Patents

Literature

46results about How to "Suppress transmission loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

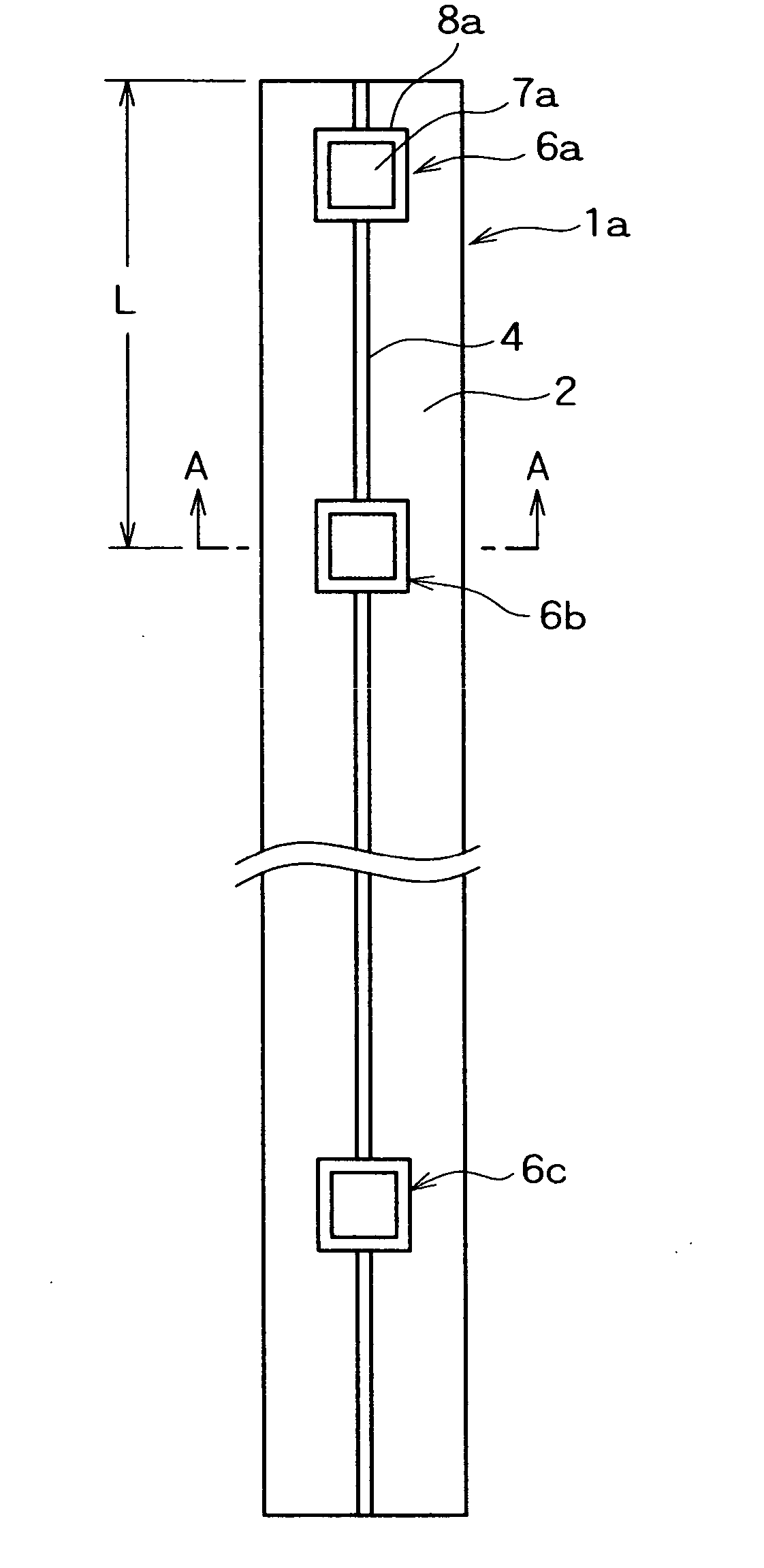

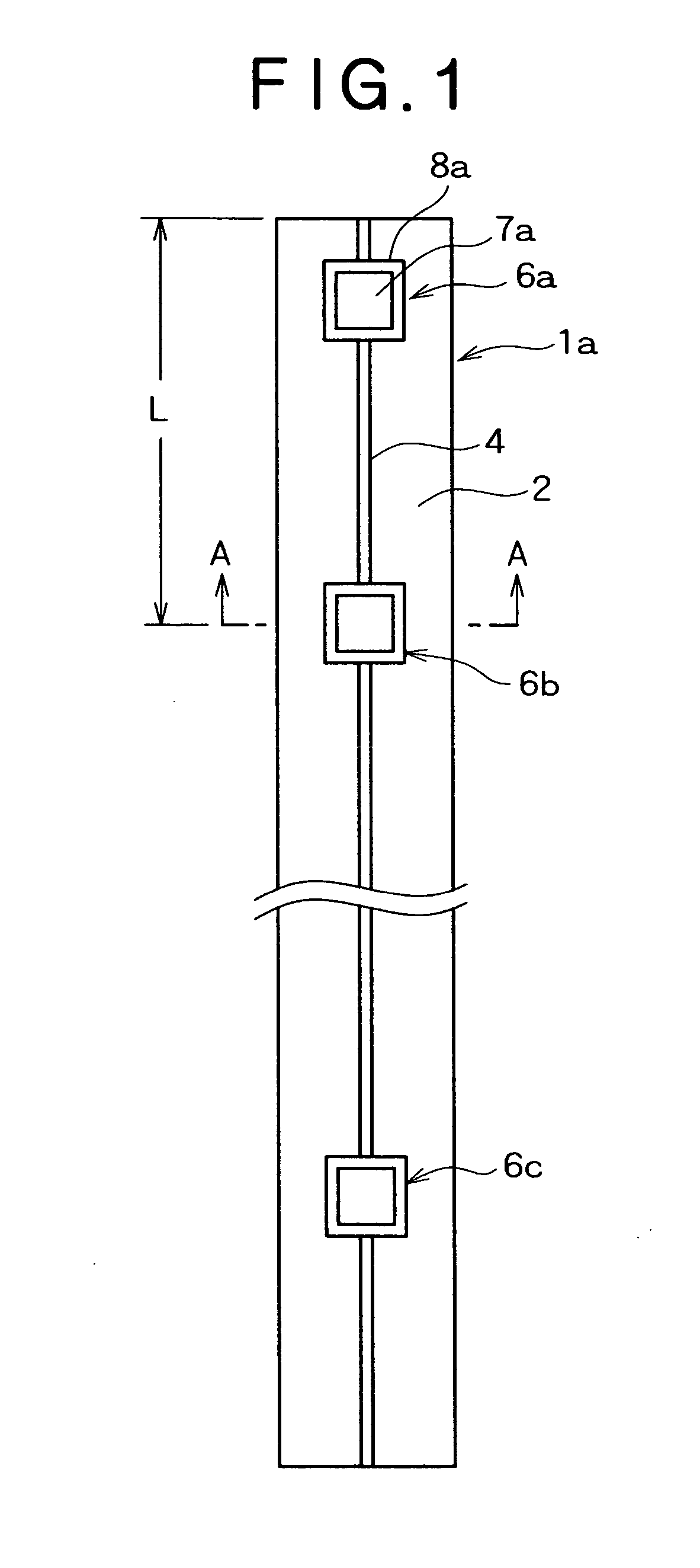

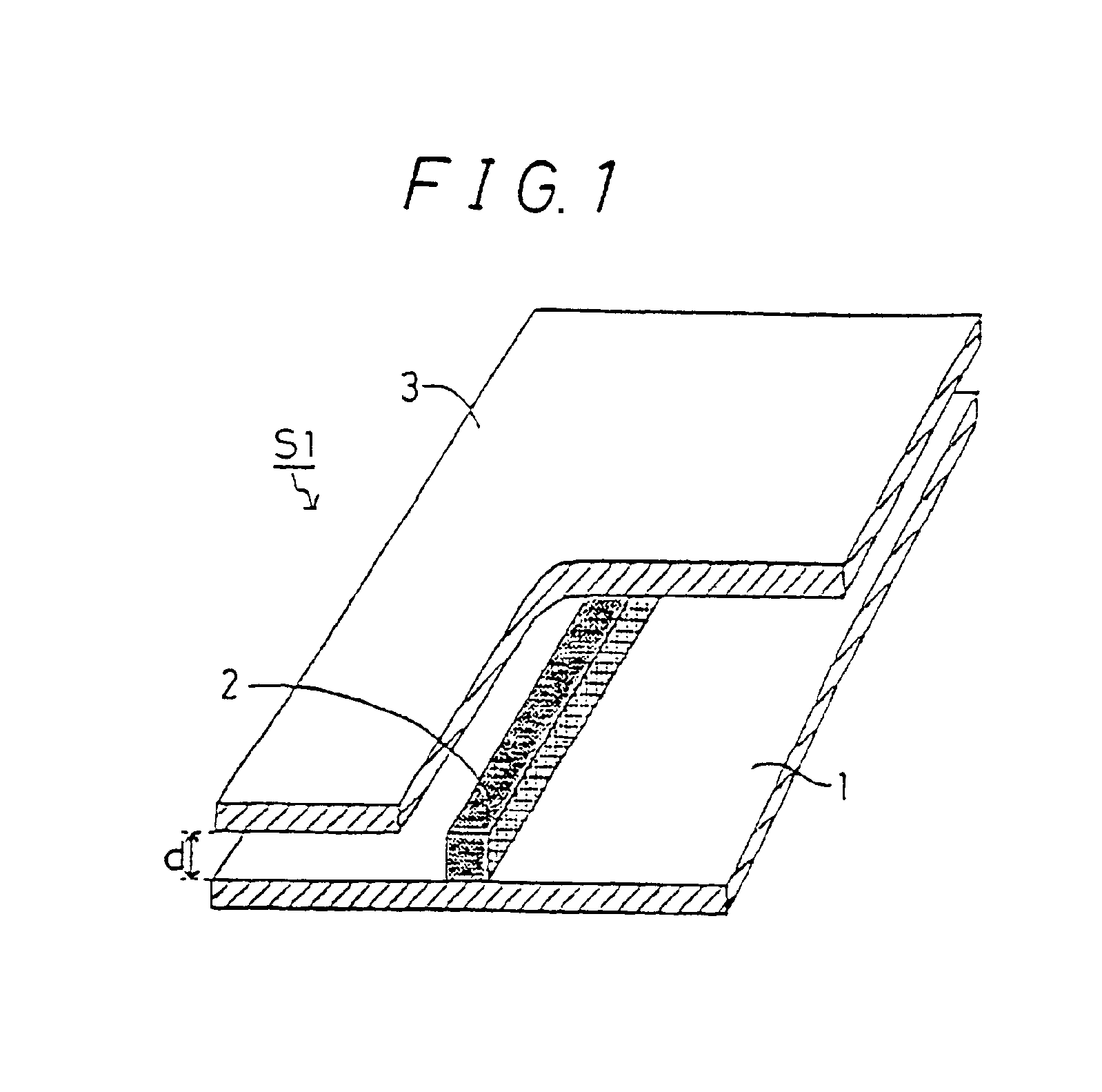

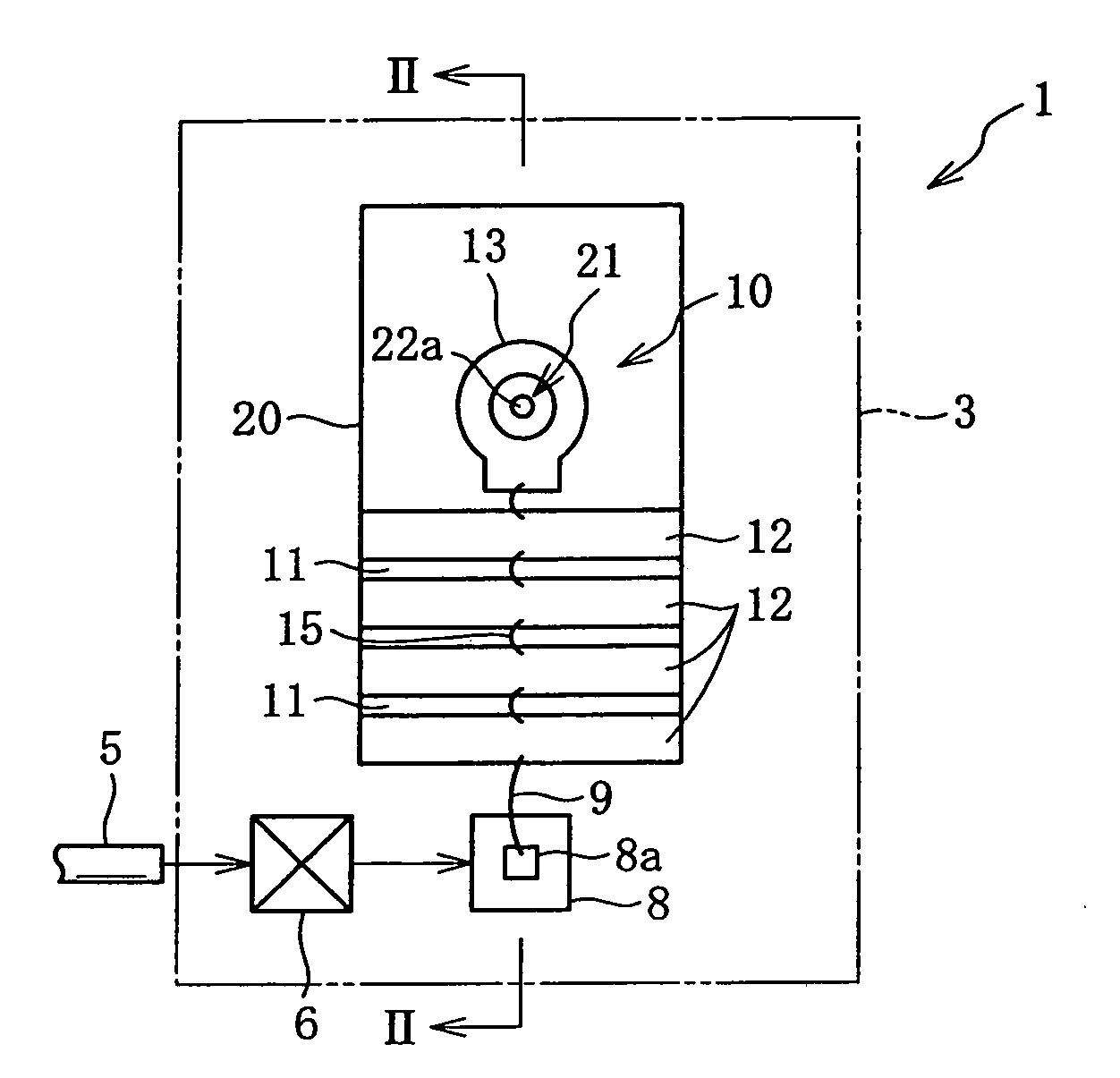

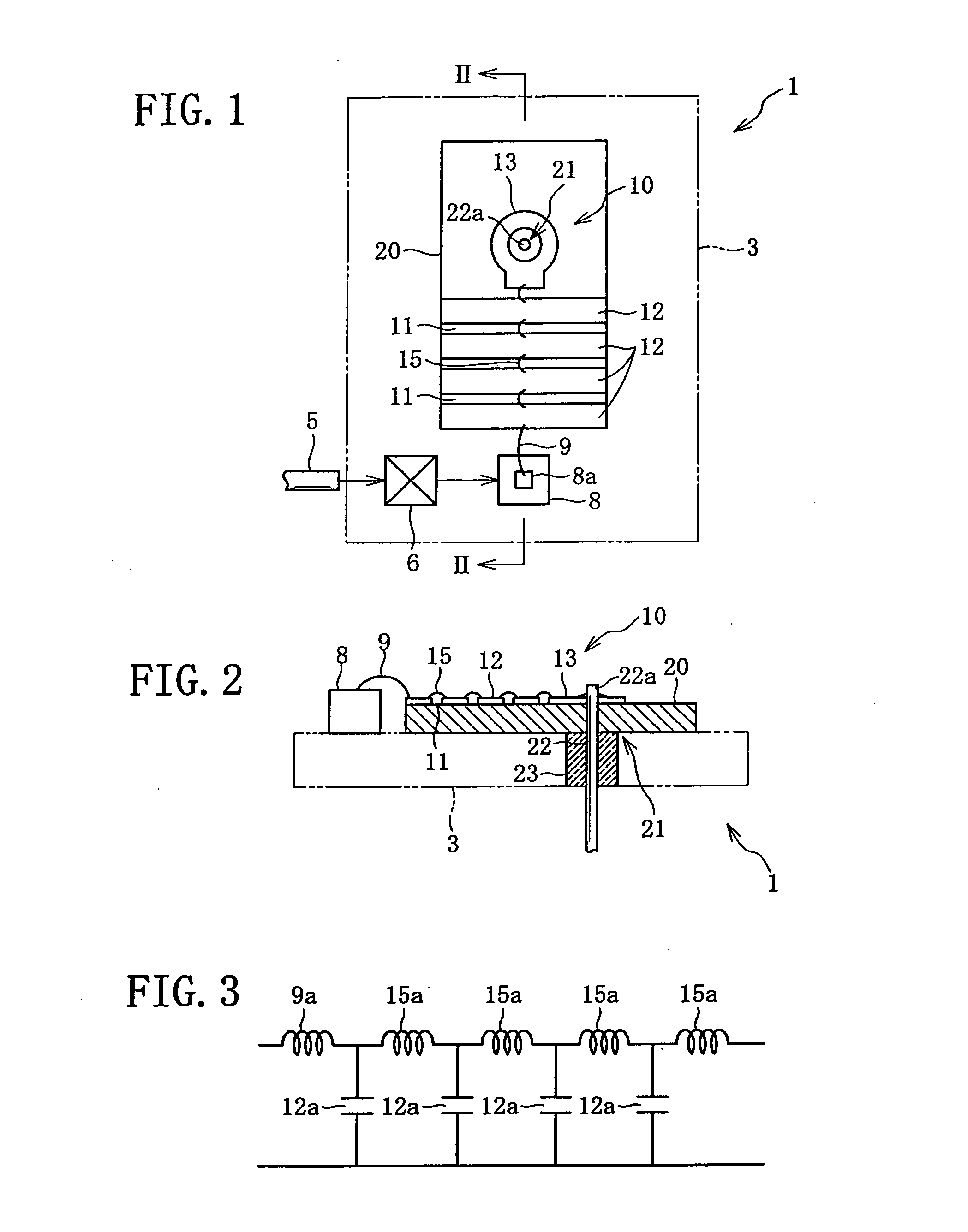

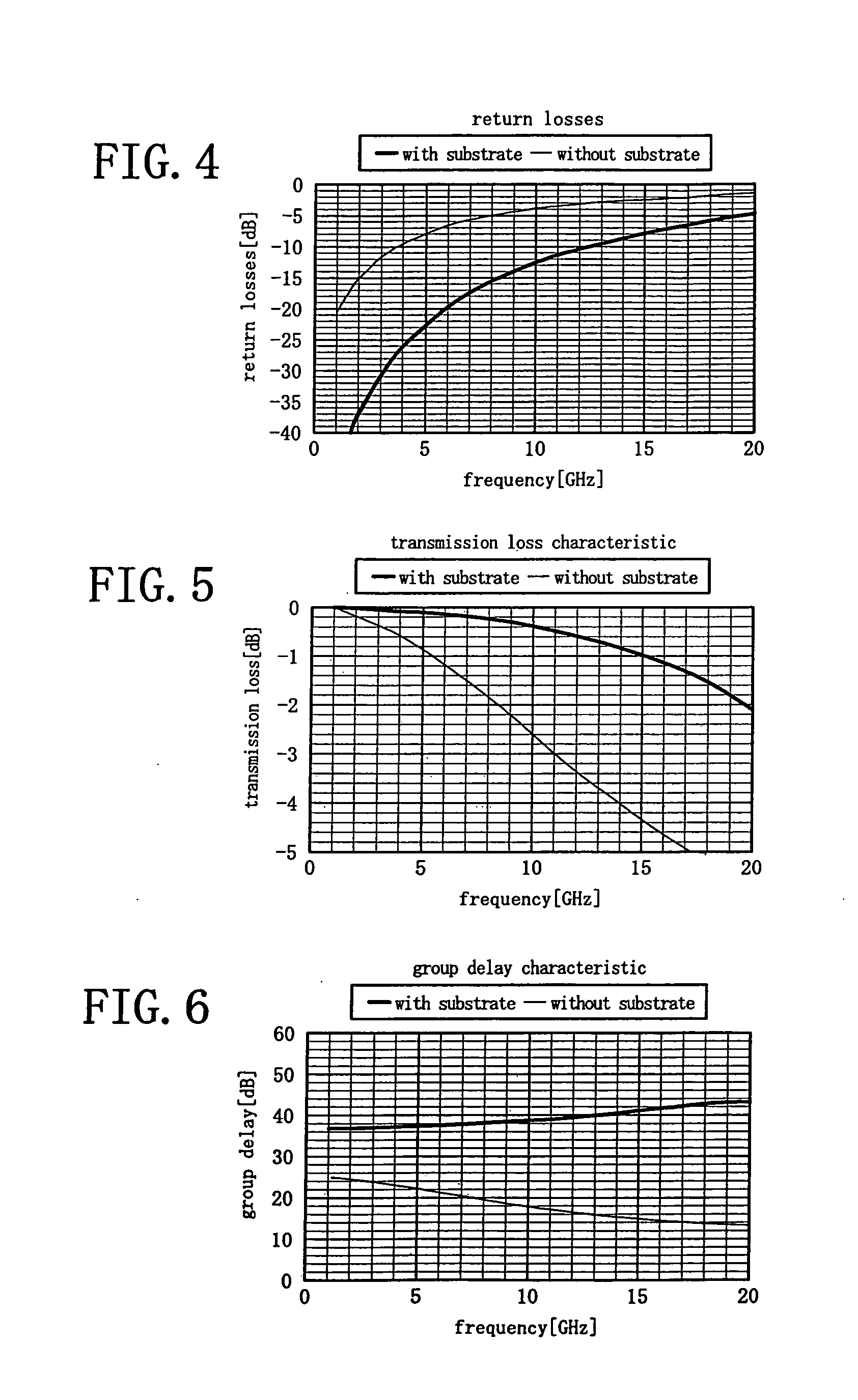

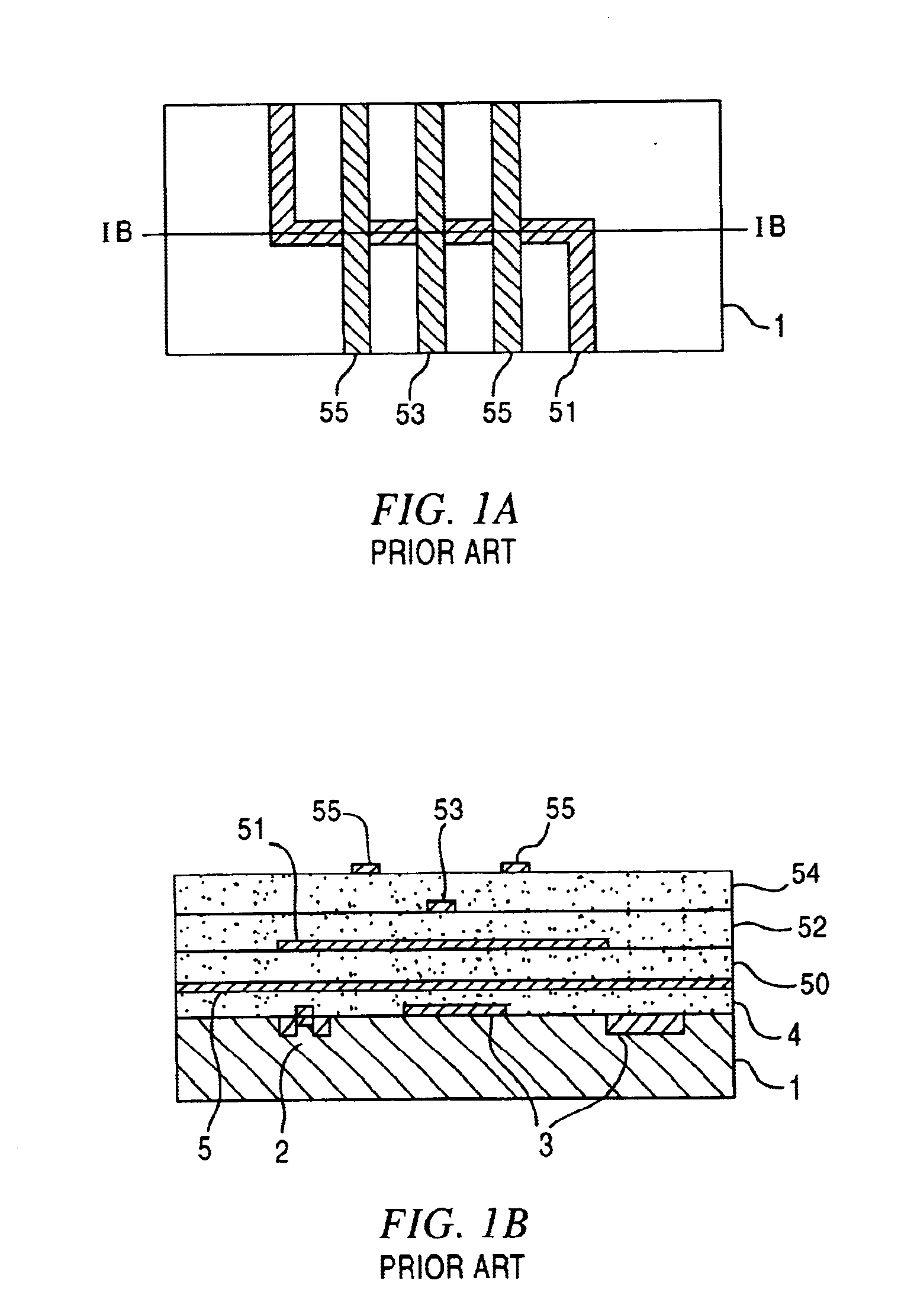

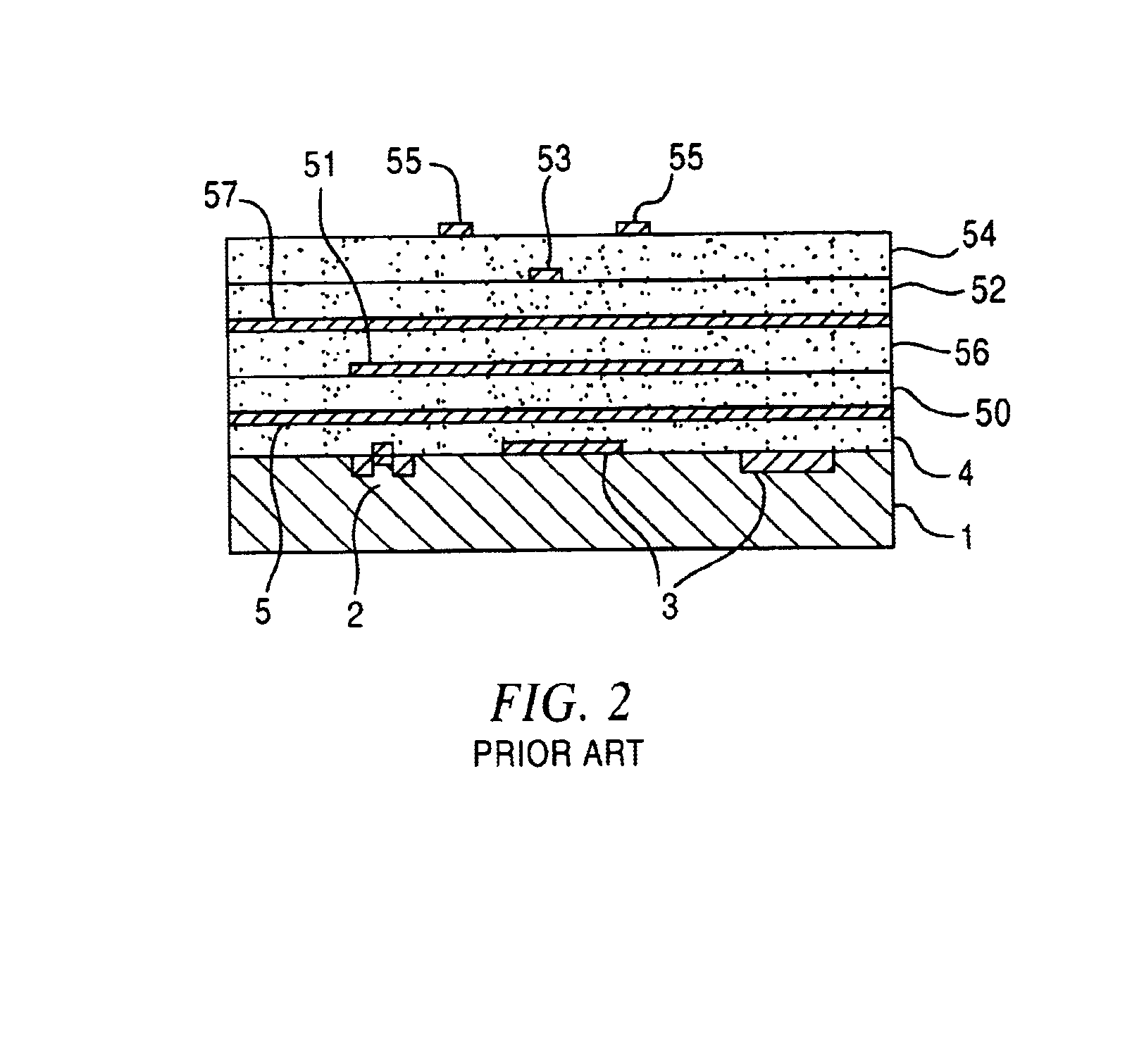

Radio lan antenna

InactiveUS20070004363A1Improve communication distanceReduce the possibilityAntenna adaptation in movable bodiesNetwork topologiesConductive materialsLayered structure

A high-frequency micro-strip line for transmitting a high-frequency wave for a wireless LAN system has a layered structure where, on a ground layer made of a conductive material, a dielectric layer made of a dielectric material and a signal line made of a conductive material are successively laid. The high-frequency micro-strip line further includes a patch antenna comprising a dielectric plate made of a dielectric material and a patch made of a conductive material, which are successively laid into a layered structure, the patch antenna being electrically connected to the signal line. A wireless-communication RF signal transmission device capable of being applied to such a line is also provided.

