Laser-arc composite partition additive manufacturing process and device

An additive manufacturing and laser technology, applied in the field of laser-arc composite heat source additive manufacturing process and equipment, can solve problems such as low-cost production efficiency and high forming accuracy, improve utilization, solve dimensional accuracy and surface quality Not high, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

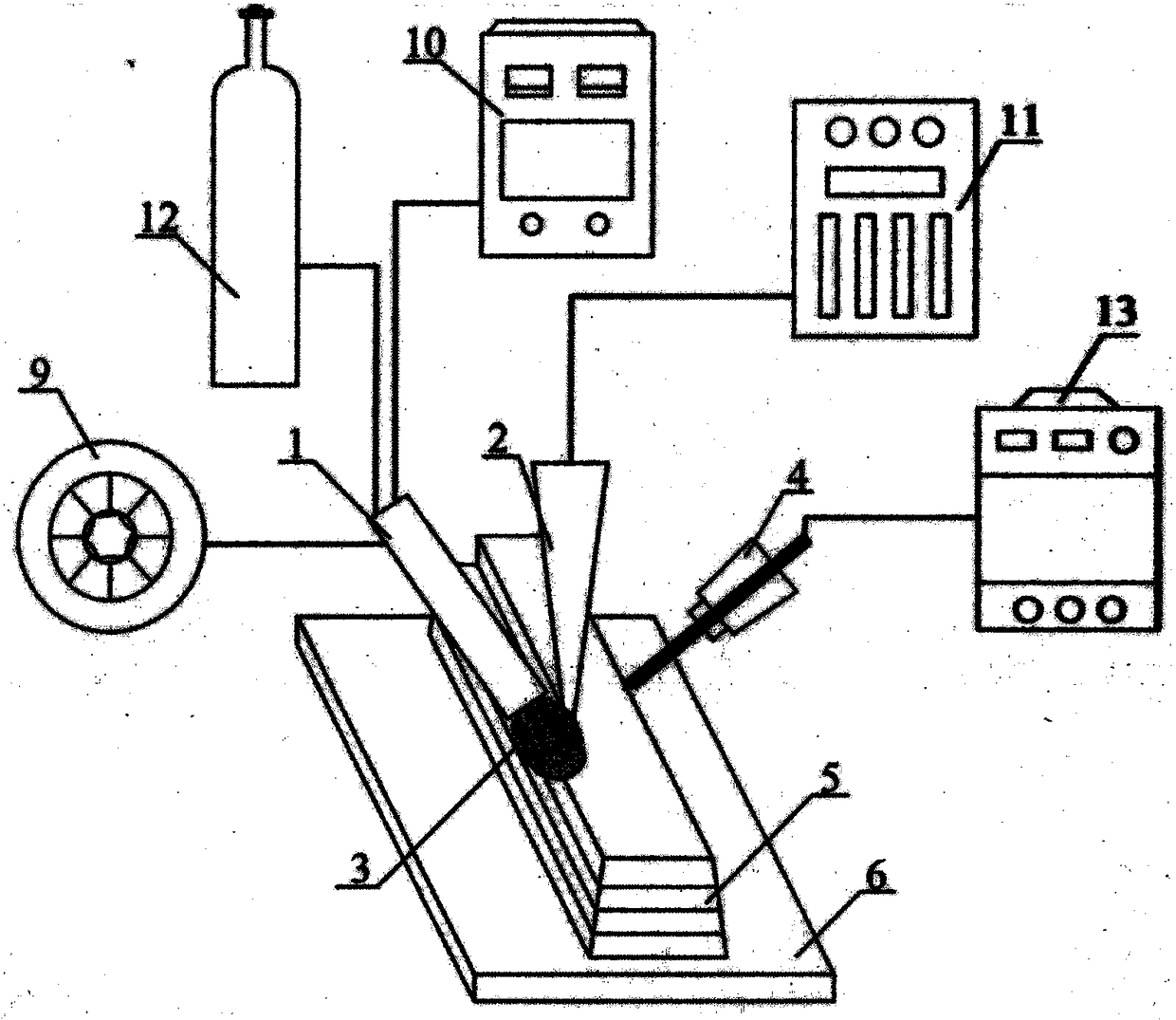

[0024] A laser-arc composite additive manufacturing process and equipment of the present invention will be described in detail below in conjunction with the accompanying drawings. A laser-arc composite partition additive manufacturing process and equipment, characterized in that the preparation method includes the following steps:

