Novel transmission shaft and friction stir welding process thereof

A technology of friction stir welding and friction stir, which is applied in the field of vehicle engineering, can solve the problems that the coaxiality of the shaft fork and the shaft tube is not easy to guarantee, and the welding joint is weakened, so as to reduce the production cost and improve the performance index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Concrete implementation steps of the present invention are as follows:

[0031] 1. Shaft fork structure design:

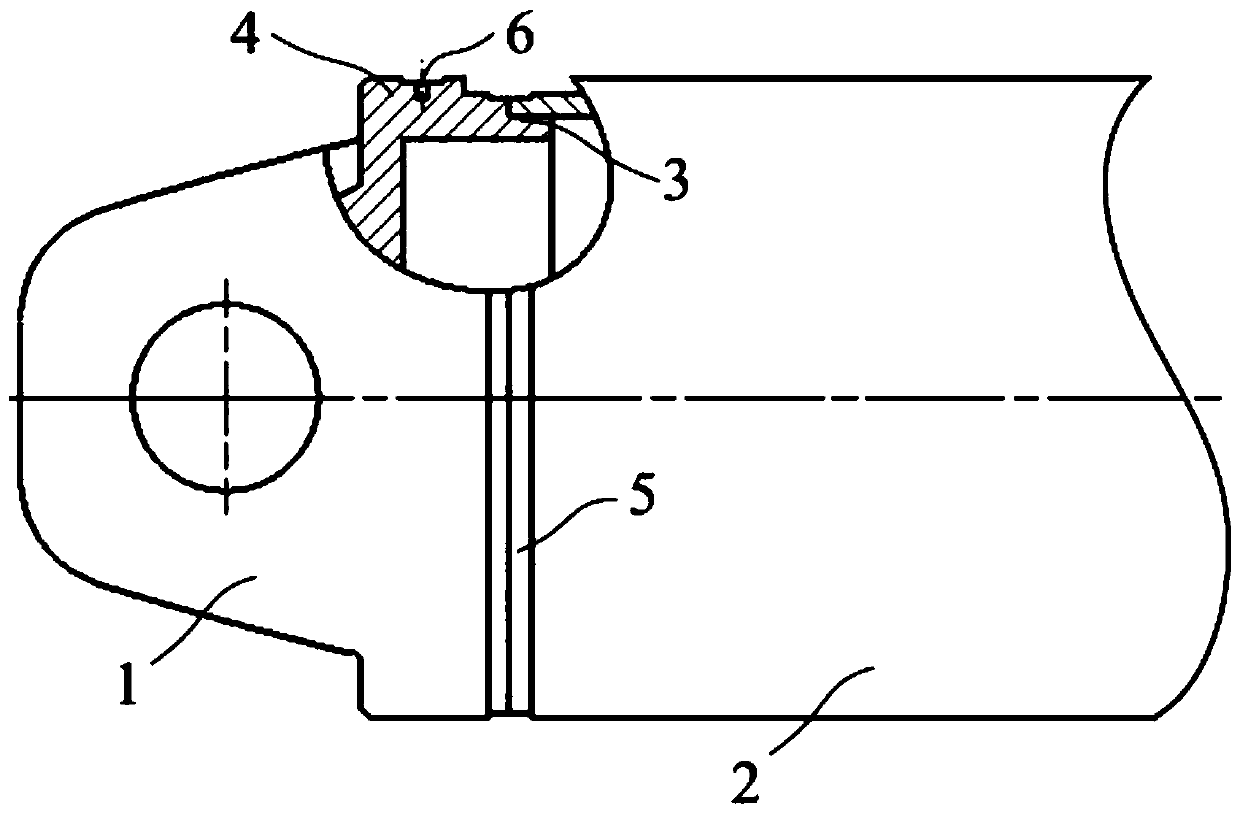

[0032] Such as figure 1 As shown, a new transmission shaft is welded by an aluminum alloy shaft fork (or steel shaft fork) 1 and an aluminum alloy shaft tube 2, and the welding process used is friction stir welding. The connecting end of the shaft fork 1 and the shaft tube 2 is designed with an overlapping step 3, and the outer circle of the shaft fork 1 adjacent to the overlapping step 3 is designed with a tangential small boss 4 (wherein the small boss 4 of the steel shaft fork is pre-set A guide groove 6) is provided, and the shaft tube 2 is sleeved on the overlapping step 3 of the shaft fork 1 .

