Engine dry cylinder liner machine body foam model and manufacturing method thereof

A foam model, engine cylinder technology, applied in the direction of manufacturing tools, casting molds, cores, etc., can solve the problems of inaccurate structural dimensions of castings, molten metal drift, affecting product quality, etc., to solve the problem of dimensional accuracy, prevent drift, The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

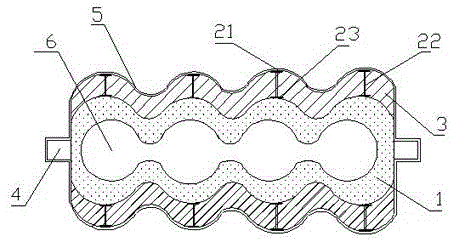

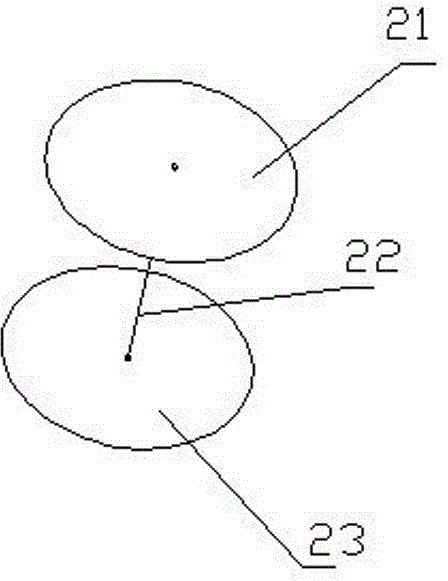

[0022] combine figure 1 , 2 Describe this embodiment, a foam model of engine dry-type cylinder liner body, the water jacket part between the engine cylinder liner and the body is provided with a water jacket sand core, and the body foam model 3 outside the water jacket sand core 1 is provided with Several fixed support cards. figure 1 Shown is the foam model of the water jacket part of the dry cylinder liner body of the four-cylinder engine, and the shape of the water jacket sand core 1 matches the shape of the water jacket part. When manufacturing a dry-type cylinder liner body in the lost foam casting technology, due to the limited gap between the water jacket part between the cylinder liner and the shell, sand filling is often not solid, resulting in the leakage of molten metal between the body and the cylinder liner, resulting in waste products , and the water jacket sand core 1 of the present invention is installed in the water jacket part between the cylinder liner and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com