Owner:KOBE STEEL LTD

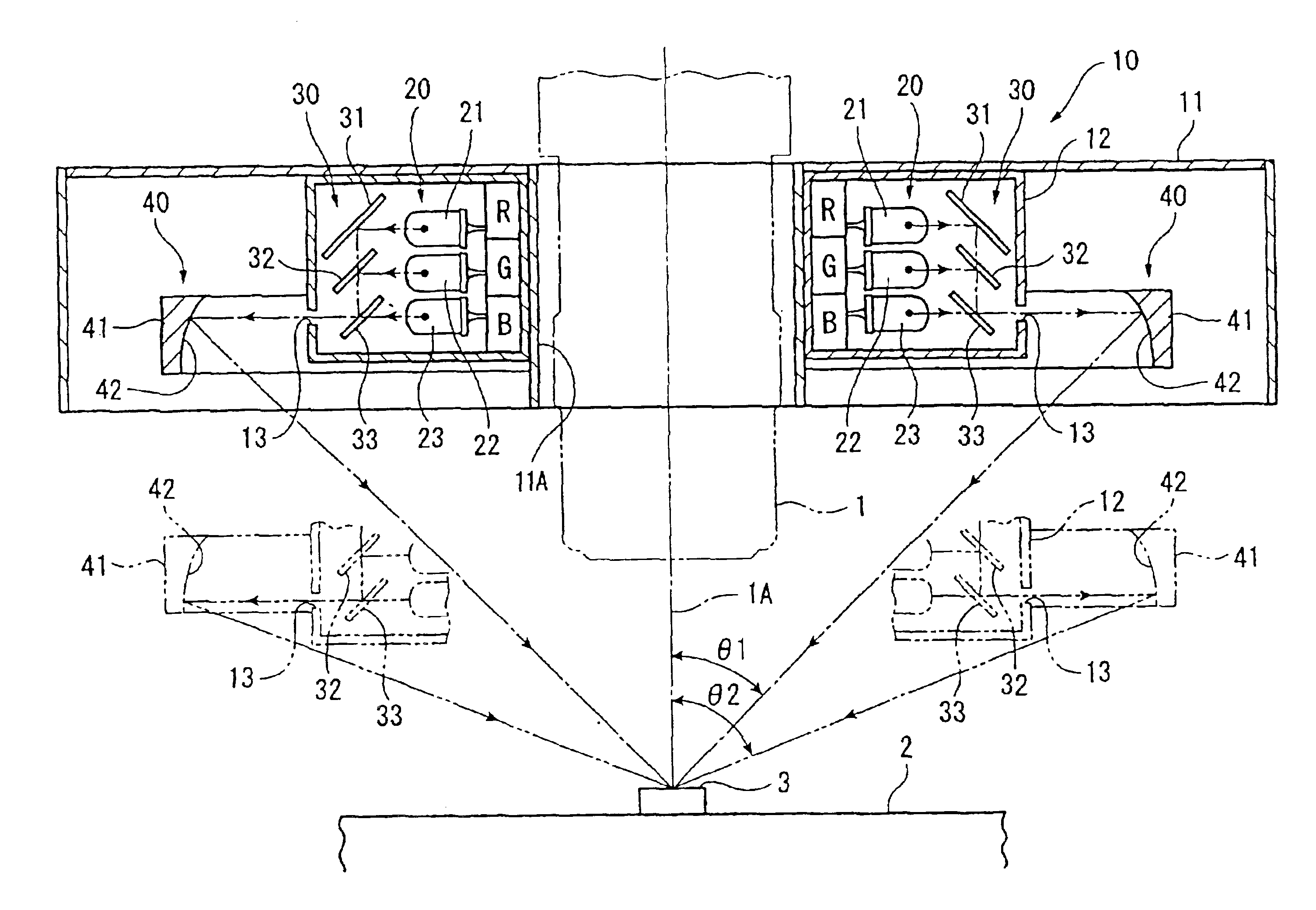

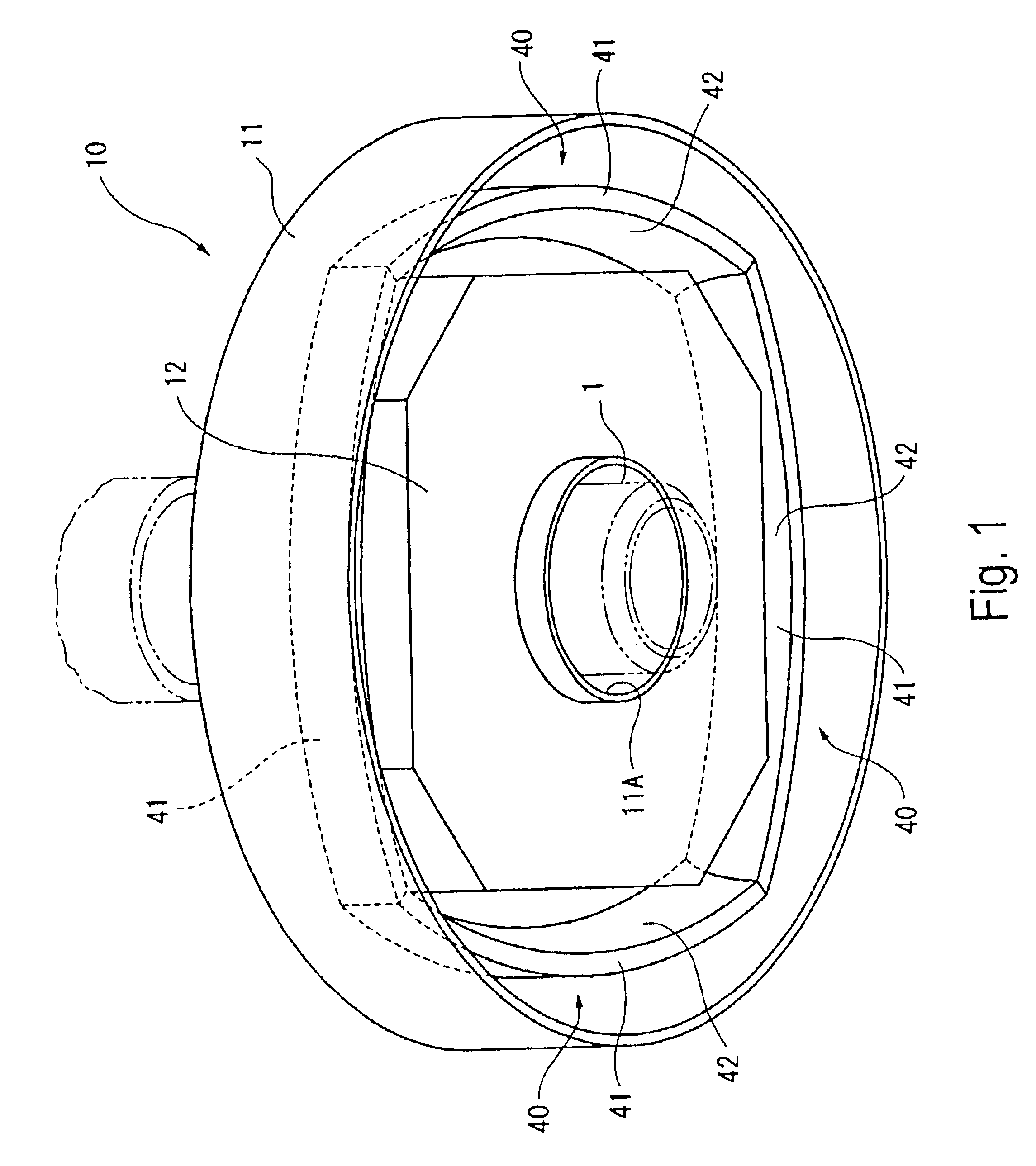

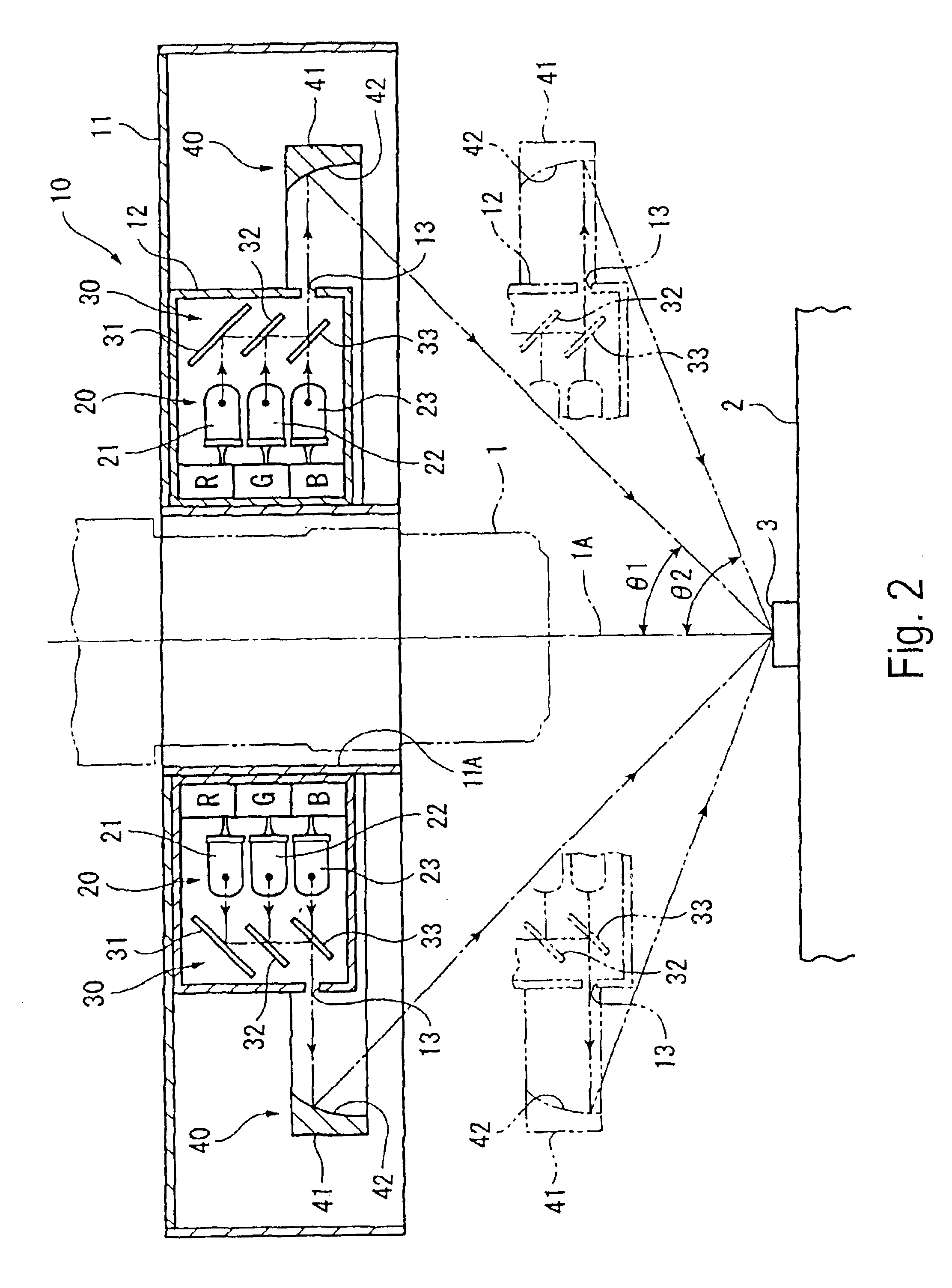

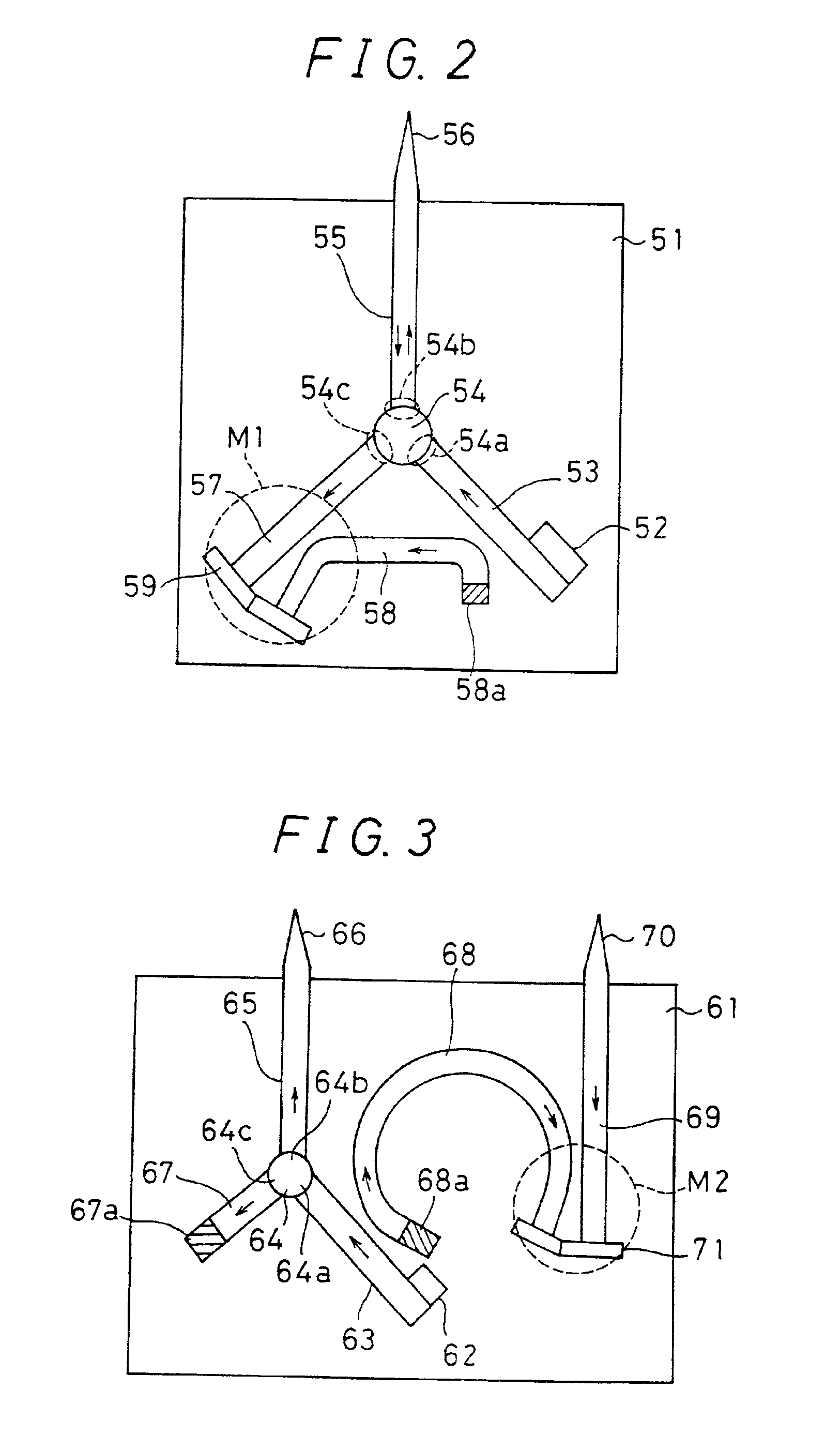

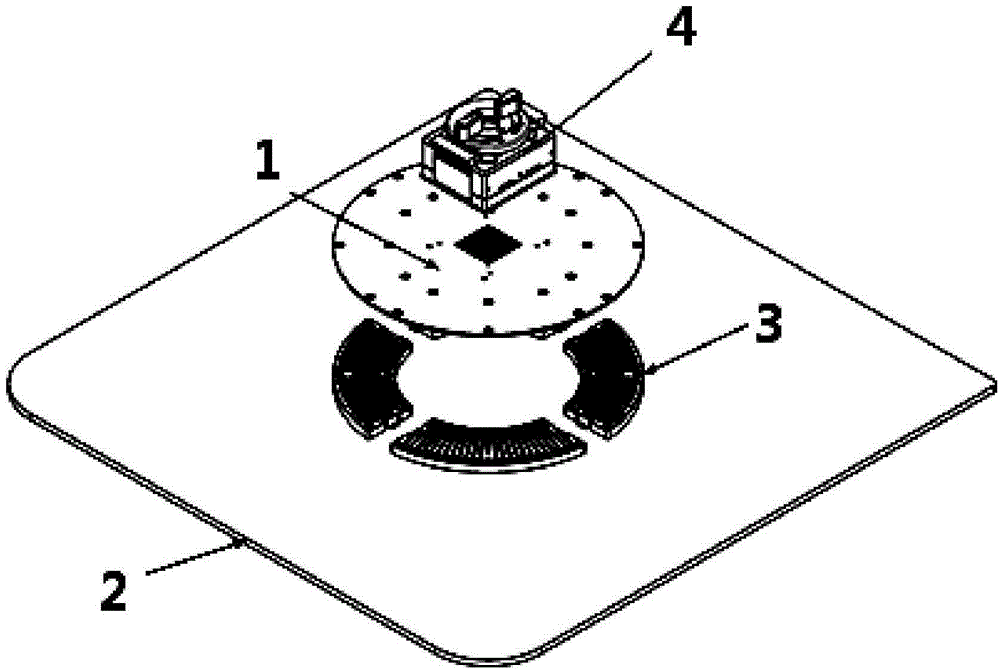

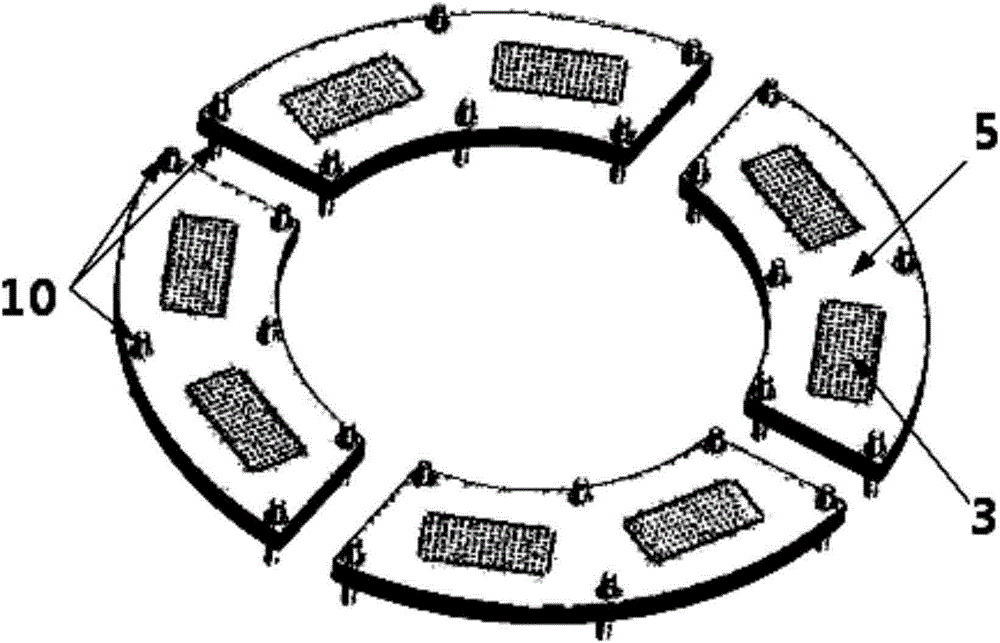

Ring illuminator

InactiveUS6857762B2Improve accuracyLow costPoint-like light sourceOperating tablesDirect illuminationOptical axis

A plurality of light emitting elements comprise a number of groups having light emitting colors different from each other. The light emitting element groups are arranged in ring shapes about an optical axis of an optical system in a plane or planes substantially orthogonal to the optical axis. A combining unit combines radiation light beams of different light emitting colors to generate illumination light having a given hue. The combining unit is provided downstream of the light emitting elements along a light emitting direction. A focusing unit focuses the illumination light in the direction toward the optical axis and is provided downstream of the combining unit. Accordingly, it is possible to direct illumination light having uniform and non-irregular hue, the hue corresponding to a surface color of an object to be measured, to the object to be measured.

Owner:MITUTOYO CORP

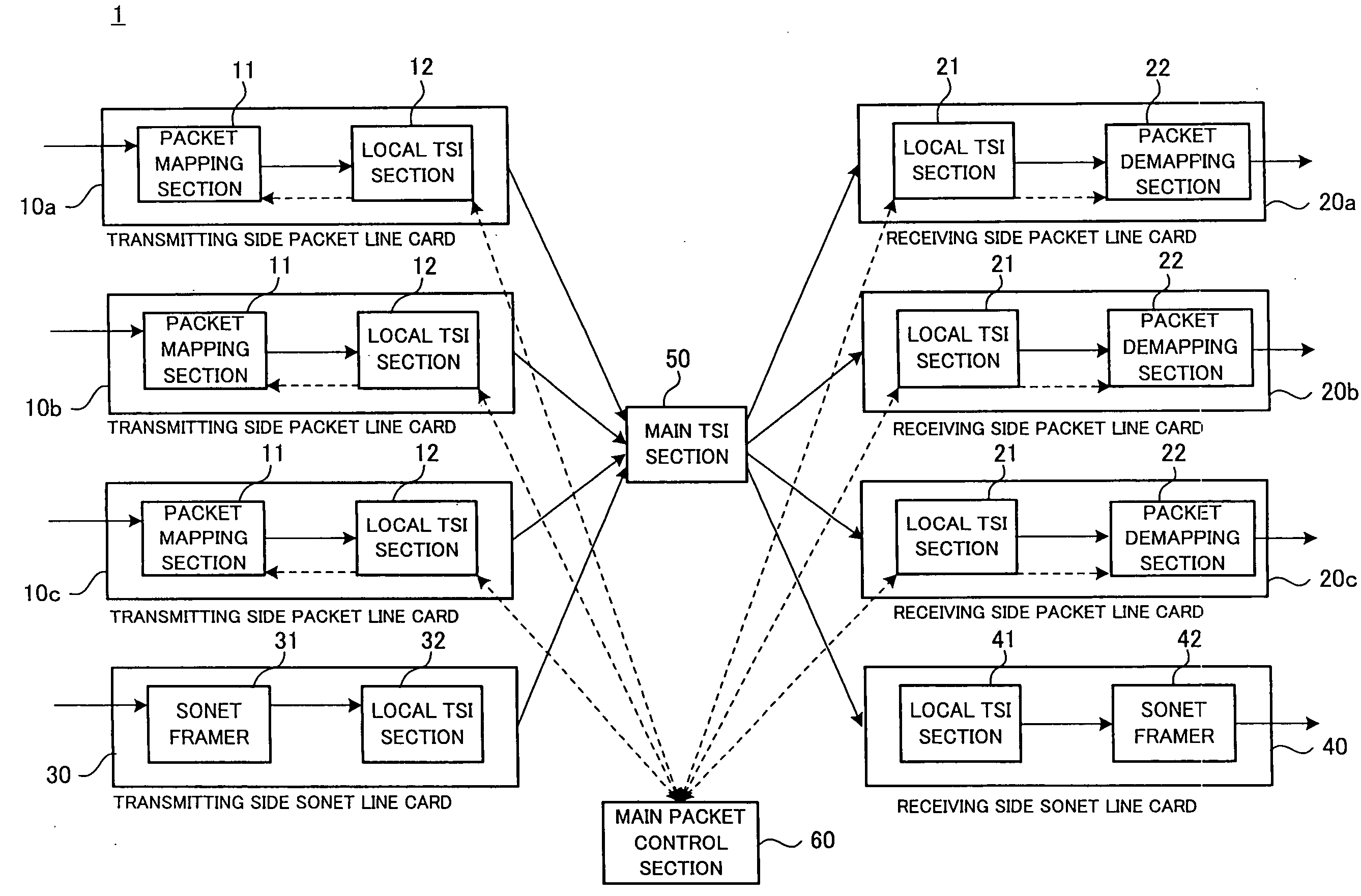

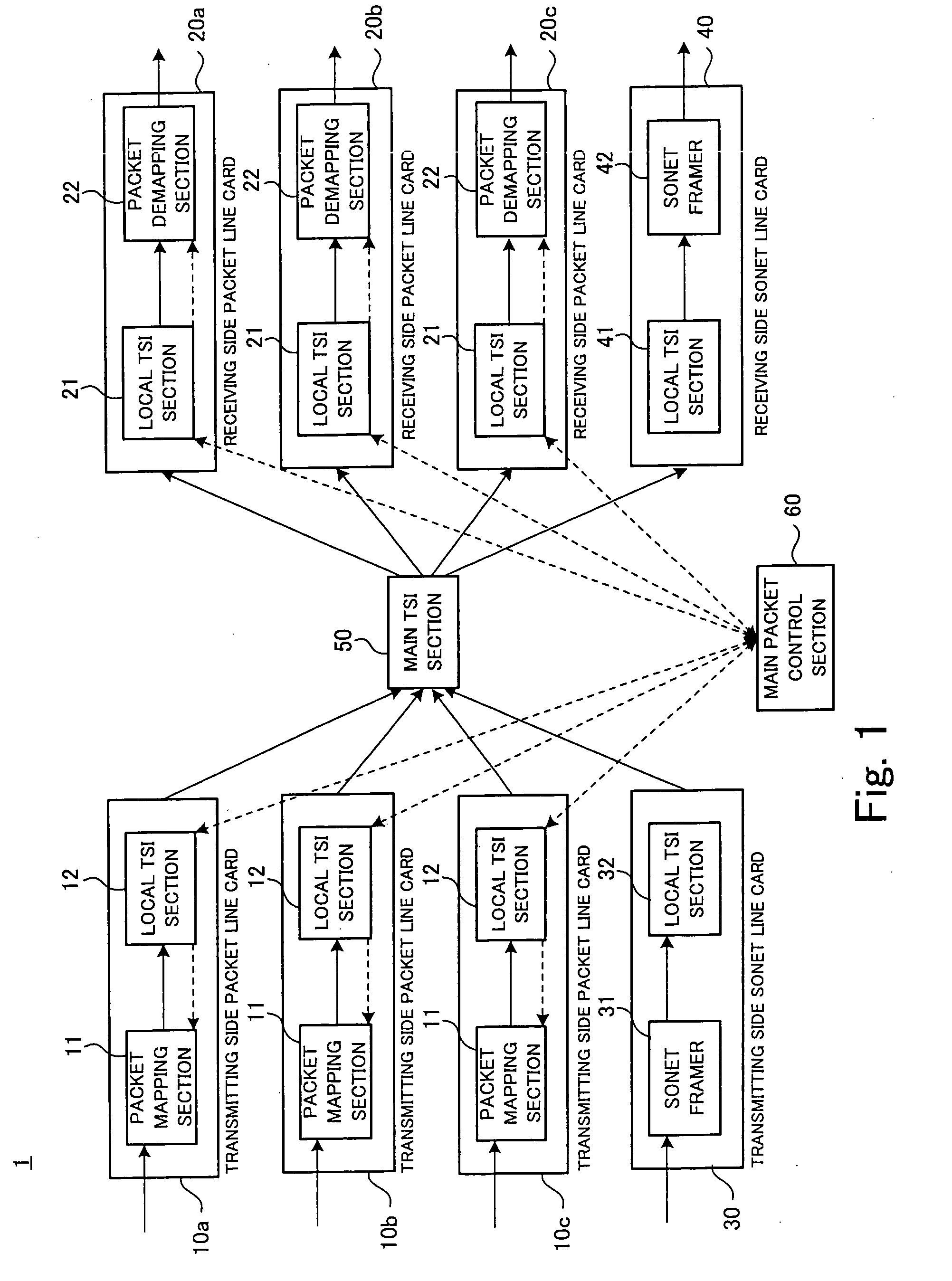

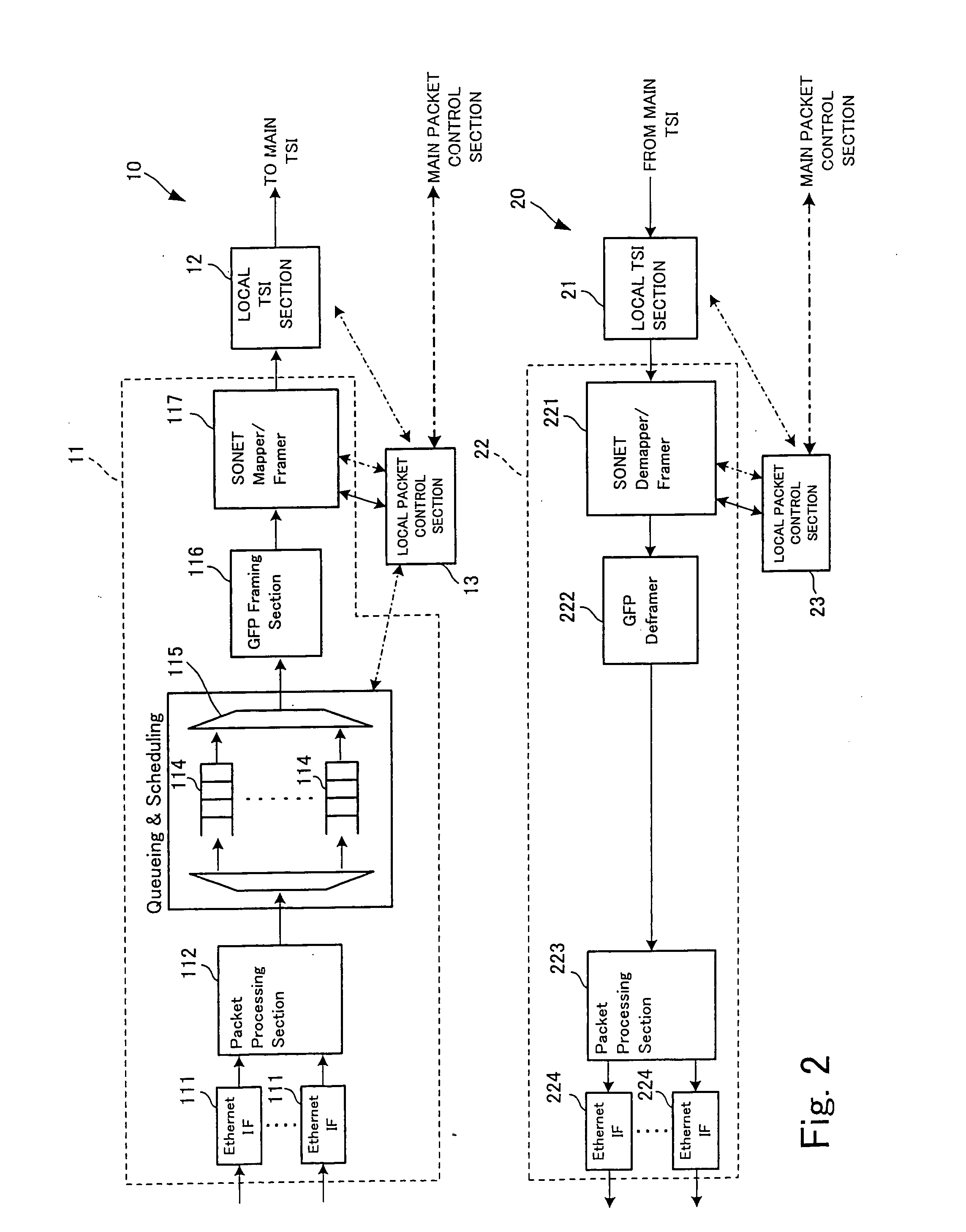

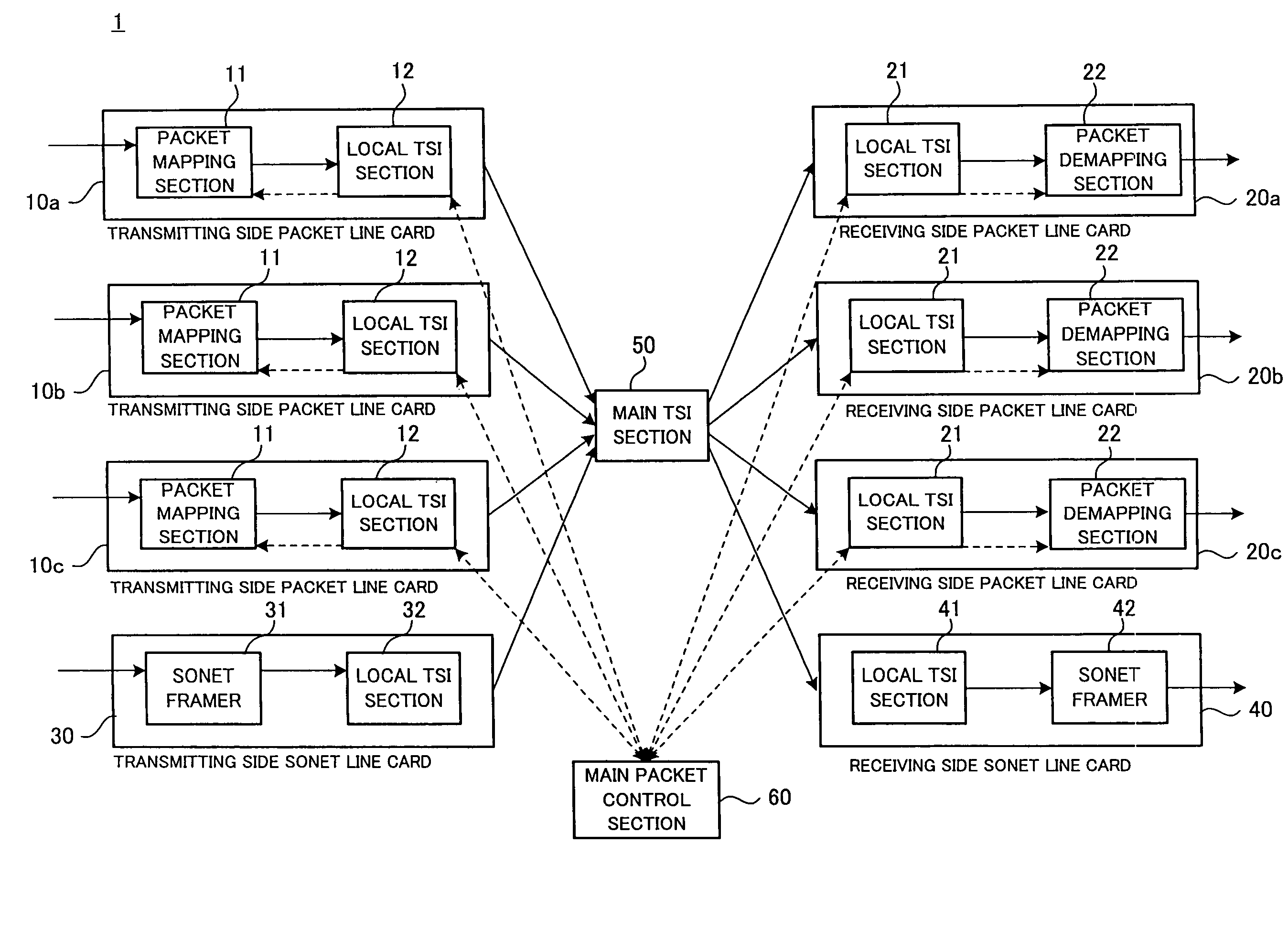

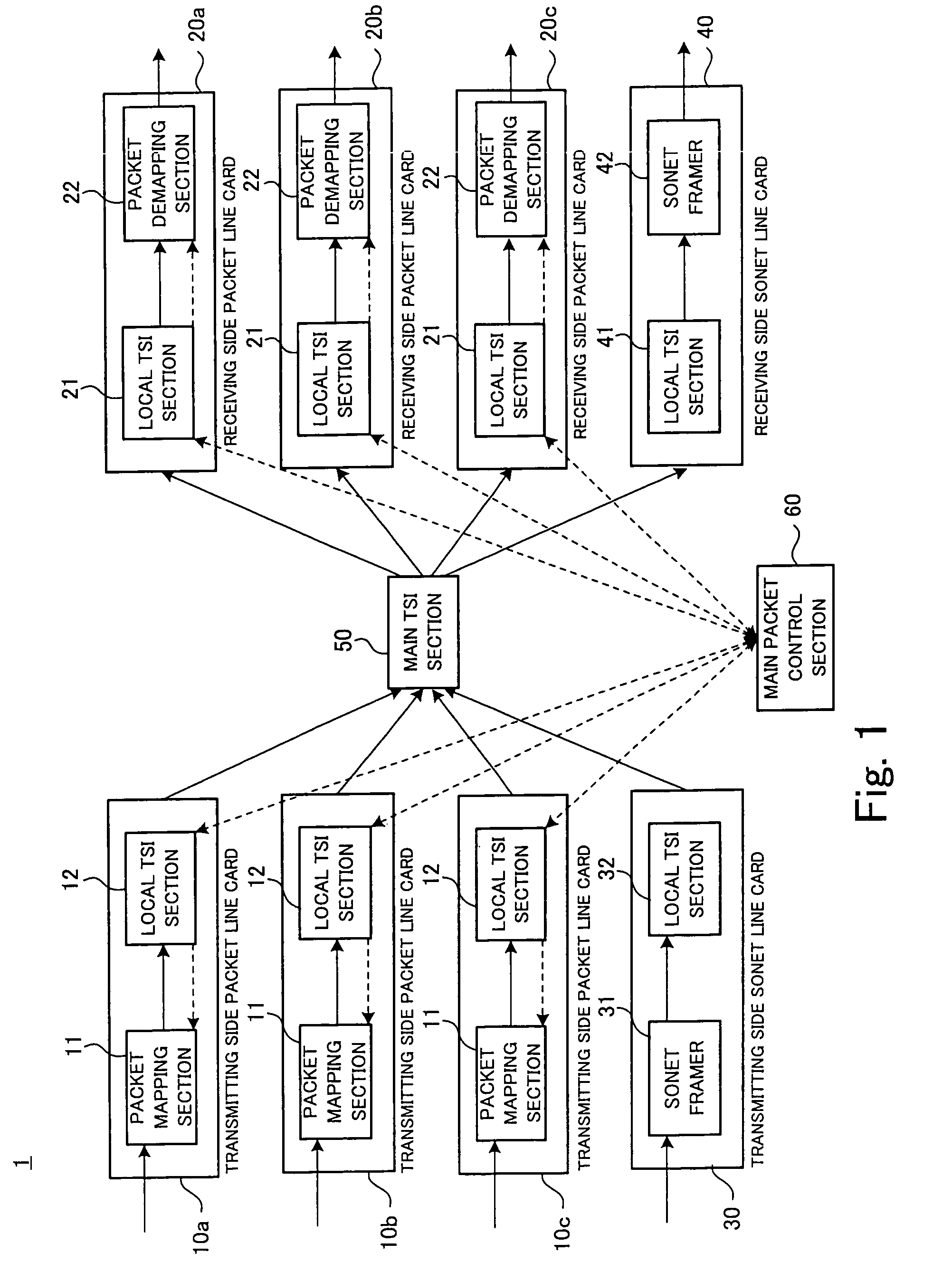

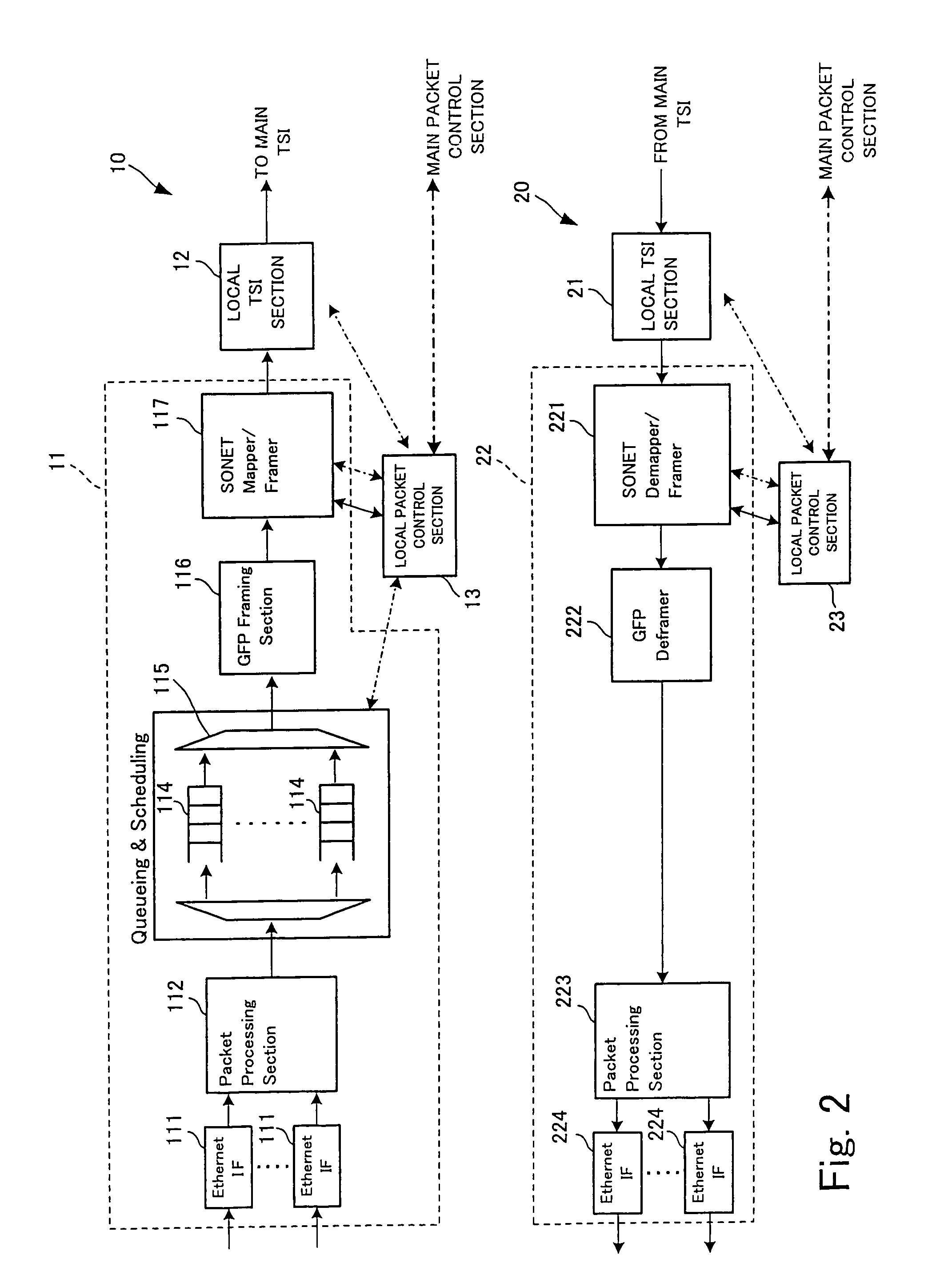

Transmission apparatus

InactiveUS20080037581A1Suppress lossSuppress transmission lossError preventionTransmission systemsData conversionVariable-length code

The present invention provides a transmission apparatus including transmitting side line interfaces which convert packet format data sent from an asynchronous network to a SONET / SDH frame format and then transmit the data, multiple receiving side line interfaces which receive the SONET / SDH frame format data and convert the data to packet format data and a circuit switching section which performs circuit switching. The transmitting side line interfaces include a variable length frame mapping section which converts the packet format data to variable length frame format data and a time division multiplexing mapping section which converts the variable length frame format data to the SONET / SDH frame format data. The receiving side line interfaces include a variable length frame demapping section which reconverts the SONET / SDH frame format data to variable length frame format data.

Owner:FUJITSU LTD

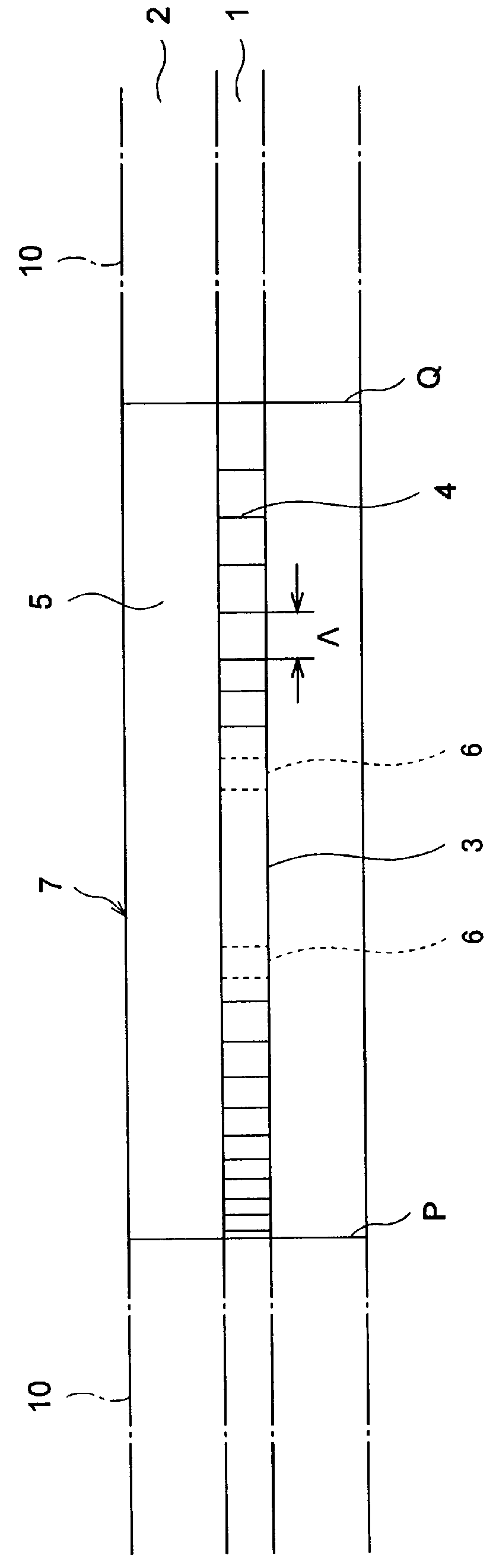

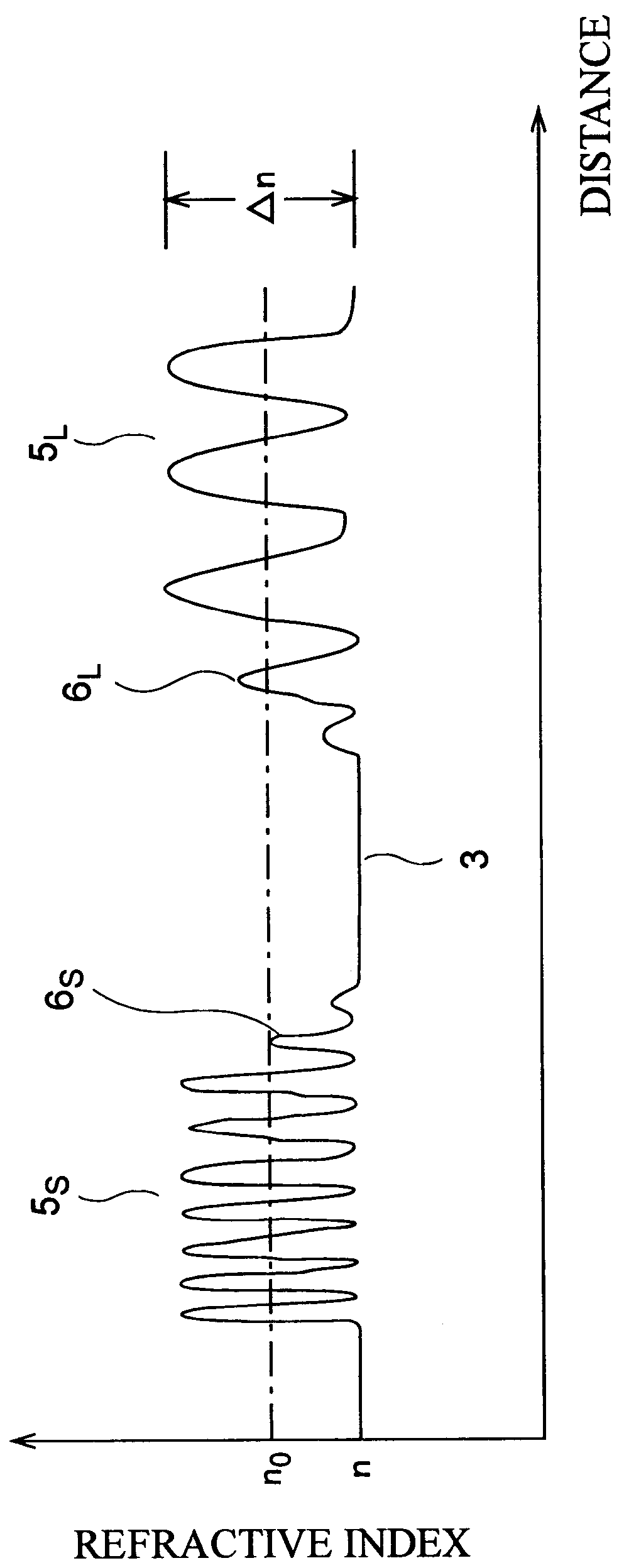

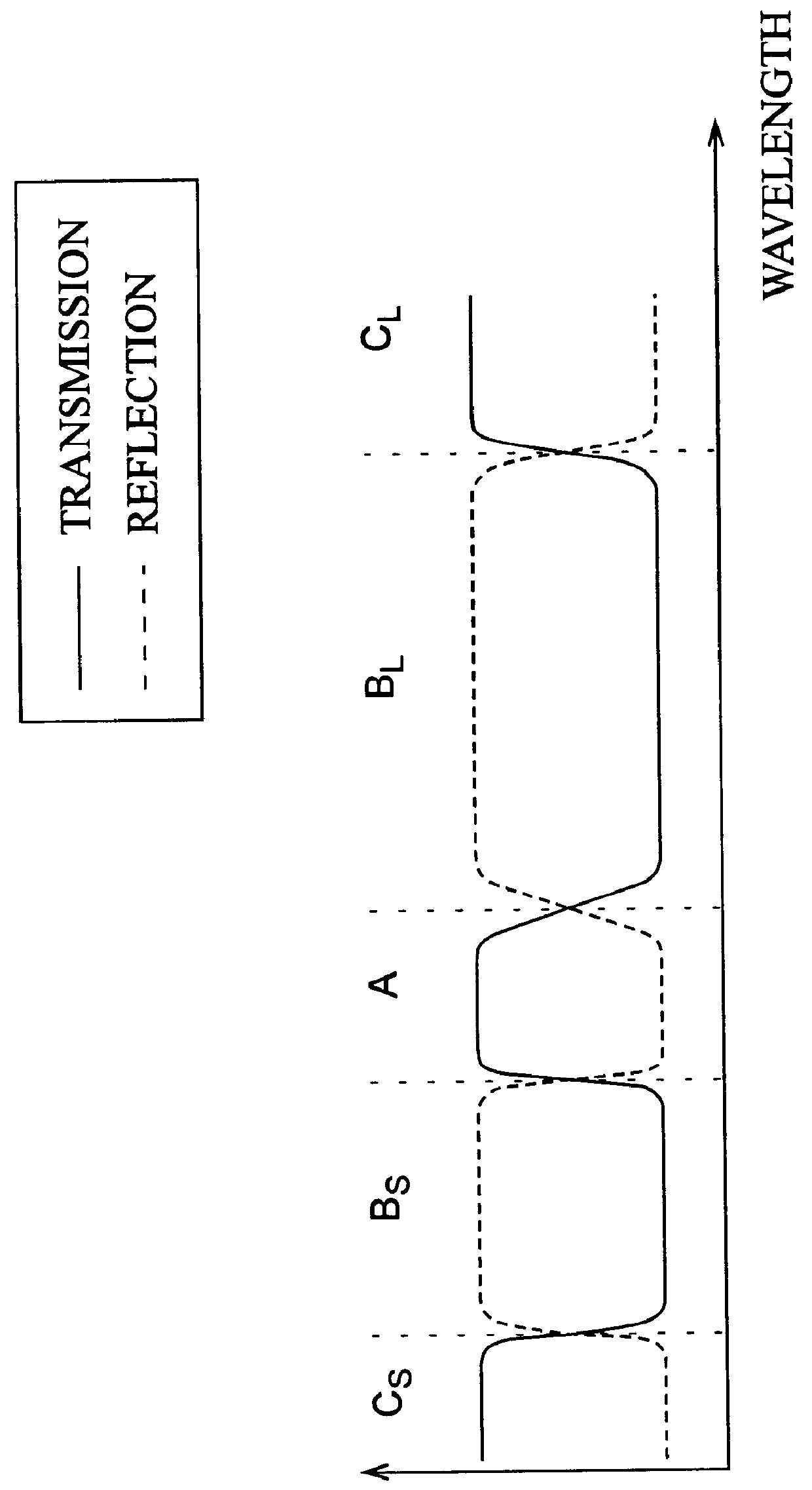

Diffraction grating type band-pass filter and method of making the same

InactiveUS6021242AImprove transmission lossSpread the wordCladded optical fibreOptical filtersBand-pass filterRefractive index

A band-pass filter formed in an optical waveguide, provided with a diffraction grating group having a period LAMBDA of refractive index fluctuation changing in an axial direction with substantially a constant changing width DELTA n, comprises two periodic refractive index variable areas having periodes LAMBDA different from each other; a zero area, disposed therebetween, having substantially a constant refractive index; and boundary areas, disposed between the zero area and the respective periodic refractive index variable areas, in which the changing width of refractive index monotonously changes between 0 and DELTA n.

