Nickel-based welding wire for main equipment of nuclear island of nuclear power station

A technology for main equipment and nuclear power plants, applied in the field of welding wire and nickel-based welding wire, which can solve the problems of high cost and dependence on imports, and achieve the effect of less defects, stable process and good process performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

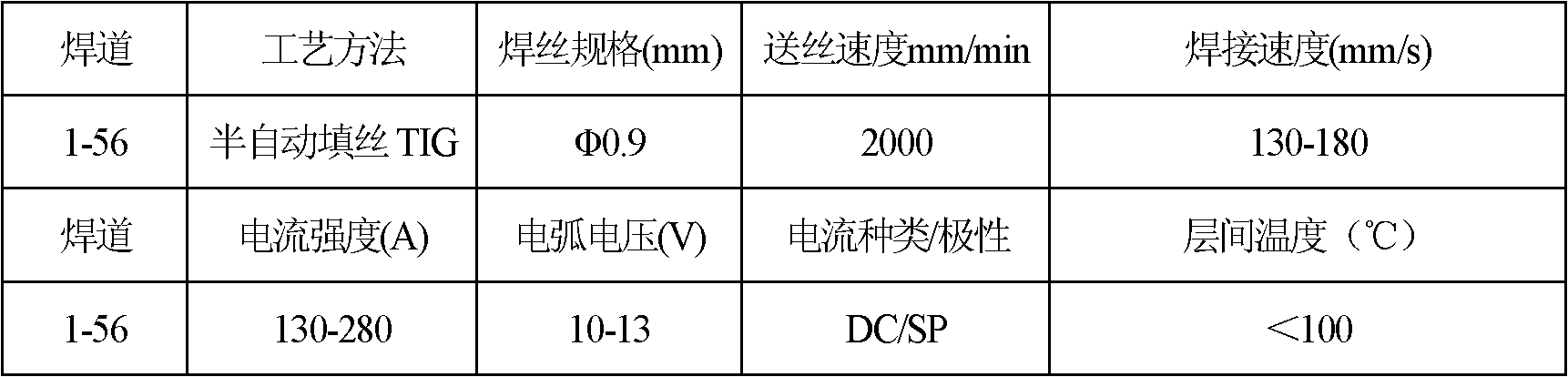

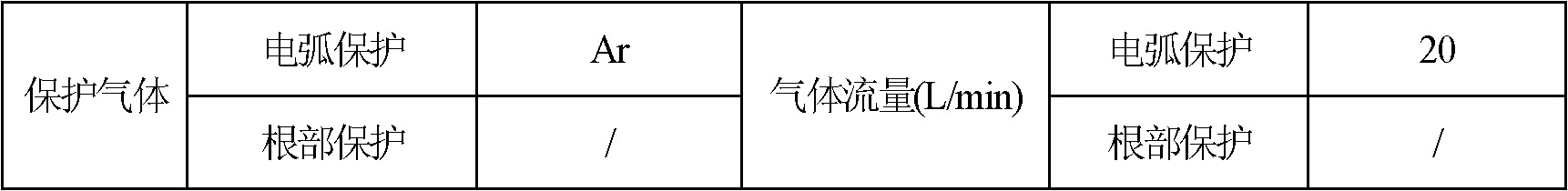

Examples

Embodiment Construction

[0019] In the present invention, the welding wire can be smelted in a vacuum induction furnace, or can be smelted in an electric furnace plus refining outside the furnace, as long as the final chemical composition of the welding wire can meet the requirements of the above content of the invention.

