Carton production overlapping device for batch transportation

A stacking device and carton technology, applied in transportation and packaging, packaging, papermaking, etc., can solve the problems of high production labor cost, large labor volume, low efficiency, etc., to reduce labor intensity, improve production efficiency, and ensure structural integrity. Effect

Pending Publication Date: 2022-06-21

江苏鸿凯包装有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, when the existing cartons are laminated after slotting and crimping, most carton processing manufacturers use manual methods to laminate the cartons. Low, high production labor costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

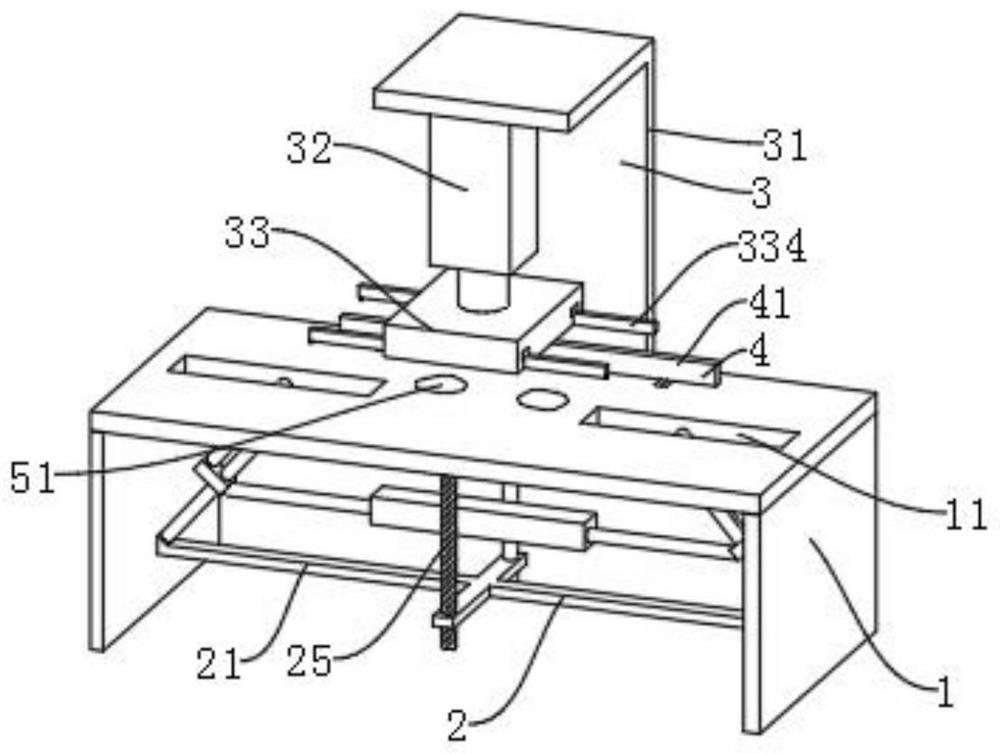

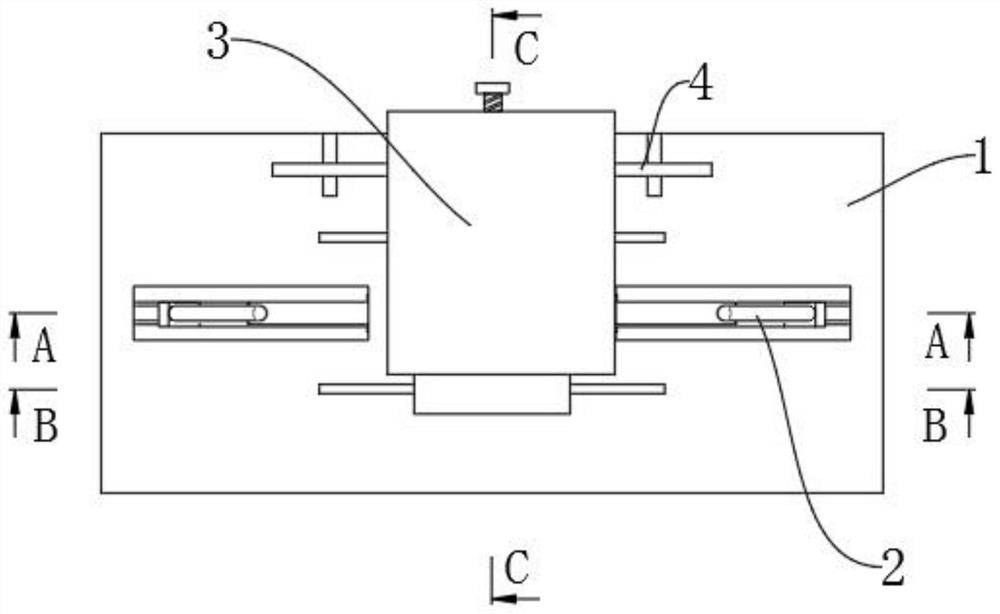

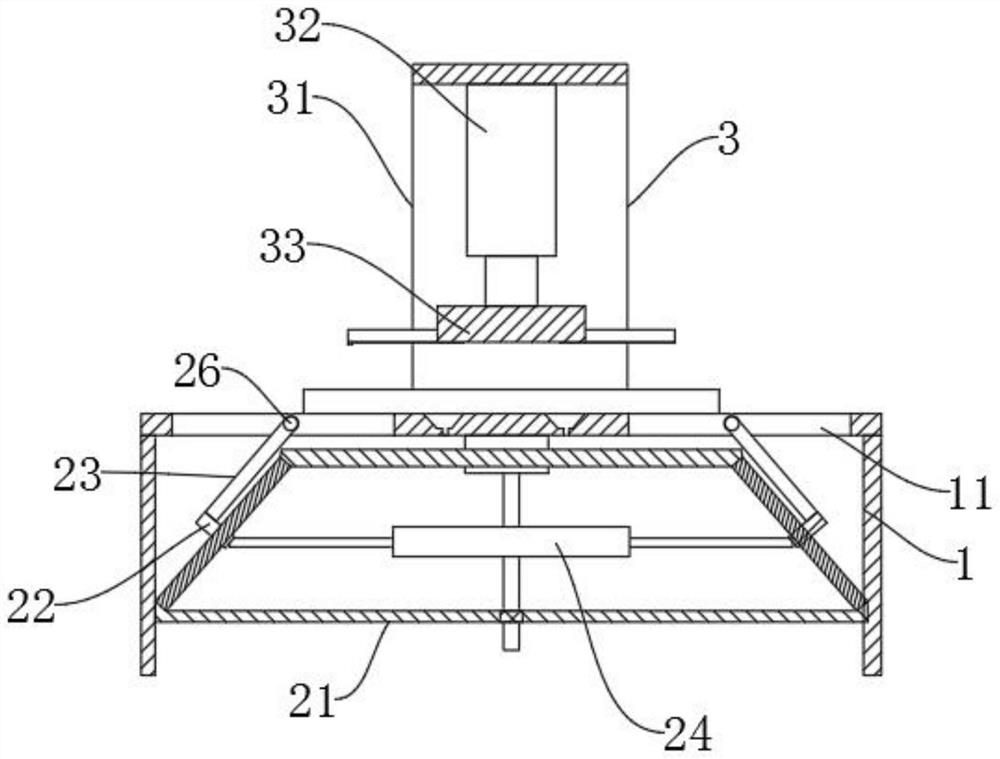

The carton production overlapping device for batch transportation comprises a rack, two receding strip-shaped holes are formed in the middle of the upper end face of the rack in the length direction of the rack in a spaced mode, the ends of the two receding strip-shaped holes are opposite, and the inner side of the rack is provided with receding strip-shaped holes capable of penetrating through the receding strip-shaped holes. The jacking mechanism is arranged on the rack and enables the folded plates on the two sides of the materials to be overturned upwards by more than 90 degrees, and a pressing mechanism capable of pressing the folded plates on the two sides of the overturned materials downwards and enabling the folded plates to be overlapped above the middles of the materials is arranged above the rack. Due to the arrangement of the jacking mechanism, the turnover angle of the folded plates on the two sides of the materials can be larger than 90 degrees, the function of overlapping the materials is completed in combination with the downward pressing mechanism, the function of automatically folding the materials is achieved, the production efficiency is improved, and the labor intensity is reduced.

Description

technical field [0001] The invention relates to the technical field of carton production, in particular to a carton production lamination device for batch transportation. Background technique [0002] Carton is the most widely used packaging product. According to different materials, there are corrugated cartons, single-layer cardboard boxes, etc., with various specifications and models. Cartons are commonly used with three layers and five layers. Seven layers are rarely used. Each layer is divided into Lining paper, corrugated paper, core paper, surface paper, lining and surface paper include tea board paper, kraft paper, corrugated paper for core paper, the color and feel of various papers are different, and the paper produced by different manufacturers is also different. Cutting is required, and after the cutting is completed, the corresponding position of the cardboard needs to be slotted, and the place that needs to be laminated is crimped, and then the materials are la...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B31B50/07B31B50/26B31B50/00

CPCB31B50/07B31B50/26B31B50/006

Inventor 董开

Owner 江苏鸿凯包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com