Thermal deformation error compensation method for dry-cutting numerically-controlled gear hobbing machine tool and workpieces

A compensation method and gear hobbing technology, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve problems such as failure to meet dimensional requirements and poor dimensional consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

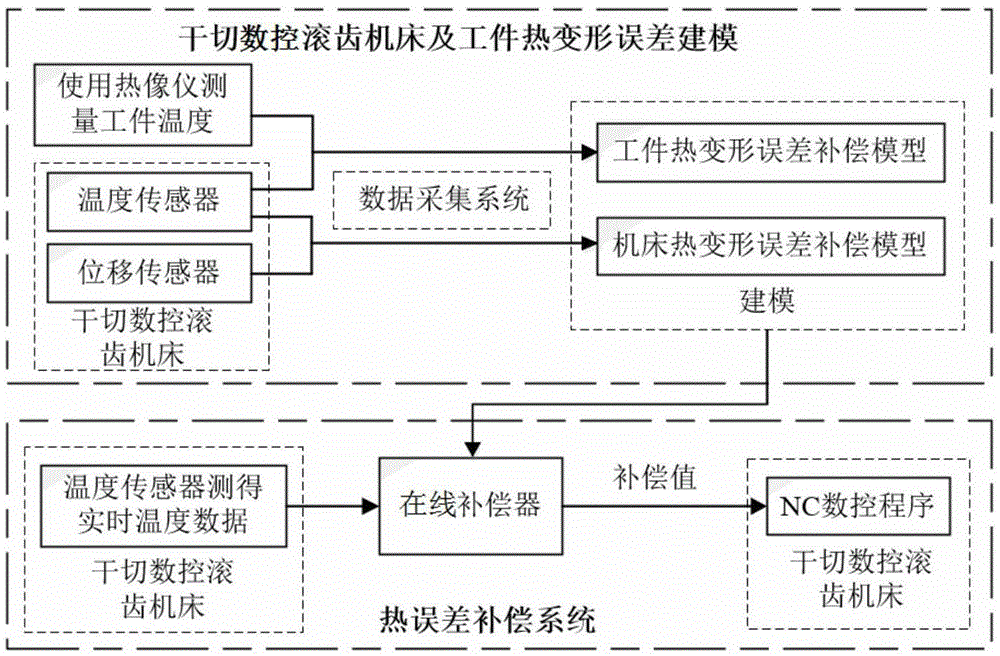

[0065] see figure 1 , a dry cutting CNC gear hobbing machine tool and a thermal deformation error compensation method of the workpiece. While using the thermal deformation error compensation system of the CNC machine tool to compensate the thermal deformation error of the dry cutting CNC gear hobbing machine tool, the same compensation system is used to compensate the thermal deformation error of the dry cutting CNC gear hobbing machine tool. The thermal deformation error of the processed workpiece is compensated. In this embodiment, the straight tooth workpiece is taken as an example, and the analysis principle of the helical tooth workpiece is the same, and this embodiment only introduces the modeling and compensation of the thermal deformation error of the machine tool in the X direction (the radial direction of the workpiece), and the thermal deformation error modeling and compensation of the machine tool in the Y direction and Z direction. The deformation error modeling a...

Embodiment 2

[0173] The main part of this embodiment is the same as that of Embodiment 1. Specifically, an example of compensation is performed when using the YE3120CNC7 dry-cut CNC gear hobbing machine tool produced by Chongqing Machine Tool Group Co., Ltd. to process an automobile transmission gear with a modulus of 2.5mm and a number of teeth of 36. The steps are as follows :

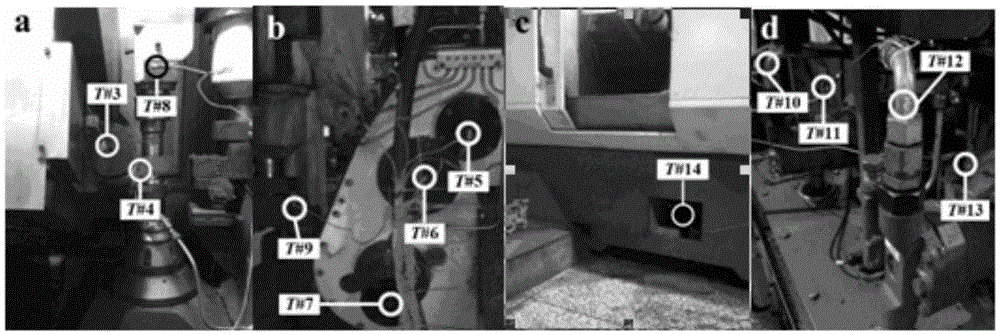

[0174] 1) Combining the structural features of YE3120CNC7 dry cutting CNC gear hobbing machine tool and the thermal image of the machine tool during processing, determine the thermal sensitive points of the dry cutting CNC gear hobbing machine tool, and arrange 13 temperature sensors "T#2"-"T# at the thermal sensitive points 14", "T#1" temperature sensor is suspended outside the machine tool to measure the ambient temperature, specifically as figure 2 shown.

[0175] According to the temperature data collected by the temperature sensor in the actual processing, the temperature variables are fuzzy clustered, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com