Transmission apparatus using a plastic fiber

A technology of plastic optical fiber and transmission device, which is applied to the device for controlling the output parameters of the laser, the coupling of the cladding fiber, the optical waveguide, etc. , the effect of distance extension, stable transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

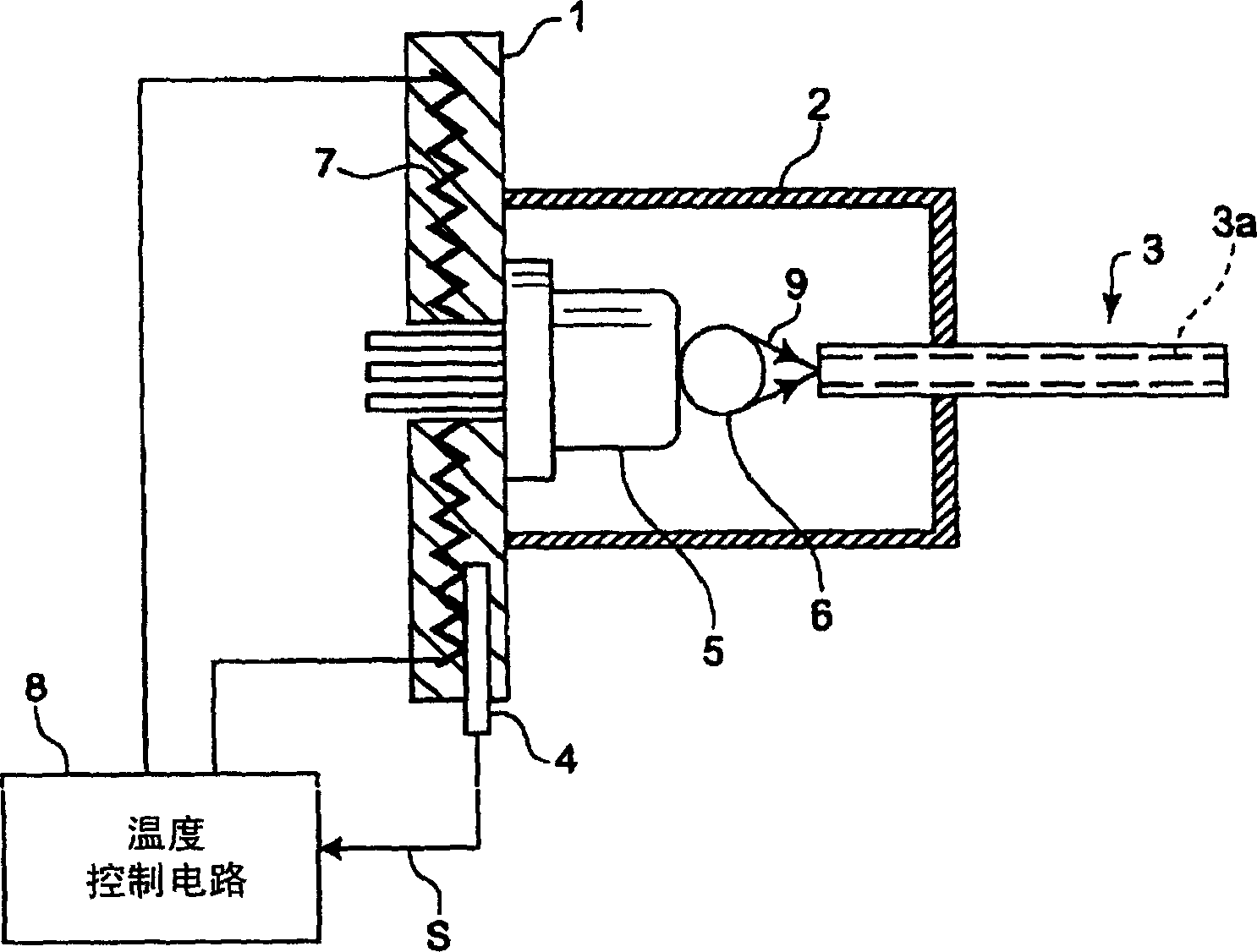

[0037] figure 1 A partly cutaway side view showing a transmission device using a plastic optical fiber according to the first embodiment of the present invention. The part shown here is a part constituting the optical signal transmission module part, and includes a substrate 1, a can-shaped housing 2 mounted on the substrate 1, and a plastic optical fiber whose one end is inserted into the housing 2 as shown in the figure. 3. The thermistor 4 disposed in the hole penetrated into the substrate 1, the column part is installed on the above-mentioned substrate 1 and the end surface emitting semiconductor laser 5 housed in the housing 2 is also housed in the housing 2 The ball lens in 6. Furthermore, an electric heater 7 is built in the substrate 1, and a temperature control circuit 8 is provided to drive the electric heater 7 based on an output signal from the thermistor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com