High-speed test system and processing method thereof for ATE machine

A test system and machine technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of lack of maintainability, waste of resources in the test system, short-circuiting and virtual welding in manual welding, and reduce Development cost and cycle, guaranteed reuse and maintenance, and improved high-speed signal integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

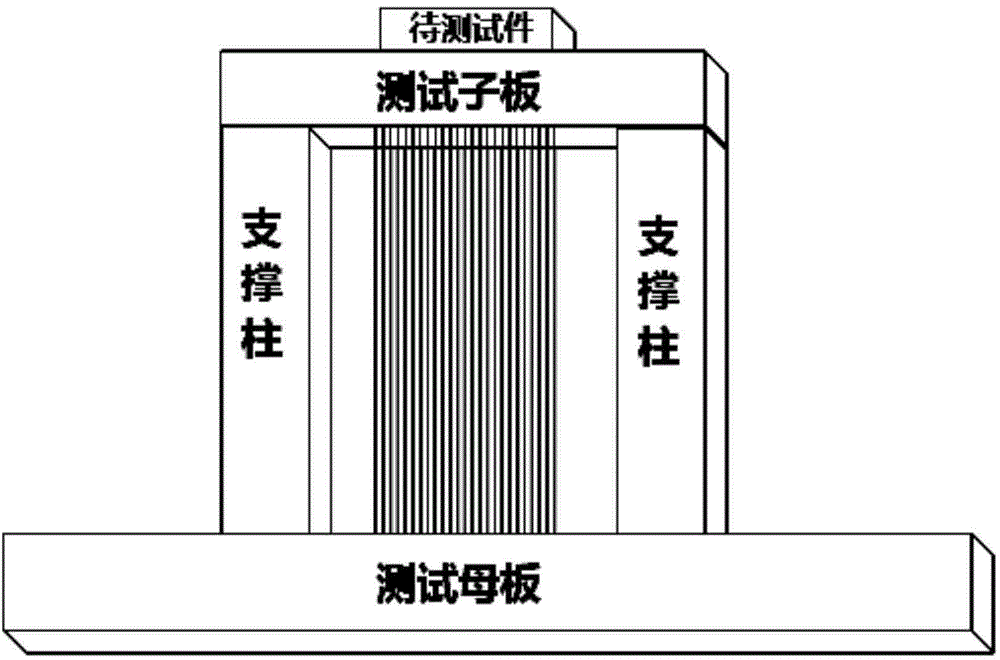

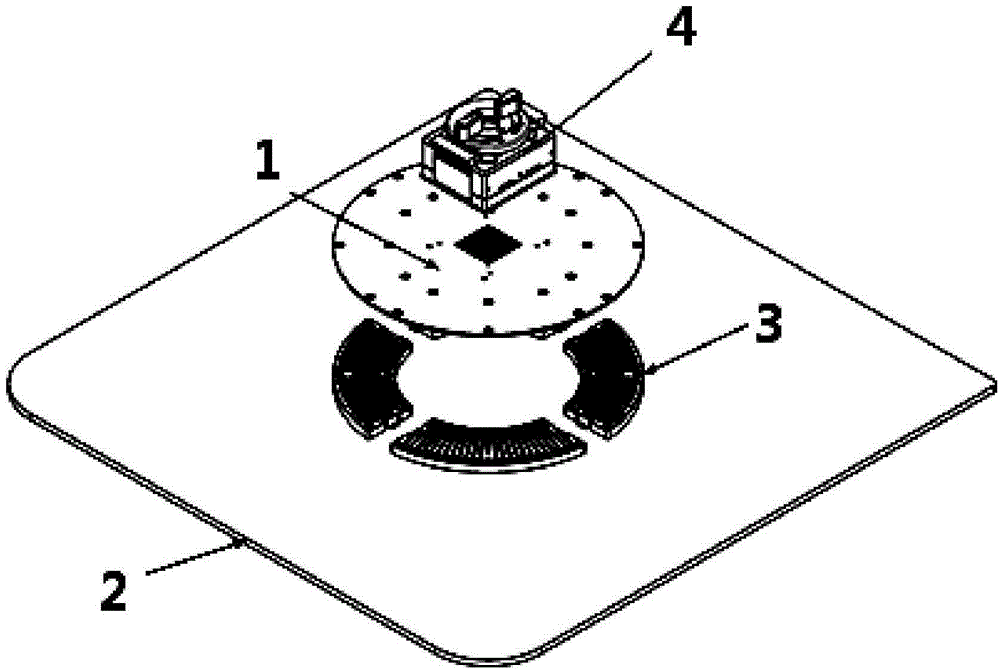

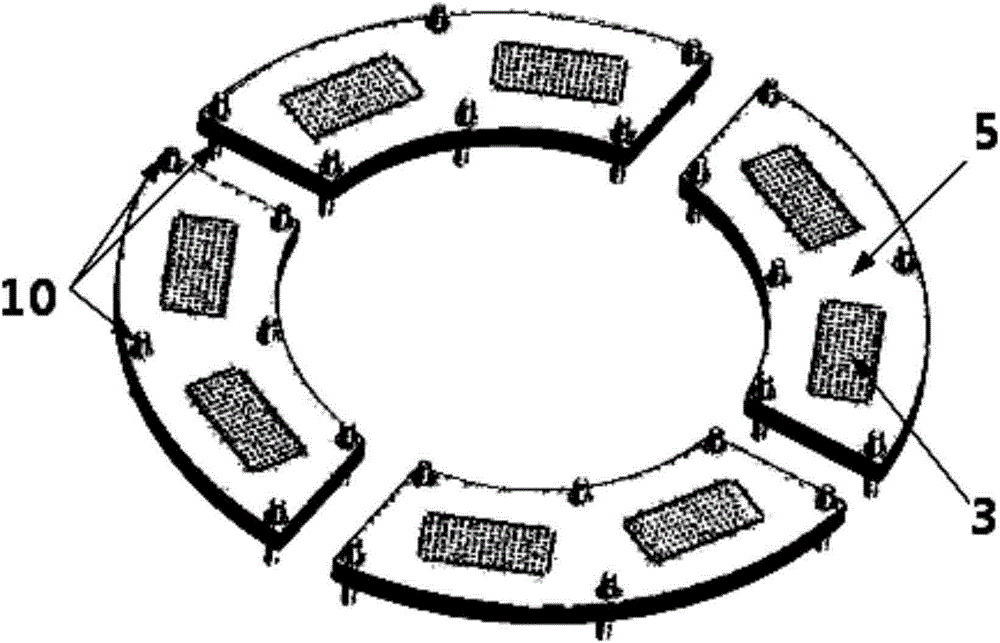

[0038] Such as figure 2 As shown, the test system of the present invention carries out structural and electrical connections by pressing and screwing the device to be tested, the test socket 4, the test sub-board 1, the pogo pin connector array 3, and the test motherboard 2, and finally passes the test system Docking with the motherboard to complete the power supply and the interaction test between the signal and the device under test. The entire pogo pin connector array is divided into 4 rectangular modules according to 90° sector and can be disassembled. The final forming structure of the pogo pin connector array is as follows image 3 shown. For each pogo pin connector, the specific structure is decomposed as follows: First, fix the stud on the metal base 5, and pass the stud directly through the stud mounting hole 6 on the metal base 5, and the raised ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com