Four-freedom degree industrial robot

A technology of industrial robots and degrees of freedom, applied in manipulators, manufacturing tools, etc., can solve problems such as low rigidity, large inertia, complex structure, etc., and achieve the effect of strong bearing capacity, large working space, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

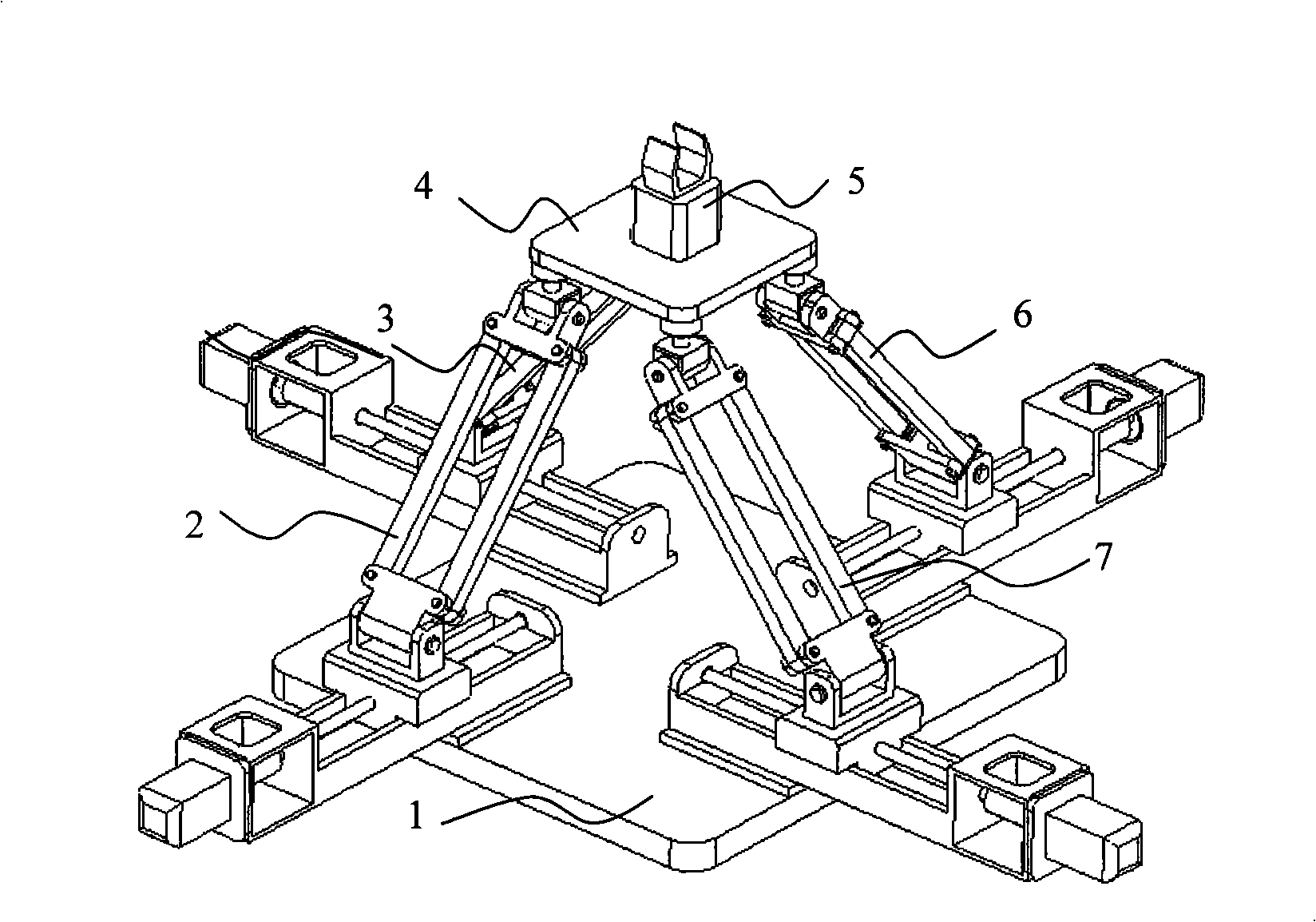

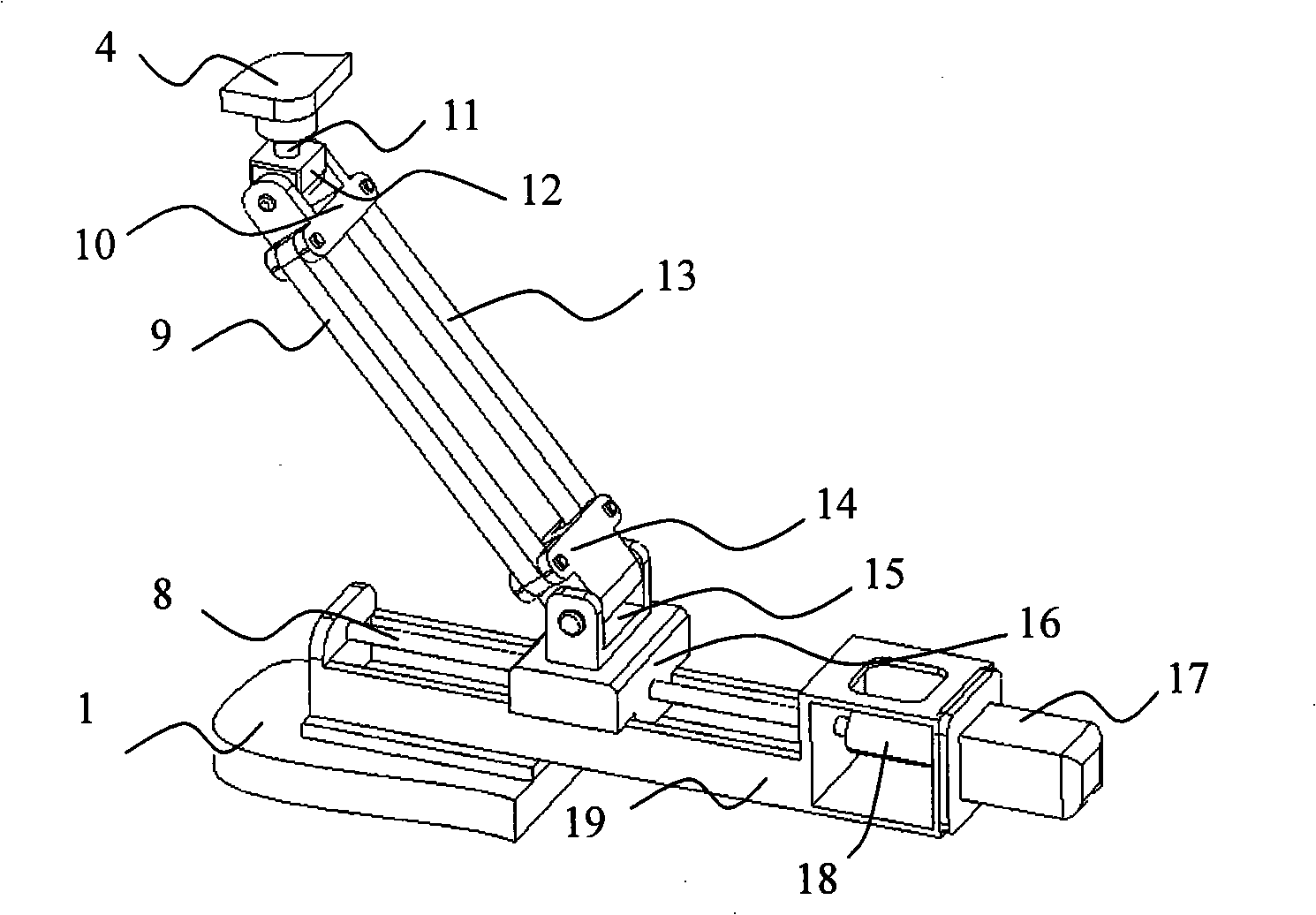

[0009] figure 1 It is an embodiment disclosed by the present invention. This four-degree-of-freedom industrial robot mainly includes parts such as a base 1, a motion platform 4, four motion branch chains (2, 3, 6, 7) with the same structure, and tools or fixtures 5. In the kinematic branch chains (2, 3, 6, 7) with the same structure, the four connecting rods (9, 10, 13, 14) are respectively connected by four revolving pairs to form a parallelogram mechanism; the ball screw nut Auxiliary 8, sliding table 16, AC servo motor 17, coupling 18, sliding table seat 19 and so on form the linear movement driving unit; connecting rod 10 is connected with rotating shaft 11 vertically installed on motion platform 4 through rotating pair 12, and connecting rod 14 The sliding table 16 of the linear movement drive unit is connected through the rotating pair 15; the nut of the ball screw nut pair 8 is firmly connected with the sliding table 16,

[0010] The ball screw of the ball screw nut pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com