Owner:SUMITOMO ELECTRIC IND LTD

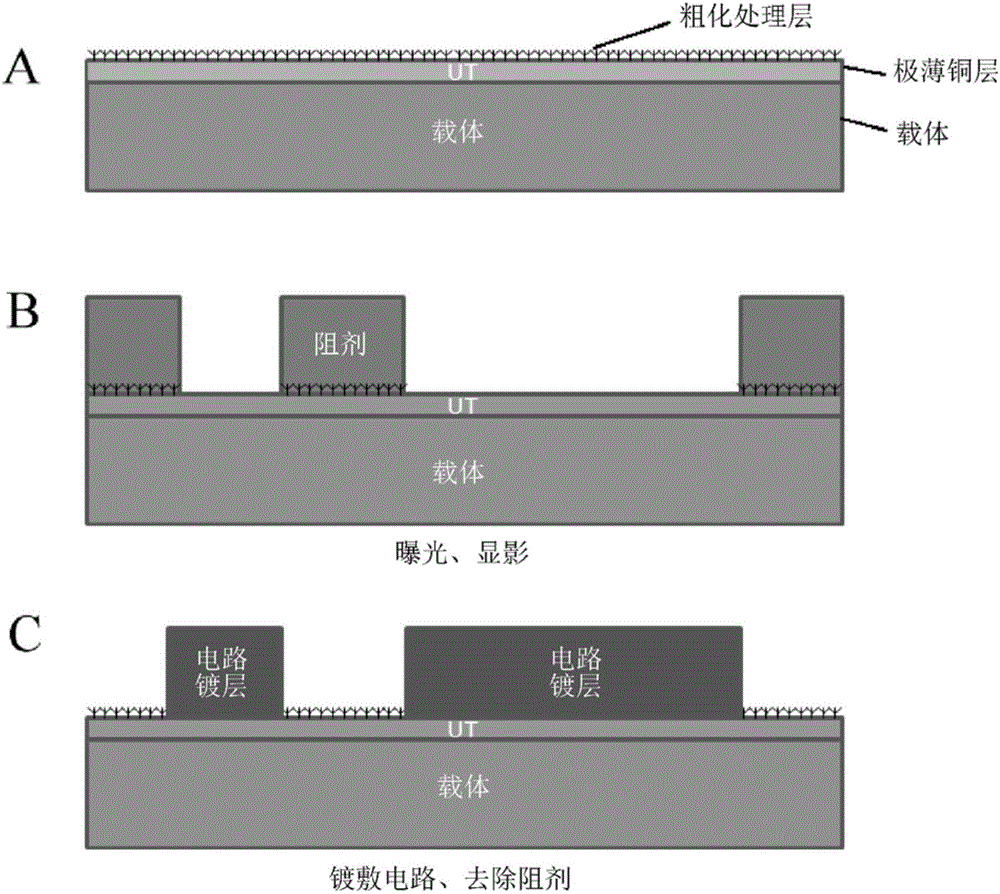

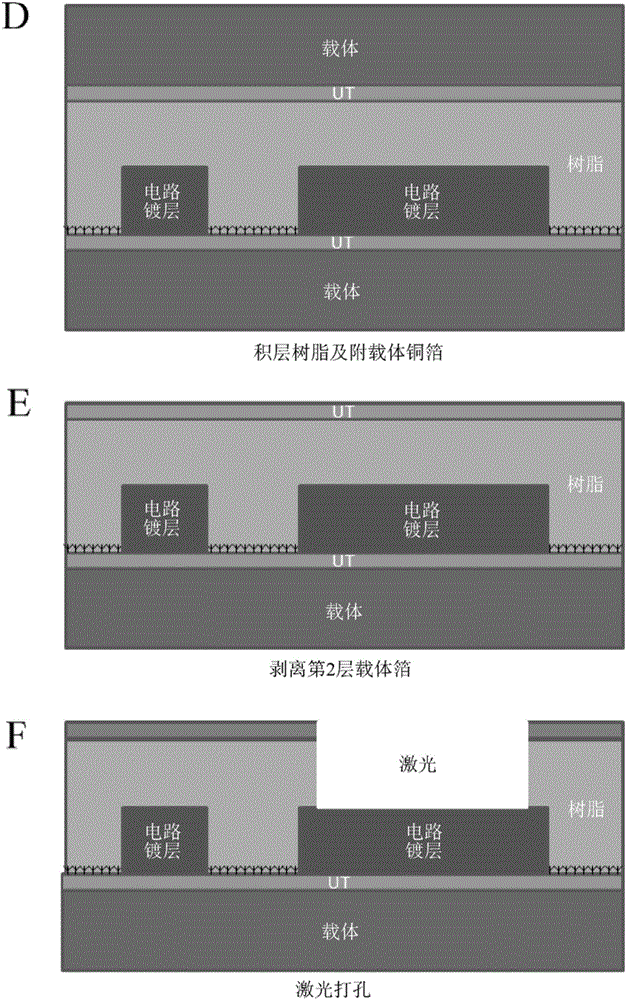

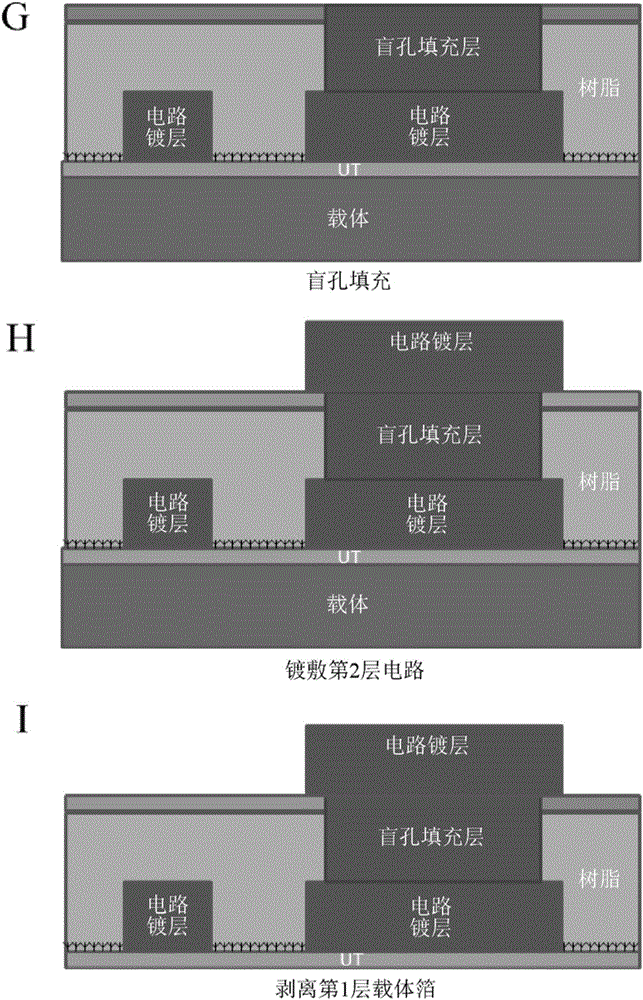

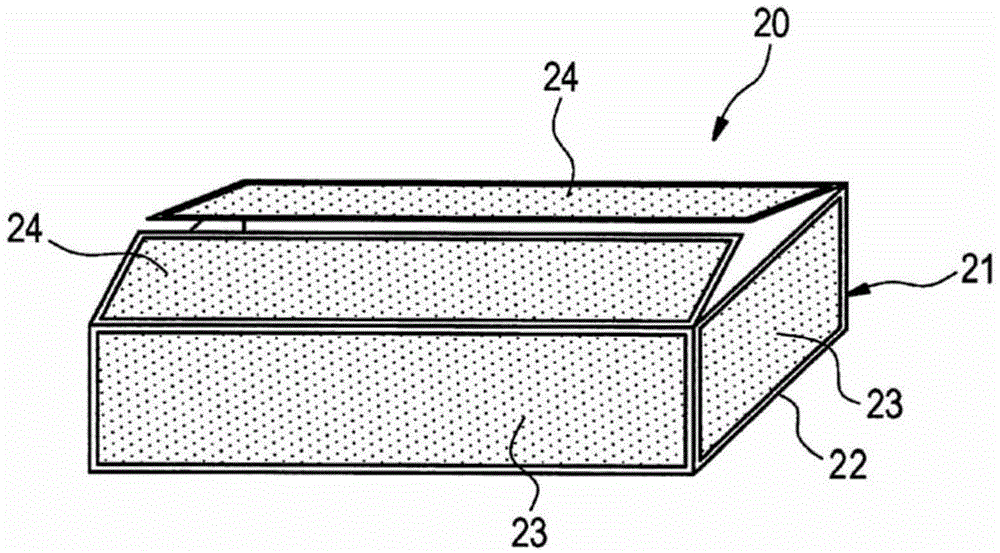

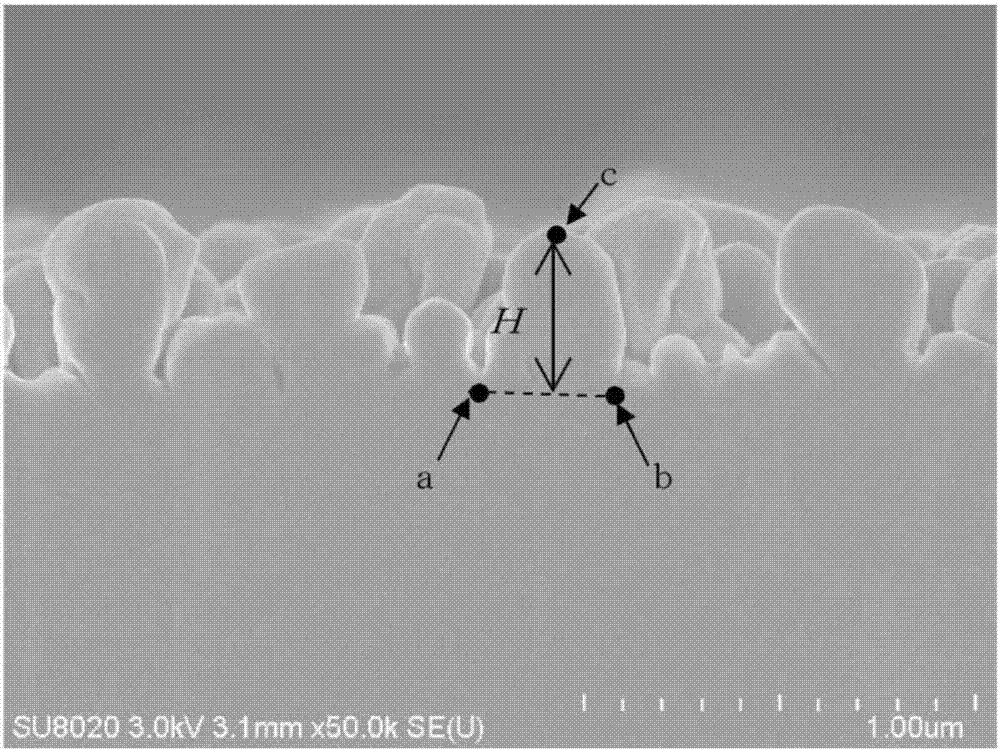

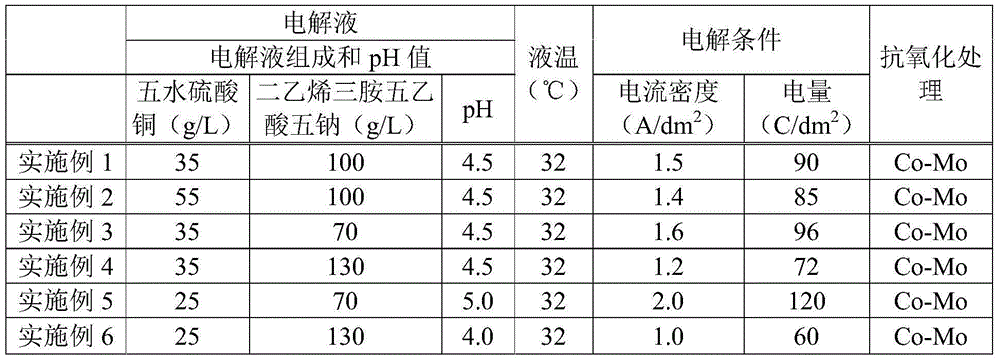

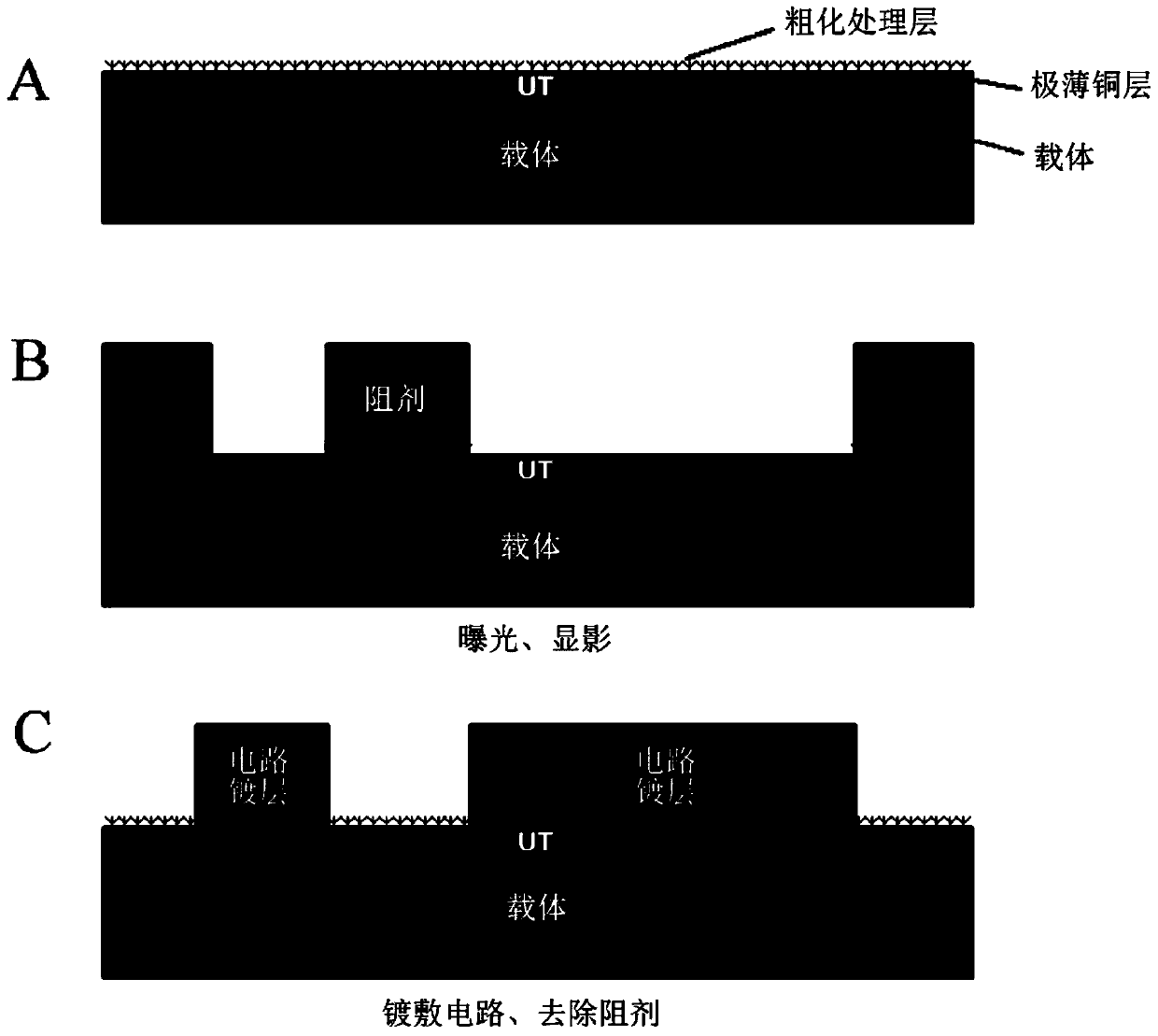

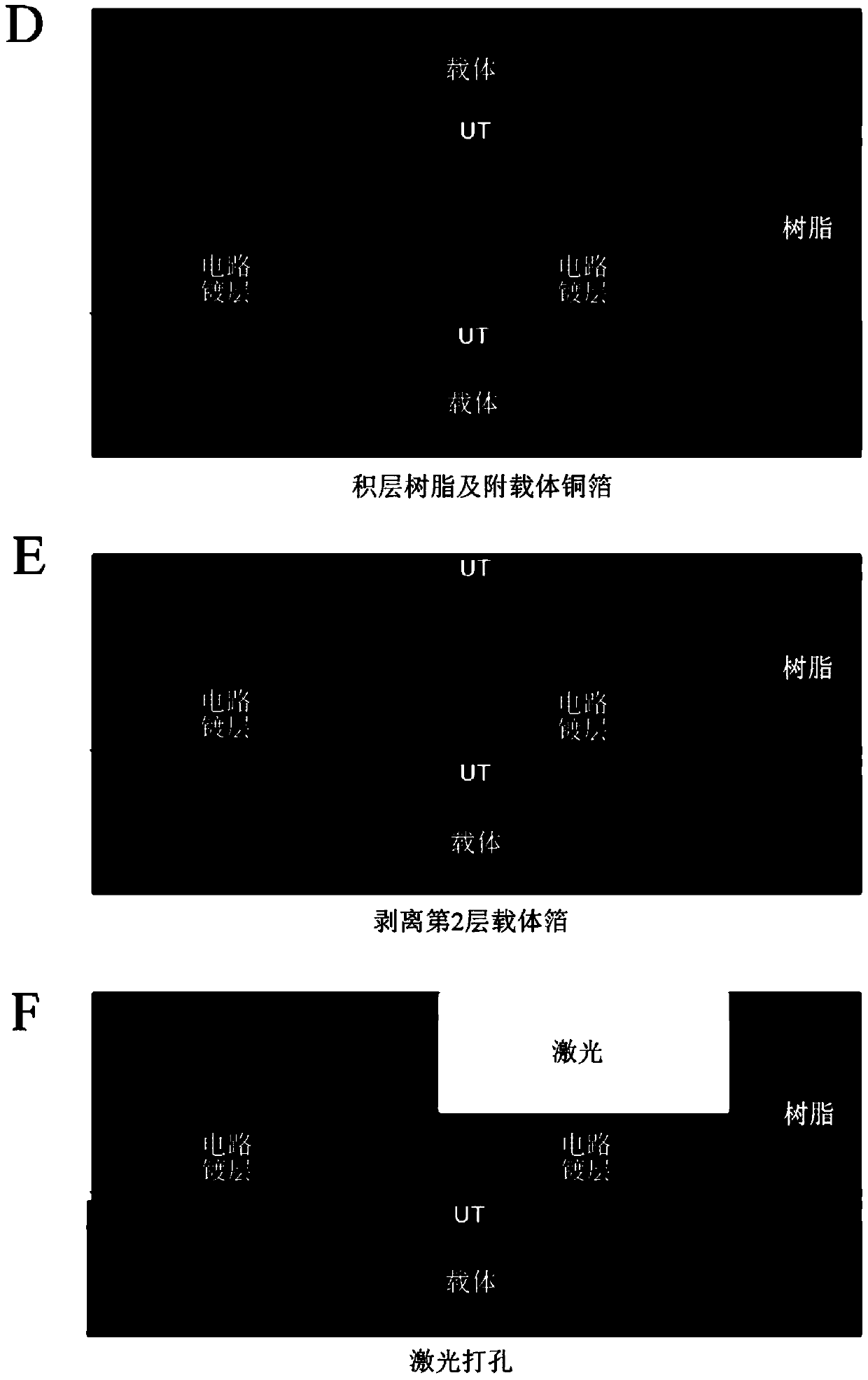

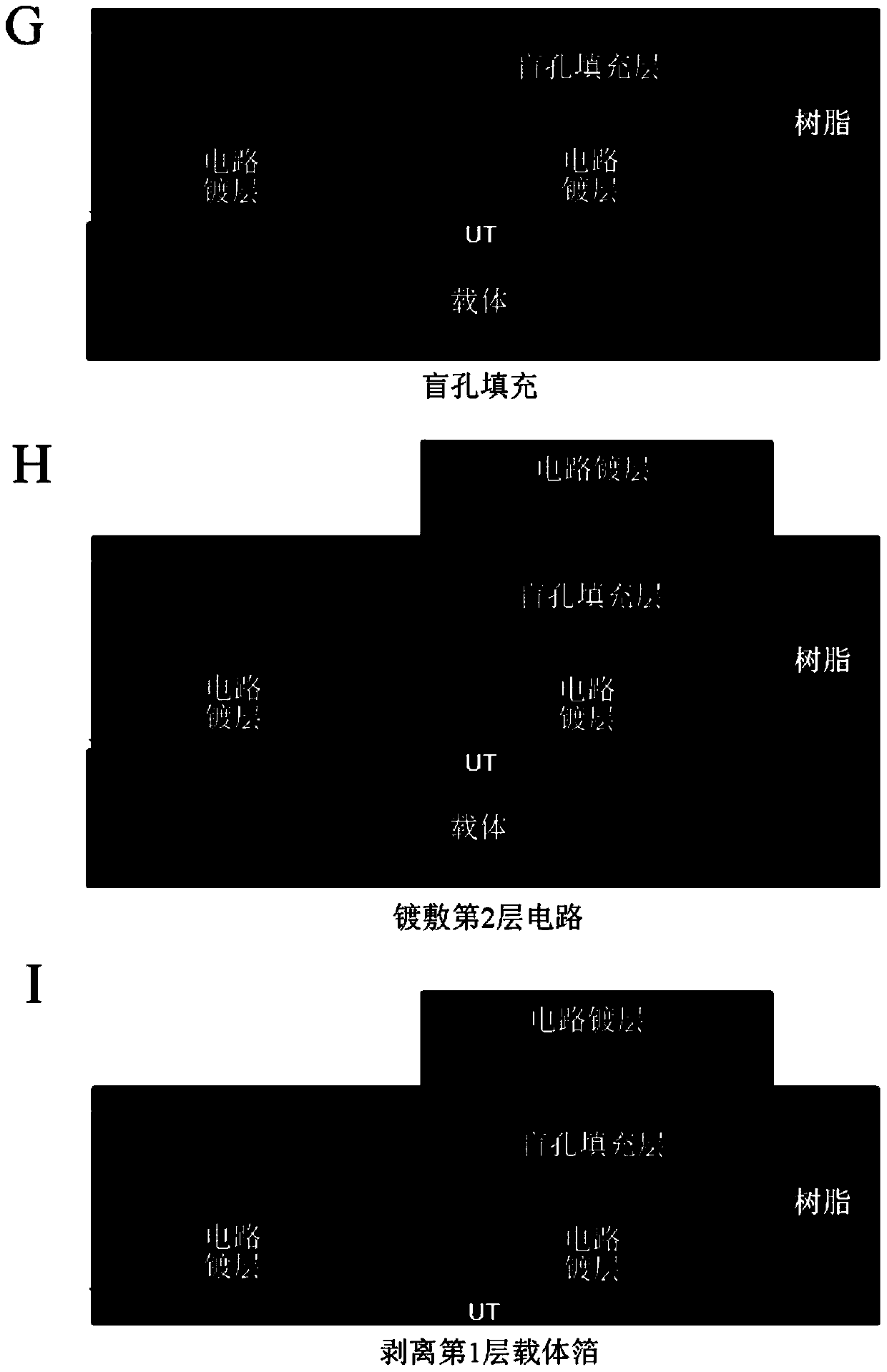

Surface-processed copper foil, copper foil with carrier, laminated body, printed circuit board, electronic equipment, manufacturing method for surface-processed copper foil and manufacturing method for printed circuit board

ActiveCN105323958AHigh peel strengthSuppress transmission lossInsulating substrate metal adhesion improvementPrinted circuit aspectsDissolutionCopper foil

The present invention relates to a surface-processed copper foil, a copper foil with a carrier, a laminated body, a printed circuit board, an electronic equipment, a manufacturing method for the surface-processed copper foil and a manufacturing method for the printed circuit board. The surface-processed copper foil has good peeling strength and is capable of preventing transmission loss even though it is applied to a high frequency circuit board. The surface-processed copper foil of the present invention sequentially comprises: a copper foil, a metal layer including at least one element selected from a group composed of Ni, Co, Zn, W, Mo and Cr, and a surface-processed layer formed with chrome oxide. The adhesion amount of the elements selected from the group composed of Ni, Co, Zn, W, Mo and Cr in the metal layer is 200-2000[mu]g / dm<2>. After a heat process for 10 minutes under 250 DEG C, if the surface-processed copper foil is soaked in a nitric acid liquid whose concentration is 20 mass% and temperature is 25 DEG C for 30 seconds under a state that only the surface of the surface-processed layer is exposed, the dissolution amount of copper in the nitric acid liquid is less than 0.0030g / 25cm<2>.

Owner:JX NIPPON MINING & METALS CO LTD

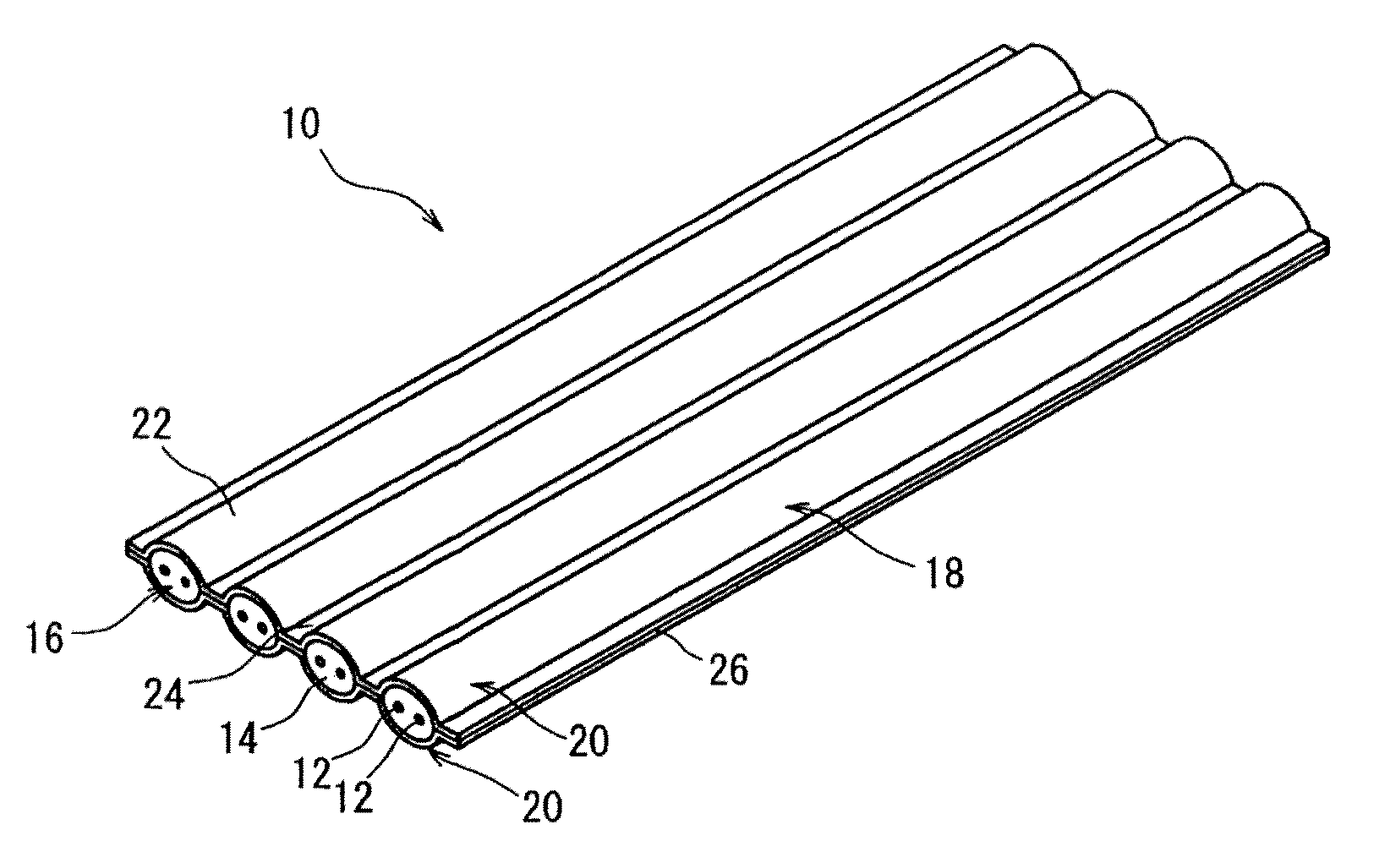

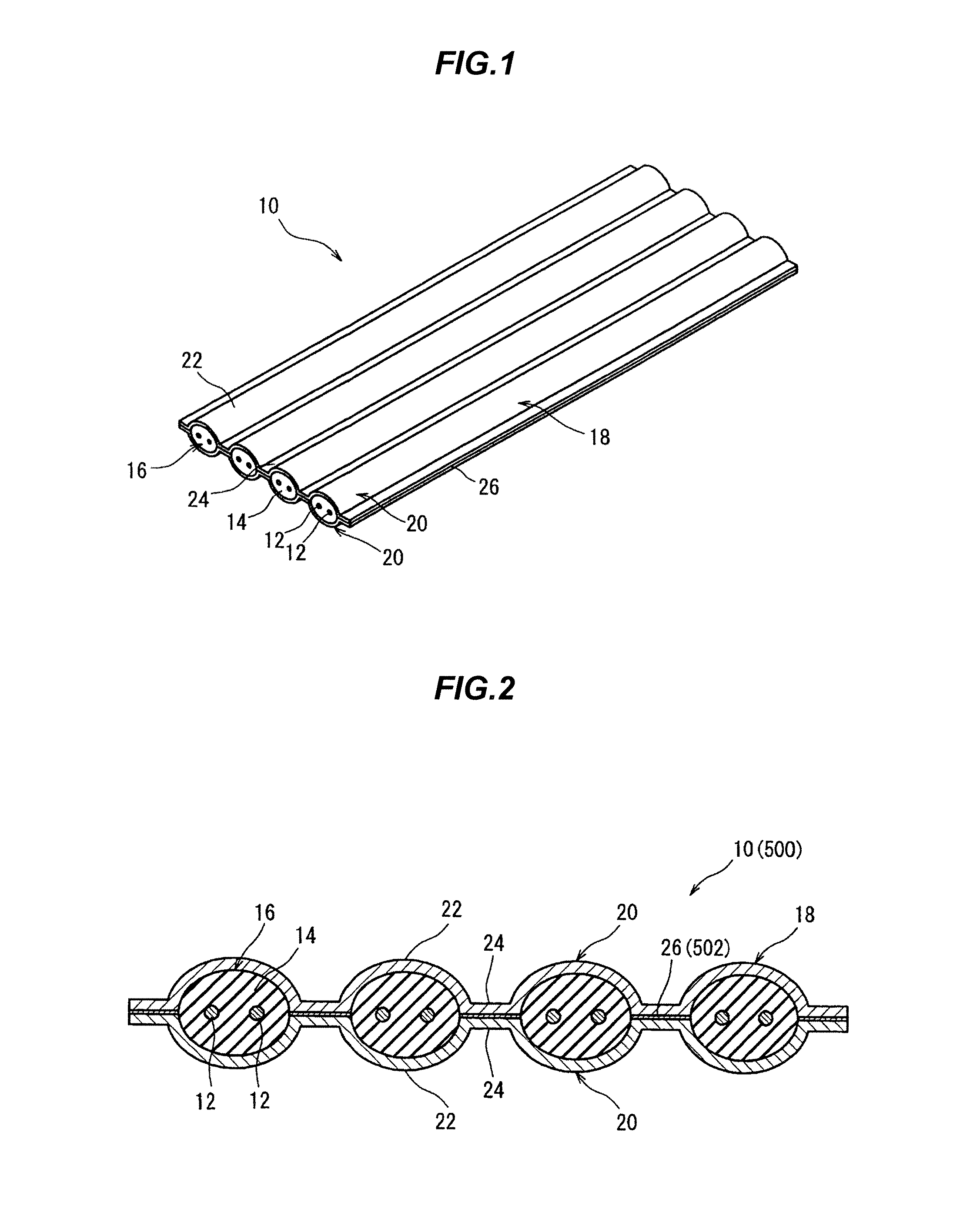

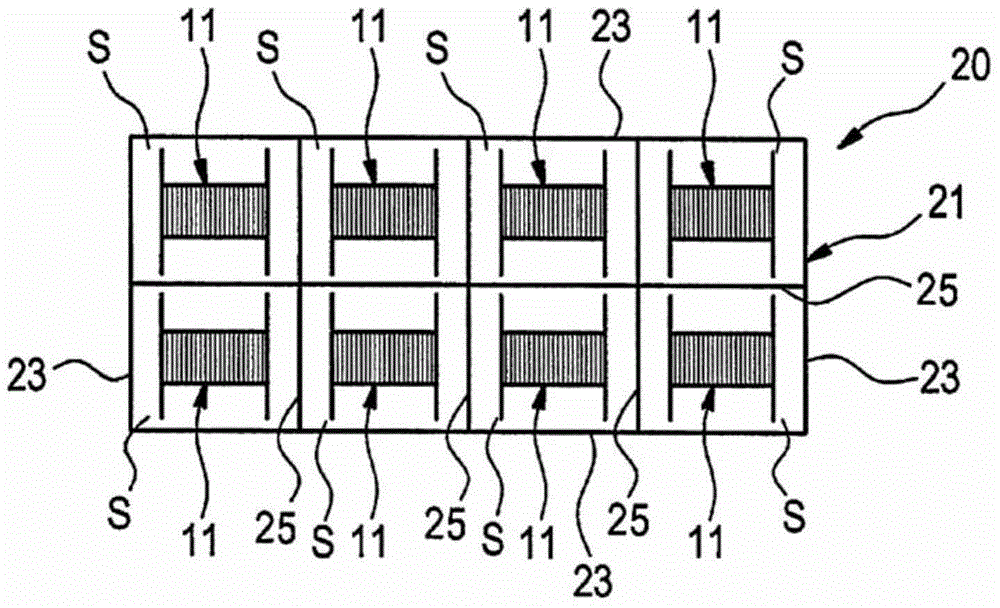

Shielded flat ribbon cable and method for fabricating a shielded flat ribbon cable