[0033] 2. Friction stir welding process:

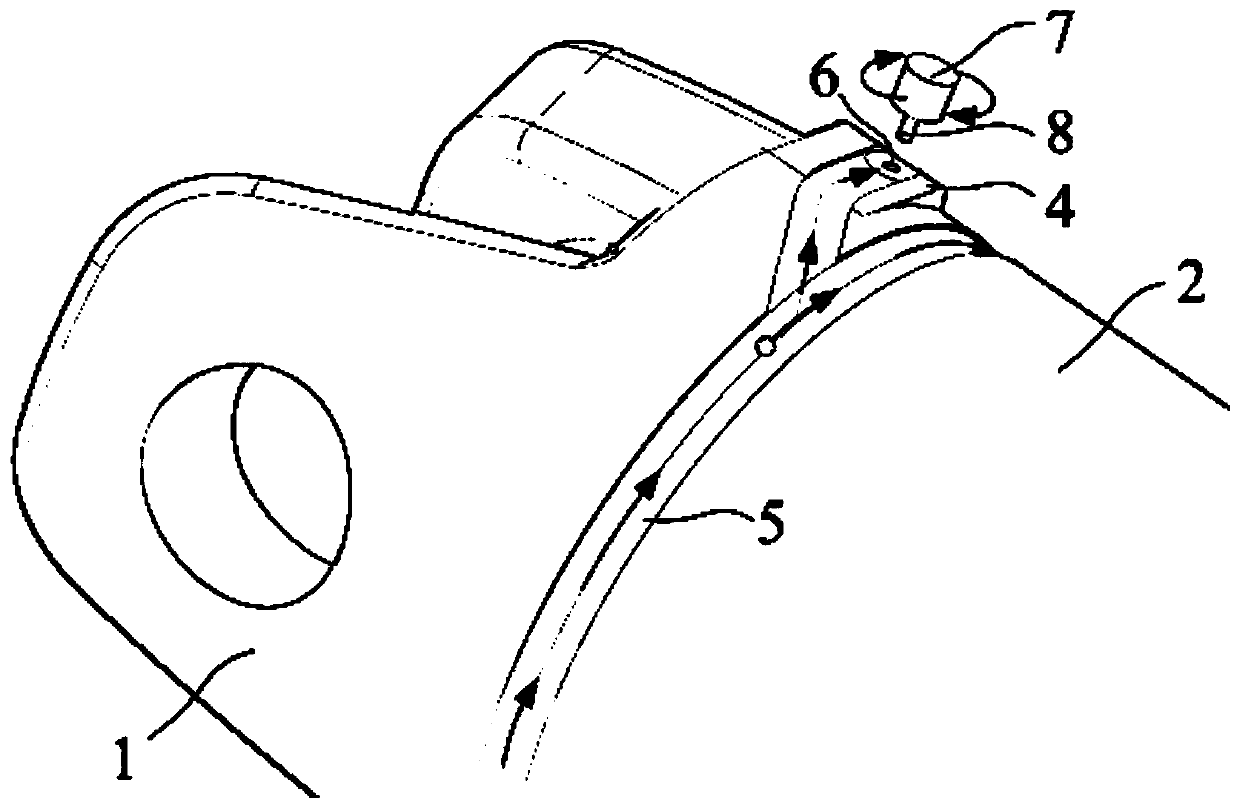

[0034] Such as figure 2 As shown, the shaft fork 1 and the shaft tube 2 are welded by an automatic friction stir welding machine, and the stirring needle 8 on the high-speed rotating stirring head 7 presses down t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com