Magnetoelastic grinding burn detection method for acid-corrosion-resistant steel gear

A technology of grinding burn and detection method, applied in the field of grinding burn detection, can solve problems such as the influence of gear roughness and dimensional accuracy, the inapplicability and improvement of acid corrosion detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

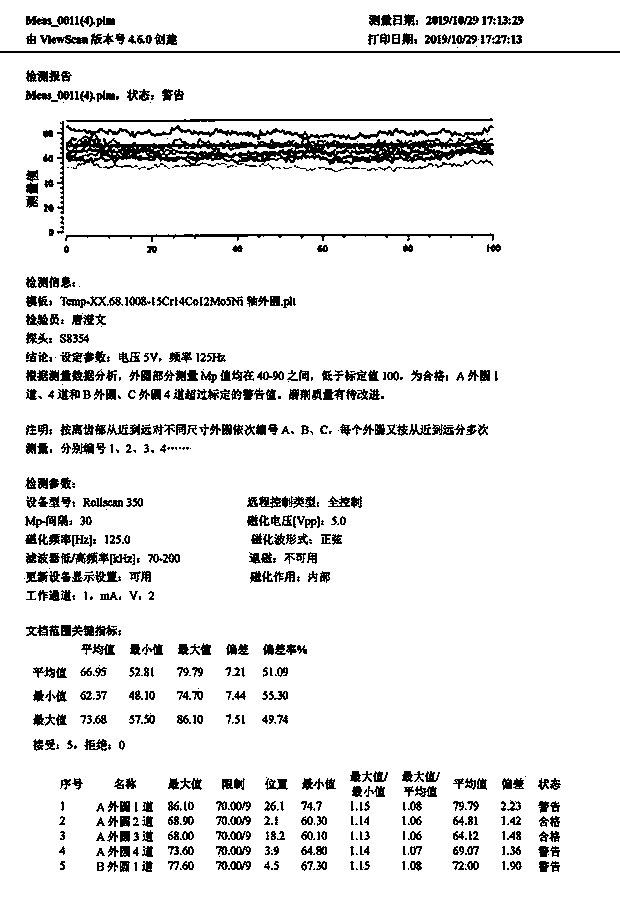

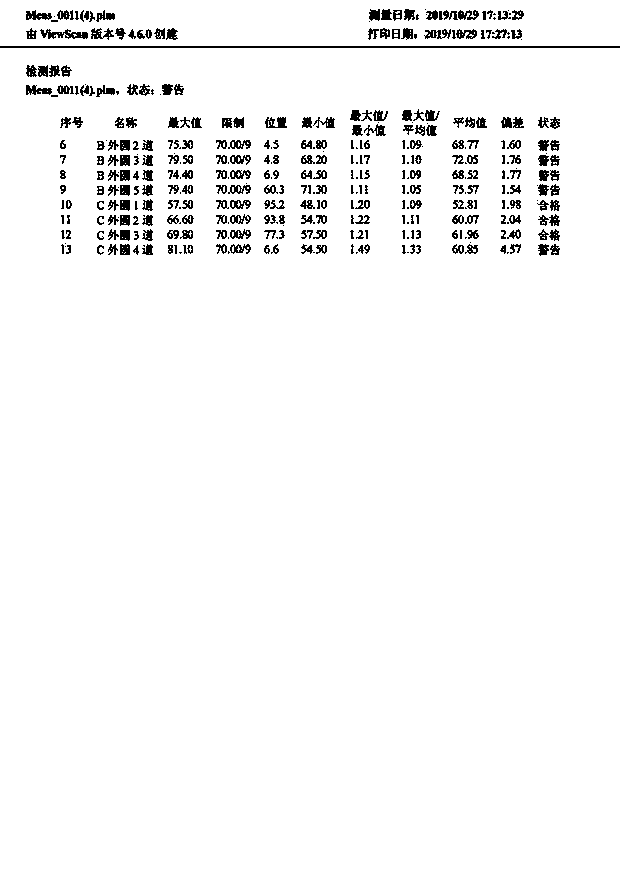

[0031] There is a gear part to be tested. This part is processed by 15Cr14Co12Mo5Ni steel forging billet. The outer circle of the shaft is a non-carburized quenching surface with a hardness value of 48-52HRC. Chip burn detection.

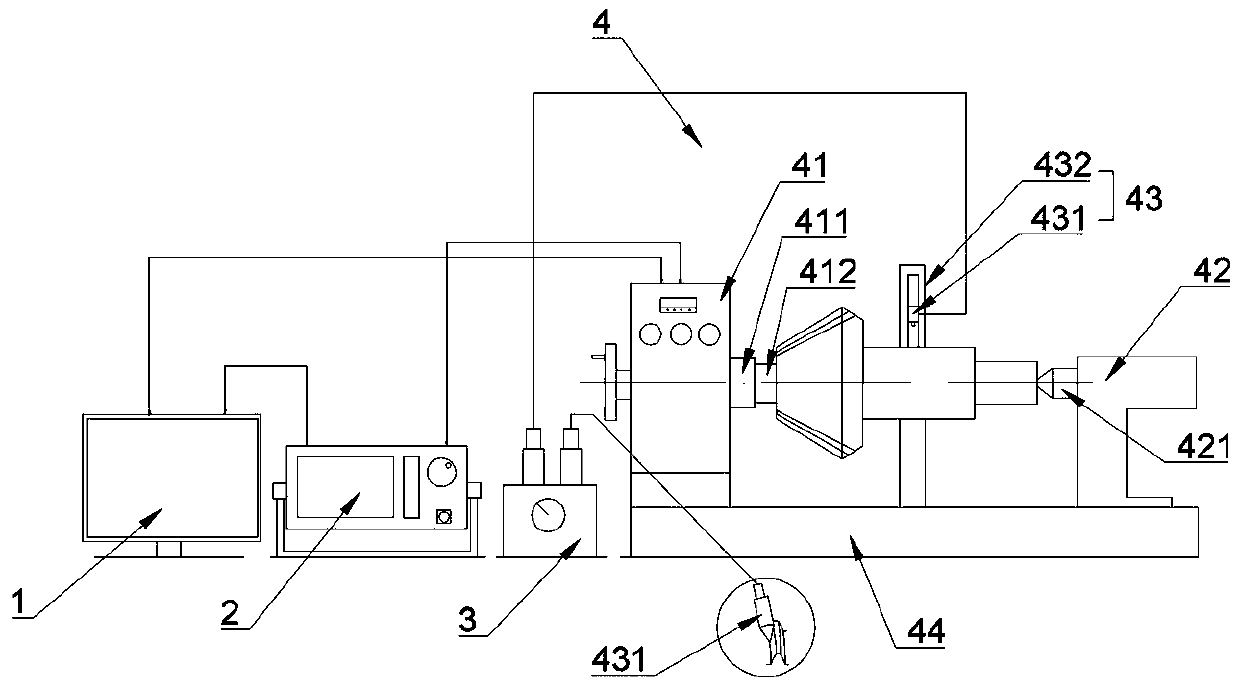

[0032] The magnetoelastic grinding burn detection method for acid-resistant steel gears of the present invention specifically comprises the following steps:

[0033] 1. Preparations before formal testing:

[0034] (1) The main unit 2, detection probe 431 and other parts have been installed. In this embodiment, the main engine 2 adopts a Rollscan350 type grinding burn detector.

[0035] (2) A number of control gear parts were made using conventional gear steel, and the acid etching test and the magnetic elastic grinding burn test were carried out respectively, and the correlation between the acid etching test results and the magnetic elastic grinding burn test results was obtained.

[0036] The gear parts after the acid corrosion test are classifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com