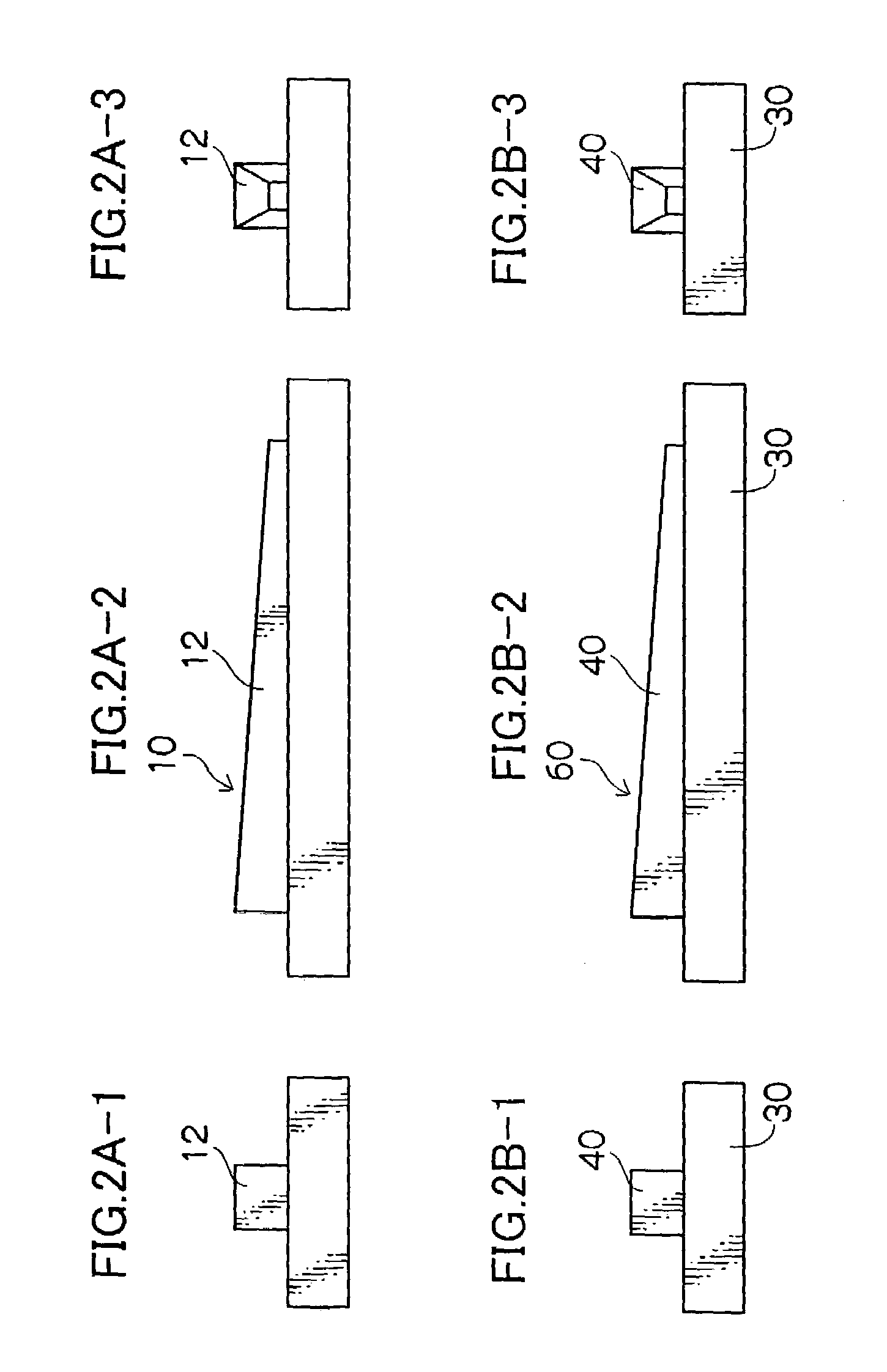

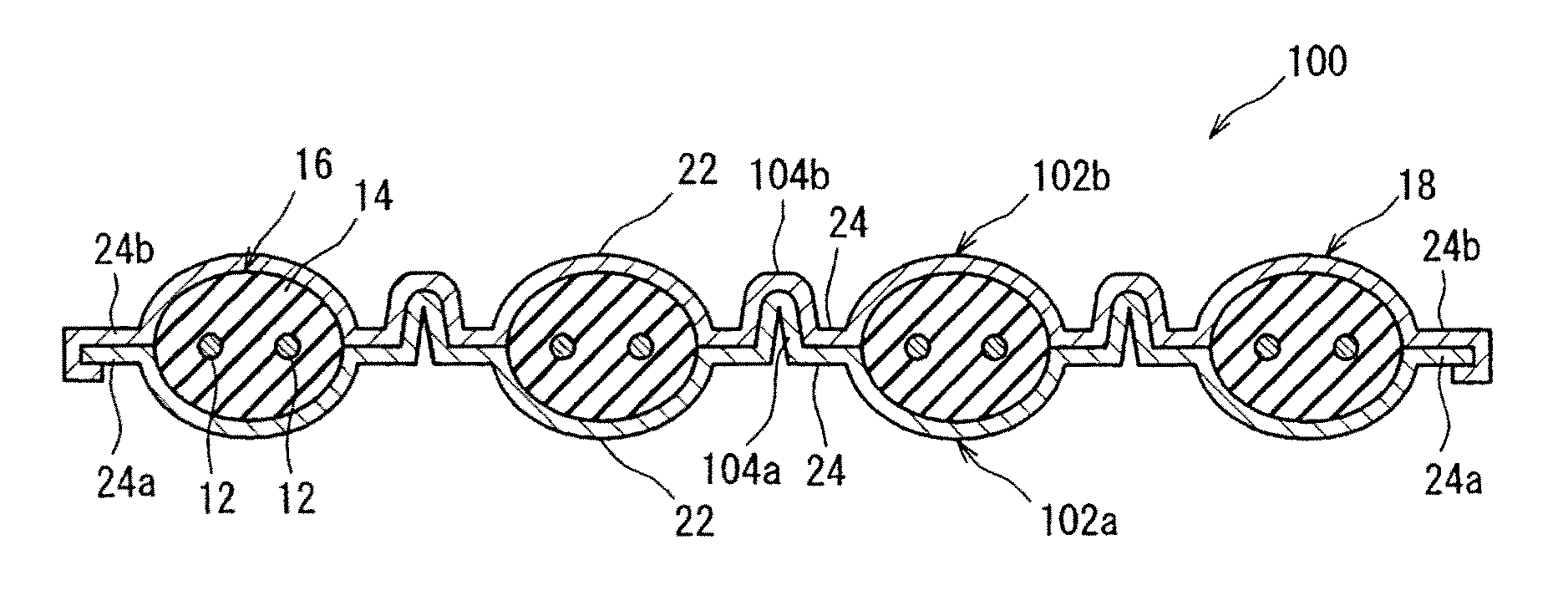

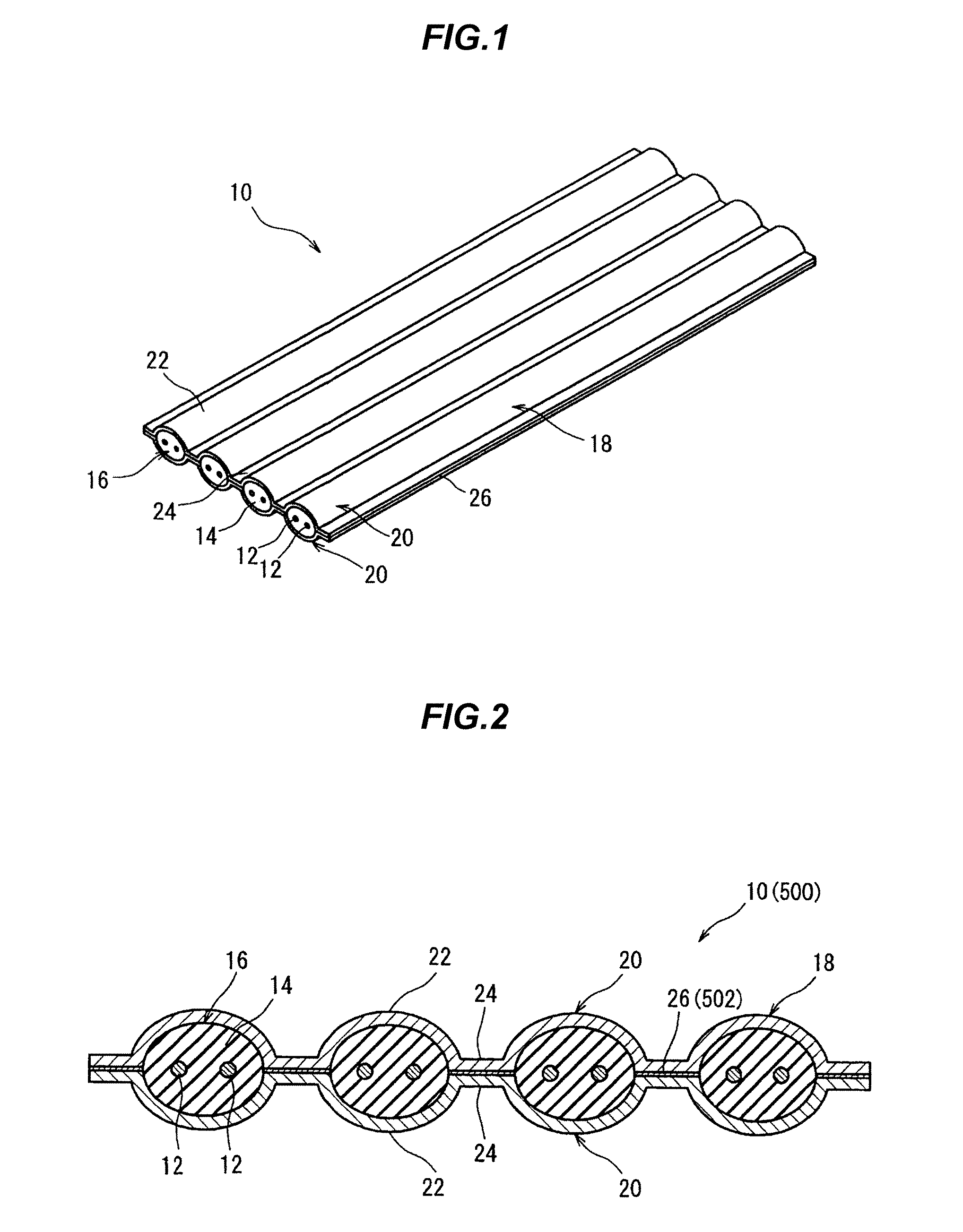

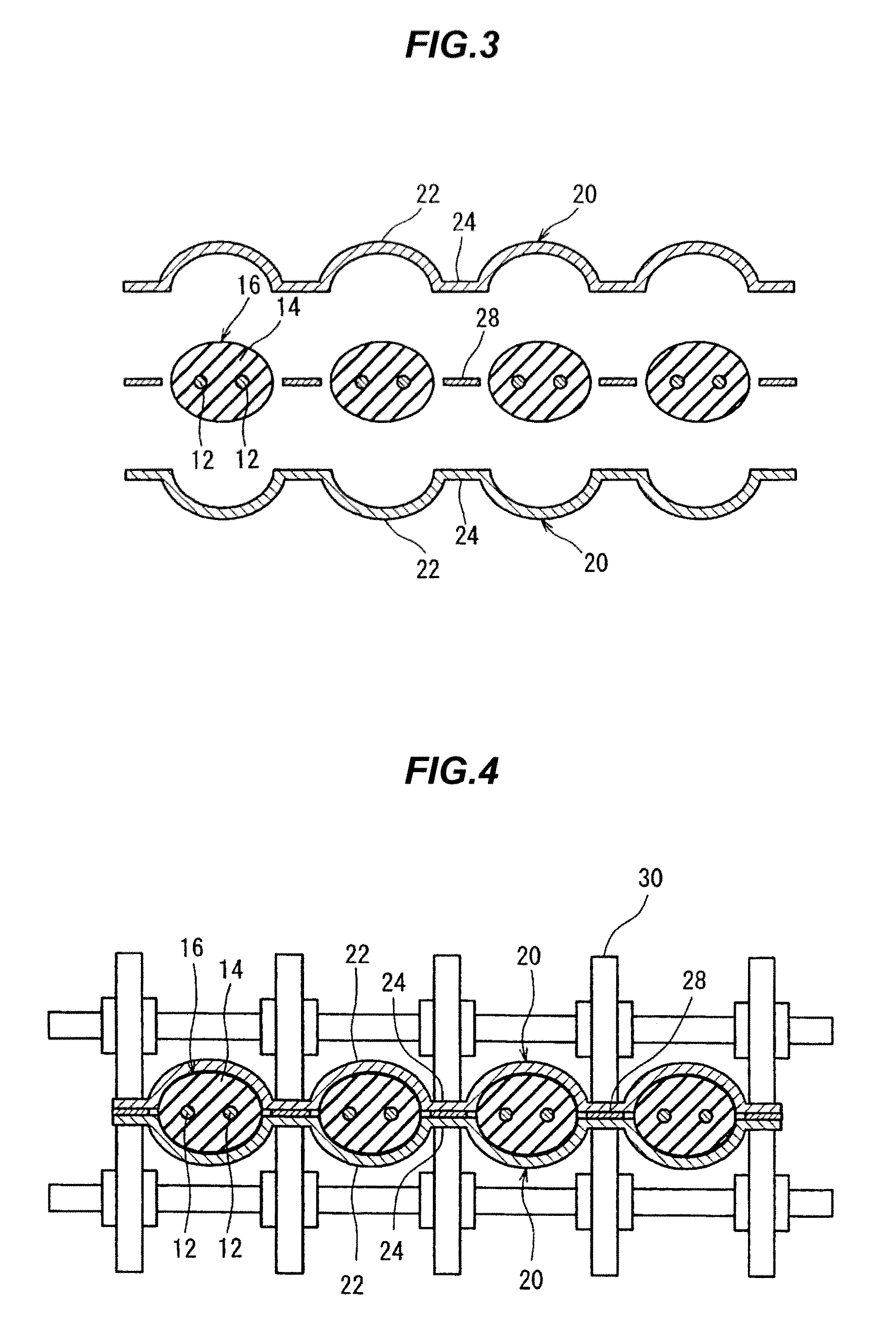

ActiveUS20120267143A1Improve electromagnetic shielding performanceSuppress transmission lossLine/current collector detailsMagnetic/electric field screeningEngineeringMechanical engineering

A shielded flat ribbon cable includes a plurality of insulated conductors being spaced parallel to each other, the insulated conductors each including an inner conductor and an insulation coating the inner conductor; an outer conductor bundling the insulated conductors together, the outer conductor including a first shell and a second shell in association with each other to sandwich the insulated conductors therebetween, each of the first shell and the second shell including a plurality of grooves covering outer surfaces of the insulated conductors, and a plurality of edge portions integral with both sides of the grooves, and gap formation-suppressing means for suppressing formation of gaps between the edge portions of the first shell and the edge portions of the second shell, respectively.

Owner:HITACHI METALS LTD

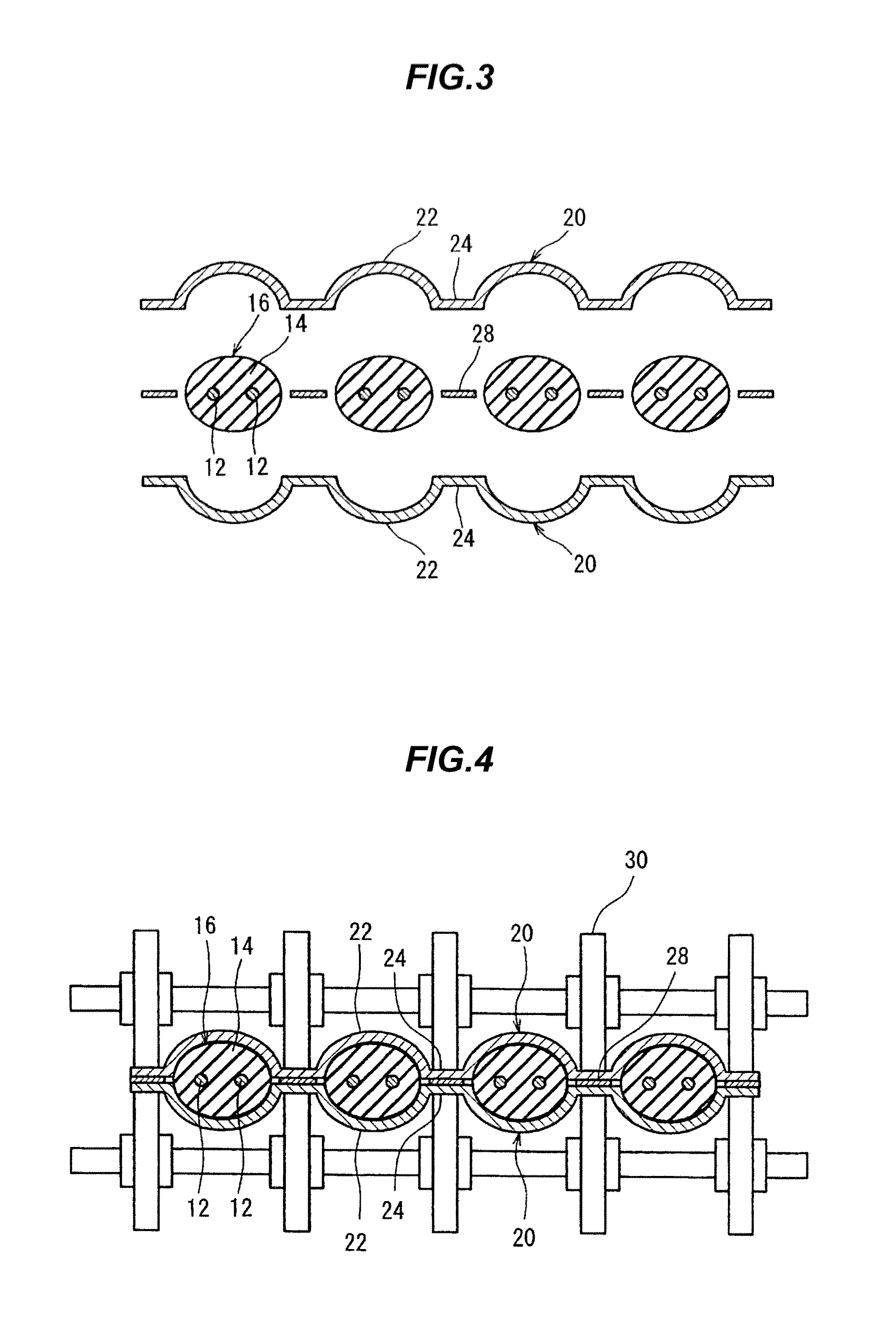

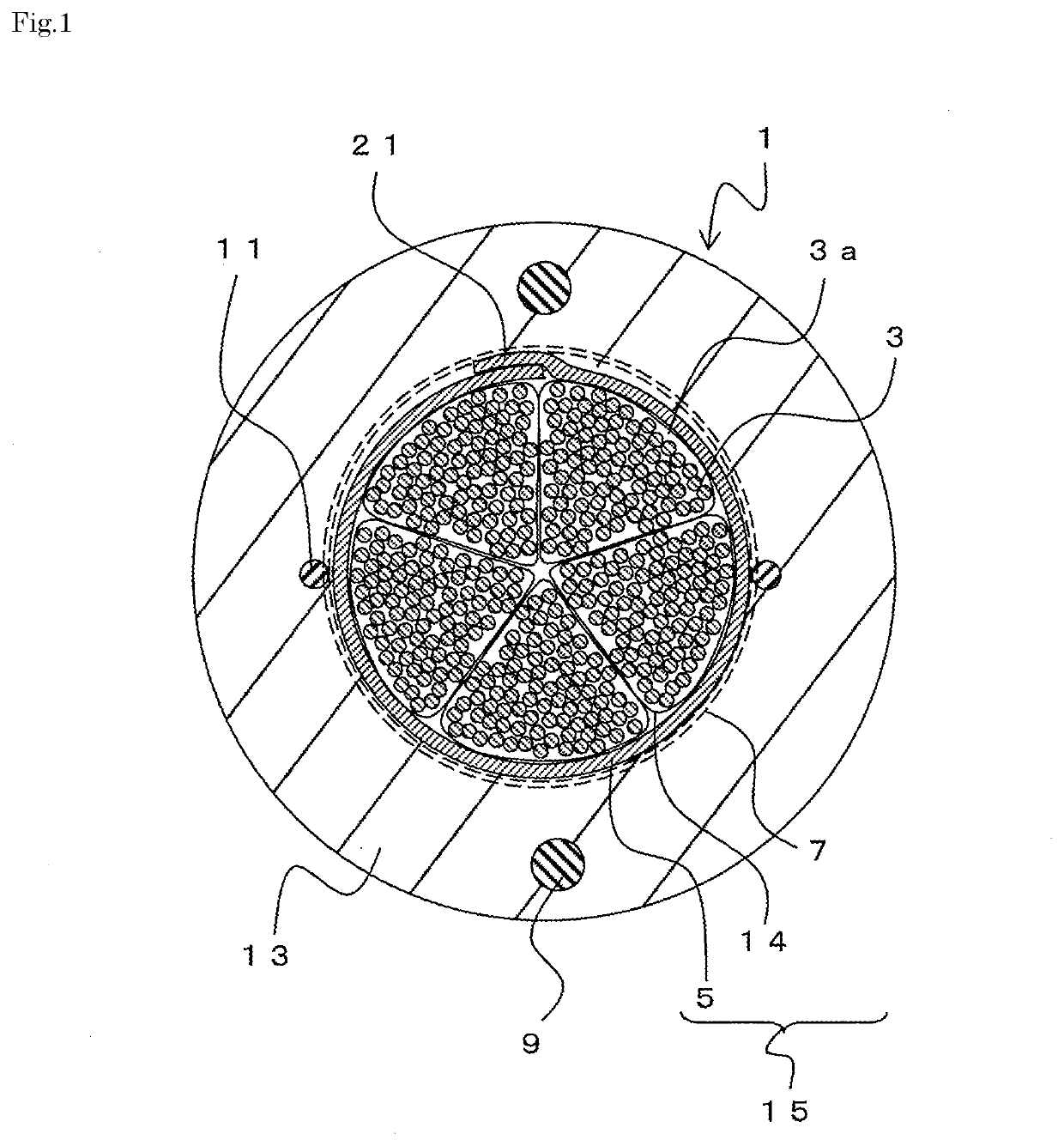

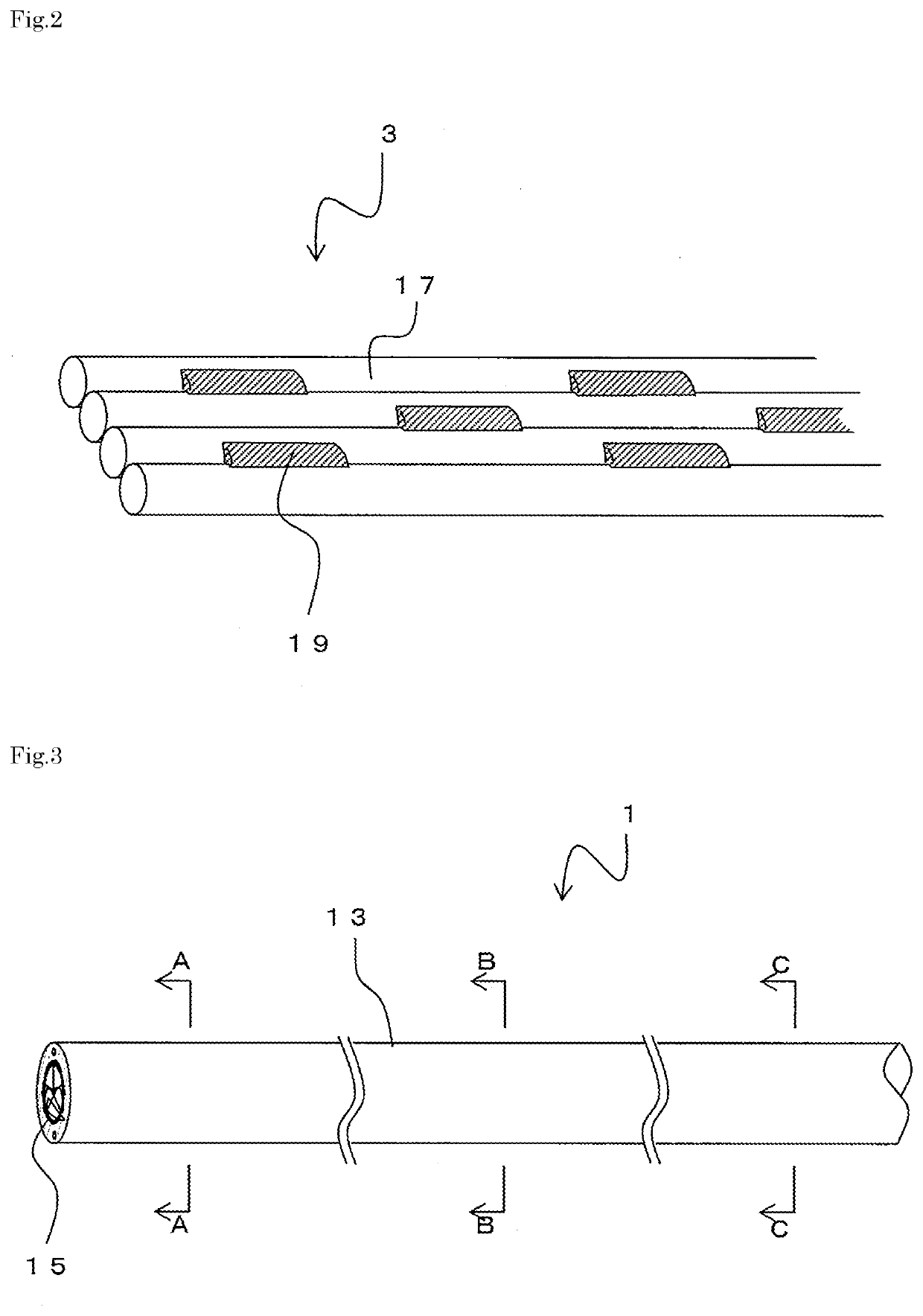

Optical fiber winding method, reeled optical fiber, and optical fiber transport method

InactiveCN103818775ASuppress transmission lossAvoid unwindingContainers for annular articlesFilament handlingFiberBobbin

The invention provides an optical fiber winding method, a reeled optical fiber, and an optical fiber transport method. The fiber winding method can prevent a fiber reel from releasing when the transmission loss of the fiber is reduced at the same time. When a fiber (10) having a diameter of about 250 [mu]m is being wound on a bobbin (11) and a winding tension is set as T (N) and a transverse pitch is set as P (mm), the optical fiber (10) is wound on the bobbin (11) with T / P2 larger than or equal to 0.5 N / mm2 and smaller than or equal to 6.3 N / mm2.

Owner:SUMITOMO ELECTRIC IND LTD

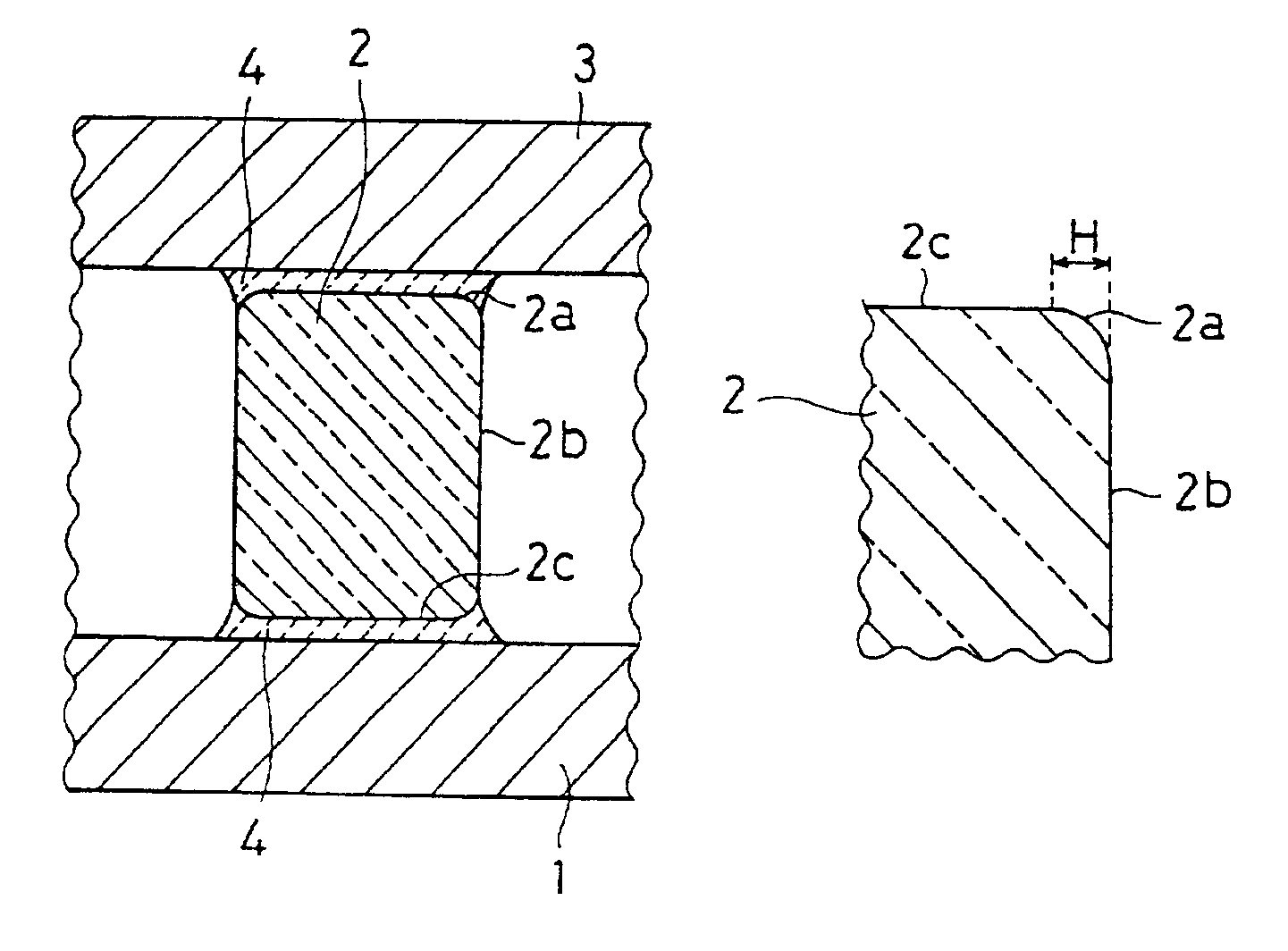

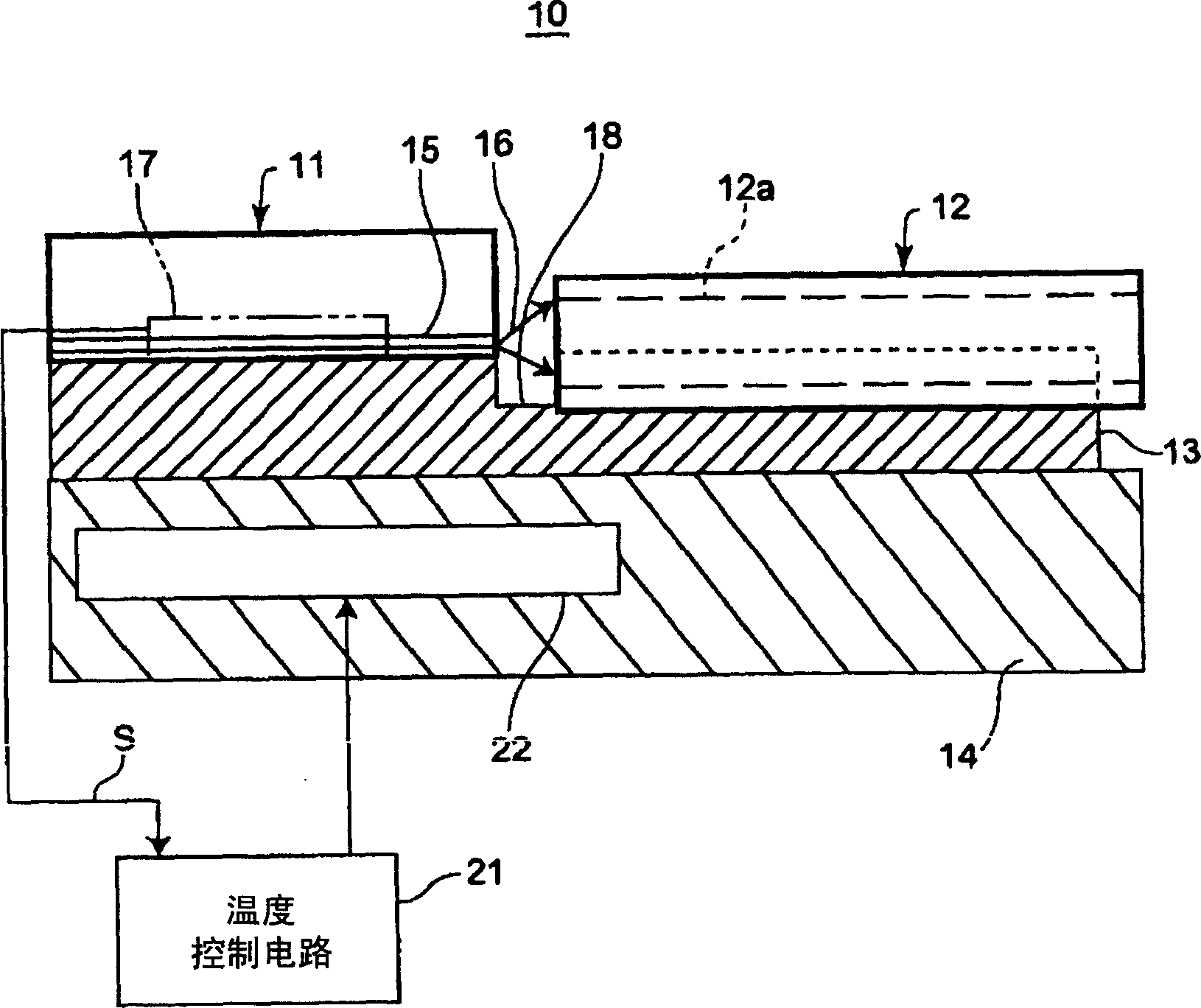

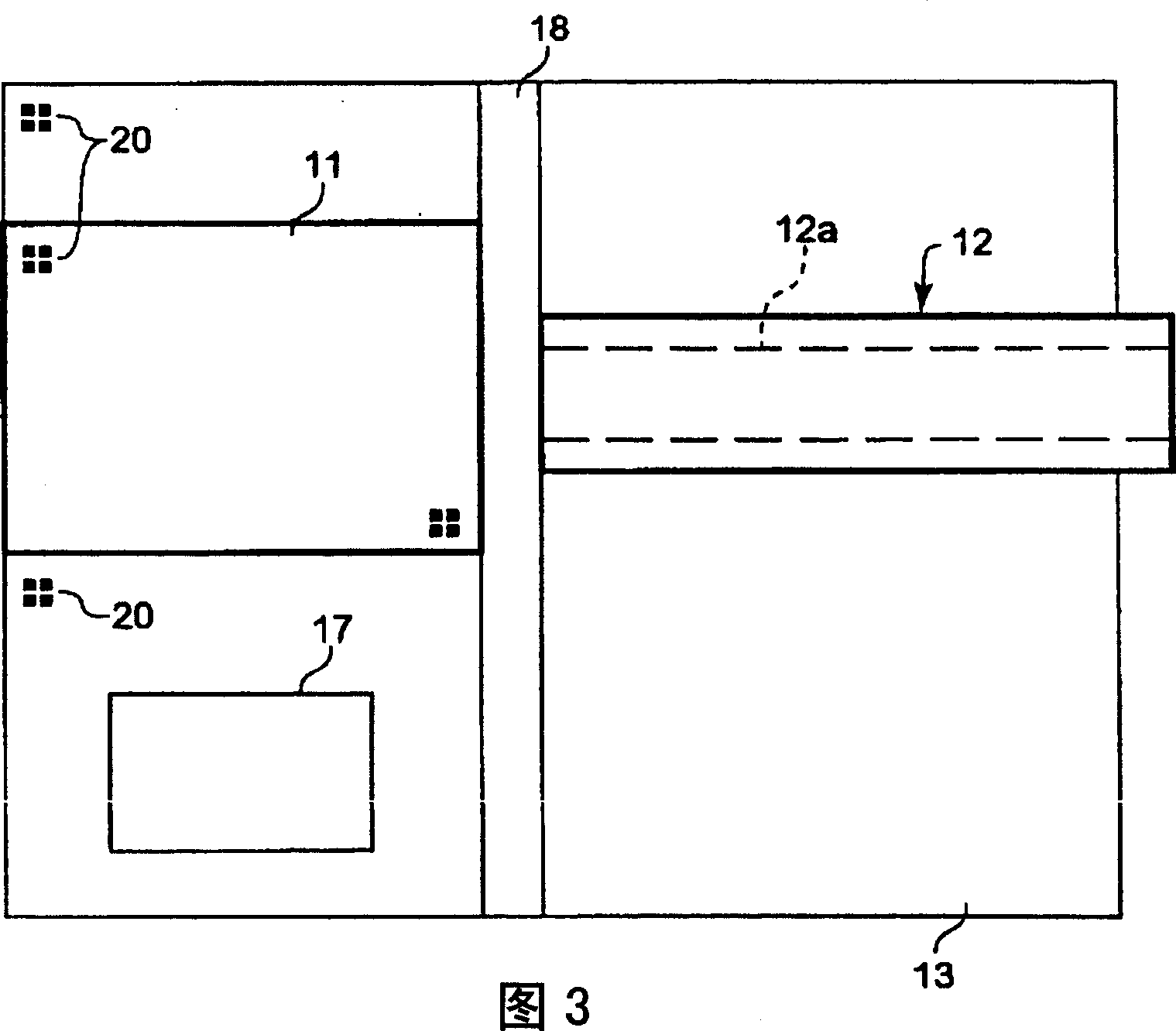

Non-radiative dielectric waveguide and millimeter wave transmitting/receiving apparatus

InactiveUS6882253B2Improve reliabilitySmall radius of curvatureWaveguidesCoupling devicesDielectricElectrical conductor

The invention provides a highly-reliable, low-loss non-radiative dielectric waveguide. According to one aspect of the invention, a non-radiative dielectric waveguide comprises parallel planar conductors arranged at an interval of half or below of a high-frequency signal wavelength, and a dielectric strip interposed between the parallel planar conductors. The dielectric strip has a 0.01 to 0.3 mm-wide chamfer formed at its edge portion in a high-frequency signal transmission direction. According to another aspect of the invention, a non-radiative dielectric waveguide comprises parallel planar conductors arranged at an interval of half or below of a high-frequency signal wavelength, and a dielectric strip interposed between the parallel planar conductors. The dielectric strip is made of a ceramics having an open pore ratio of 5% or less.