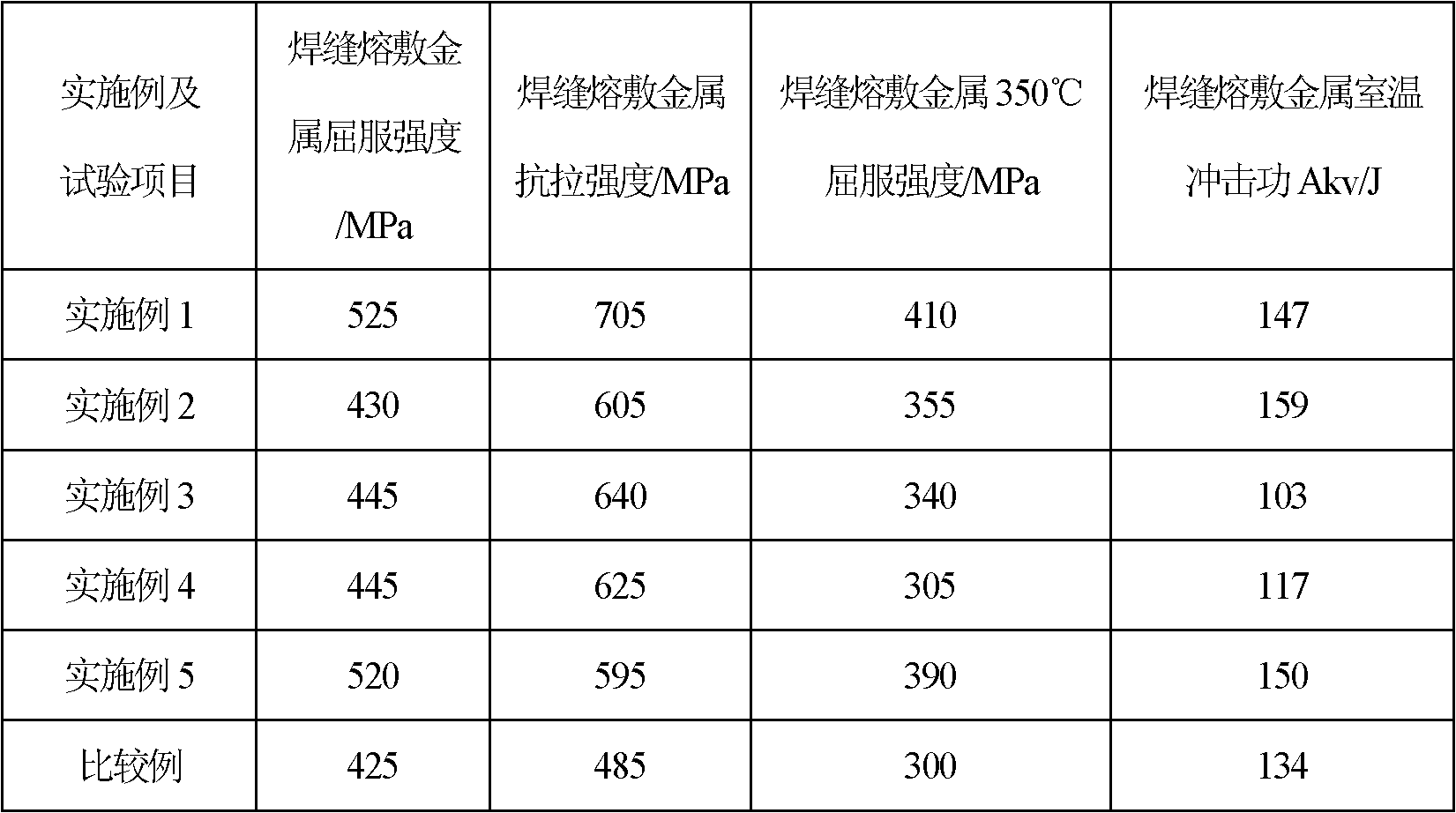

[0020] Table 1 is that the basic chemical composition of embodiment nickel base welding wire is (weight ratio %):

[0021] alloy element

Example 1

Example 2

Example 3

Example 4

Example 5

comparative example

Cr

29.49

29.98

29.96

29.91

29.51

29.91

Fe

8.83

8.82

8.81

8.84

8.80

8.88

Al

0.42

0.32

0.34

0.29

0.64

0.14

Ti

0.92

0.61

0.62

0.62

0.67

0.30

Al+Ti

1.34

0.93

0.96

0.91

1.31

0.44

mn

0.70

0.30

0.93

0.72

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com