Caesium selective absorbent and preparation method thereof

A selective, adsorbent technology, used in chemical instruments and methods, radioactive purification, other chemical processes, etc., can solve problems such as being unsuitable for fixed-bed operation, and achieve the effects of easy operation, simple equipment, and mild synthesis conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

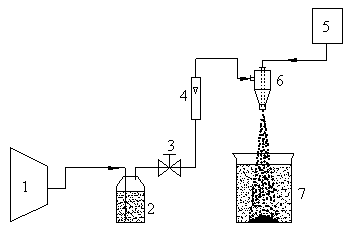

Method used

Image

Examples

Embodiment 1

[0031] (1) Polyacrylonitrile is dissolved in dimethyl sulfoxide to prepare a 4% polyacrylonitrile solution;

[0032] (2) Add potassium nickel ferrocyanide powder whose mass is 4 times the dry weight of polyacrylonitrile, with a particle size of less than 160 mesh, to the above polyacrylonitrile solution, and then fully stir at 50°C for 2 hours to mix the slurry Uniform;

[0033] (3) Put the slurry obtained in step (2) into the granulation device, after spraying through the spray hole, enter the coagulation bath to solidify and form, and make spherical particles of polyacrylonitrile / potassium ferrocyanide after cleaning, drying and other conventional procedures NiCesium selective adsorbent. The air inlet device in the granulation device used is an air compressor, the liquid inlet device is a liquid inlet tank with a capacity of 10mL, the drying device is filled with concentrated sulfuric acid, the gas flow rate is 380L / h, the coagulation bath is deionized water, and the coagul...

Embodiment 2

[0036] (1) Polyacrylonitrile is dissolved in dimethyl sulfoxide to prepare a 2% polyacrylonitrile solution;

[0037] (2) Add potassium ferrocyanide cobalt powder, whose mass is 9 times the dry weight of polyacrylonitrile, with a particle size of less than 160 mesh, to the above polyacrylonitrile solution, and then fully stir at 40°C for 2 hours to mix the slurry Uniform;

[0038] (3) Put the slurry obtained in step (2) into the granulation device, after spraying through the spray hole, enter the coagulation bath to solidify and form, and make spherical particles of polyacrylonitrile / potassium ferrocyanide after cleaning, drying and other conventional procedures Cobalt and cesium selective adsorbent. The air inlet device in the granulation device used is an air compressor, the liquid inlet device is a liquid inlet tank with a capacity of 10mL, the drying device is filled with concentrated sulfuric acid, the gas flow rate is 380L / h, the coagulation bath is deionized water, and ...

Embodiment 3

[0040] (1) Polyacrylonitrile is dissolved in dimethyl sulfoxide to prepare a 20% polyacrylonitrile solution;

[0041] (2) Add potassium ferrocyanide cobalt powder whose mass is 1 times the dry weight of polyacrylonitrile, particle size less than 160 mesh, to the above polyacrylonitrile solution, and then fully stir at 60°C for 2 hours to mix the slurry Uniform;

[0042](3) Put the slurry obtained in step (2) into the granulation device, after spraying through the spray hole, enter the coagulation bath to solidify and form, and make spherical particles of polyacrylonitrile / potassium ferrocyanide after cleaning, drying and other conventional procedures Cobalt and cesium selective adsorbent. The air inlet device in the granulation device used is an air compressor, the liquid inlet device is a liquid inlet tank with a capacity of 10mL, the drying device is filled with concentrated sulfuric acid, the gas flow rate is 380L / h, the coagulation bath is deionized water, and the coagula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com