Owner:KYOCERA CORP

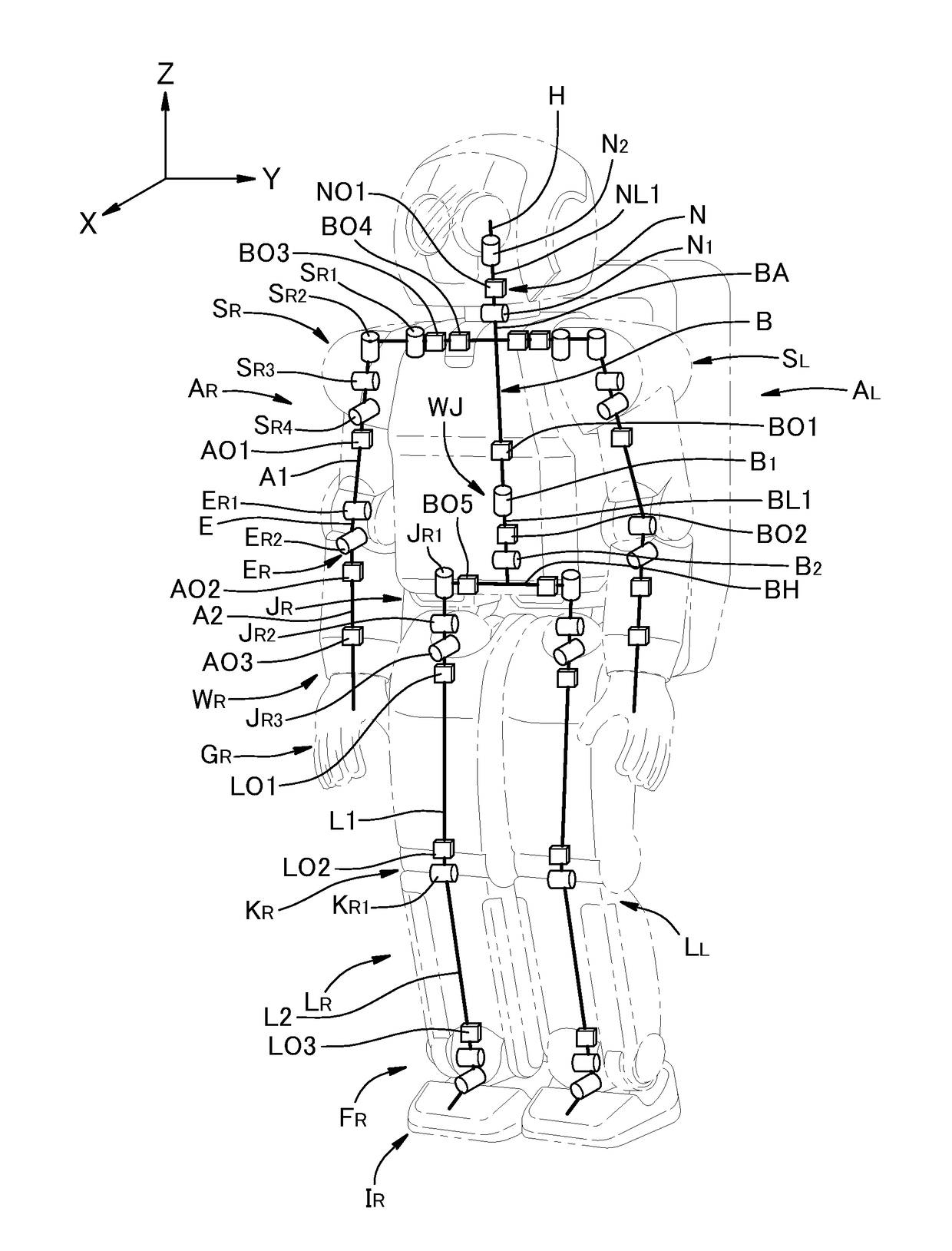

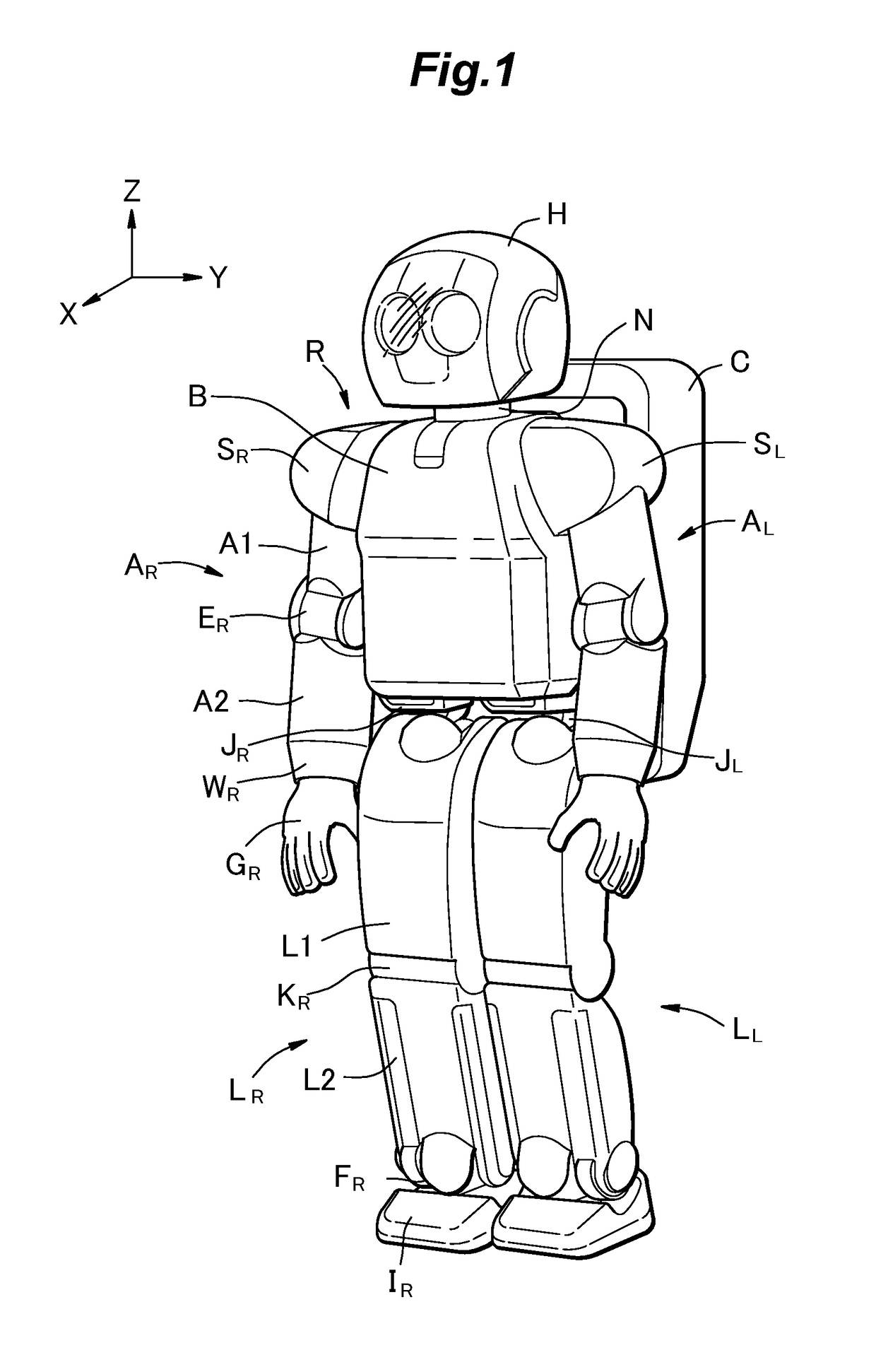

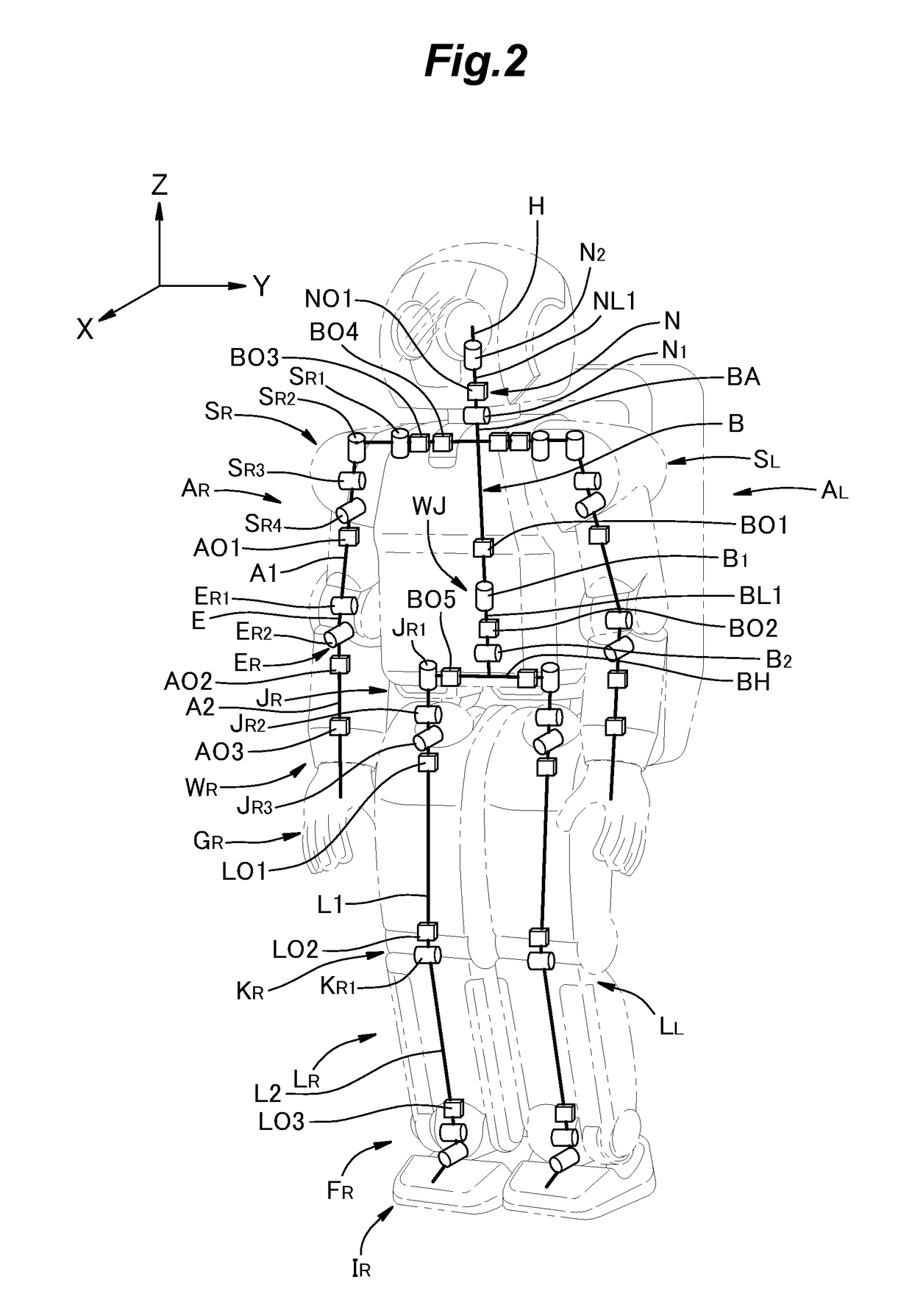

Optical fiber network for transmitting signals in a robot

ActiveUS20170309169A1SimpleTransmission loss becomes largeProgramme-controlled manipulatorNon-electrical signal transmission systemsVIT signalsTransceiver

In an optical fiber network for transmitting optical signals in a robot having three or more joints connecting a plurality of links in series such that the links include two end links located at either end and intermediate links provided between the two end links, and the links connected by the joints are moveable relative to each other, a plurality of optical transceiver modules are provided on the links such that at least one optical transceiver module is provided on each link; and a plurality of optical fiber cables connect the optical transceiver modules in a ring; wherein at least one end of each optical fiber cable connecting the optical transceiver modules provided on different links is connected to one of the optical transceiver modules provided on the intermediate links.

Owner:HONDA MOTOR CO LTD

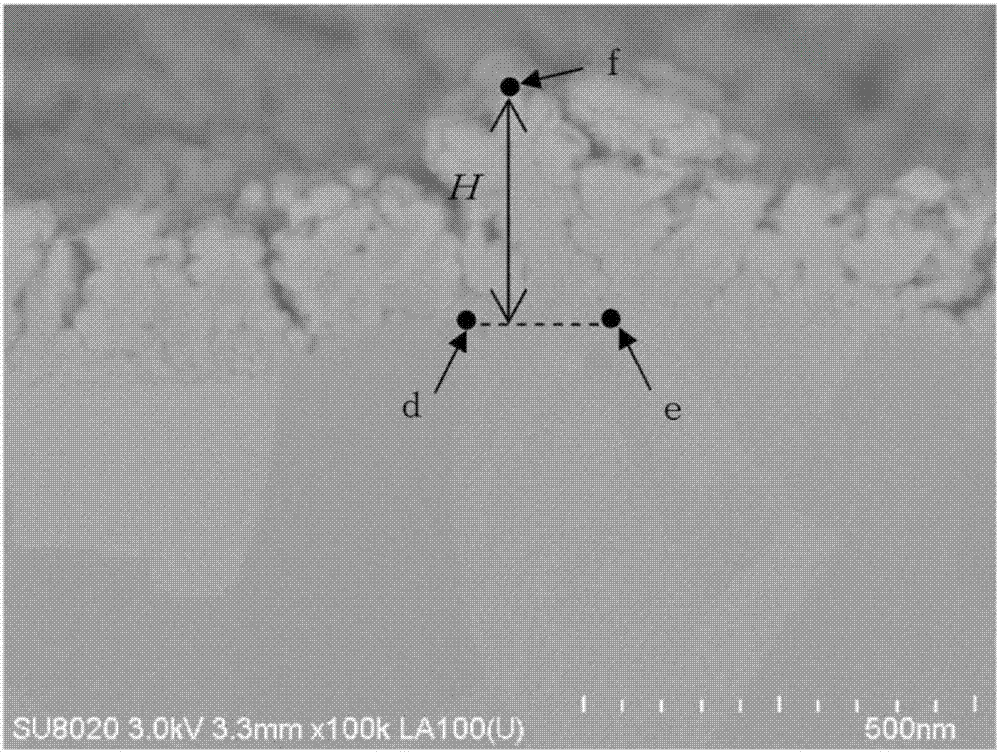

Surface-treated copper foil for printed circuit board, copper-clad laminate for printed circuit board, and printed circuit board

ActiveCN107109679AImprove legibilityExcellent adhesionInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentCopper foilMaterials science

A surface-treated copper foil that is for a printed circuit board and that has a silane coupling agent layer on a surface on which roughened particles have been formed. The average height of the roughened particles on the silane-coupling-agent-layer surface is 0.05 [mu]m or more but less than 0.5 [mu]m, the BET surface area ratio of the of the silane-coupling-agent-layer surface is 1.2 or higher, and the micro-surface coefficient Cms of the silane-coupling-agent-layer surface is 2.0 or higher but less than 8.0.

Owner:FURUKAWA ELECTRIC CO LTD

Process for producing polymer optical waveguide

InactiveUS6962667B2Firmly connectedSuppress transmission lossOptical articlesBundled fibre light guidePolymer optical waveguideMaterials science

A process for producing a polymer optical waveguide including the steps of: preparing a mold by applying a mold-forming resin layer onto a master template, peeling the layer from the master template to obtain a template, and cutting both ends of the template to expose a concave portion; bringing the mold into close contact with a film used for a cladding layer; introducing, by capillarity, a UV-curable resin or heat-curable resin by contacting the resin with one end of the mold; curing the introduced resin and removing the mold from the film; and forming a cladding layer on film on which the core has been formed, wherein a sectional area, a sectional shape, or both of a sectional area and a sectional shape of the core changes in a longitudinal direction of the core, and both end faces of the core have different areas.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Shielded flat ribbon cable and method for fabricating a shielded flat ribbon cable

ActiveUS8946556B2Excellent in high-frequency property and electromagnetic shielding propertyImprove electromagnetic shielding performanceCoaxial cables/analogue cablesLine/current collector detailsRibbon cableEngineering

