Optical fiber winding method, reeled optical fiber, and optical fiber transport method

A transportation method and optical fiber technology, applied in transportation and packaging, conveying filamentous materials, rigid containers, etc., can solve the problems of increased transmission loss, loose optical fiber winding, low winding tension, etc., to improve workability, Effect of suppressing transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] (1) Evaluation of unwinding

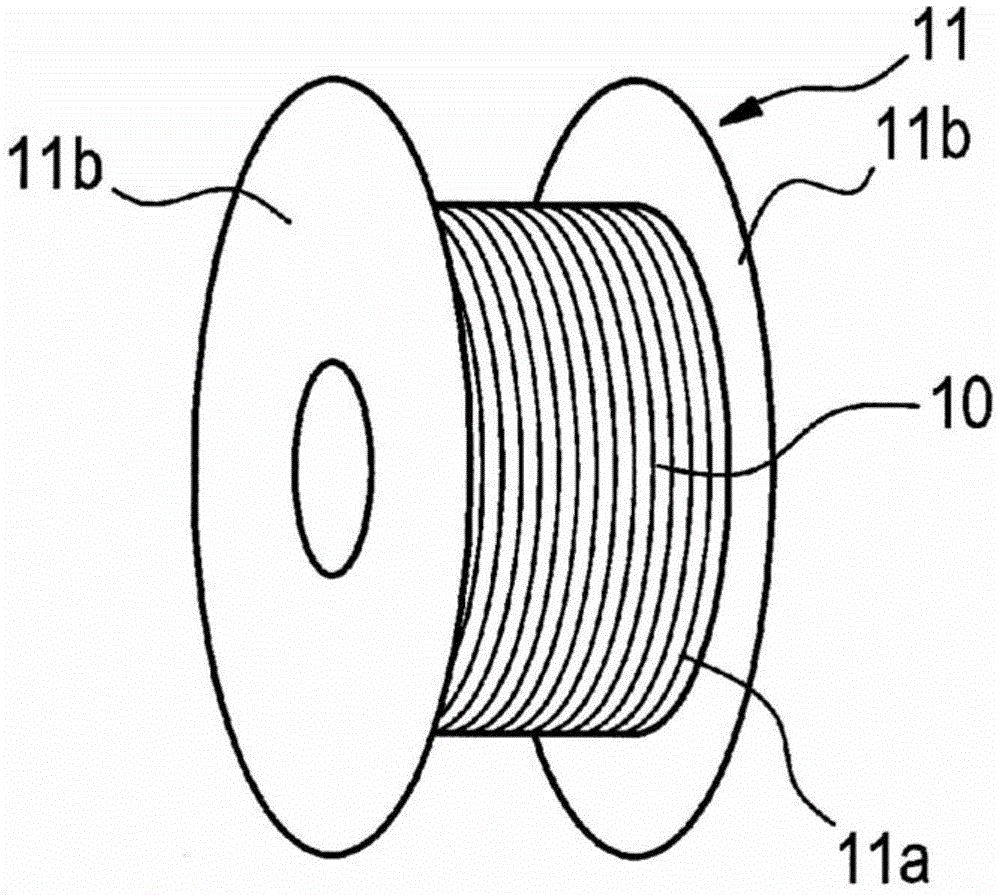

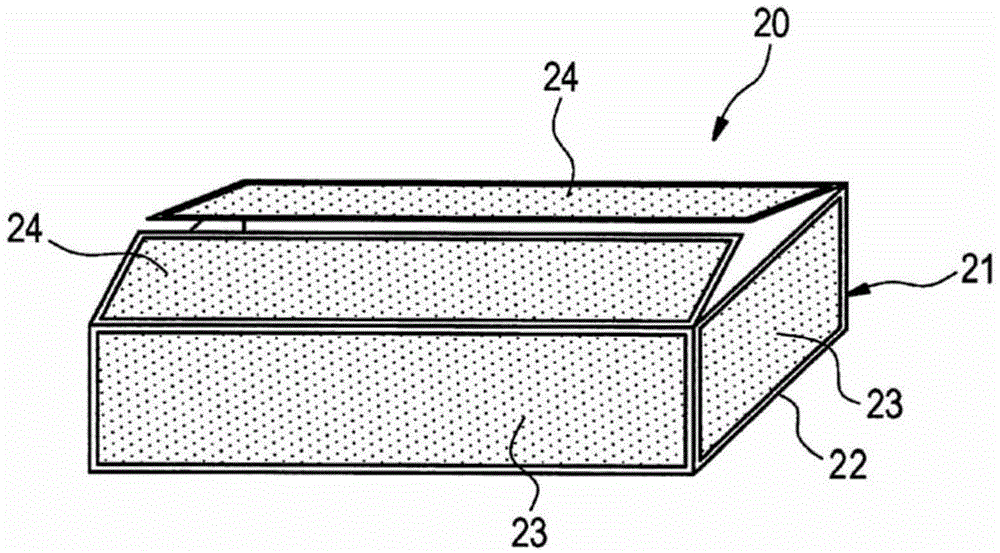

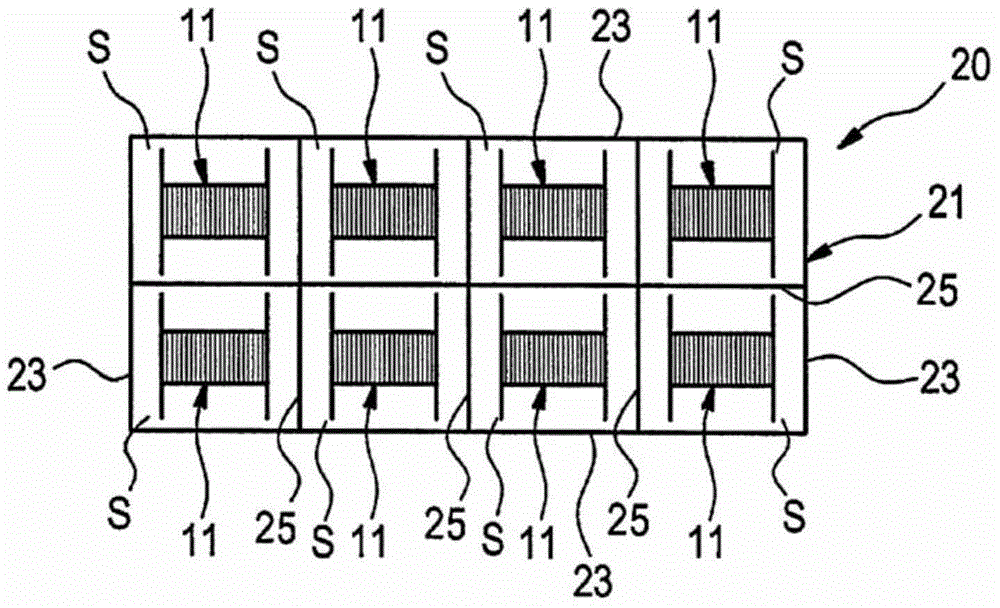

[0043] Eight bobbins 11 on which optical fibers 10 of a predetermined length were wound were accommodated in the packing box 20 , and the packing box 20 was dropped from a height of 300 mm, and unwinding of the optical fibers 10 in the packing box 20 at this time was evaluated. Prepare T / P as shown in Table 1 2 With from 0.2N / mm 2 to 7.0N / mm 2 The spools 11 of the 6 values were evaluated for the unwinding of the optical fiber 10 after the drop test of each spool.

[0044]Specifically, the bobbin 11 after the drop test was confirmed by visual observation and contact inspection, and whether unwinding of the optical fiber 10 occurred was evaluated. In Table 1, "○" indicates that no unwinding was found through visual inspection and contact inspection, and "△" indicates that there is no problem with visual inspection, but if the optical fiber 10 wound on the bobbin 11 is touched by hand, the winding of the optical fiber 10 The winding is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com