Inorganic nanometer gas condensation sand insulation material and preparation method thereof

A technology of inorganic nano and thermal insulation materials, applied in the field of thermal insulation materials, can solve the problems of complex composition, cumbersome preparation process, and failure to realize nano-pores of porous materials, and achieve the effects of good thermal insulation and reasonable hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Select 100 kilograms of the above-mentioned aerospace-grade nano-silica airgel, add 5 kilograms of hydrofluoric acid aqueous solution with a concentration of 15% (percentage by weight), mix at room temperature in the above-mentioned equipment 1, and make the silica sol.

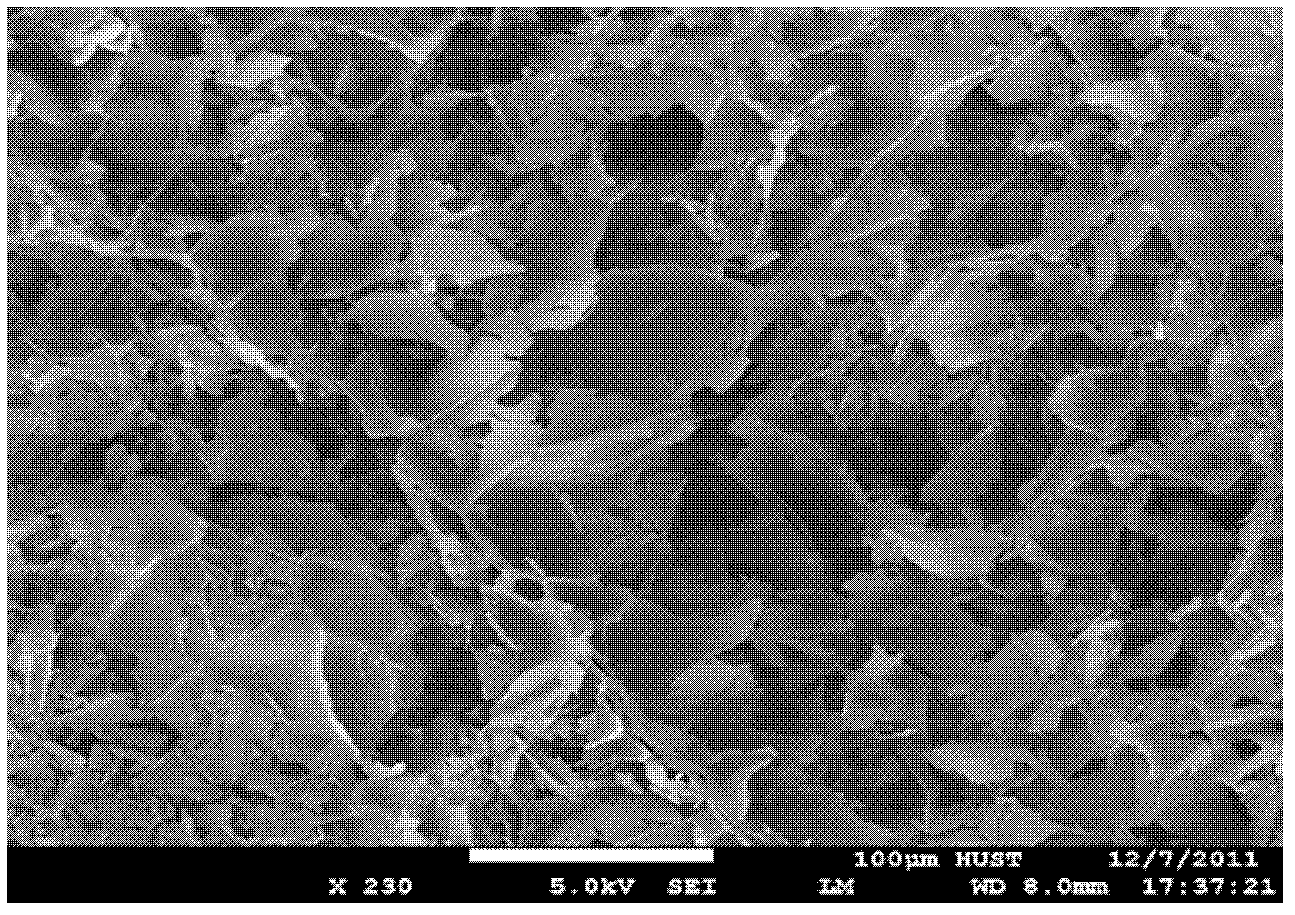

[0088]Break 100 kg of rock wool to a particle size of less than 3 mm, mix it with the airgel in the above-mentioned sol state in the above-mentioned equipment 1, and run it in the above-mentioned equipment 2 for 5 minutes, after completing the catalysis, dry it at room temperature to form a Silica airgel is a granular air-condensed sand insulation material.