Owner:HITACHI METALS LTD

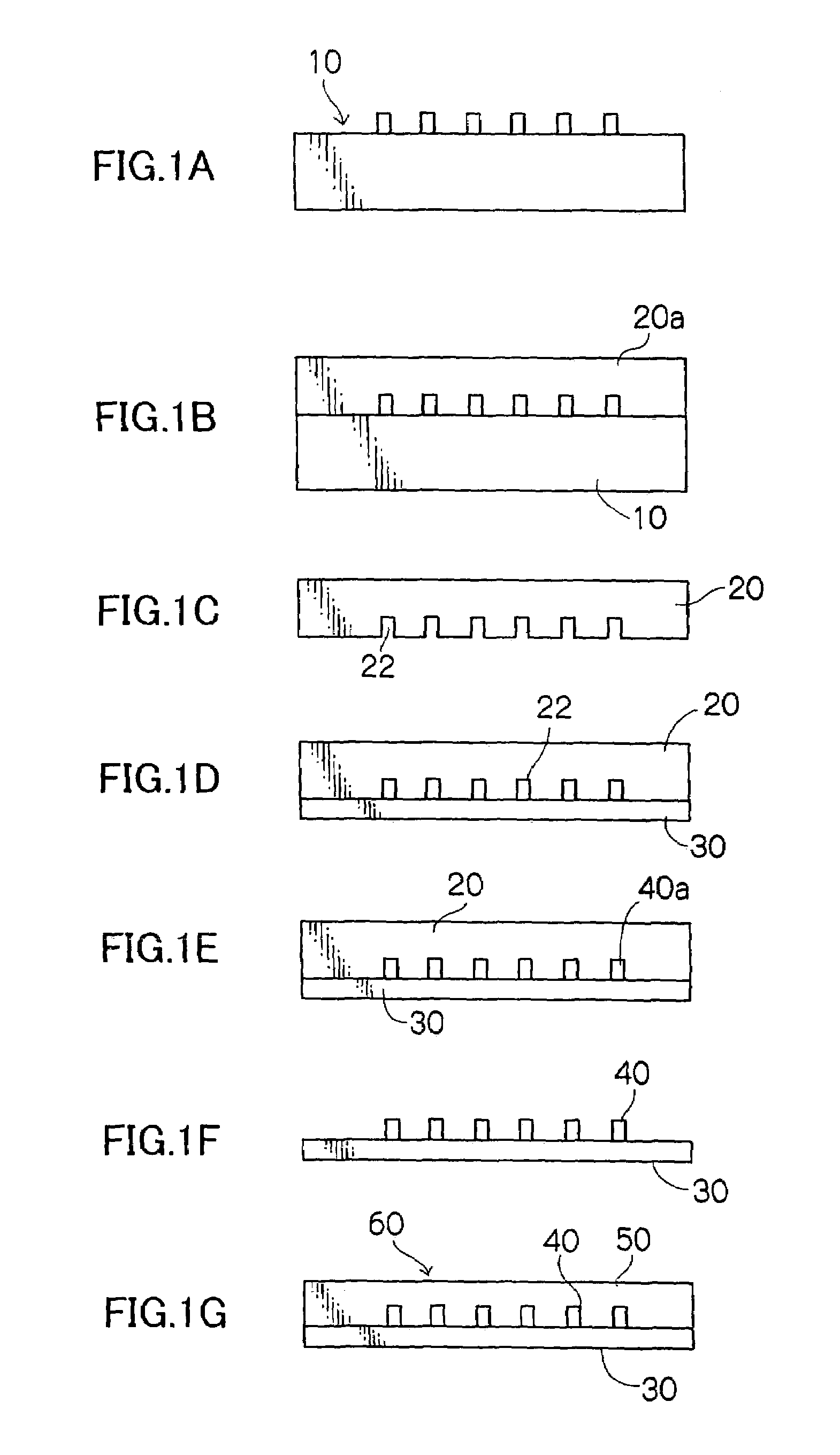

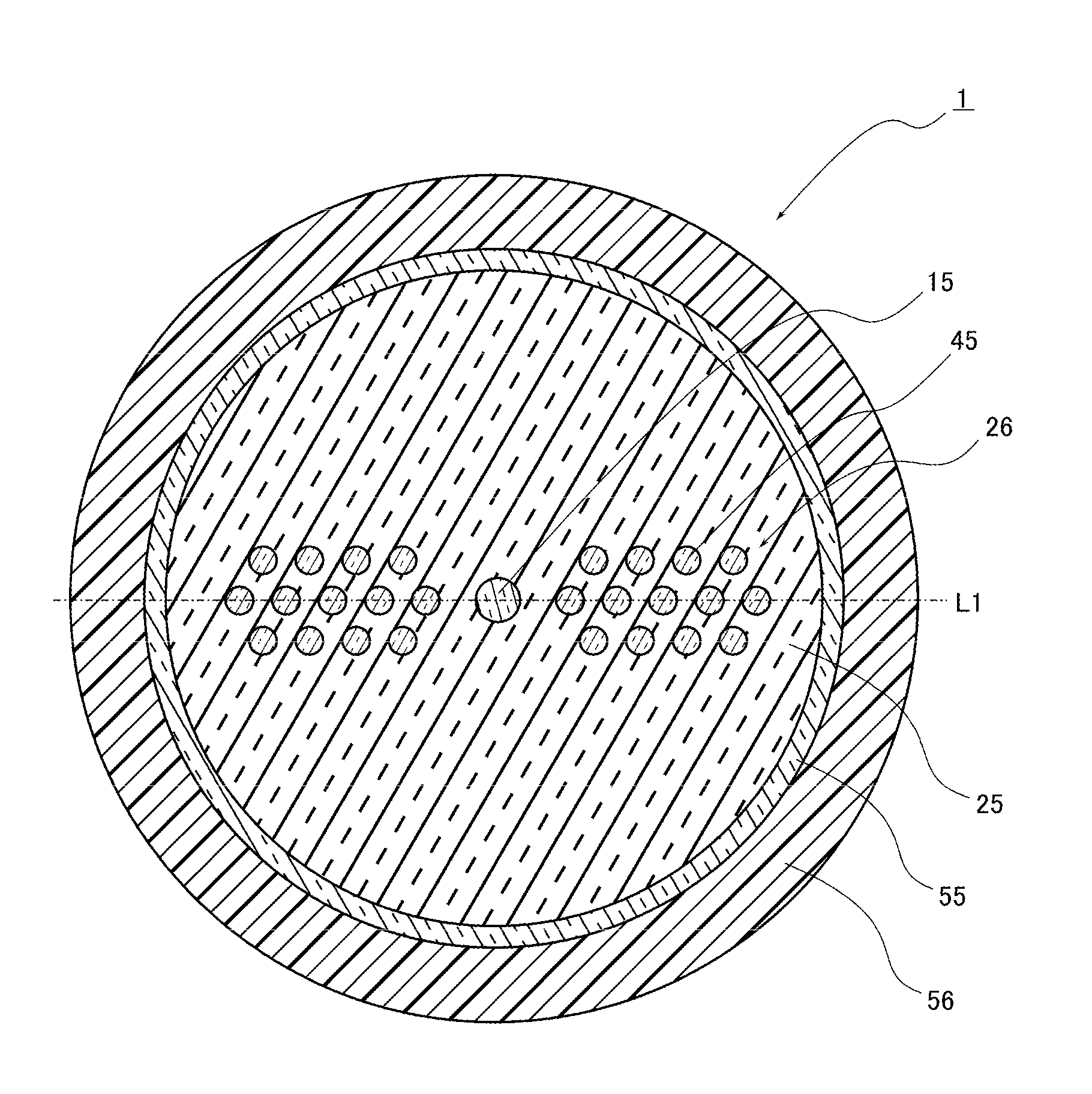

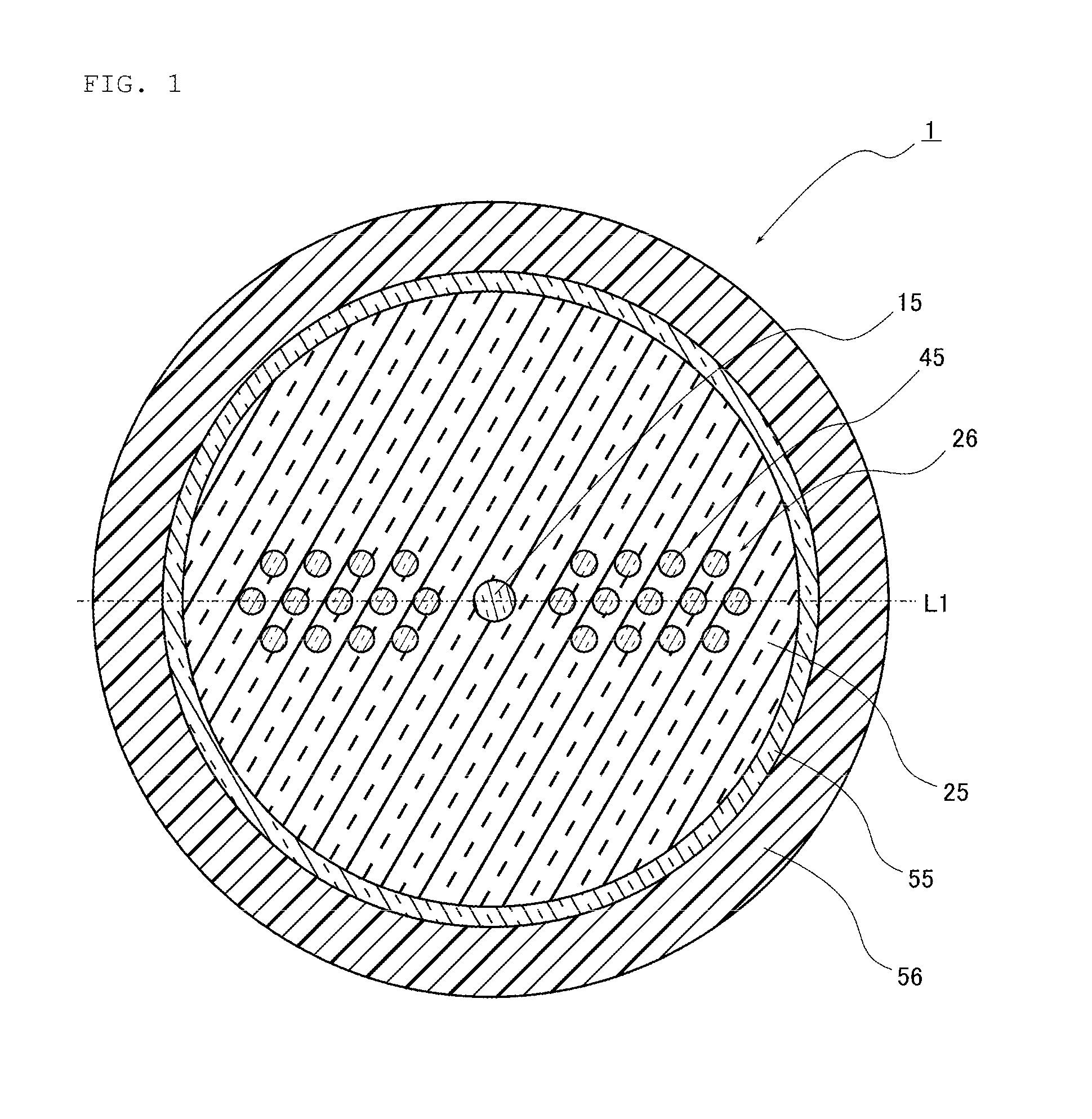

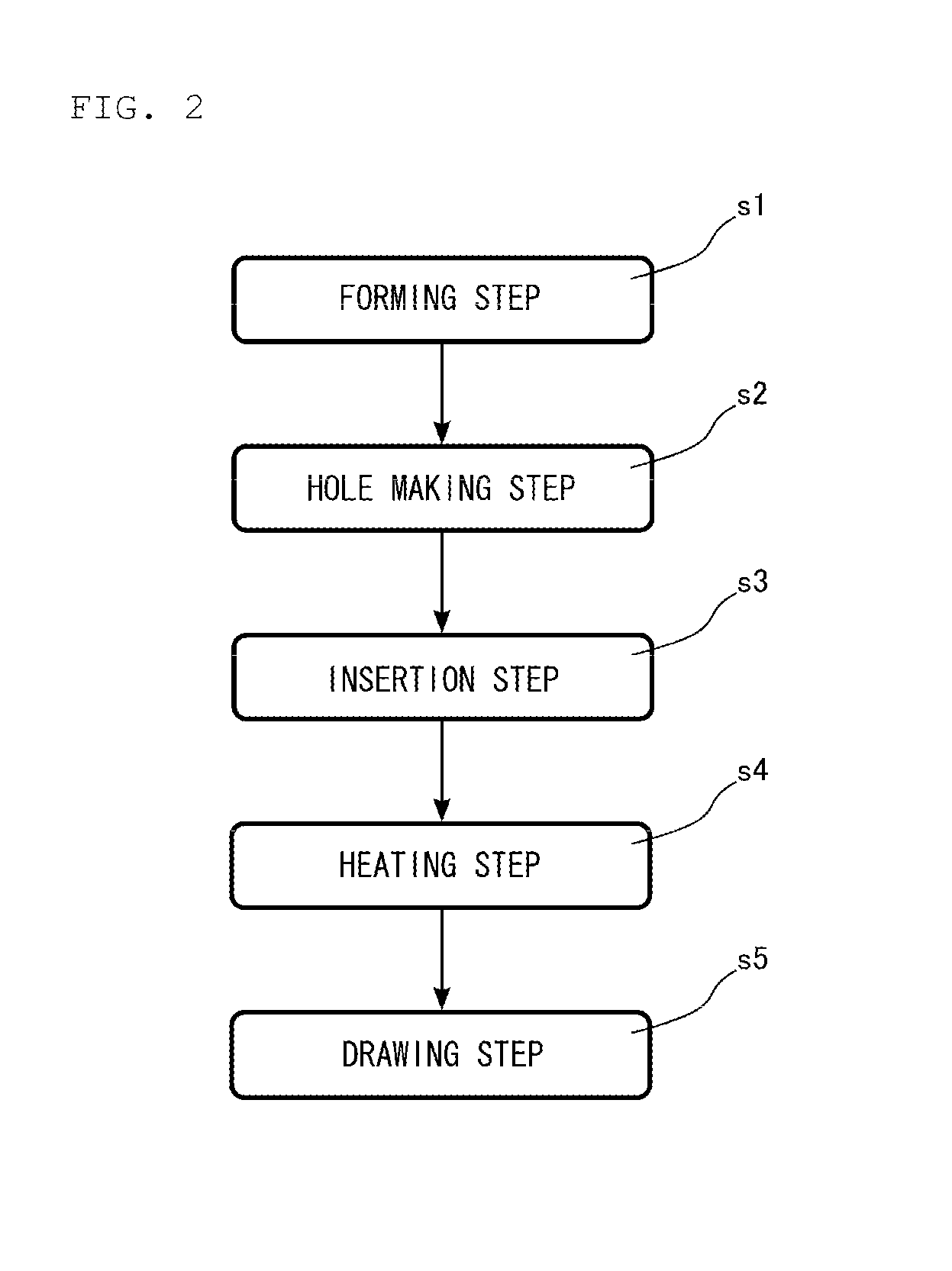

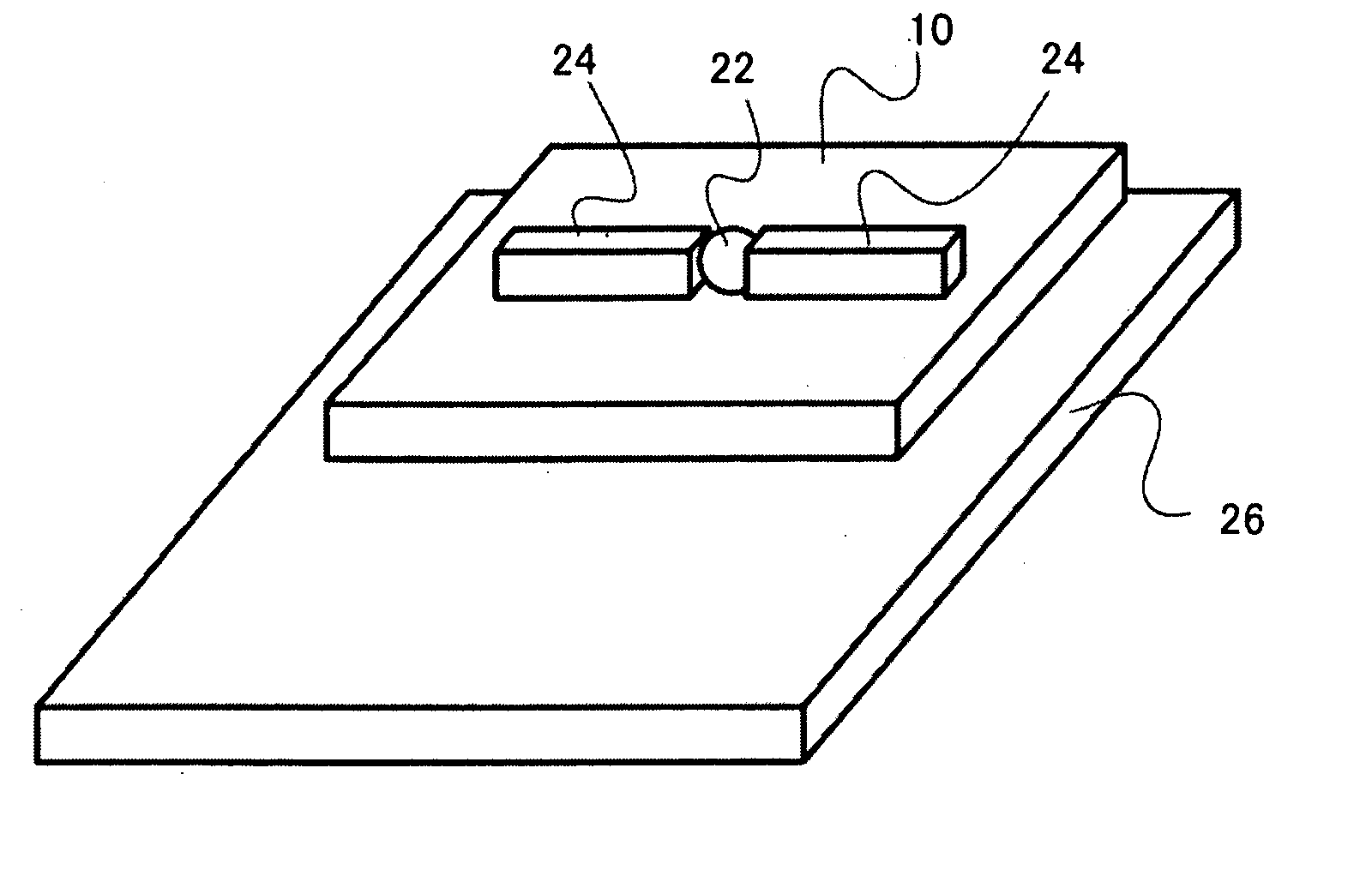

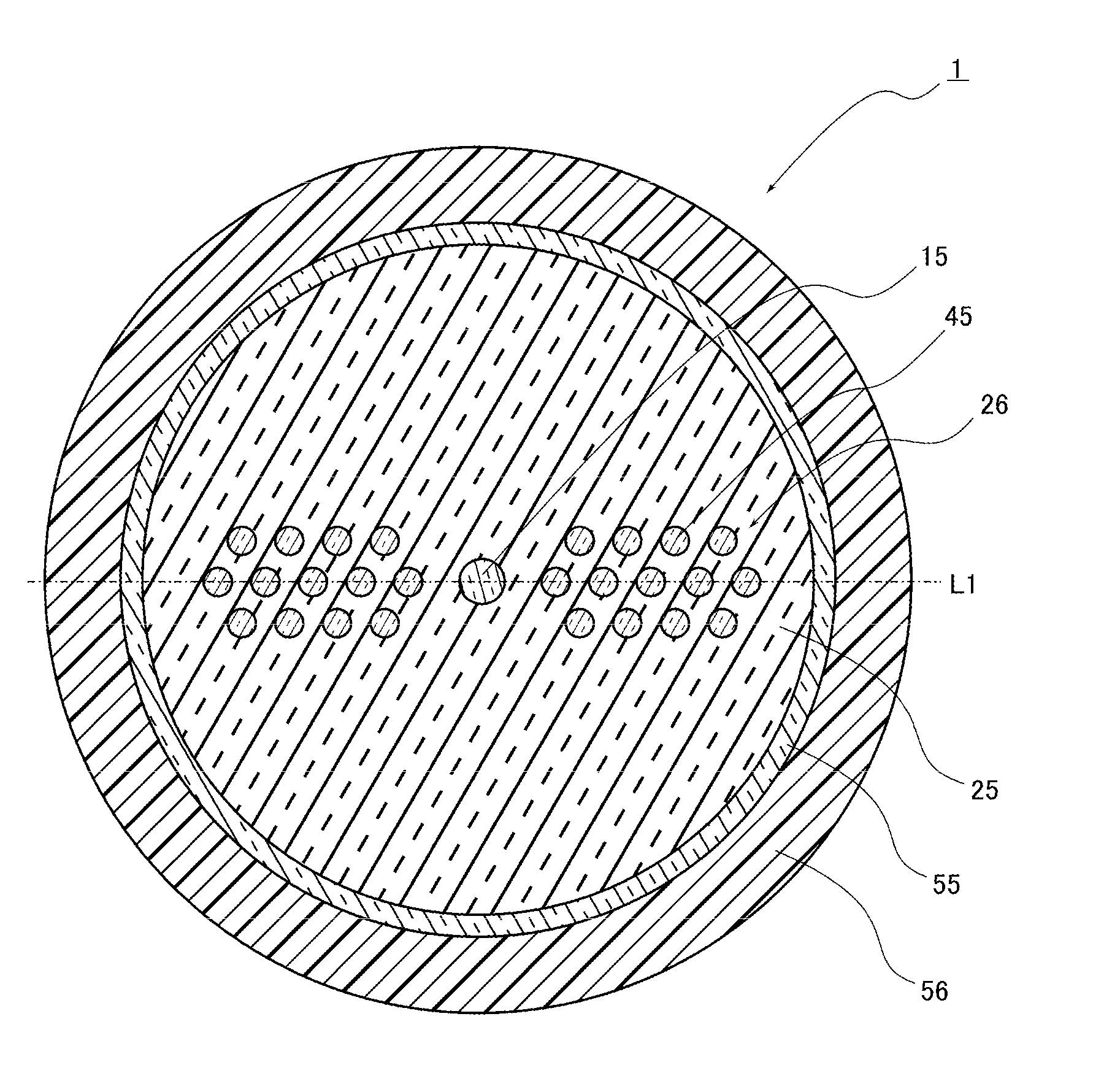

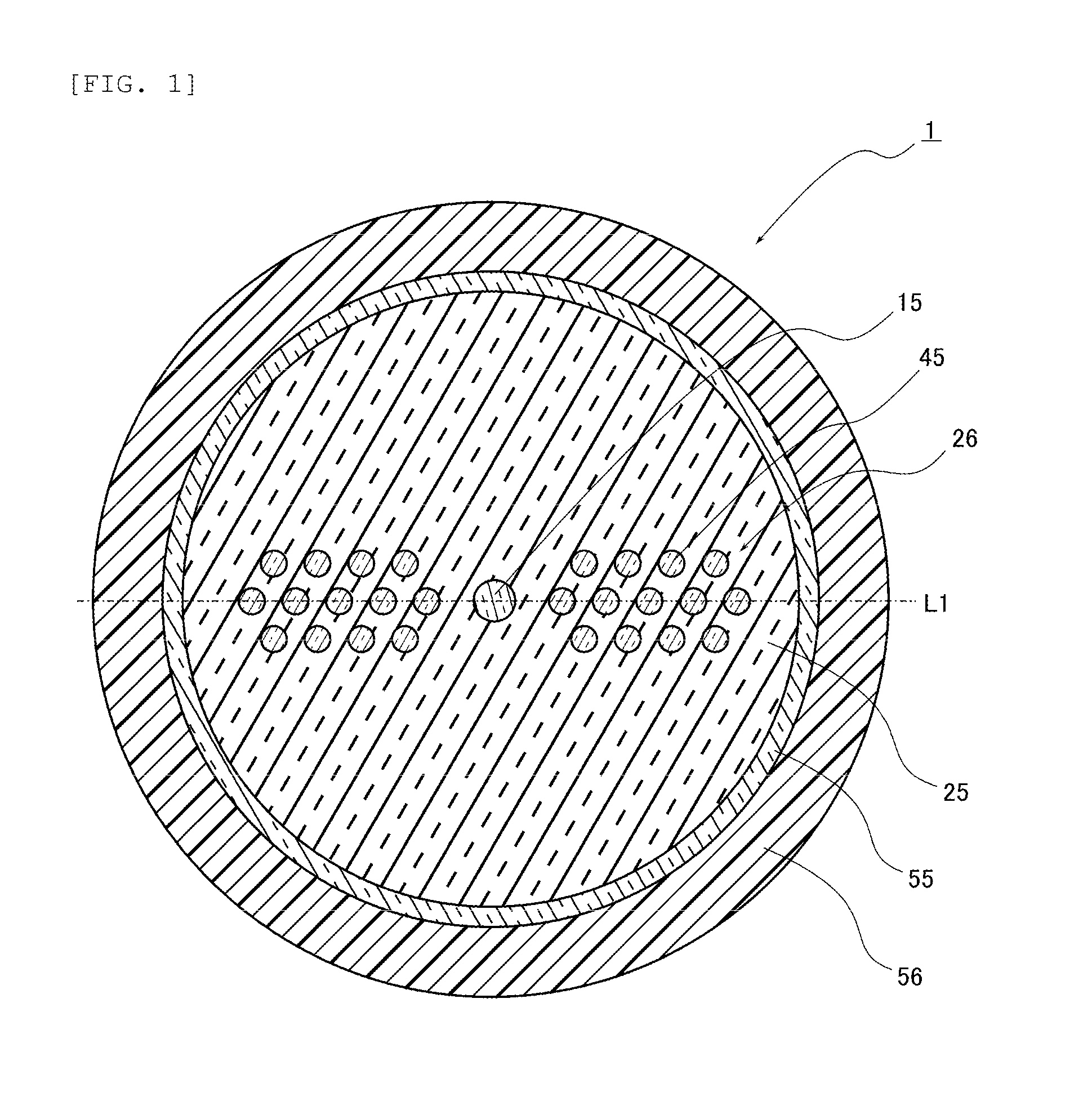

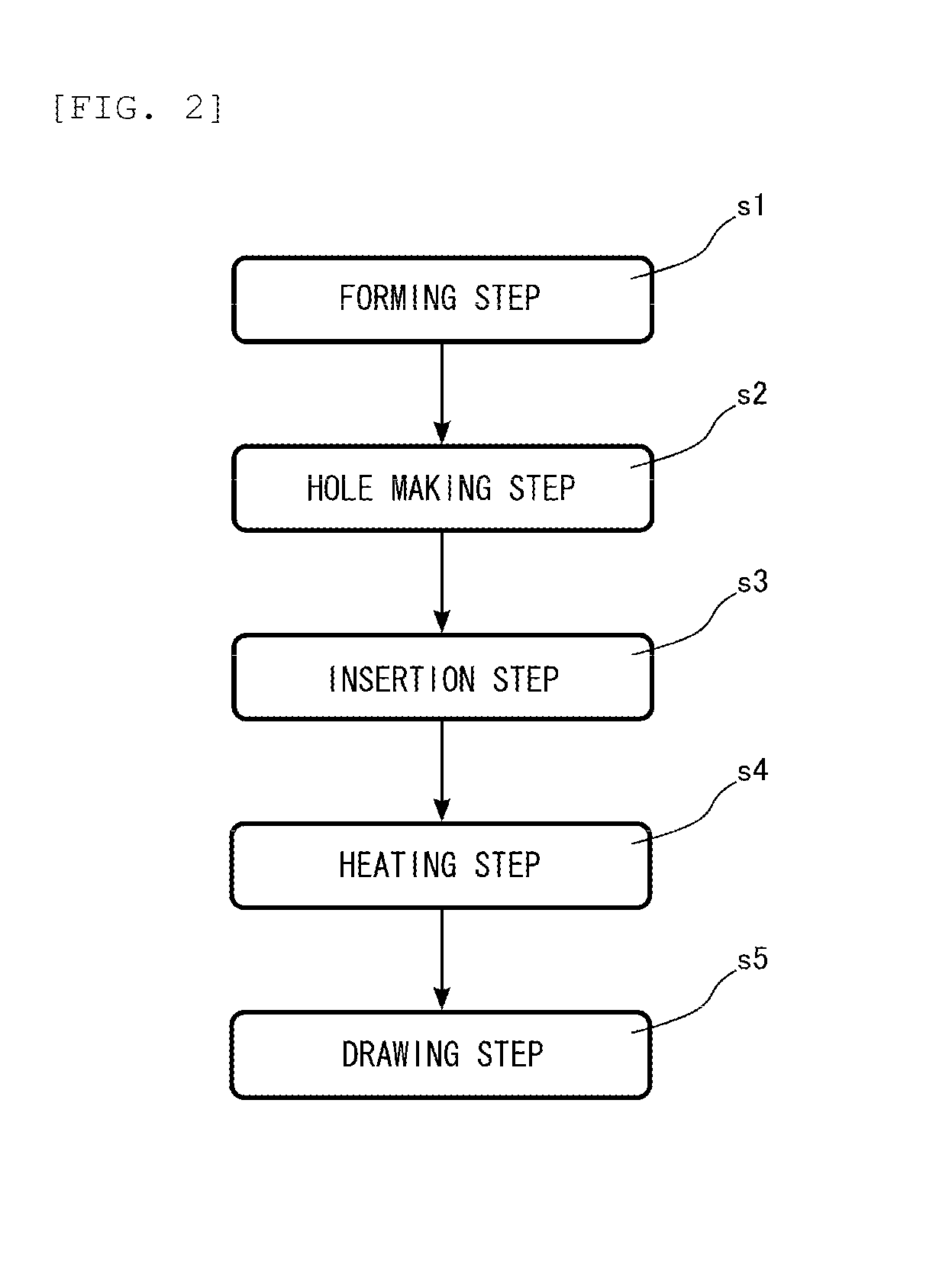

Method of manufacturing photonic band gap fiber base material and fiber

InactiveUS8381548B2Suppress transmission lossGlass making apparatusOptical fibre with polarisationPhotonic bandgapMetallurgy

A method of manufacturing a photonic band gap fiber base material includes: a forming step of continuously forming a columnar core glass body 10 and a clad glass body 20 which coats the core glass body to obtain an intermediate base material 110; a hole making step of making holes 30 in the clad glass body 20; an insertion step of inserting in the holes 30 a plurality of bilayer glass rods 40 in which an outer layer 42 which has the same refractive index as the clad glass body coats high refractive index portions 41 having a higher refractive index than a refractive index of the clad glass body 20; and a heating step of heating the intermediate base material 110 and integrating the intermediate base material 110 and the bilayer glass rods 40.

Owner:FUJIKURA LTD

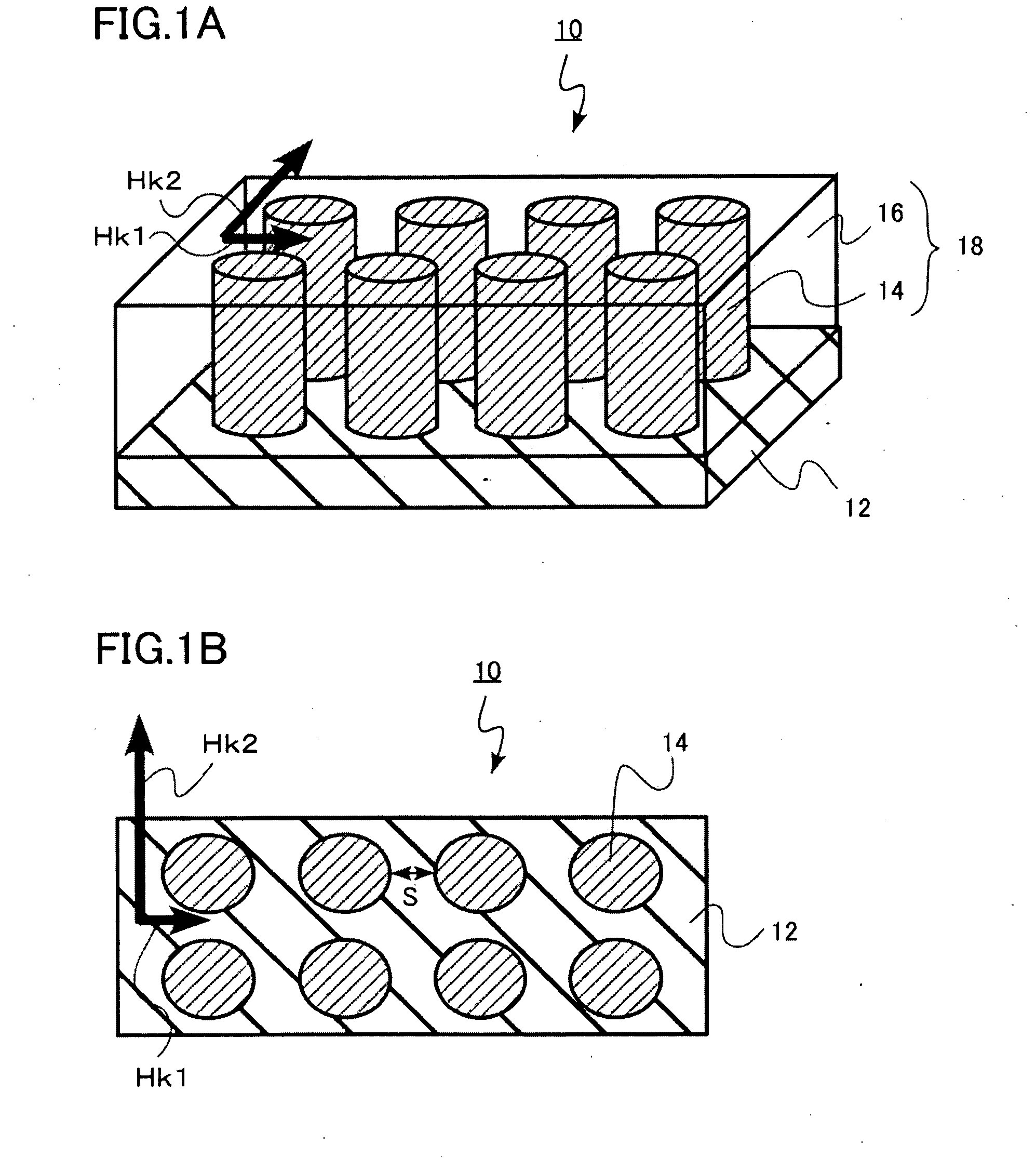

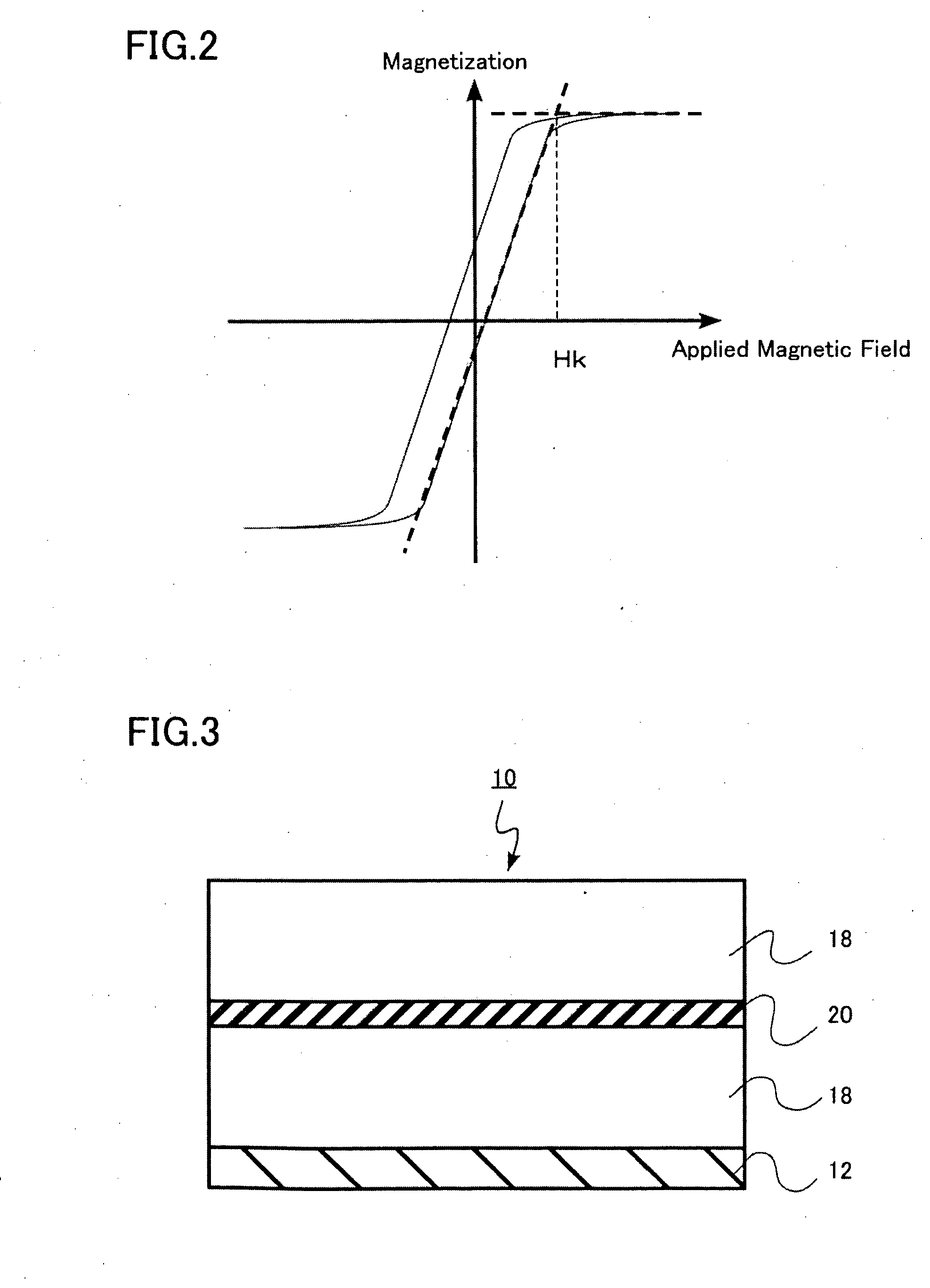

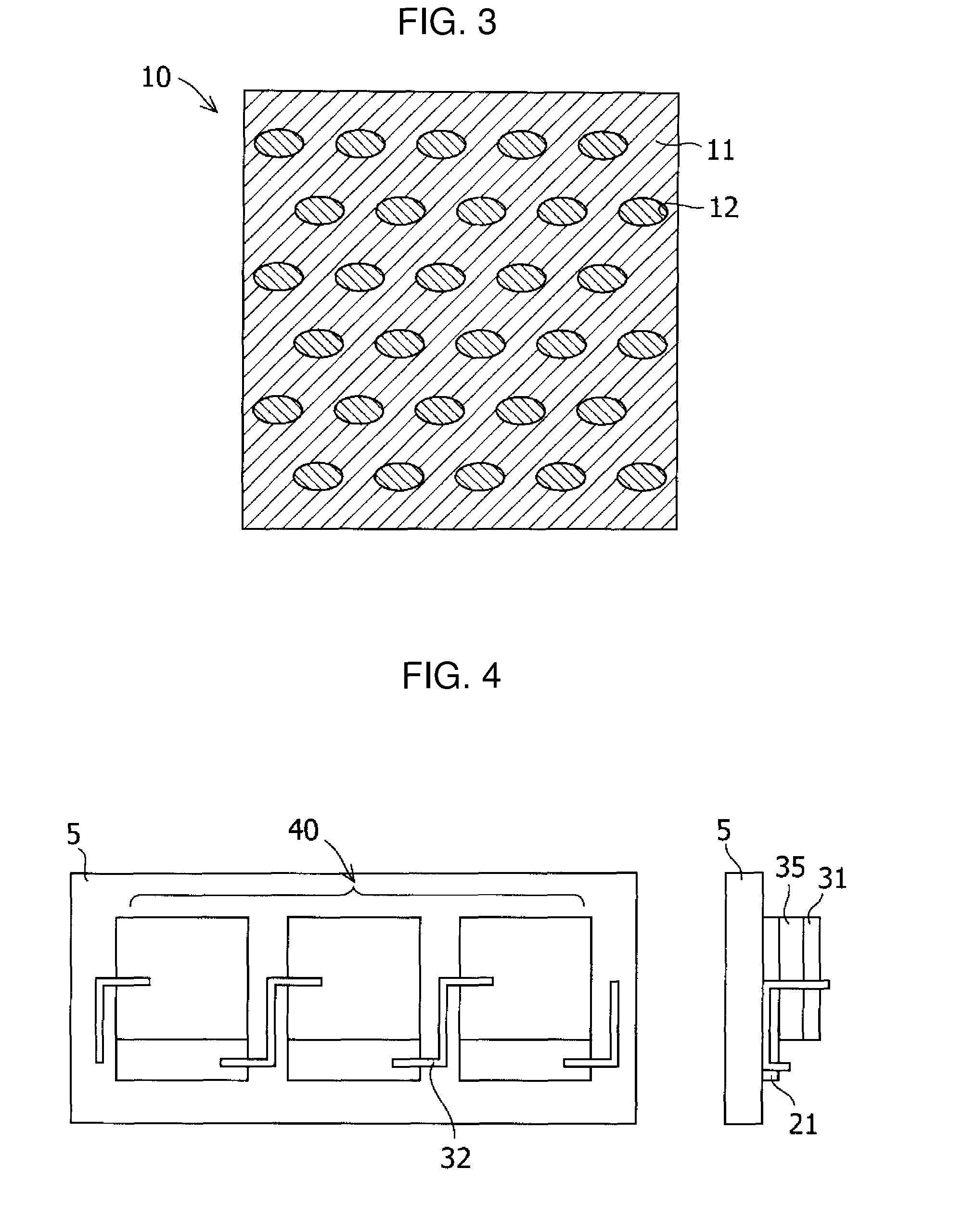

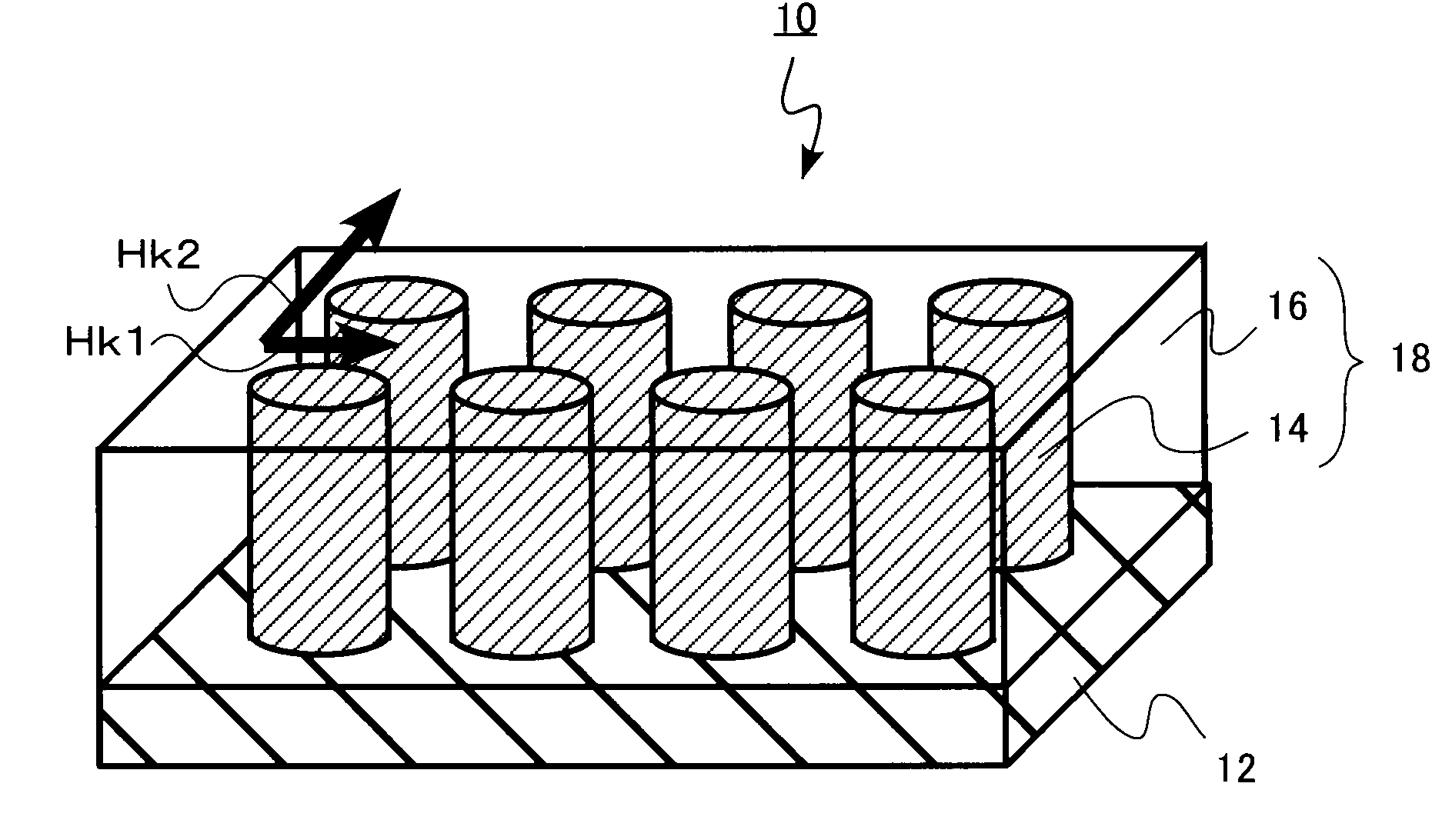

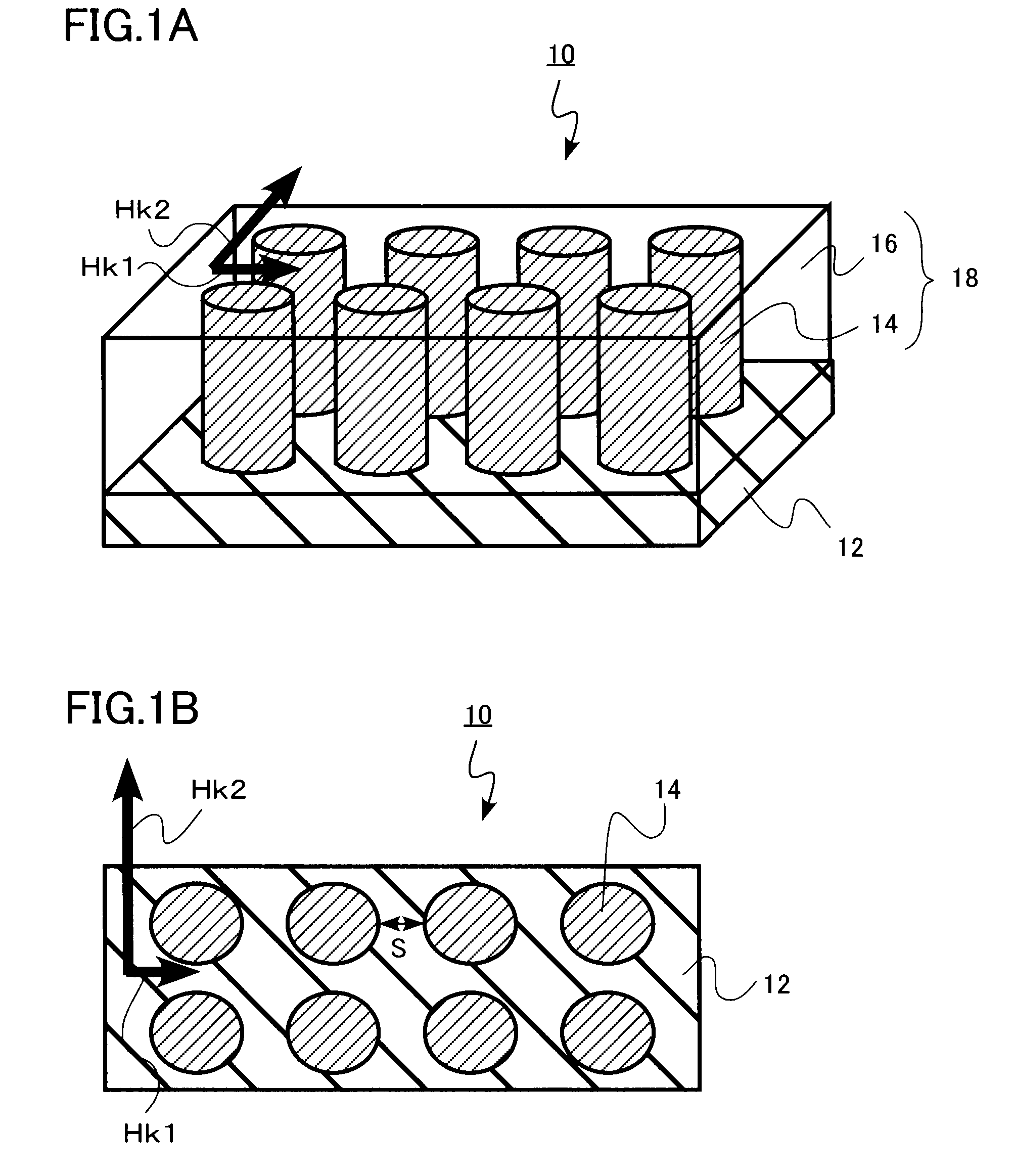

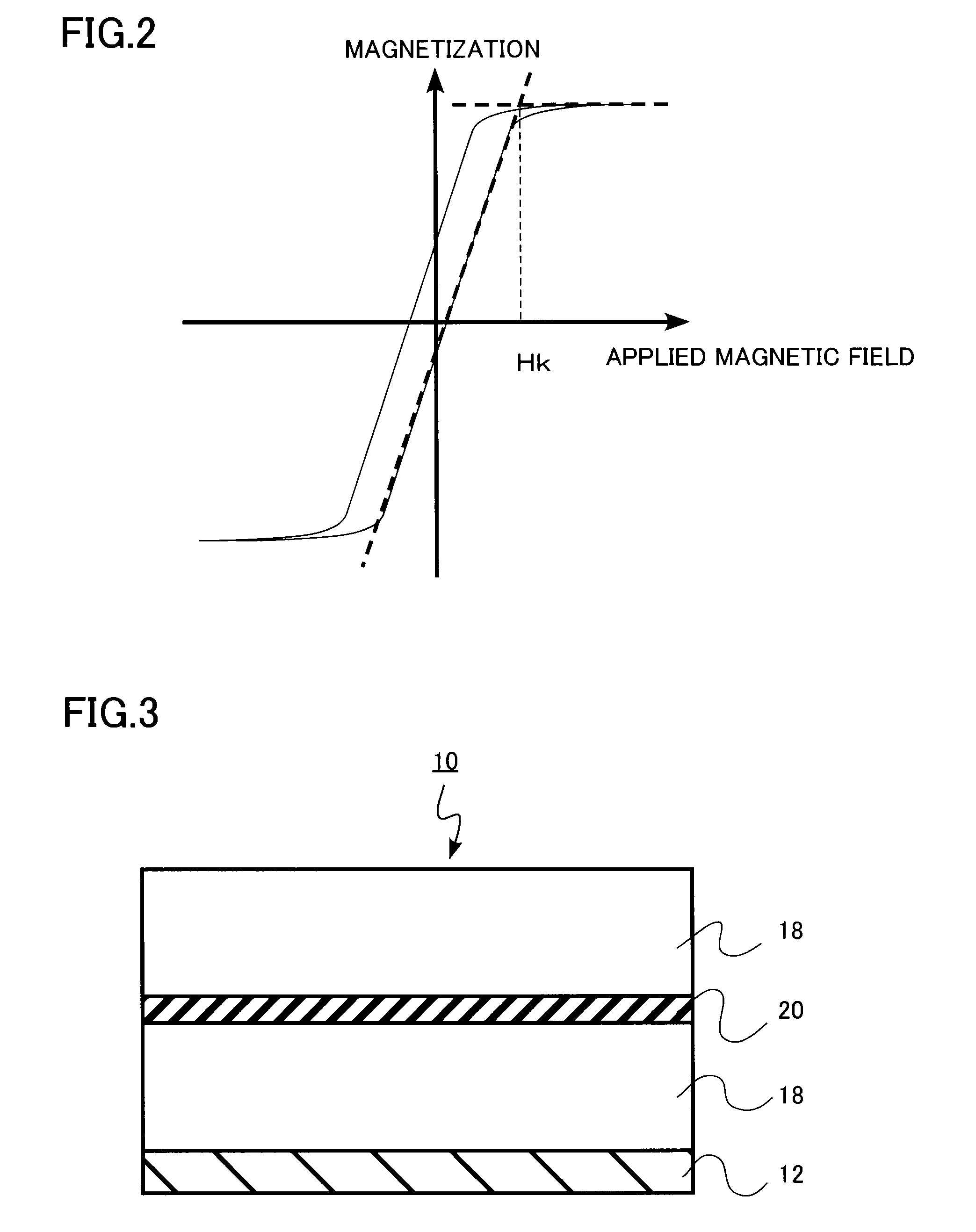

High-frequency magnetic material and antenna device using thereof

InactiveUS20090058750A1Suppress transmission lossNanostructure applicationNanomagnetismIn planeMagnetic phase

A superior high-frequency magnetic material having a smaller ratio (μ″ / μ′) of the real part μ′ of permeability and the imaginary part μ″ of permeability in a high-frequency region and an antenna device using thereof are provided. The high-frequency magnetic material includes a substrate and a composite magnetic film formed on the substrate that consists of a magnetic phase forming a plurality of columnar bodies whose longitudinal direction is directed in a direction perpendicular to a surface of the substrate and an insulator phase filling gaps of the columnar bodies, and the magnetic phase is amorphous and has in-plane uniaxial anisotropy of Hk2 / Hk1≧3 and Hk2≧3.98×103 A / m when a minimal anisotropic magnetic field in a plane in parallel with the surface of the substrate is Hk1 and a maximal anisotropic magnetic field is Hk2.

Owner:KK TOSHIBA

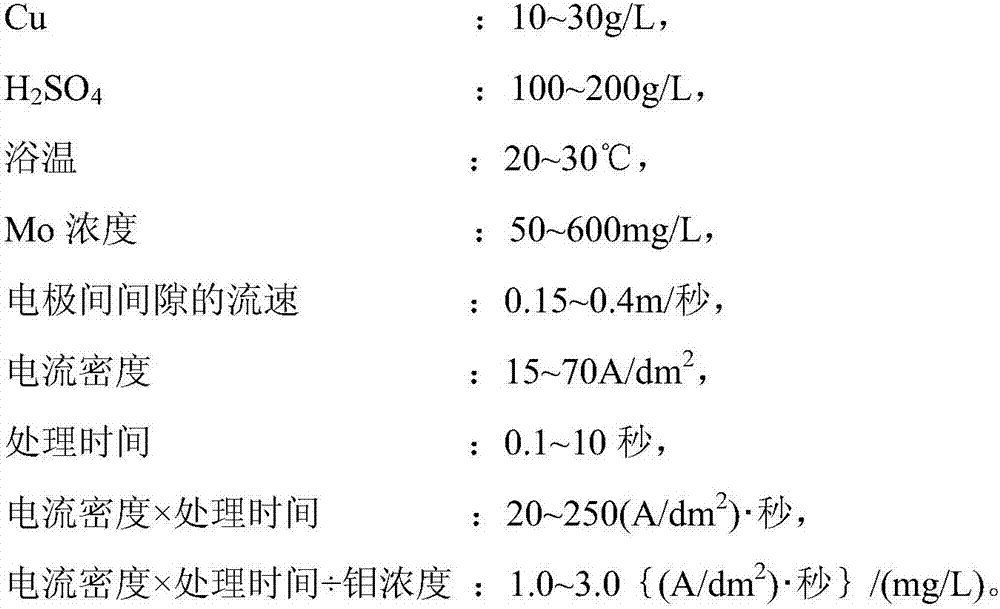

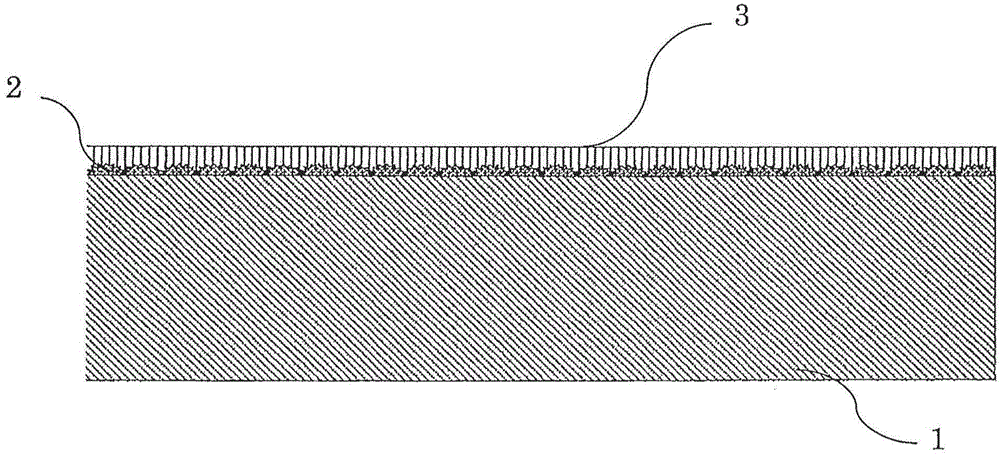

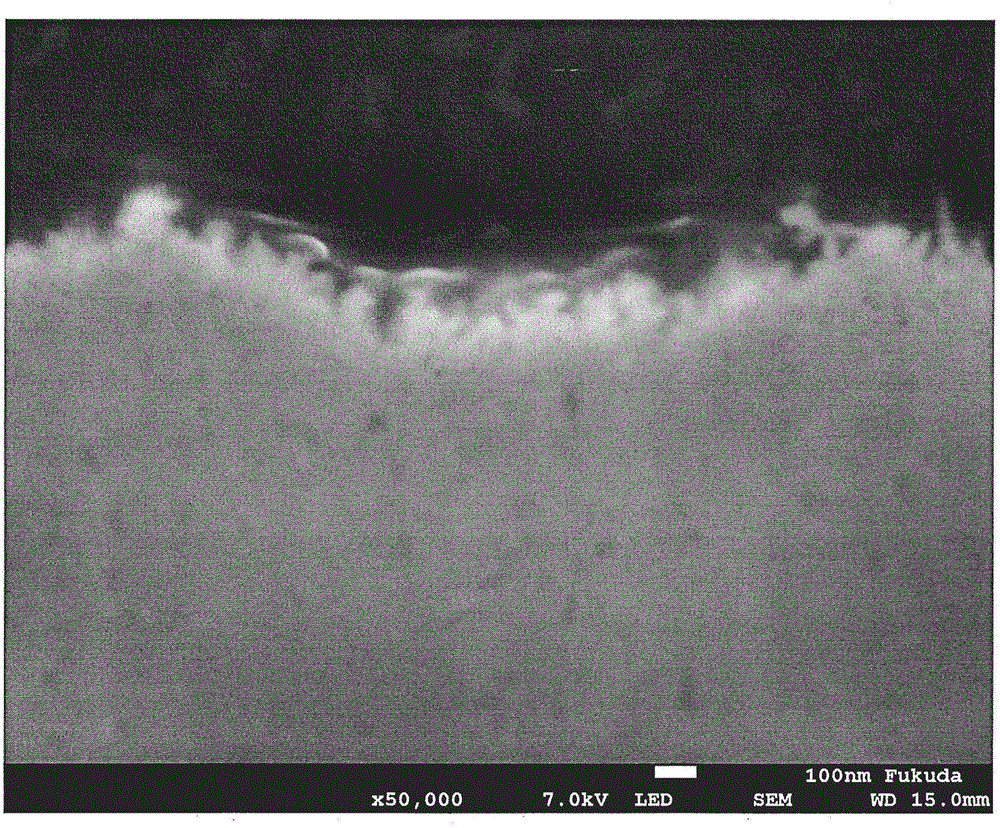

Treatment copper foil, copper-clad laminate using the treatment copper foil, and print circuit board

ActiveCN106211567ASuppress transmission lossReduce transmission lossInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentCopper foilOxidation resistant

To provide a highly transparent treatment copper foil preferable for a print circuit board, which has excellent transmission characteristics, a high peeling strength with a resin base material, and a low degree of cloudiness (HAZE level) after etching. There is provided a treatment copper foil for a copper-clad laminate, including a roughening treatment layer 2 on at least one surface of an untreated copper foil 1 and an antioxidation treatment layer 3 on the roughening treatment layer 2. The roughening treatment layer 2 is made of fine copper particles with primary particles having diameters of 40nm to 200nm, and the antioxidation treatment layer 3 contains molybdenum and cobalt. The ten point height of irregularities, Rz of the treatment surface to be adhered to an insulating resin base material is 0.5 mum to 1.6 mum, and the color difference delta E*ab between the untreated copper foil 1 and the treatment surface is 45 to 60.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

Photoelectric conversion module

InactiveUS20100230582A1Suppress transmission lossLoss of characteristicRadiation pyrometrySolid-state devicesElectricityPhotoelectric conversion

A photoelectric conversion module includes a photoelectric conversion element that converts an arriving optical signal transmitted via an optical fiber into an electrical signal, a signal output section that outputs a photoelectrically converted electrical signal to the exterior, an impedance matching circuit provided between an output electrode of the photoelectric conversion element and the signal output section, and a substrate upon which this impedance matching circuit is mounted, with the impedance matching circuit including a plurality of metallic coating layers formed upon the surface of the substrate with gaps being left between them, and a plurality of metallic connecting lines that electrically connect together adjacent ones of these metallic coating layers.

Owner:KYOSEMI CORP

Method of manufacturing photonic band gap fiber base material and method of manufacturing photonic band gap fiber

InactiveUS20120151968A1Suppress transmission lossGlass making apparatusOptical fibre with polarisationPhotonic bandgapHole making

A method of manufacturing a photonic band gap fiber base material includes: a forming step of continuously forming a columnar core glass body 10 and a clad glass body 20 which coats the core glass body to obtain an intermediate base material 110; a hole making step of making holes 30 in the clad glass body 20; an insertion step of inserting in the holes 30 a plurality of bilayer glass rods 40 in which an outer layer 42 which has the same refractive index as the clad glass body coats high refractive index portions 41 having a higher refractive index than a refractive index of the clad glass body 20; and a heating step of heating the intermediate base material 110 and integrating the intermediate base material 110 and the bilayer glass rods 40.

Owner:THE FUJIKURA CABLE WORKS LTD

High frequency semiconductor device

InactiveUS6853054B2Reduce transmission lossImprove featuresSemiconductor/solid-state device detailsSolid-state devicesTransmission lossGround plate

A high frequency semiconductor device including wiring layers which are formed above a semiconductor substrate and in which transmission lines are formed by combining with a ground plate having a potential fixed at the ground potential, at least one crossing portion in which the wiring layers mutually cross, with insulating interlayers provided therebetween, and at least one separation electrode being selectively provided on one of the insulating interlayers, the at least one separation electrode having a potential fixed at the ground potential. Accordingly, in the high frequency semiconductor device, electrical interference between two crossing wiring layer is prevented and transmission loss is suppressed.

