Edge covering method and device of plastic honeycomb sandwich panel

A technology of plastic honeycomb and sandwich panels, applied in the directions of lamination devices, transportation and packaging, chemical instruments and methods, etc., can solve the problems of easy re-opening of upper and lower skins and failure of edge sealing, so as to achieve smooth folding and improving. Efficiency, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

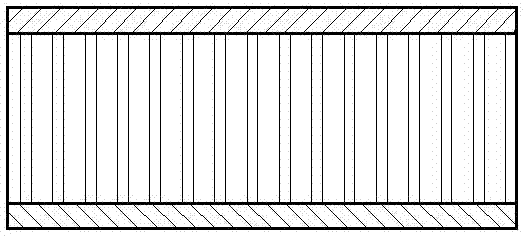

[0044] First, prepare the plastic honeycomb sandwich panel with glass fiber reinforced PP as the upper and lower skin and PP honeycomb in the middle, and cut the lower skin to Figure 5 The extent shown by the solid line, the upper epidermis is cut to Figure 5 In the range shown by the dotted line, the plastic honeycomb in the hemming area is also removed, as shown in Figure 6shown. The width of the wrapping area is set at 25-40mm.

[0045] After the plate is positioned and fixed on the tooling, a high-temperature component with a temperature of 220°C corresponding to the shape of the edge-wrapping area of the plate is dropped from above, and after the high-temperature component is dropped into place, if Figure 9 As shown, the lower epidermis outside the contours of the product is softened.

[0046] After the high-temperature parts are withdrawn, the turning mechanism operates, and the lower skin is pushed upwards and bonded to the side of the PP honeycomb. On the uppe...

Embodiment 2

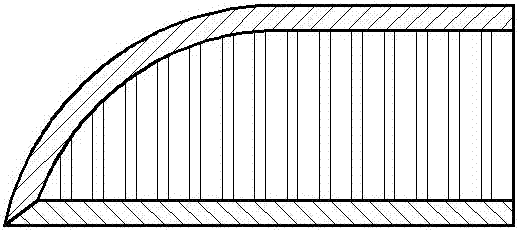

[0048] First, prepare the plastic honeycomb sandwich panel with glass fiber reinforced PP as the upper and lower skin and PP honeycomb in the middle, and cut the lower skin to Figure 4 The extent shown by the solid line, the upper epidermis is cut to Figure 4 In the dotted line range shown, the plastic honeycomb in the hemming area is Figure 7 The sloped excess shown can be machined with a sloped CNC milling cutter. The width of the hemming area is set at 13-18mm.

[0049] After the plate is positioned and fixed on the tooling, a high-temperature component with a temperature of 260°C corresponding to the shape of the edge-wrapping area of the plate is dropped from above. After the high-temperature component falls into place, if Figure 9 As shown, the honeycomb outside the outline of the product is completely melted, and the lower skin is also softened.

[0050] After the high-temperature parts are withdrawn, the folding mechanism operates, and the lower skin is pushed...

Embodiment 3

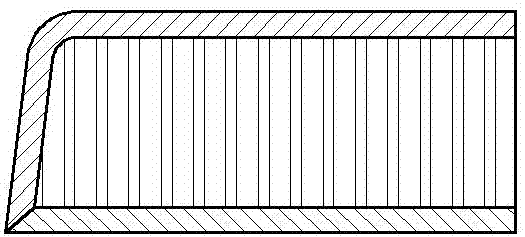

[0052] First, prepare the plastic honeycomb sandwich panel with glass fiber reinforced PP upper and lower skins and PP honeycomb in the middle, and the lower skin is also equipped with surface materials, and the lower skin is cut to Figure 4 The extent shown by the solid line, the upper epidermis is cut to Figure 4 In the dotted line range shown, the plastic honeycomb in the hemming area is as Figure 8 As shown, there is no regularity in height. The width of the wrapping area is set at 25-40mm. The cutting method of the wrapping area can be to cut out the contour lines of the upper skin and the lower skin, and then in the process of removing the waste area, the plastic honeycomb between the two contour lines is randomly removed.

[0053] After the plate is positioned and fixed on the tooling, a high-temperature component with a temperature of 280°C corresponding to the shape of the edge-wrapping area of the plate is dropped from above. After the high-temperature compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com