Novel high-strength/tenacity aluminum alloy and preparation method thereof

A high-strength, high-toughness, aluminum alloy technology, which is applied in the field of new high-strength, high-toughness aluminum alloys and their preparation, can solve problems such as unsatisfactory fracture toughness of aluminum alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

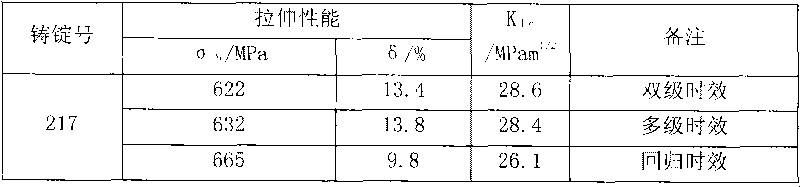

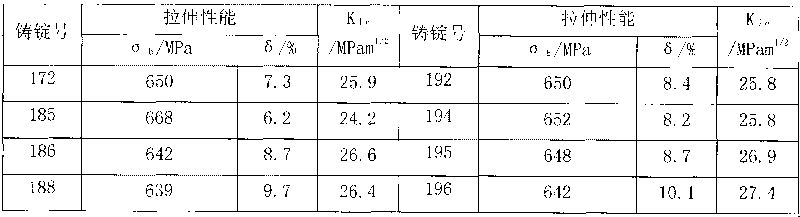

[0021] Below in conjunction with embodiment technical solution of the present invention will be described in further detail:

[0022] Table 1 shows an example of the chemical composition and weight percentage of the novel high-strength and high-toughness aluminum alloy proposed by the present invention.

[0023] Table 1: Chemical composition and weight percentage of new high-strength and high-toughness aluminum alloys

[0024] Ingot No.

Zn

Mg

Cu

Zr

Cr

V

Ti

Fe

Si

172

9.24

2.00

1.82

0.12

-

-

0.03

<0.10

<0.08

185

9.17

1.92

1.95

0.12

-

-

0.03

<0.10

<0.08

186

9.05

2.01

1.86

0.13

-

-

0.04

<0.10

<0.08

188

9.92

1.98

1.92

-

0.22

-

0.03

<0.10

<0.08

192

9.96

1.95

1.83

-

0.23

-

0.04

<0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com