Embodiment 2

[0090] Select 100 kg of the above-mentioned aerospace-grade silica airgel, add 10 kg of nitric acid aqueous solution with a concentration of 12% (percentage by weight), and mix in the above-mentioned equipment 1 at room temperature to make the silica sol.

[0091] Crush 100 kg of perlite to less than 3 mm, mix it with the airgel in the above sol state in the above equipment 1, and run it in the above equipment 2 for 3 minutes, after completing the catalysis, dry it at room temperature to form a Airgel is a granular air-condensed sand insulation material.

Embodiment 3

[0093] Select 100 kilograms of the above-mentioned aerospace-grade silica airgel, add 15 kilograms of hydrochloric acid aqueous solution with a concentration of 15% (weight percentage), and mix in the above-mentioned equipment 1 at room temperature to make the silica sol.

[0094] 100 kg of vermiculite particles are crushed to less than 3 mm, mixed with the airgel in the above-mentioned sol state in the above-mentioned equipment 1, and catalytically run in the above-mentioned equipment 2 for 6 minutes. Silica airgel is a granular airset sand insulation material.

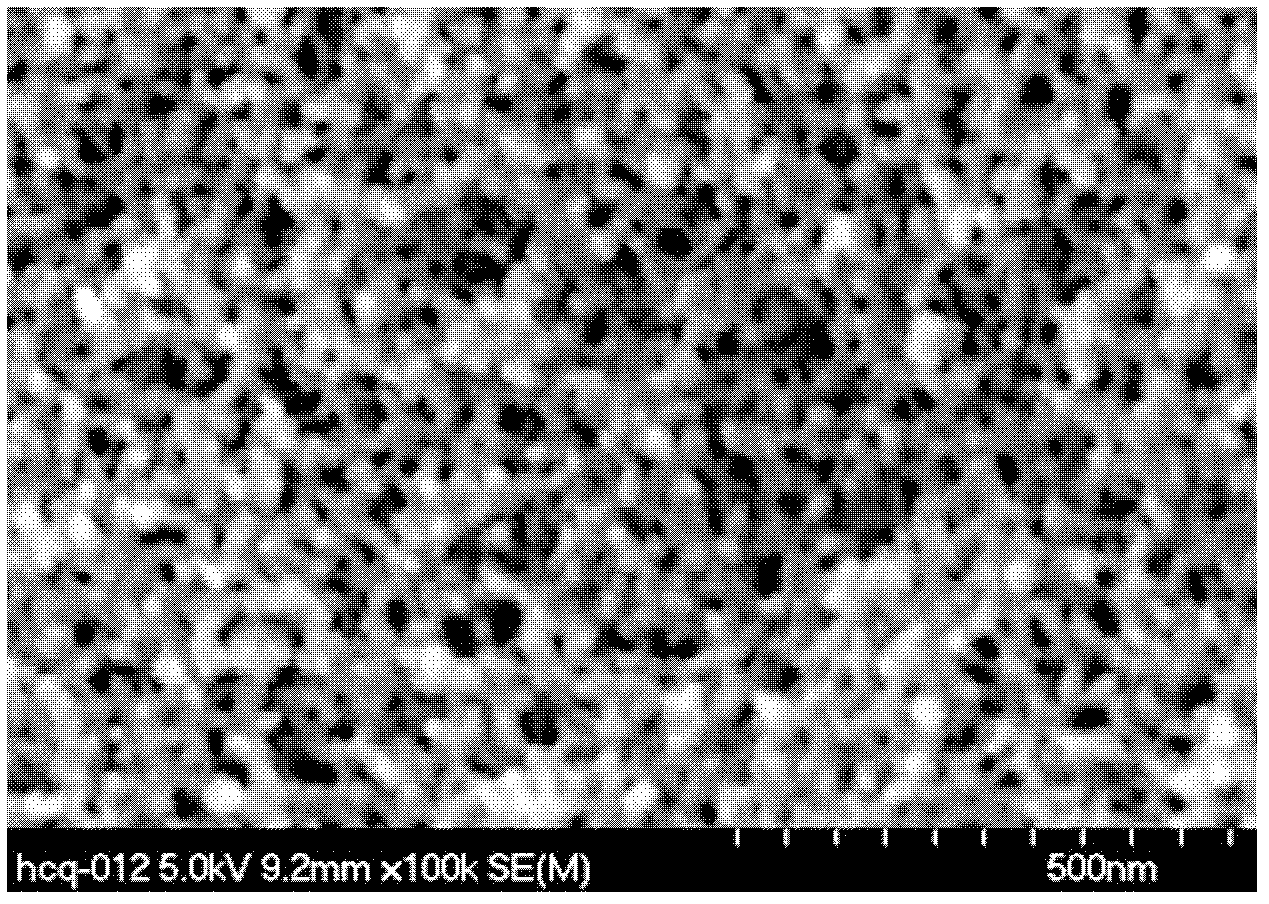

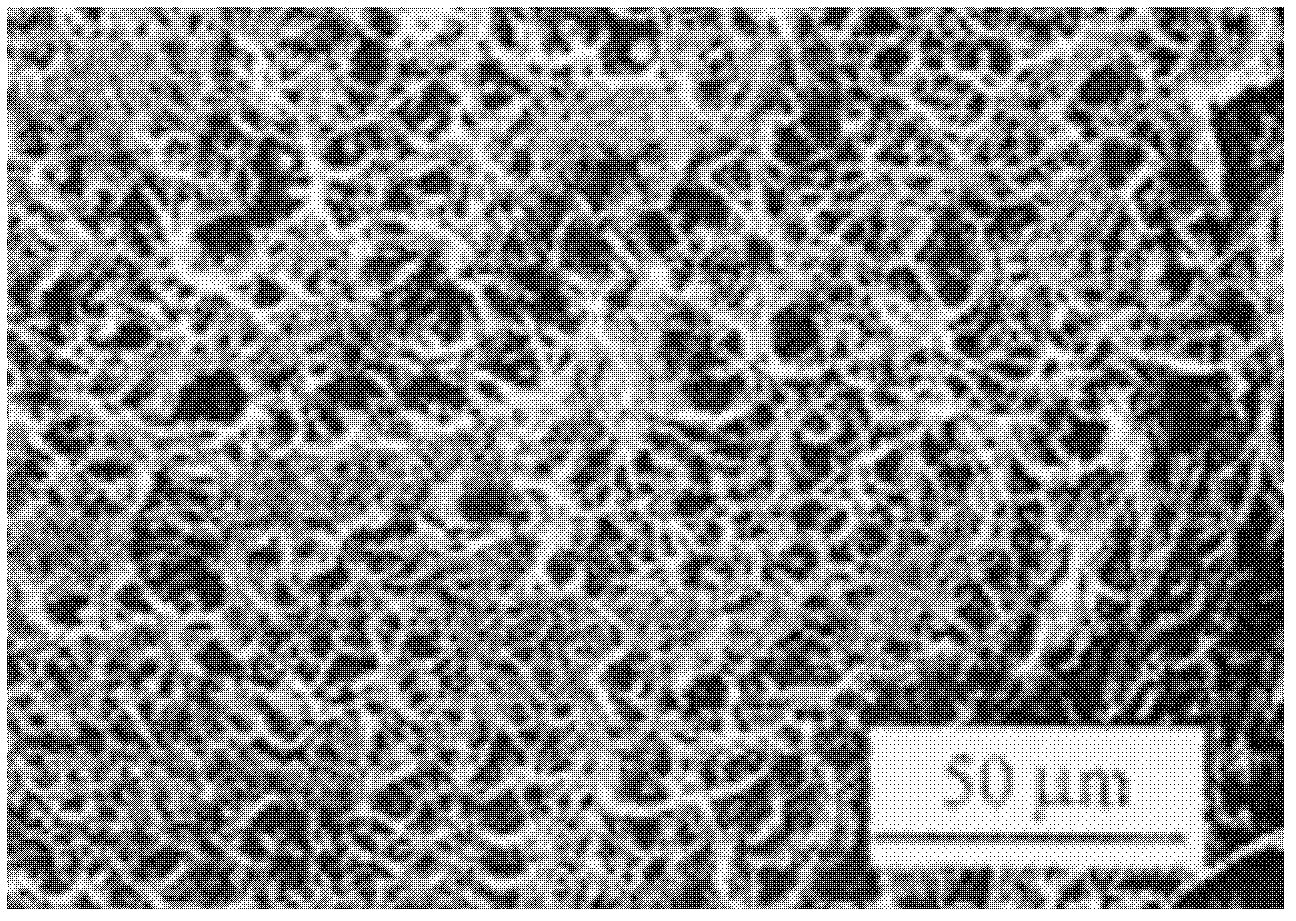

[0095] The inorganic nano-air coagulated sand that above-mentioned embodiment obtains, particle size is 0.1-2mm, and bulk density (weight per unit volume) is 50-100kg / m 3 , The thermal conductivity is 0.016-0.023W / m.K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com