Working method for foam cutting machine using thermal cutting technology

A working method, thermal cutting technology, applied in the field of machinery, can solve problems such as unsuitable for mass production and demanding occasions, low dimensional accuracy of finished products, high labor intensity, etc., to solve the problem of dimensional accuracy of finished products, simple and practical structure, fast cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

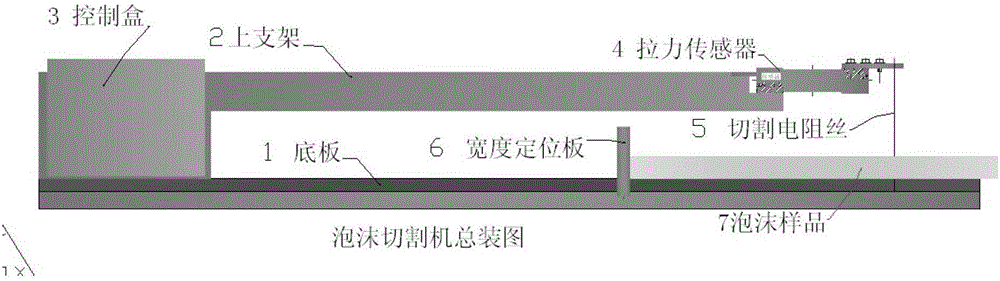

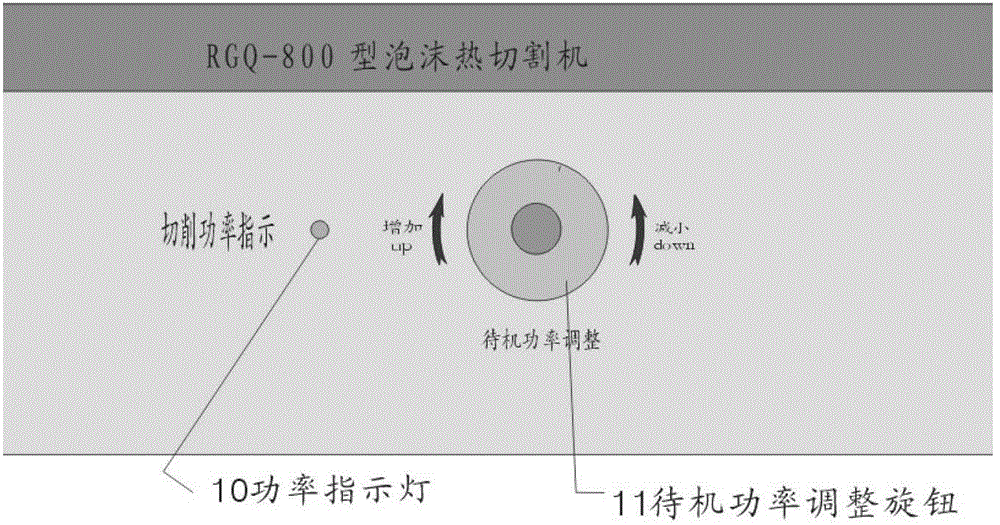

[0012] see figure 1 and figure 2 , the embodiment of the present invention includes:

[0013] A working method of a foam cutting machine using thermal cutting technology, its working steps: the first step: place the foam to be cut on the bottom plate of the machine and close to the width positioning plate, connect the power and turn on the switch; the second step: Adjust the potentiometer knob on the panel so that the resistance wire can cut the melted foam when it is basically not pushed; the third step: adjust the positioning plate according to the size to be cut. The size of the foam to be cut, and then tighten the positioning plate; Step 4: Push t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com