Design method for setting 10-degree wiring of high-speed signals on single PCB (Printed Circuit Board)

A high-speed signal and design method technology, applied in the electronic field, can solve problems such as unfavorable PCB board design, unsightly appearance, and difficult to achieve 10° wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

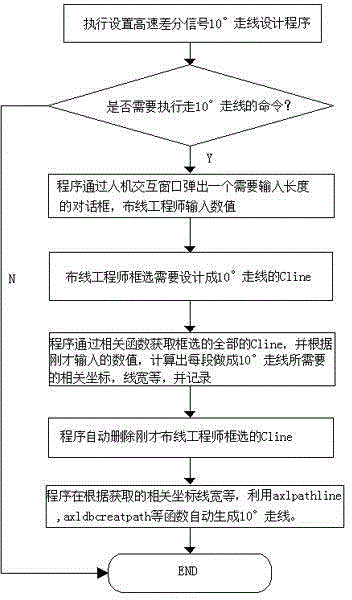

[0267] Below with reference to accompanying drawing, the present invention is further described by specific embodiment:

[0268] After the wiring engineer completes the routing in the traditional way, execute the design tool, and then the wiring engineer selects the relevant Cline that needs to be designed as a 10° routing, and enters the length of each segment to be 10° (this is based on the entire routing The length of the line is determined by the length of the line, which can be filled in freely), and the program will automatically complete the design of the 10° line according to the steps in the flow chart.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com