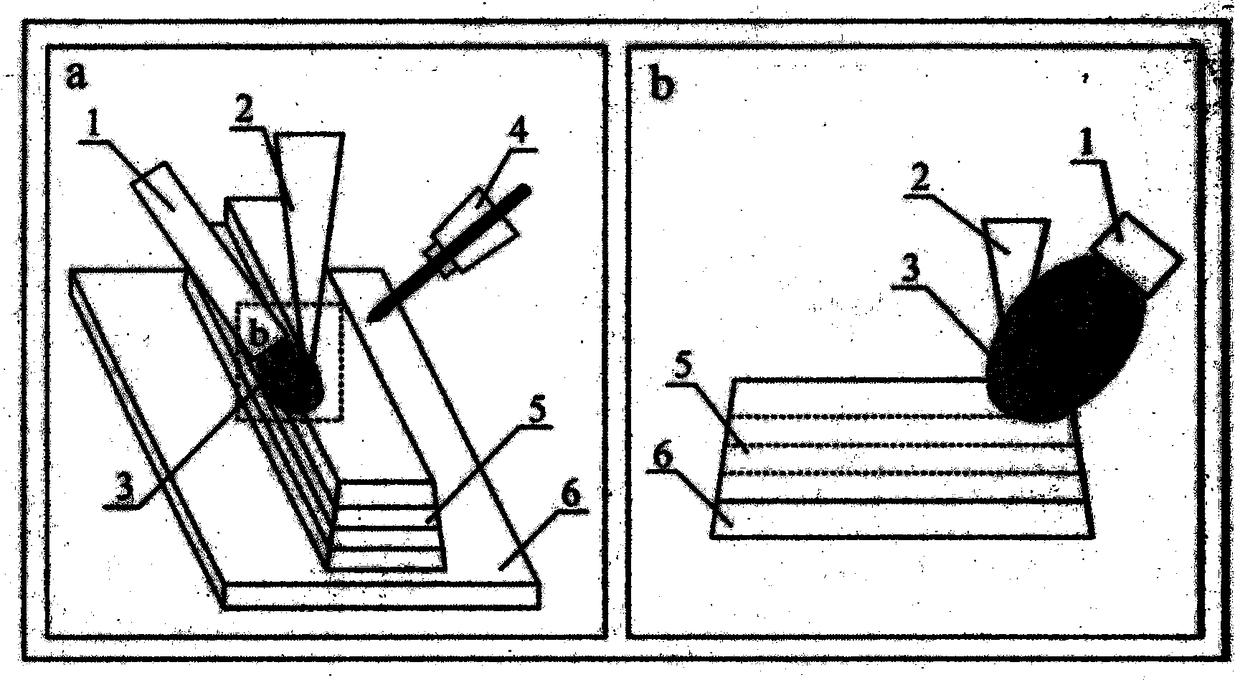

[0025] For the additive manufacturing of 5356 aluminum alloy trapezoidal parts, the method of sub-area manufacturing is adopted. The cross-sectional size of the part is 1.5mm at the bottom, 10mm at the bottom, and 10mm high. Laser-MIG composite additive manufacturing is used in areas with a width greater than 3mm, such as figure 2 As shown; laser additive manufacturing is used in areas with a width of less than 3mm, such as image 3 shown. The test substrate is 200mm×200mm×19mm 6061 aluminum alloy plate, and the filling material is ER5356 aluminum alloy wire with a diameter of 1.2mm. Before the experiment, the oxide film on the surface of the a...

Embodiment 2

[0029] A laser-arc composite additive manufacturing process and equipment of the present invention will be described in detail below in conjunction with the accompanying drawings. A laser-arc composite partition additive manufacturing process and equipment, characterized in that the preparation method includes the following steps:

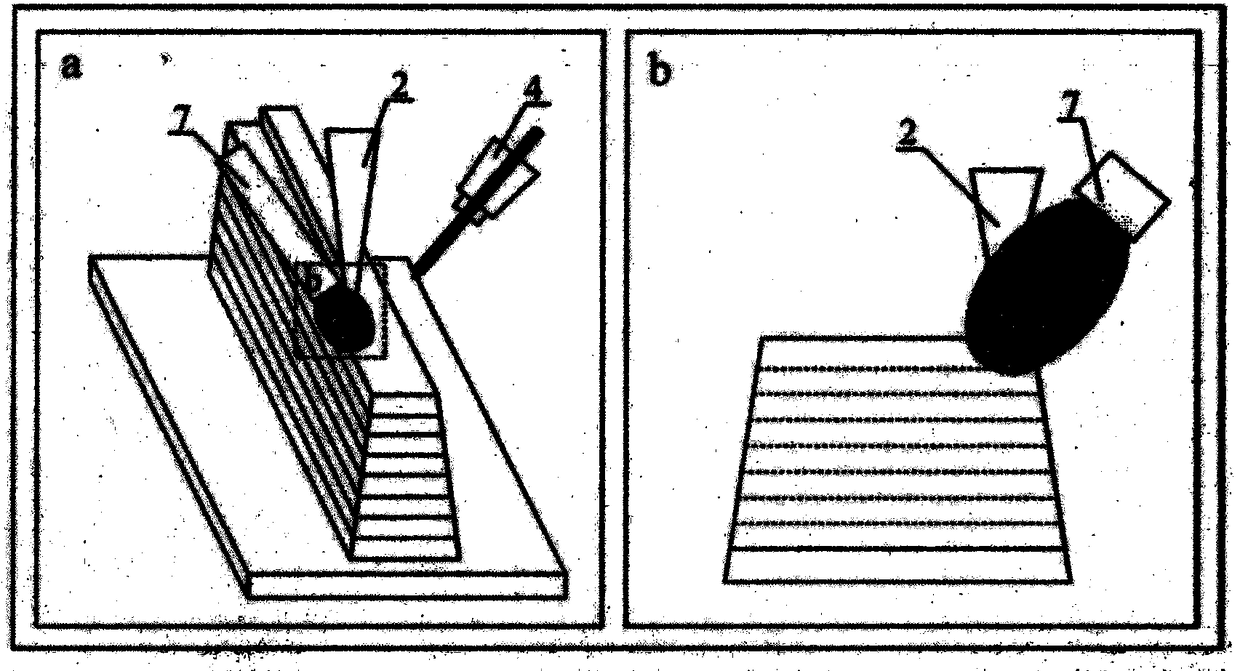

[0030] For the additive manufacturing of 4043 aluminum alloy trapezoidal parts, the method of sub-area manufacturing is adopted. The cross-sectional size of the part is 1.5mm at the bottom, 10mm at the bottom, and 10mm high. Laser-TIG composite additive manufacturing is used in areas with a width greater than 3mm, such as Figure 4 As shown; laser additive manufacturing is used in areas with a width of less than 3mm, such as image 3 shown. The test substrate is 200mm×200mm×19mm 6061 aluminum alloy plate, and the filling material is ER4043 aluminum alloy wire with a diameter of 1.2mm. Before the experiment, the oxide film on the surface of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com