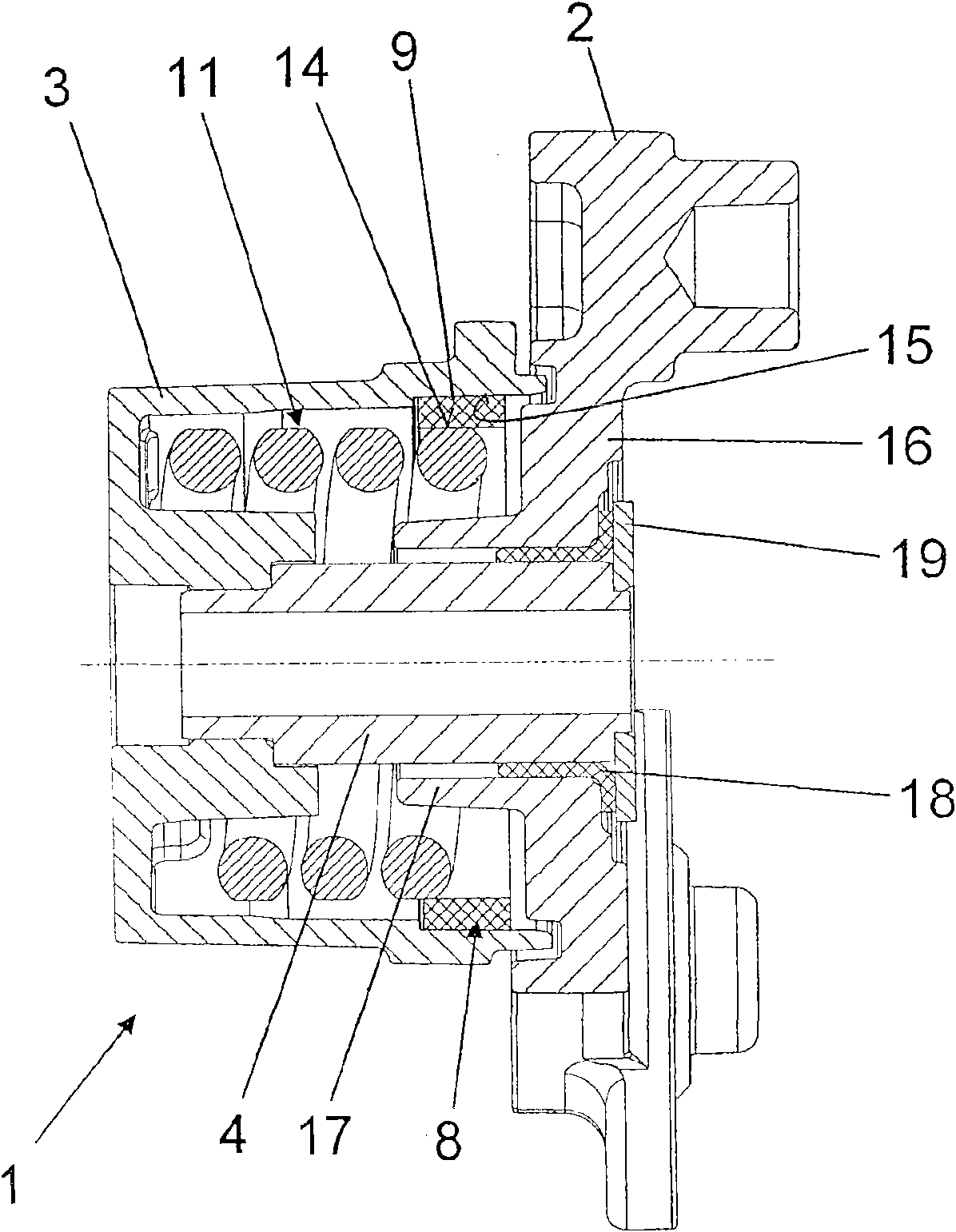

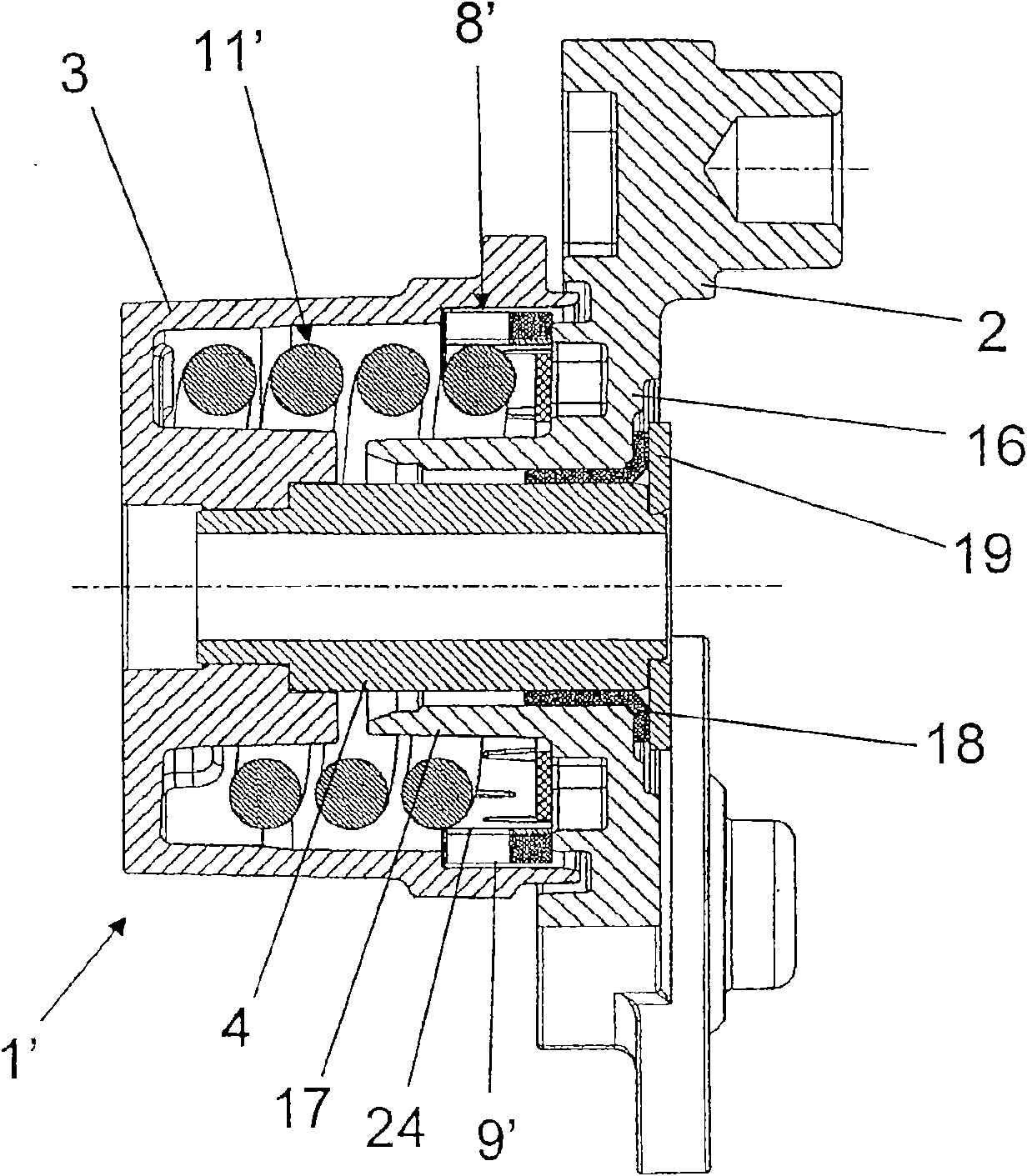

[0028] therefore, figure 1 An automatic tensioning system 1 of a traction drive drive is shown, for example for driving auxiliary assemblies on an internal combustion engine of a motor vehicle. The operating principle of such a belt tensioner is known to the skilled person. The basic structure of the tensioning system 1 basically corresponds to the applicant's patent application mentioned at the outset. Therefore, only the components essential to the invention are described in detail below.

[0029] The tensioning system 1 has a tensioning arm 2 , at one end of which a tensioning wheel (not shown) is rotatably mounted for elastic support on a traction means (for example a belt). By means of the other end, the tension arm 2 can be rotatably supported on the housing part 3 ( figure 1 , figure 2 ). For this purpose, the tensioning arm 2 has a disk hub 16 with a disk hub journal 17 protruding in the direction of the housing part 3 , which passes through the housing part 3 vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com