Owner:FUJITSU QUANTUM DEVICES LTD

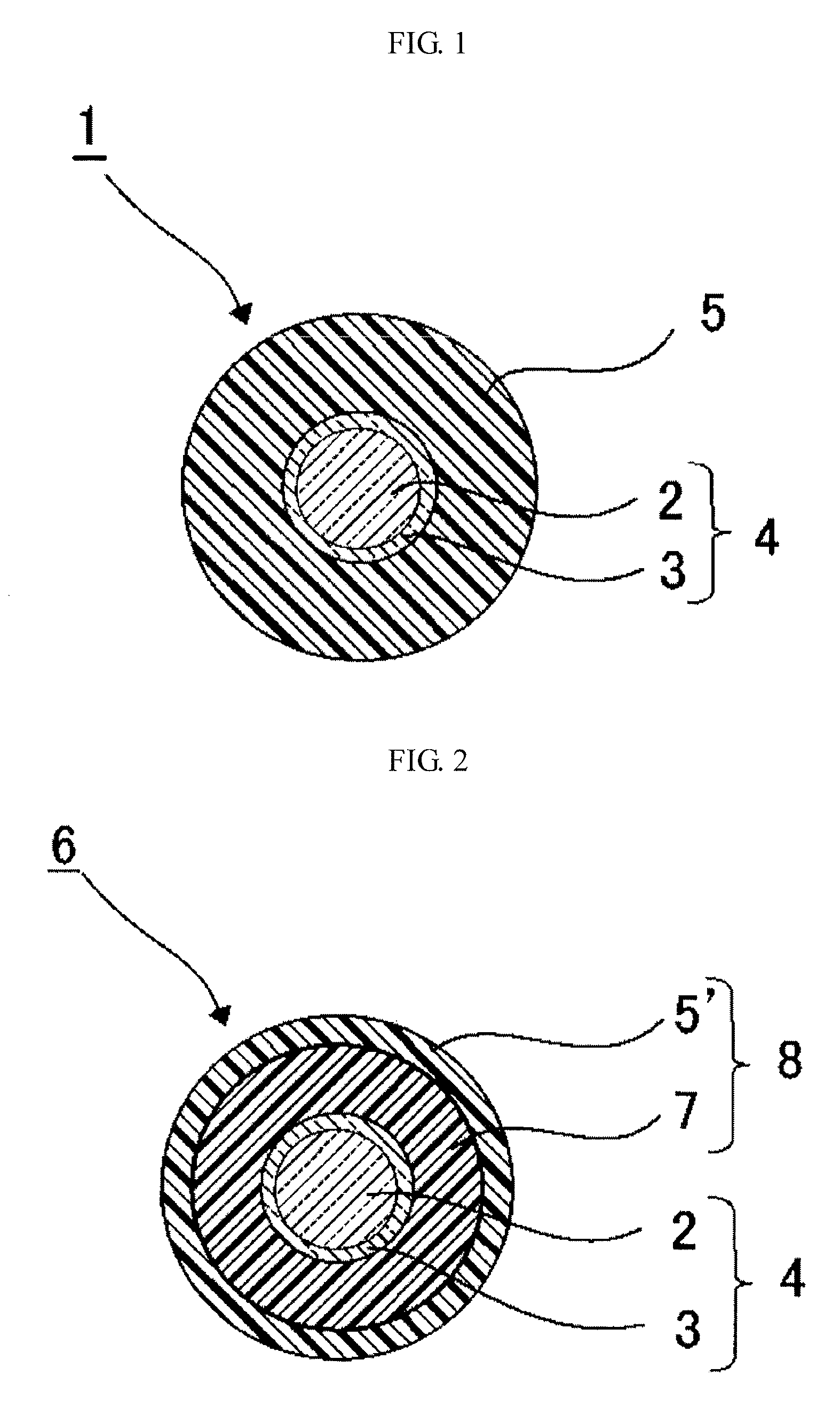

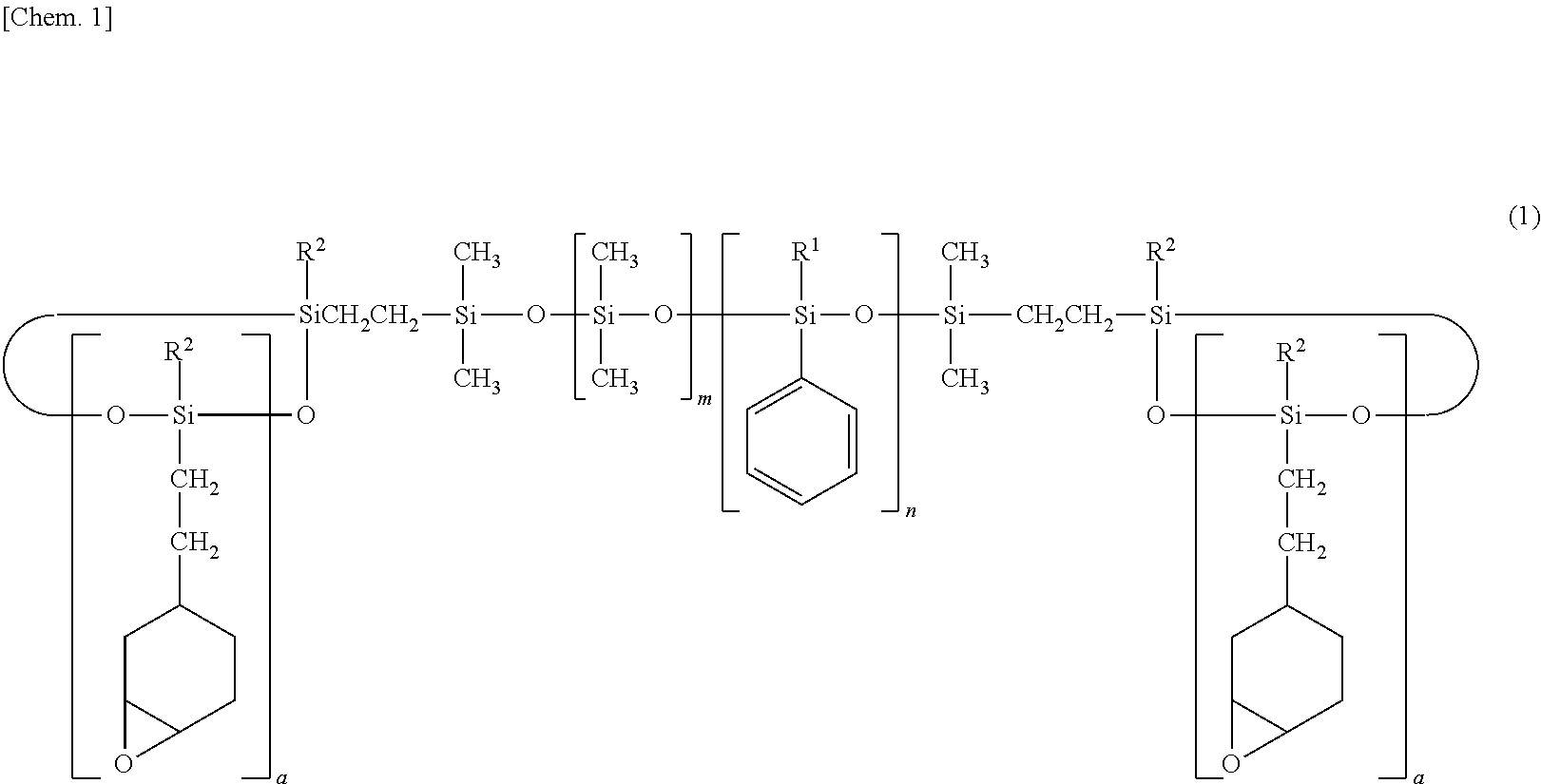

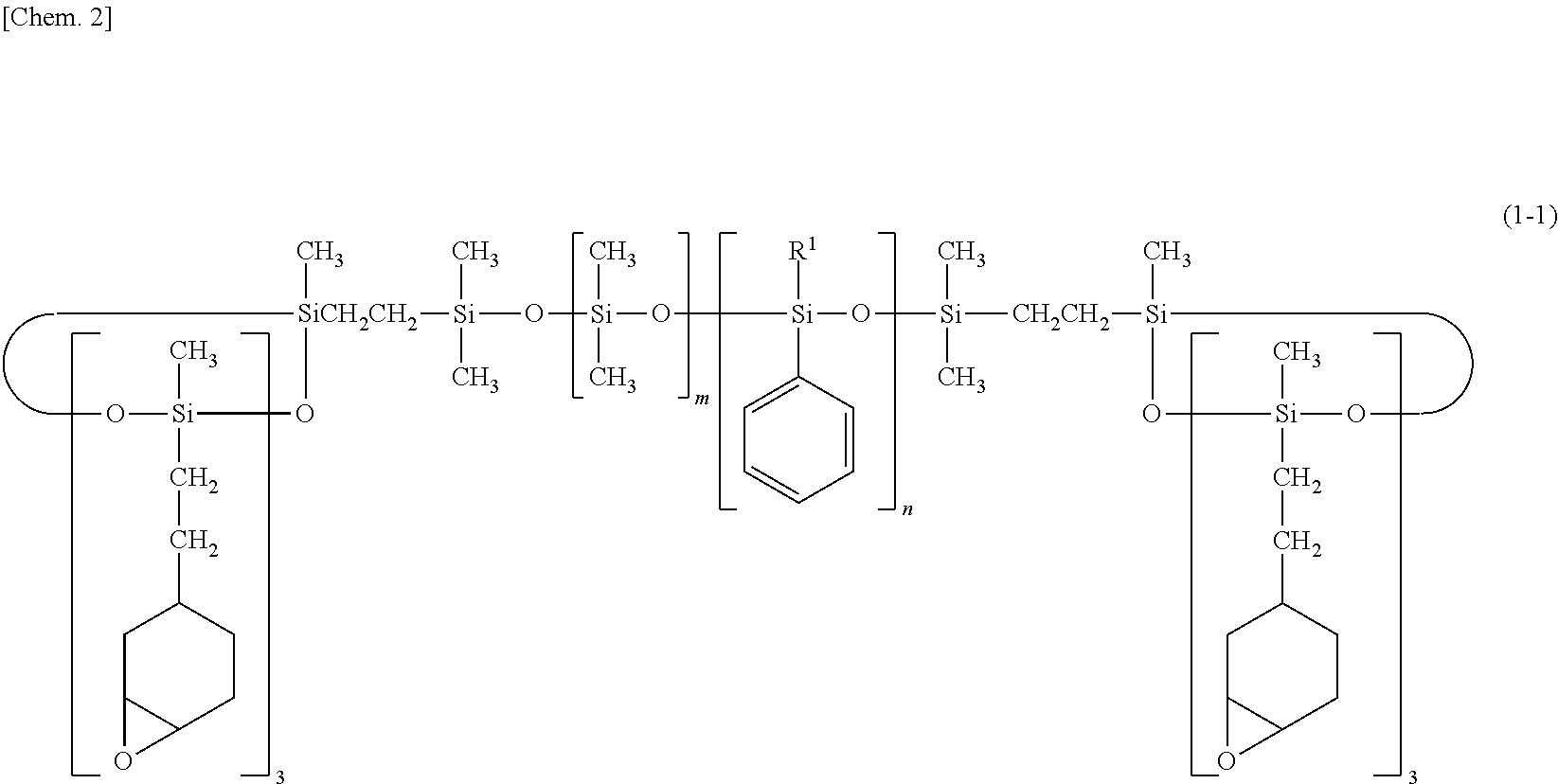

Optical fiber

ActiveUS9297950B2Heat resistance and productivitySuppress transmission lossGlass optical fibreFibre mechanical structuresGlass fiberHeat resistance

Provided is an optical fiber which is provided with heat resistance and productivity and in which a transmission loss is suppressed even in a high-temperature environment. It has, on an outer periphery of a glass fiber composed of a core part and a cladding part, a coating layer made by crosslinking an energy-curable resin composition containing a silicon compound, in which the silicon compound contained in the energy-curable resin composition of the coating layer as an outermost layer has a specified structure having a cyclic silicone site having an epoxy group and a linear silicone site, with the content of the cyclic silicone site in the compound being from 10 to 30% by mass.

Owner:SUMITOMO ELECTRIC IND LTD

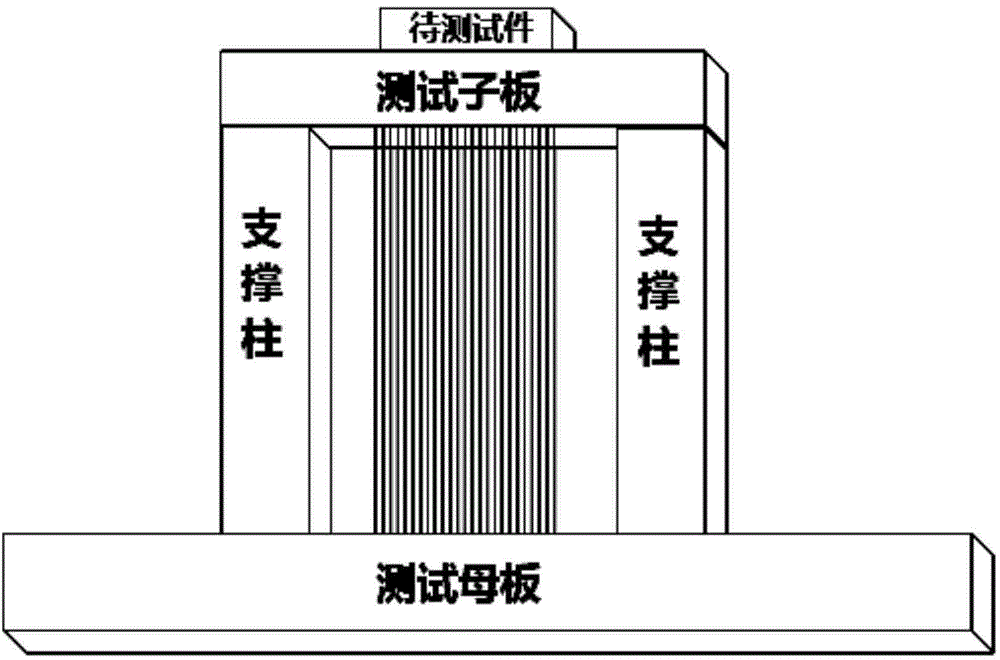

High-speed test system and processing method thereof for ATE machine

InactiveCN104914339AEasy to assemble and disassembleEasy to useElectrical testingSpeed testEngineering

Provided is a high-speed test system and processing method thereof for an ATE machine. The test system comprises a test daughter board and a test mother board. The test mother board is provided with a spring needle connector array, and the test daughter board is provided with a test socket. The test daughter board, the spring needle connector array and the test mother board are connected through a pressing screw connection mode. The processing method is characterized by, to begin with, pressing spring needles to a spring needle connector module; then, installing the spring needle connector module to a step-shaped groove reserved in a metal base through a screw connection mode; and finally, installing a stud running through the whole height of the test system to the metal base, wherein the two ends of the stud are screwed with the test daughter board and the test mother board respectively and independently, and thus pressing assembling work of the test system is finished. The high-speed test system and processing method not only can ensure repeated use and maintenance of the test system, but also can realize high-precision control of signal link impedance, and thus integrity of high-speed signal of the test system is guaranteed.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

Spin valve element and method of manufacturing same

ActiveUS20100291411A1Cheap manufacturingSuppress transmission lossAnodisationNanomagnetismEngineeringSpin valve

A spin valve element including parallelly or serially connected magnetic element groups, each magnetic element group having a plurality of magnetic elements that each include an intermediate layer of an insulating member or a nonmagnetic member sandwiched by a pair of ferromagnetic layers. The plurality of magnetic elements are further connected either in series or in parallel.

Owner:III HLDG 3

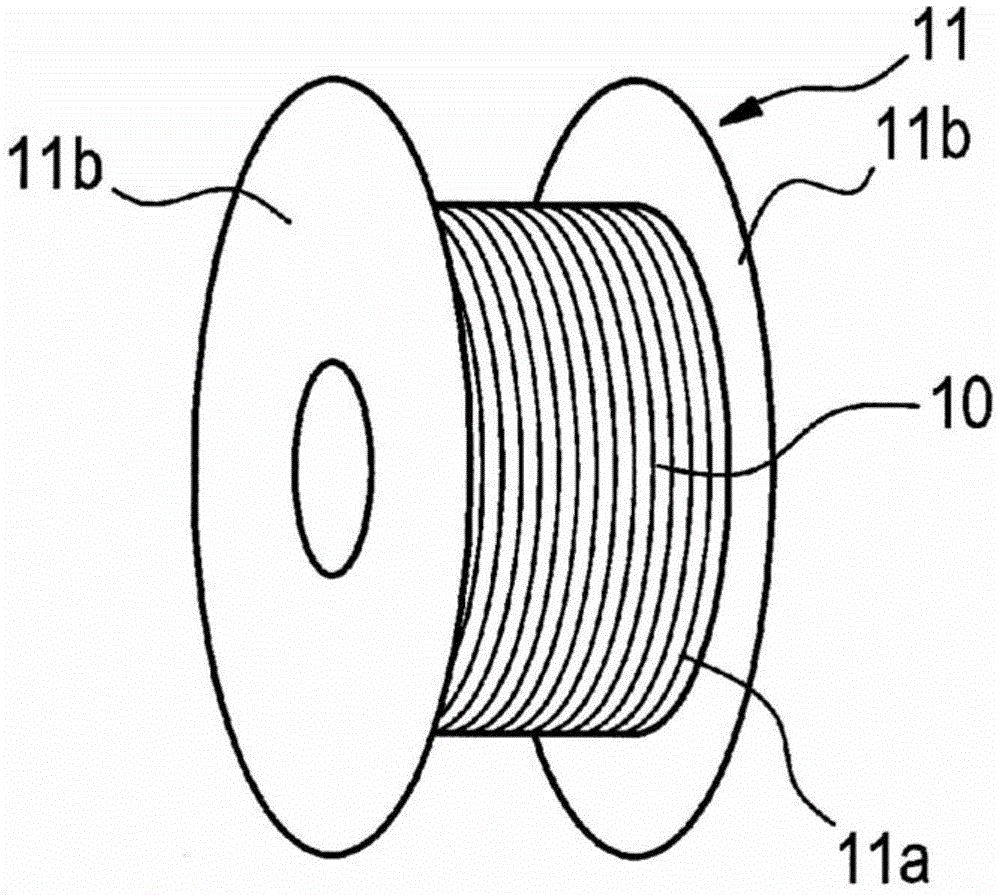

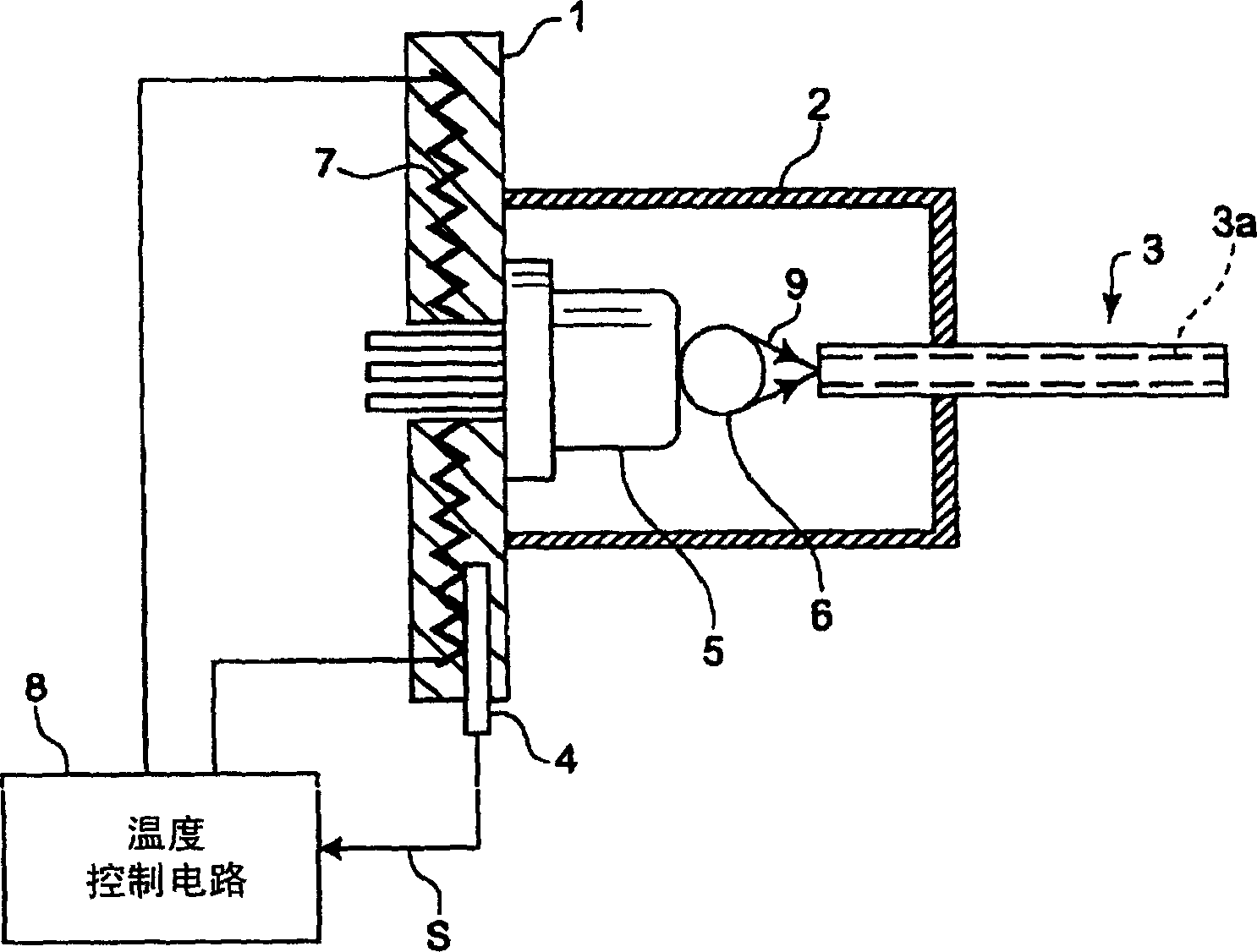

Transmission apparatus using a plastic fiber

InactiveCN1467523ALow loss characteristicSuppress transmission lossLaser detailsCladded optical fibrePlastic fiberLength wave

In the transmission apparatus comprising a PMMA plastic fiber 3 and a semiconductor light emitting element 5 to emit the light 9 transmitted through the plastic fiber 3, the element which can emit the light 9 having the wavelength within the range of 630 to 680 nm is used as the semiconductor light emitting element 5. Moreover, there is provided a temperature adjusting mechanism comprising a heating means 7 for heating the semiconductor light emitting element 5, a temperature detecting means for detecting the temperature of the semiconductor light emitting element 5, and a control circuit 8 for setting the temperature of the semiconductor light emitting element 5 to a predetermined target value which is lower than the maximum temperature assumed under the environment for locating thereof by controlling the drive of the heating means 7 based on a temperature detecting signal S outputted from the temperature detecting means 4.

Owner:FUJIFILM CORP

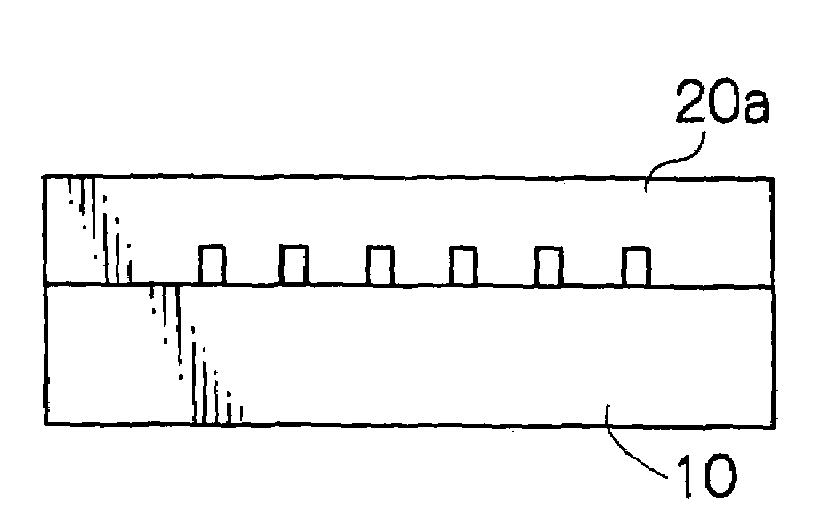

Surface-treated copper foil, copper foil with carrier, laminate, printed wiring board, electronic device, method of manufacturing surface-treated copper foil, and method of manufacturing printed wiring board

ActiveCN105323958BHigh peel strengthSuppress transmission lossInsulating substrate metal adhesion improvementPrinted circuit aspectsCopper foilUltimate tensile strength

