Processing center spindle inner bore checking fixture

A machining center and spindle technology, applied in measuring devices, instruments, and mechanical devices, etc., can solve problems such as inability to measure, achieve the effect of reliable broach, solve the problems of broach stroke and reliability, and improve processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

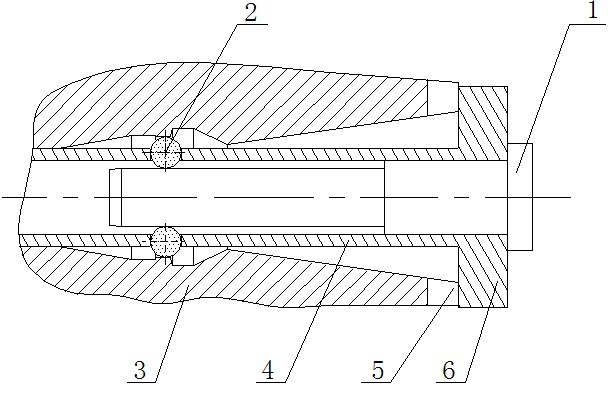

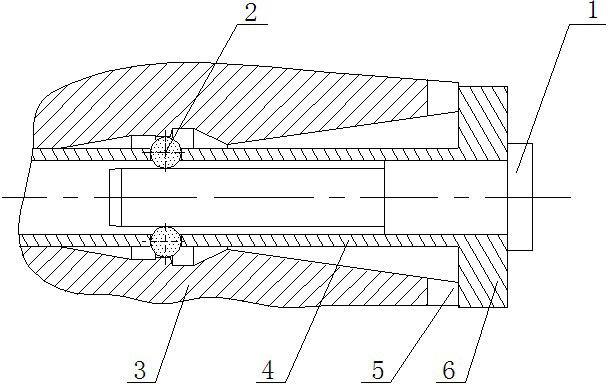

[0014] see figure 1 , the present invention is a tool for checking the inner hole of the main shaft of a machining center, which includes an inspection sleeve 4 and a go-no-go gauge 1 used in conjunction with the inspection sleeve 4. The front end of the inspection sleeve 4 extends into the inner hole of the main shaft 3, and the inspection sleeve The rear end of 4 is provided with outer edge 6, and the side wall of inspection sleeve 4 is provided with through hole, and ball 2 is installed in the through hole; , The go-no-go gauge 1 extends into the test sleeve 4.

[0015] When measuring, extend the inspection sleeve 4 loaded with balls 2 into the inner hole of the main shaft 3, then extend the through end of the go-no-go gauge 1 into the inspection sleeve 4, and the through end can pass through; then insert the stop end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com