Preparation method of tubular porous metal element with tiny permeation flux

A metal element and permeation flux technology, which is applied in the field of preparation of tubular porous metal elements with tiny permeation flux, can solve the problems of insufficient dimensional accuracy and infiltration, and achieve reuse, low requirements for production equipment, and high preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

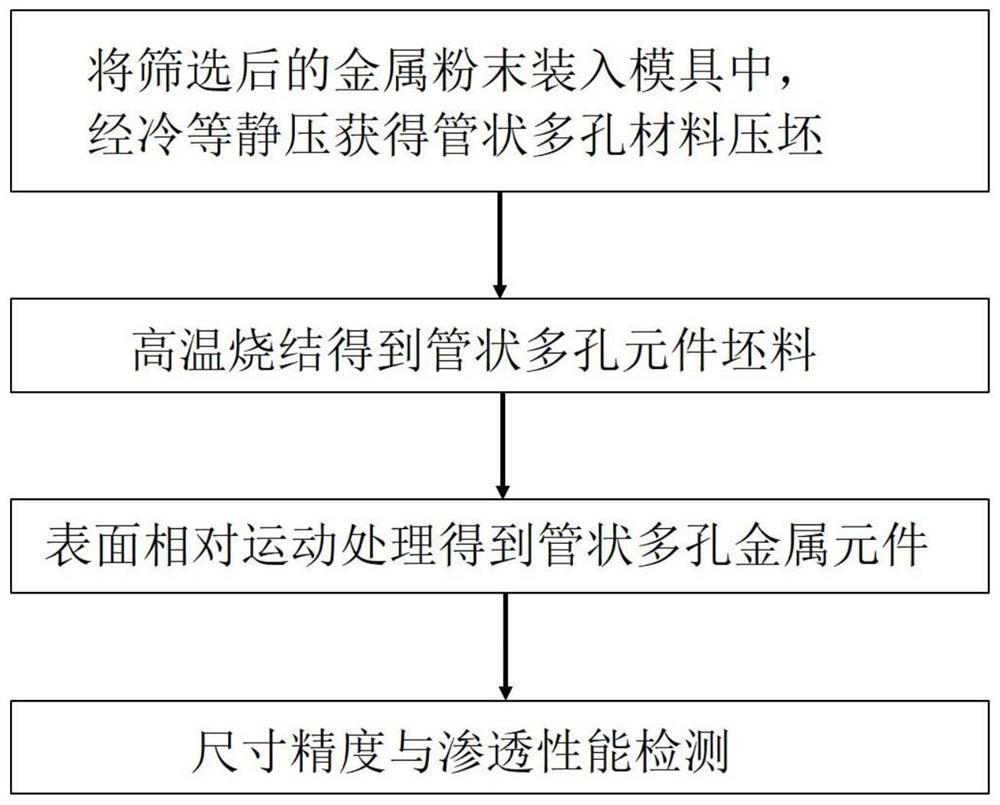

[0021] like figure 1 As shown, this embodiment includes the following steps:

[0022] Step 1. Put the screened 316L stainless steel powder into a mold for cold isostatic pressing to prepare a tubular porous material compact; the size of the tubular porous material compact is: length 2000mm, diameter 200mm, wall thickness 20mm; The pressure of cold isostatic pressing is 180MPa, and the holding time is 30s;

[0023] Step 2: Carrying out high-temperature sintering of the tubular porous material compact prepared in step 1 to obtain a tubular porous element blank; the temperature of the high-temperature sintering is 1200° C., and the holding time is 2 hours;

[0024] Step 3. Clamp the tubular porous element blank obtained in step 2 on an axially rotatable lathe, under the conditions of a speed of 100r / min, a feed rate of 0.2mm / r, and a processing capacity of 1.5mm each time , using a high-speed steel tool to process the relative movement of the surface of the blank of the tubular...

Embodiment 2

[0027] like figure 1 As shown, this embodiment includes the following steps:

[0028] Step 1. Put the screened Inconel 625 alloy powder into a mold for cold isostatic pressing to prepare a tubular porous material compact; the size of the tubular porous material compact is: length 50mm, diameter 120mm, wall thickness 12mm; The pressure of cold isostatic pressing is 160MPa, and the holding time is 30s;

[0029] Step 2: Carrying out high-temperature sintering of the tubular porous material compact prepared in step 1 to obtain a tubular porous element blank; the temperature of the high-temperature sintering is 1240° C., and the holding time is 2 hours;

[0030] Step 3: Clamp the tubular porous element blank obtained in step 2 on a lathe that can rotate axially, under the conditions of a rotation speed of 1000r / min, a feed rate of 1.2mm / r, and a processing capacity of 0.2mm each time , using a high-speed alloy tool to process the relative movement of the surface of the blank of t...

Embodiment 3

[0033] like figure 1 As shown, this embodiment includes the following steps:

[0034] Step 1. Put the screened TA0 powder into a mold for cold isostatic pressing to prepare a tubular porous material compact; the size of the tubular porous material compact is: length 500mm, diameter 20mm, wall thickness 6mm; the cold The pressure of isostatic pressing is 100MPa, and the holding time is 30s;

[0035] Step 2: Carrying out high-temperature sintering of the tubular porous material compact prepared in step 1 to obtain a tubular porous element blank; the temperature of the high-temperature sintering is 1050° C., and the holding time is 1.5 h;

[0036] Step 3. Clamp the tubular porous element blank obtained in step 2 on an axially rotatable lathe, under the conditions of a rotation speed of 475r / min, a feed rate of 0.8mm / r, and a processing capacity of 0.9mm each time , using a diamond tool to process the relative movement of the surface of the blank of the tubular porous element to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com