Owner:JX NIPPON MINING & METALS CORP

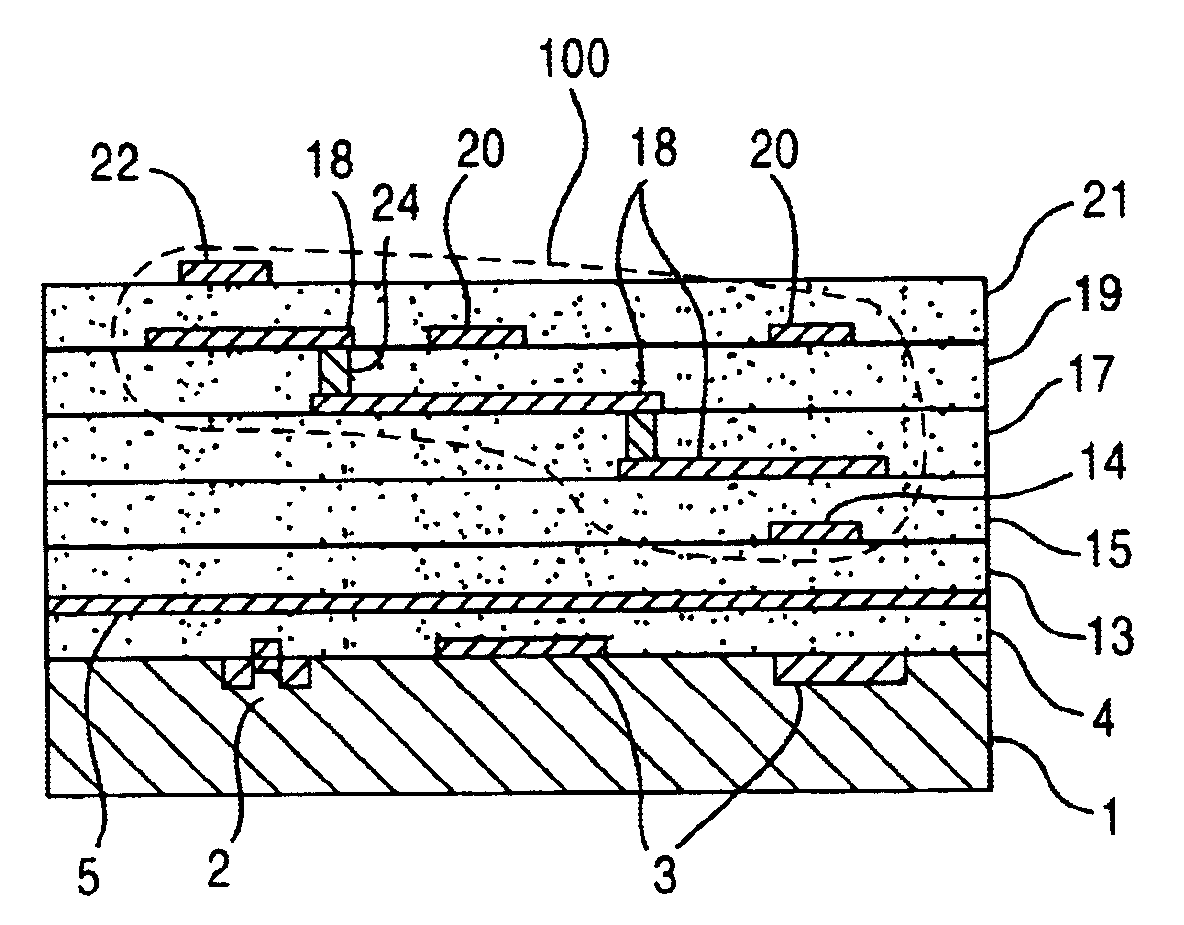

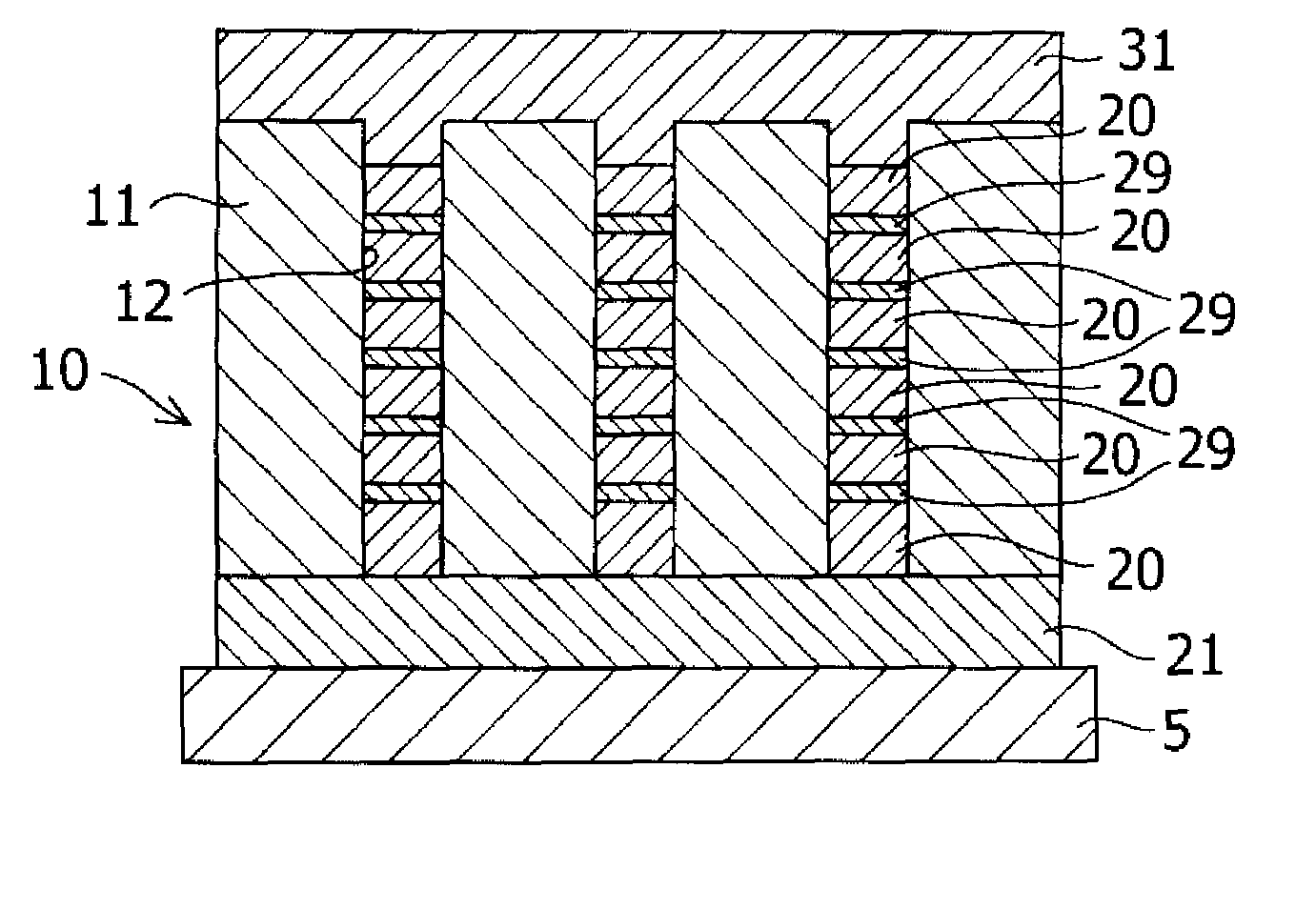

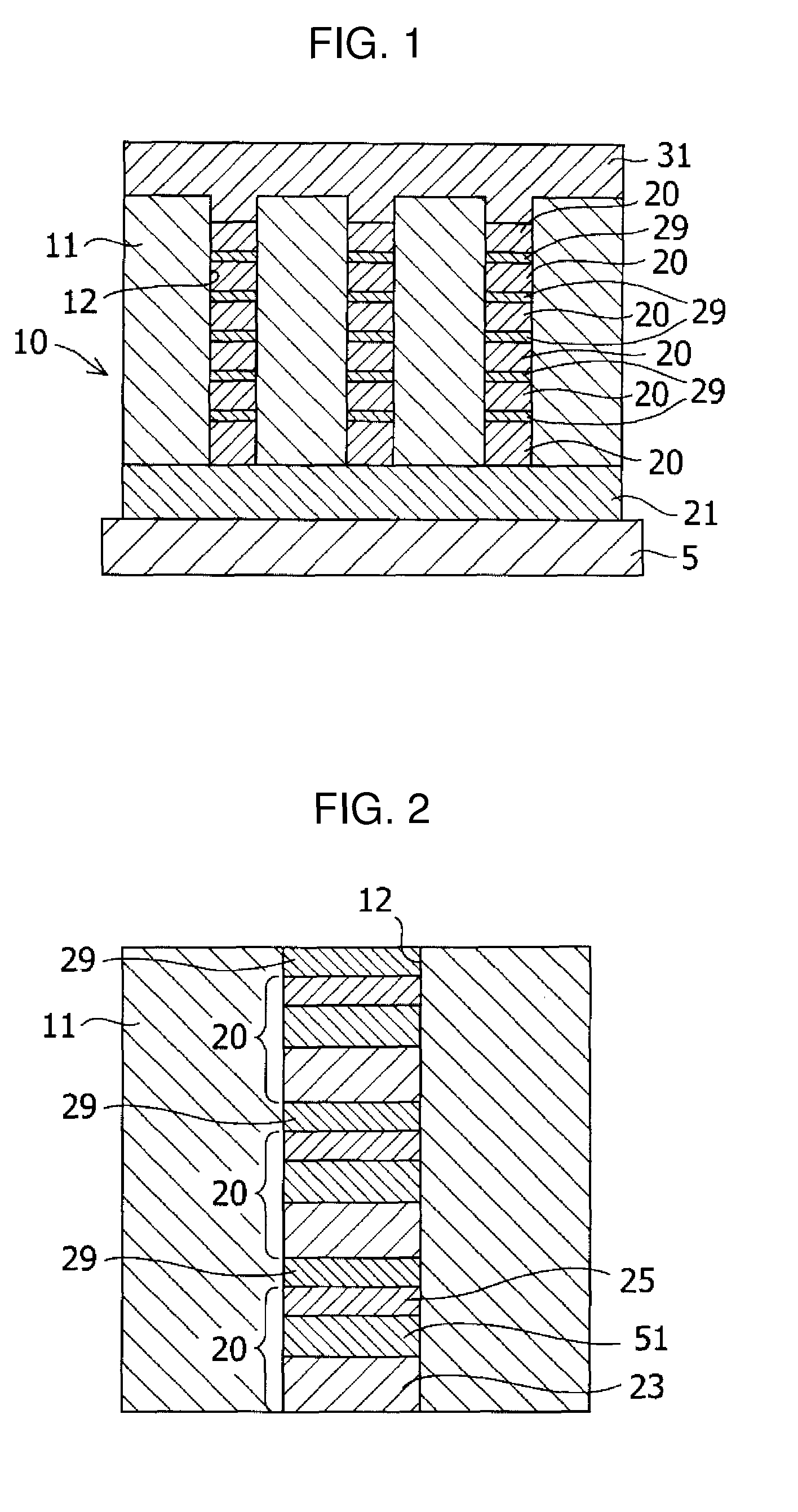

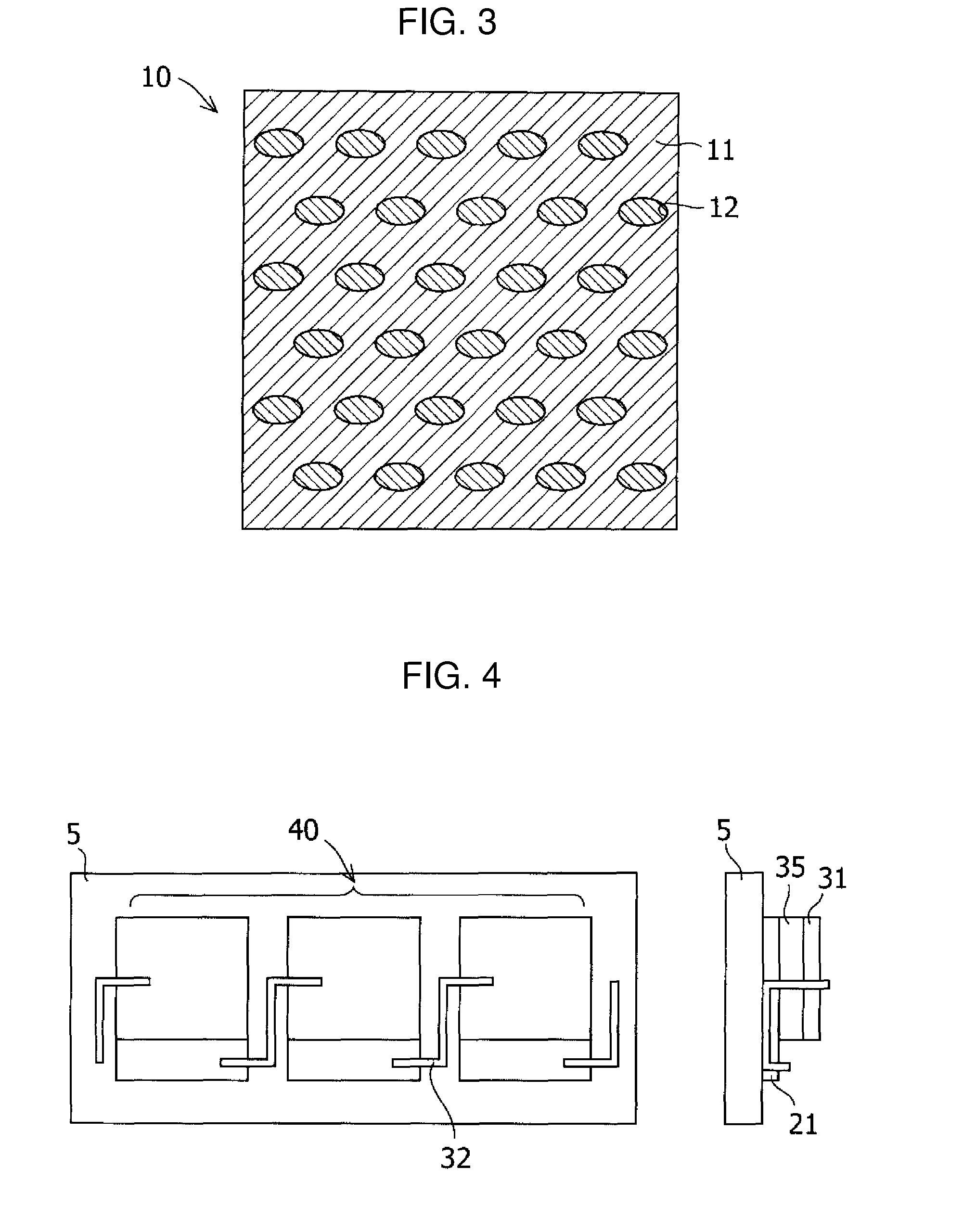

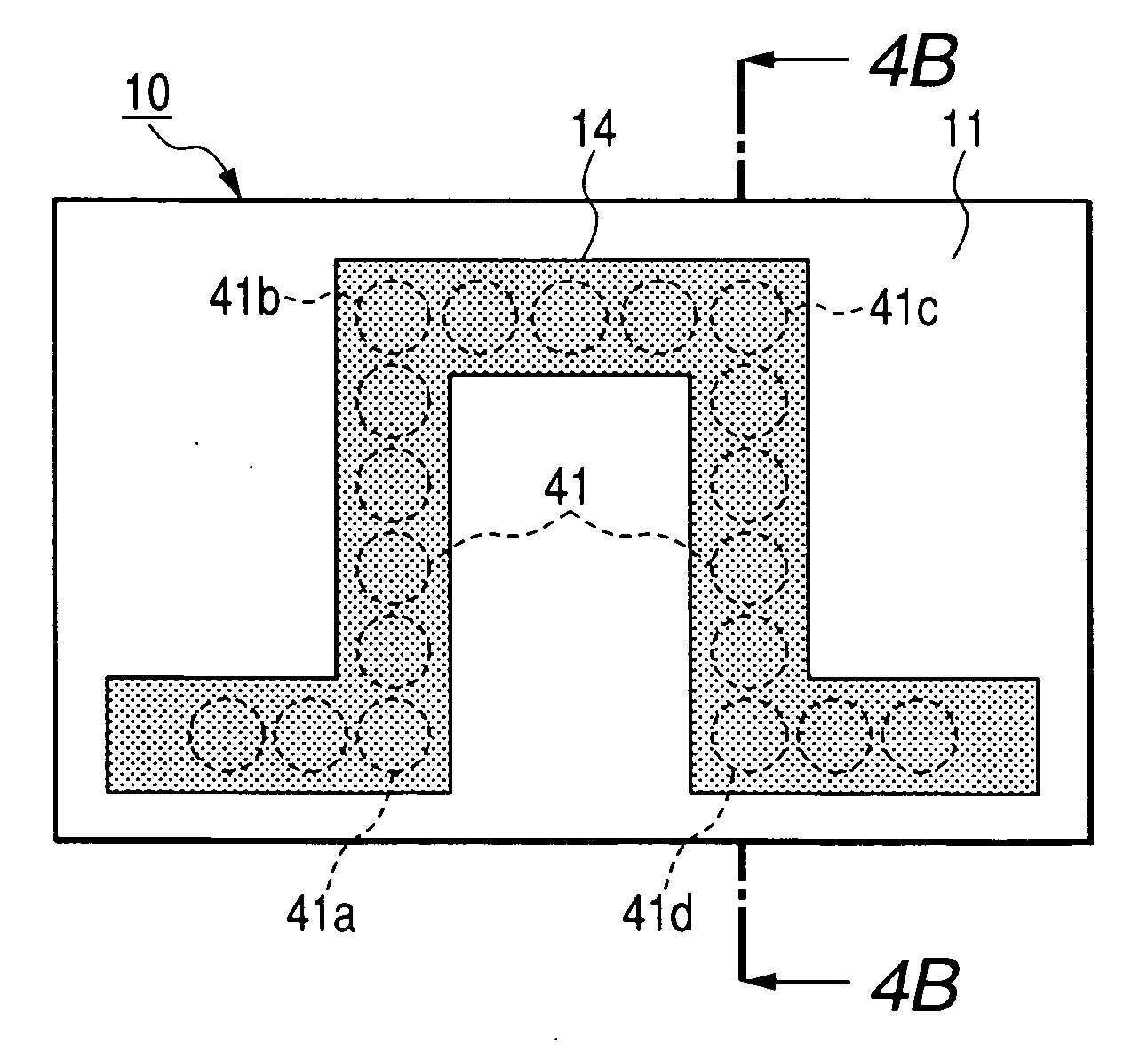

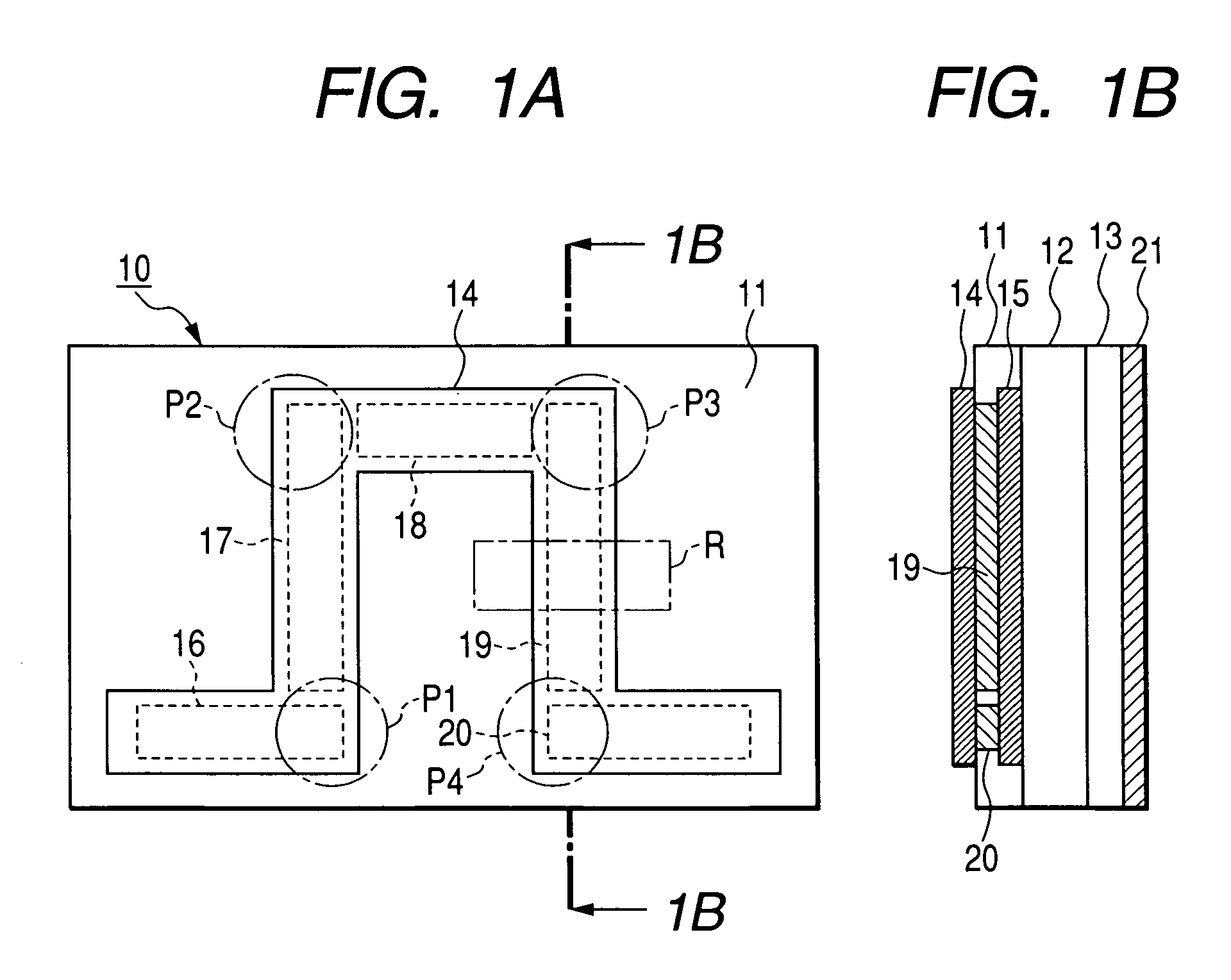

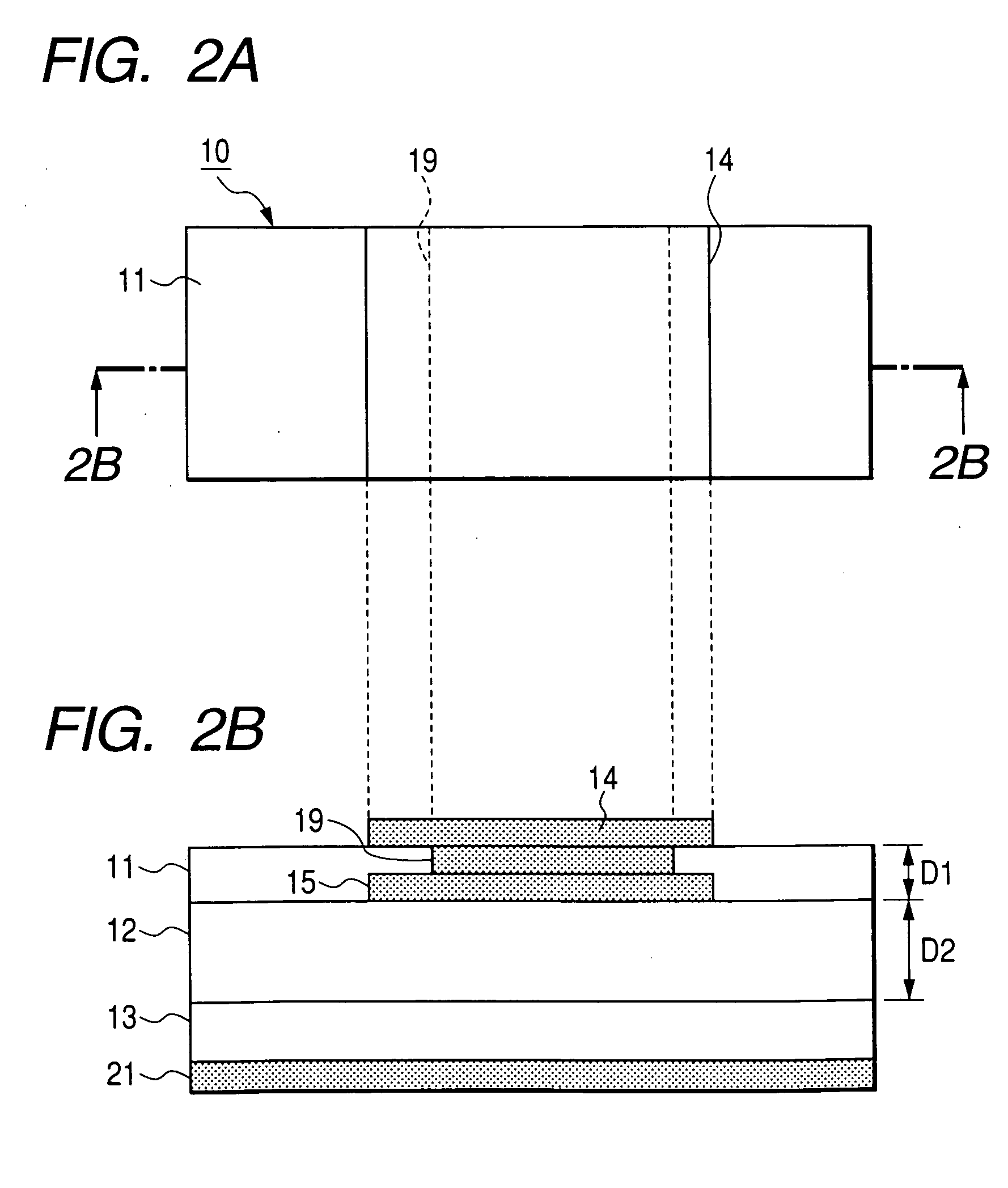

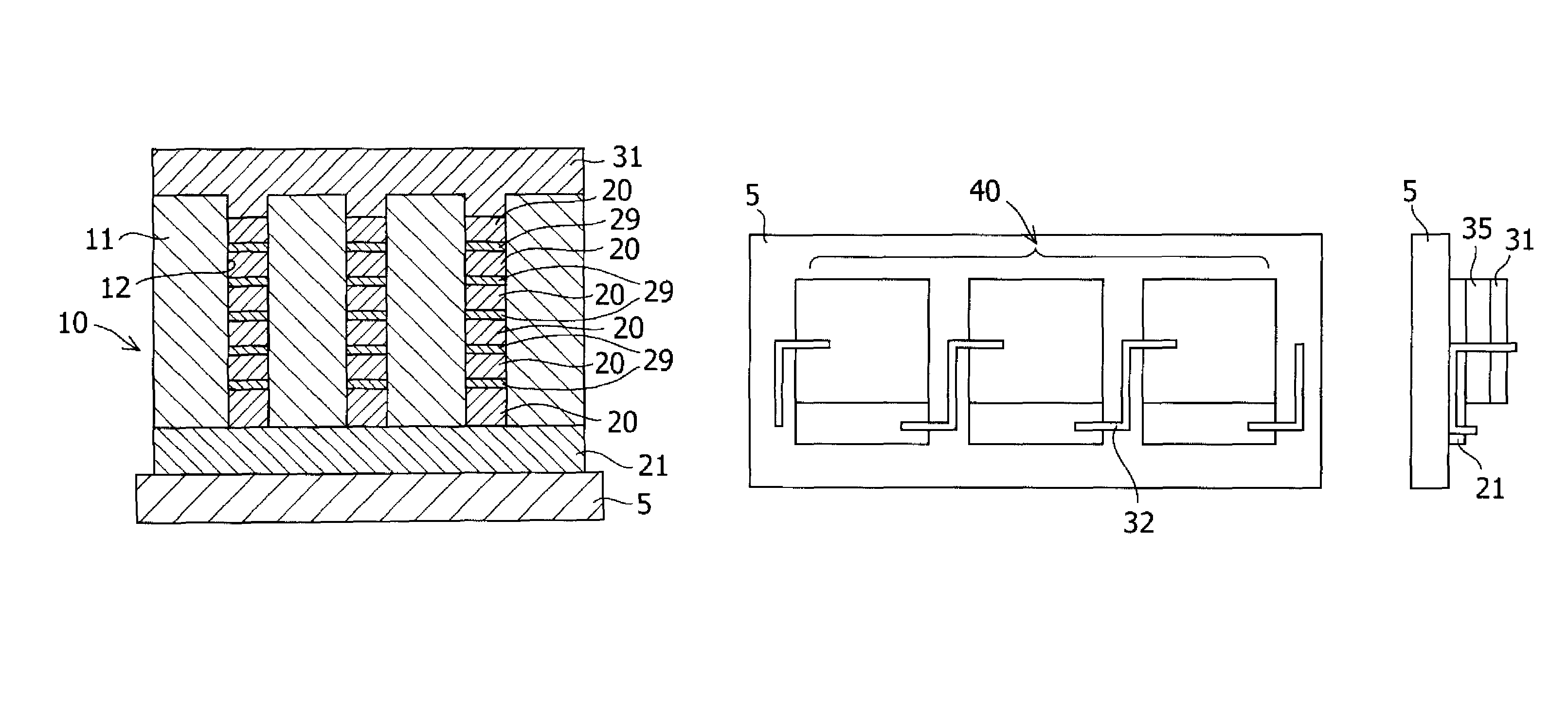

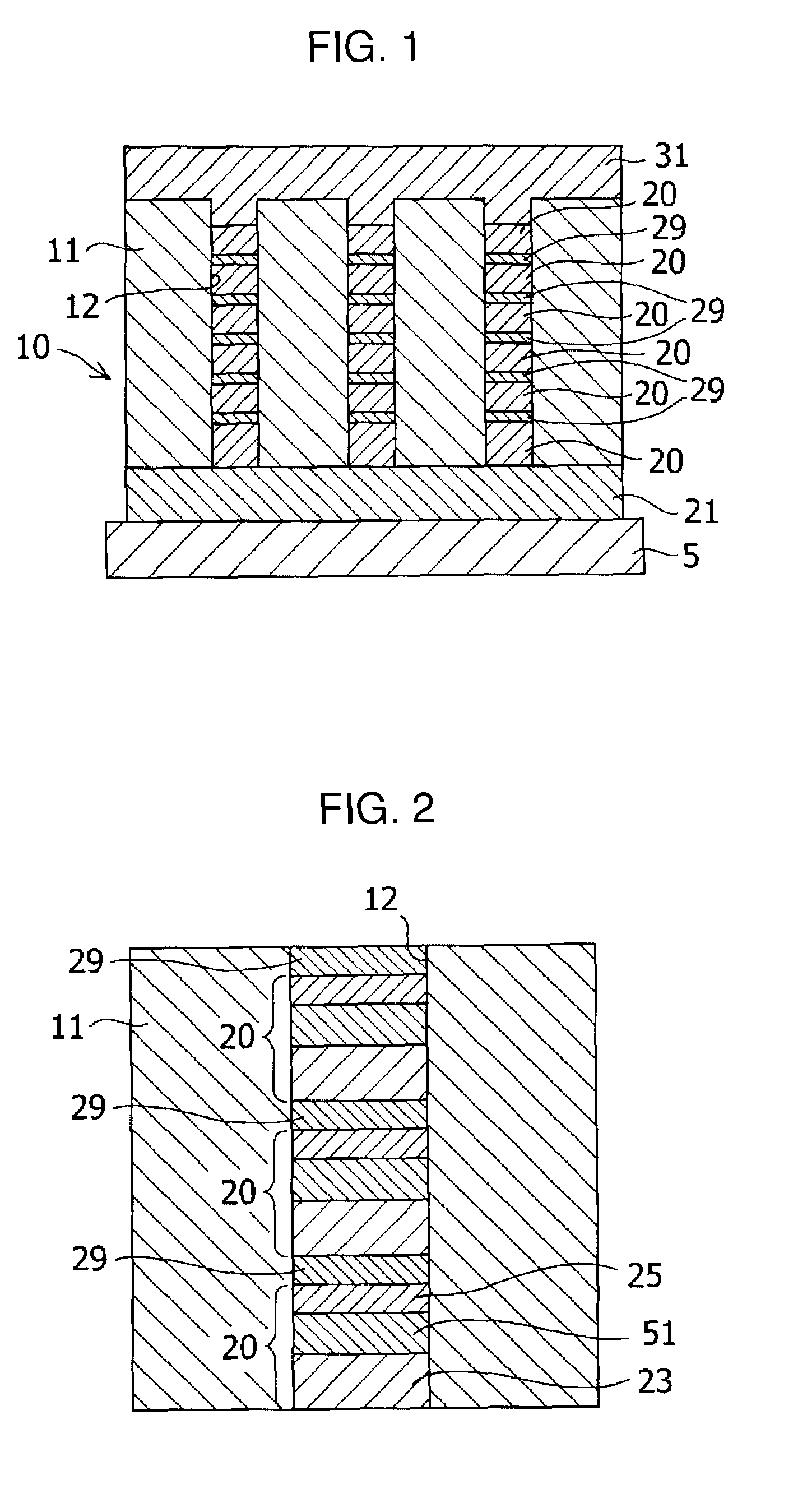

Electronic circuit unit having low transmission loss

InactiveUS20070040630A1Reduce the valueSuppress transmission lossMultiple-port networksPrinted circuit aspectsElectric forceElectrical conductor

In an electronic circuit unit for transmitting power through a transmission line 103 formed of a conductor pattern, a matching circuit 101 is connected to an output end of a power amplifier 102. The matching circuit 101 comprises a first conductor pattern 14 having bend portions P1 to P4 provided on a first dielectric substrate 11 of a laminated substrate 10 which has a plurality of dielectric layers 11 to 13, and a second conductor pattern 15 disposed opposite the first conductor pattern 14 on an adjacent second dielectric layer 12, and connecting conductors 16 to 20 provided at at least bend portions P1 to P4 of the first and second conductor patterns.

Owner:ALPS ALPINE CO LTD

Spin valve element and method of manufacturing same

ActiveUS9318248B2Suppress transmission lossLow costNanostructure applicationNanomagnetismEngineeringSpin valve

A spin valve element including parallelly or serially connected magnetic element groups, each magnetic element group having a plurality of magnetic elements that each include an intermediate layer of an insulating member or a nonmagnetic member sandwiched by a pair of ferromagnetic layers. The plurality of magnetic elements are further connected either in series or in parallel.

Owner:III HLDG 3

High-frequency magnetic material and antenna system using thereof

ActiveUS20090079650A1Suppress transmission lossRadiating elements structural formsAntenna feed intermediatesPhysicsMagnetic phase

A superior high-frequency magnetic material having a smaller ratio (μ″ / μ′) of a real part μ′ of permeability and an imaginary part μ″ of permeability in a high-frequency region and an antenna system using thereof are provided. The high-frequency magnetic material includes a substrate and a composite magnetic film formed on the substrate and made of a magnetic phase forming a plurality of columnar bodies whose longitudinal direction is directed in a direction perpendicular to a surface of the substrate and an insulator phase filling gaps of the columnar bodies. The magnetic phase contains at least one of Nb, Zr, and Hf, and Fe and B, is amorphous, and has in-plane uniaxial anisotropy of Hk2 / Hk1≧3 and Hk2≧3.98×103 A / m when a minimal anisotropic magnetic field in a plane parallel to the surface of the substrate is Hk1 and a maximal anisotropic magnetic field is Hk2.

Owner:KK TOSHIBA

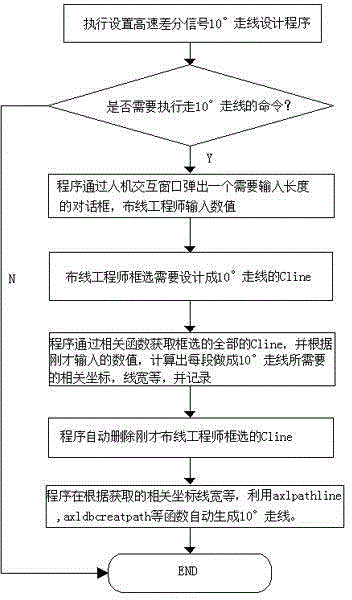

Design method for setting 10-degree wiring of high-speed signals on single PCB (Printed Circuit Board)

InactiveCN104021257ASuppress transmission lossSave design spaceSpecial data processing applicationsSignal onPrinted circuit board

The invention discloses a design method for setting 10-degree wiring of high-speed signals on a single PCB (Printed Circuit Board). A design program for setting 10-degree wiring of the high-speed signals on the single PCB is developed by use of CADENCE AXLSKILL language; during specific operations, the SKILL program is put in a wiring tool installation document; once the SKILL program is executed, a prompting dialog box is popped up; the length of each section of 10-degree wiring is input according to the dialog, and then CLine needing to be designed into 10-degree wiring is selected, and therefore, the design of 10-degree wiring can be completed. Due to the adopted design method, the design of 10-degree wiring of high-speed signals can be realized very simply, either board or PCB design space is saved, and meanwhile, the transmission losses of high-speed signals in the board due to weaving effect are also effectively inhibited; the operating method of the design tool is also very simple and convenient.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Transmission apparatus

InactiveUS7881187B2Suppress transmission lossQuality improvementError preventionTransmission systemsVariable-length codeAsynchronous network

The present invention provides a transmission apparatus including transmitting side line interfaces which convert packet format data sent from an asynchronous network to a SONET / SDH frame format and then transmit the data, multiple receiving side line interfaces which receive the SONET / SDH frame format data and convert the data to packet format data and a circuit switching section which performs circuit switching. The transmitting side line interfaces include a variable length frame mapping section which converts the packet format data to variable length frame format data and a time division multiplexing mapping section which converts the variable length frame format data to the SONET / SDH frame format data. The receiving side line interfaces include a variable length frame demapping section which reconverts the SONET / SDH frame format data to variable length frame format data.

Owner:FUJITSU LTD

Optical fiber cable and cable core production method

ActiveUS20210325620A1Never excessively tightens the optical fibersAvoid partialFibre mechanical structuresEngineeringMechanical engineering

A jacket is provided to the outer circumference of a cable core, a rip cord, and a tension member. The cable core, the rip cord, and the tension member are collectively covered by the jacket. A wrapping tape is longitudinally placed on the outer circumference of a core part so as to be wound therearound. Thus, immediately after the wrapping tape is longitudinally placed and wound, a wrap part thereof is formed so as to lie substantially straight in the axial direction of an optical fiber cable. In contrast, in an optical fiber cable, the cable core is obtained by combining and intertwining the core part and the wrapping tape. Because of this configuration, the wrap part of the wrapping tape is helically disposed in the longitudinal direction.

Owner:FURUKAWA ELECTRIC CO LTD

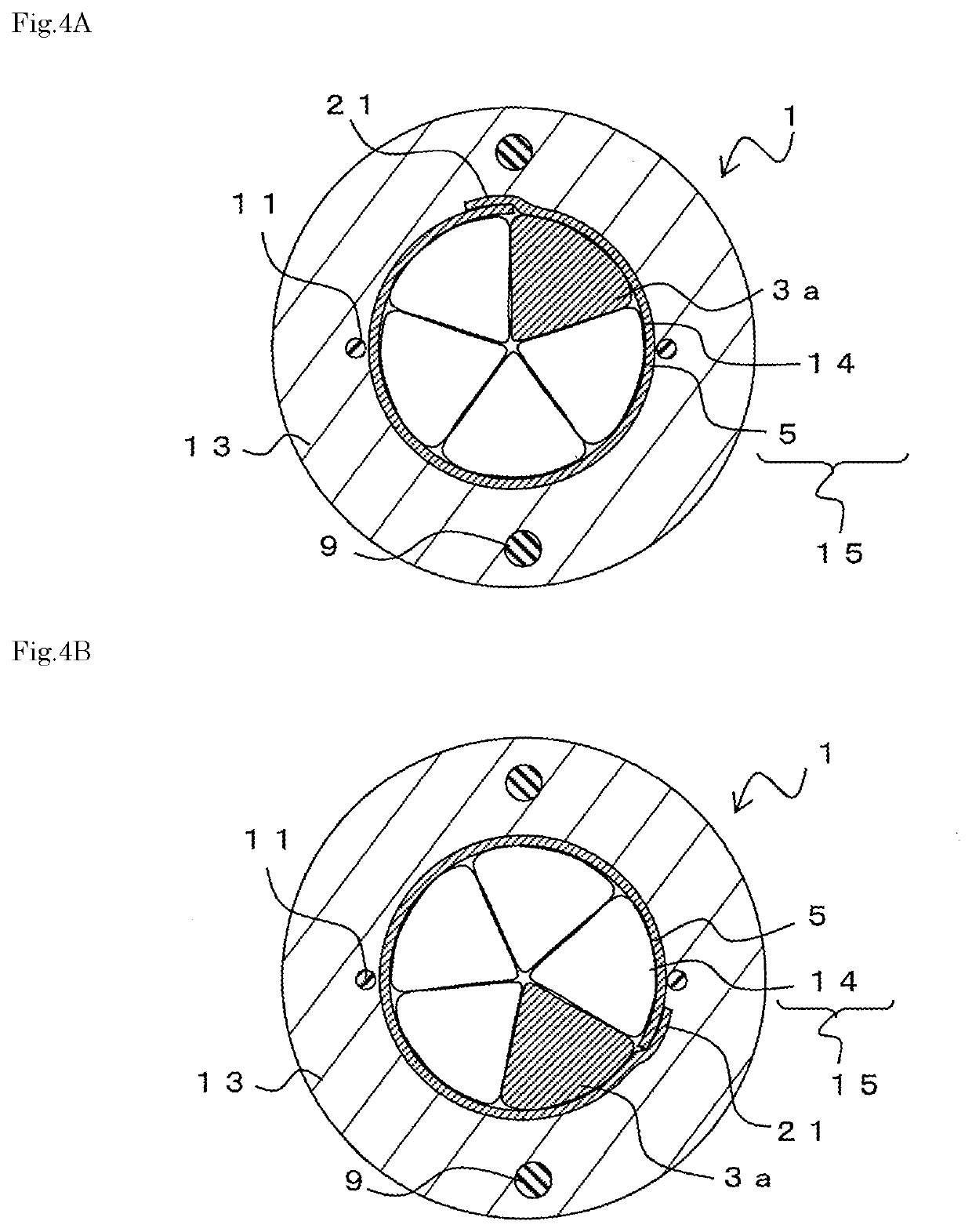

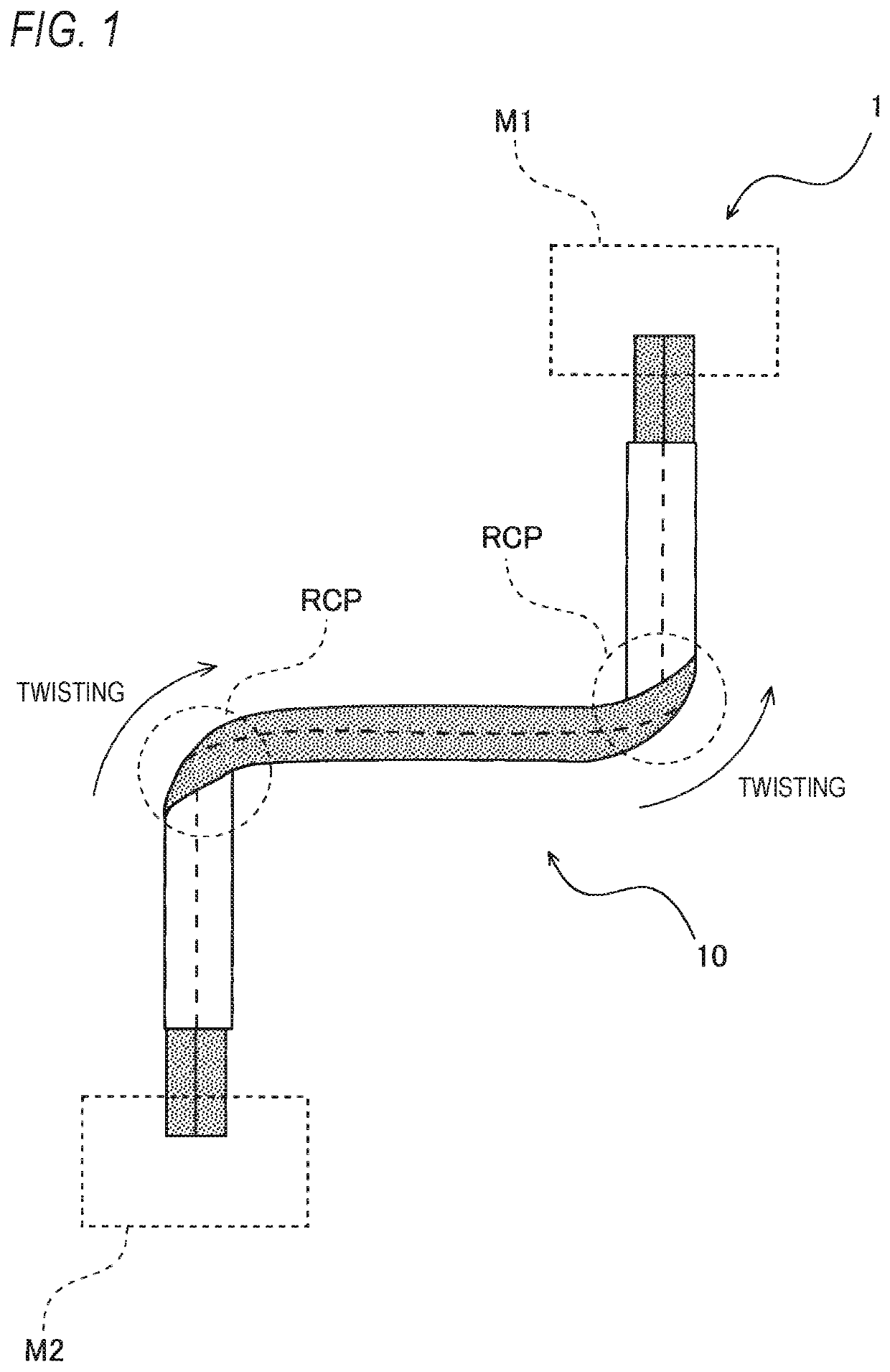

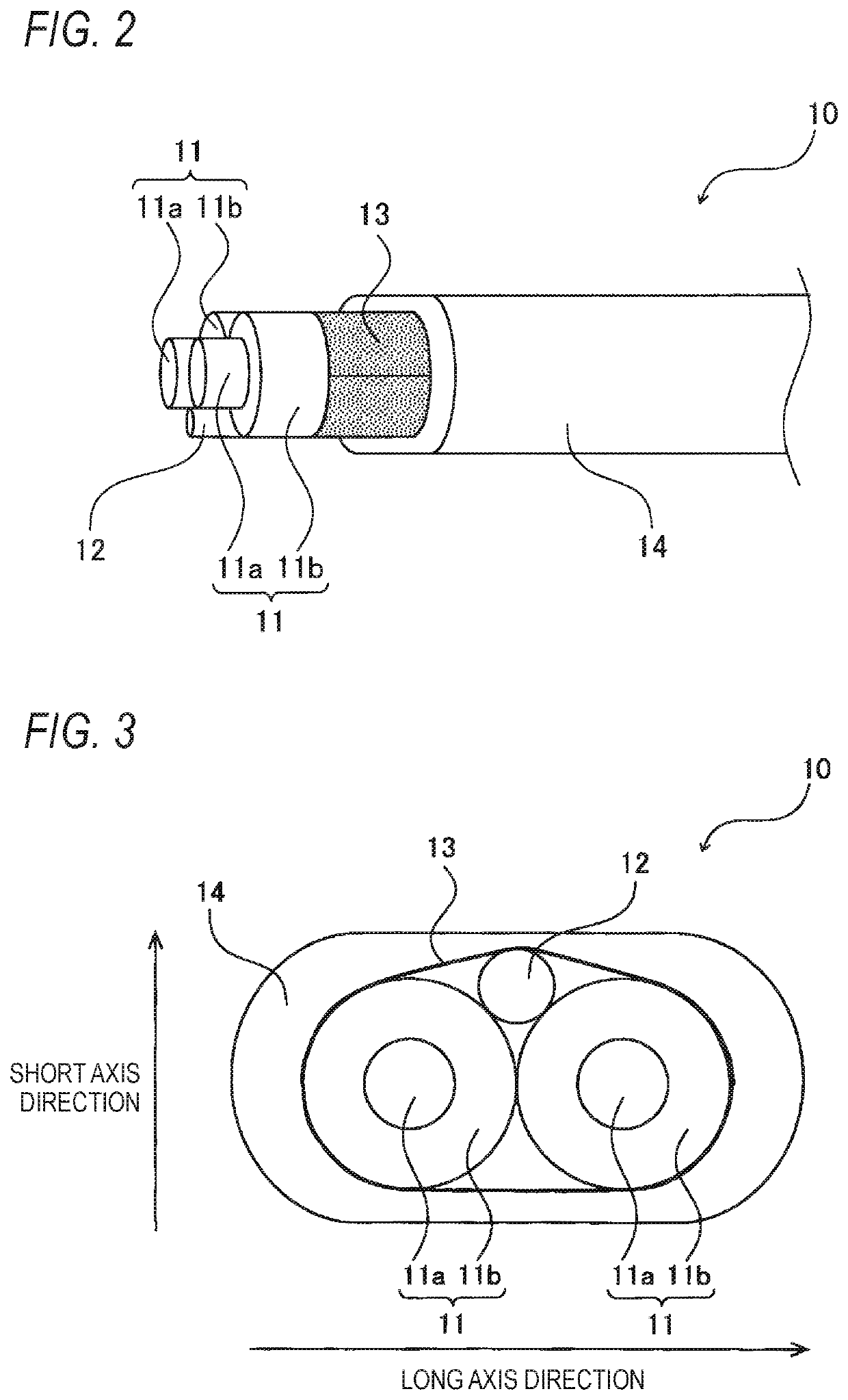

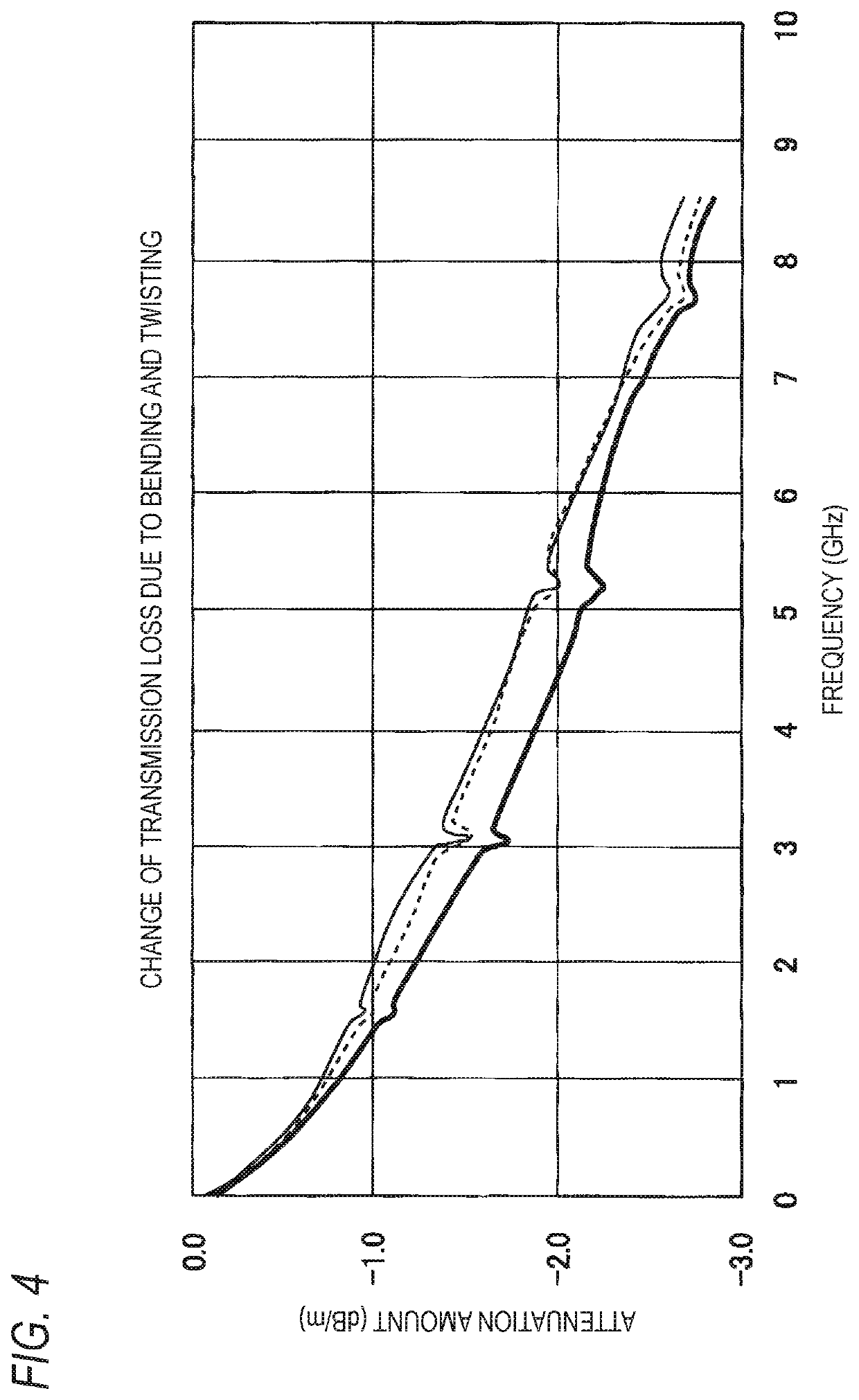

Routing structure of two-core parallel shielded electric wire

ActiveUS20200021000A1Increased transmission lossReduced characteristicsCable insulation constructionFlexible cablesStructural engineeringElectric wire

A routing structure of a two-core parallel shielded electric wire includes:two insulated electric wires that are arranged in parallel; anda shield layer that is attached around the two insulated electric wires and extends in a longitudinal direction of the two insulated electric wires.In the routing structure, the two-core parallel shielded electric wire is rerouted by bent twisting the two-core parallel shielded electric wire in a short axis direction at a route change point along a long axis direction of the two-core parallel shielded electric wire, and the number of bent twisted points in the short axis direction is 1.43 or less per meter.

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com