Integral type flanged flange production equipment and method

A kind of production equipment and integrated technology, which is applied in the direction of metal processing equipment, forming tools, feeding devices, etc., can solve the problems of pipe ellipticity, high environmental requirements and welding technical requirements, high difficulty coefficient of electric fusion welding, and difficulty in ensuring welding quality and other problems to achieve the effect of saving installation procedures, avoiding poor reliability of welds, and avoiding dimensional accuracy problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

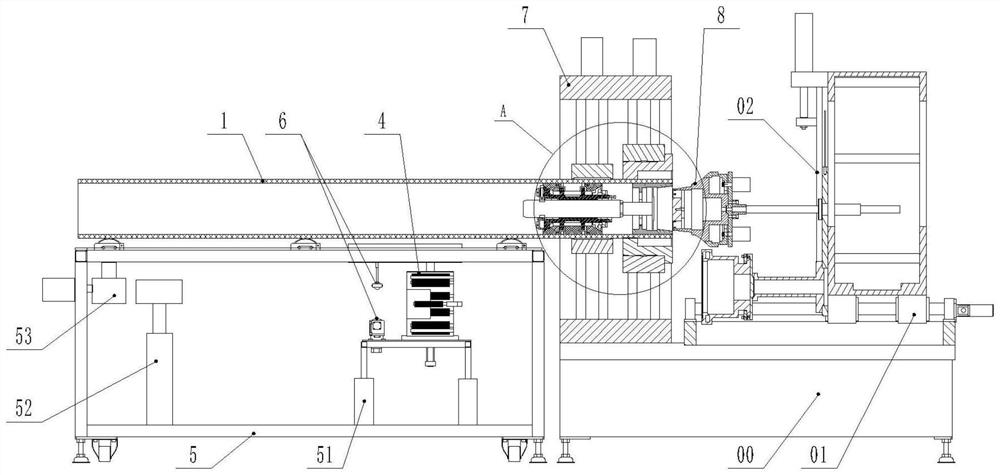

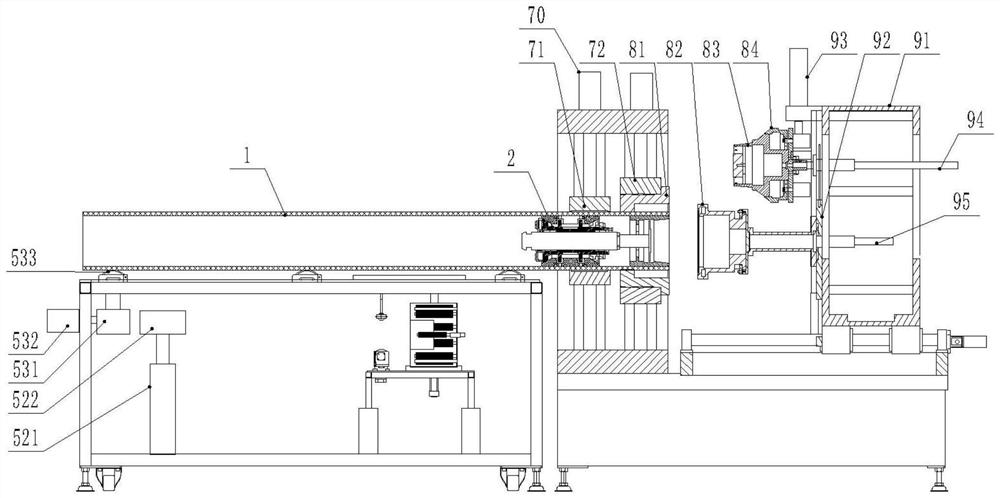

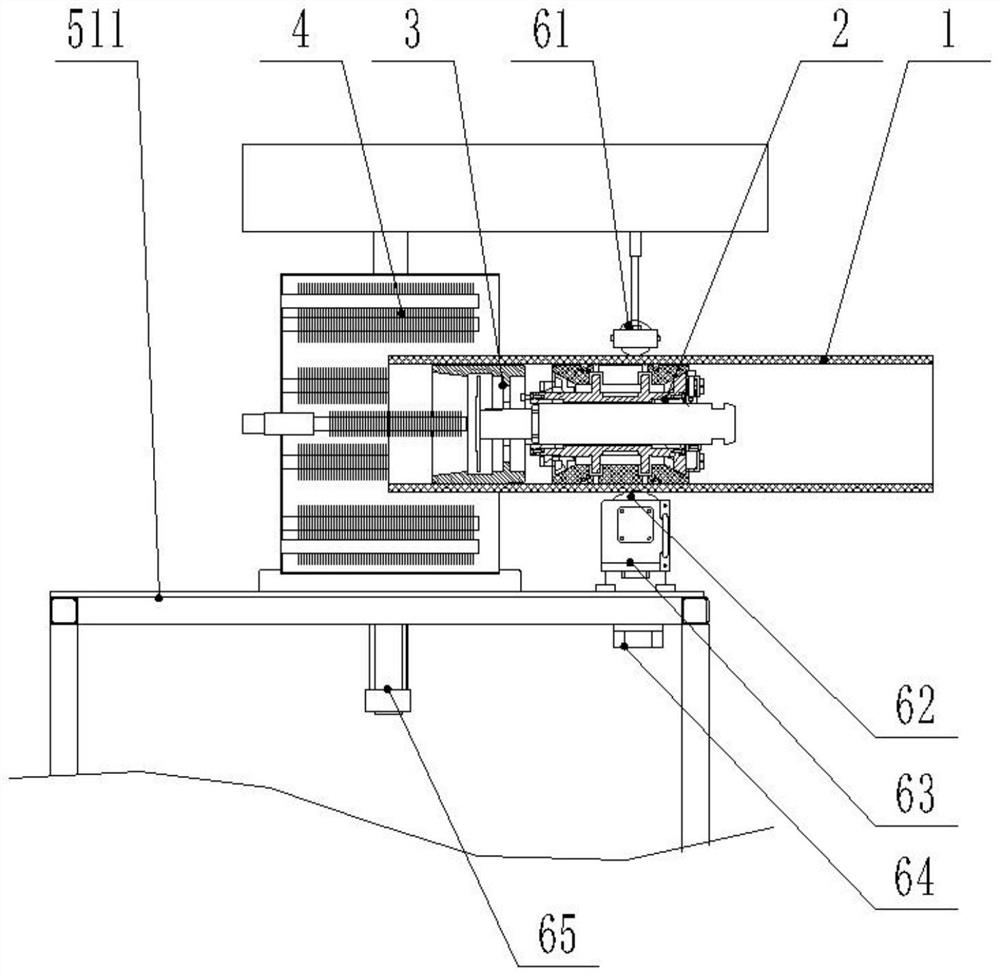

[0037] The invention discloses an integral flanging flange production equipment, such as Figure 1-2 As shown, it includes a bracket 5, the top of the bracket 5 is provided with a conveying device, the bottom is provided with a lifting mechanism 51, the lifting platform 511 of the lifting mechanism 51 is provided with a heating device 4, and the discharge end of the conveying device is provided with a flange The forming die 8, the flange forming die 8 includes a pre-expanding die and a forming die located on the base 00, the base 00 is provided with a clamping device 7, the forming die is connected with the extrusion mechanism, and the conveying device and the lifting mechanism 51 are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com