Preparation method of antimicrobial coating for metal of medical equipment

A medical device and antibacterial coating technology, applied in the field of plating metal materials, can solve the problem of high cost, and achieve the effects of low cost, good antibacterial effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of titanium oxide paint: under stirring, add ethanol, butanol, butyl titanate, nitric acid, ethyl silicate, triazole, silver nitrate and zinc nitrate in sequence, the addition amounts are 70%, 21.435%, 5%, 1.5%, 2%, 0.01%, 0.05%, 0.005%, stirring for 5 hours to prepare titanium oxide coating.

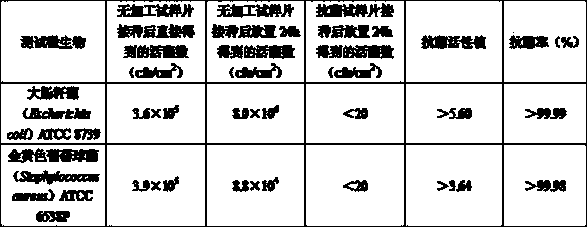

[0025] After immersing the metal of the medical device in the titanium oxide coating for 5 minutes, the metal is evenly lifted upward at a speed of 1-5cm / min, and baked at 80°C for 1 hour. Then, the metal was placed in a muffle furnace and calcined at 150° C. for 4 hours. After being taken out, it is naturally cooled to room temperature to obtain a metal antibacterial coating for medical devices. The surface of the coating is smooth, still has the color of the underlying metal material, does not turn black, and has a good antibacterial effect, and the antibacterial rate against Staphylococcus aureus and Escherichia coli is above 99.98%.

[0026] Test report of titan...

Embodiment 2

[0058] Preparation of titanium oxide paint: under stirring, add ethanol, isopropanol, butanol, isopropanol titanate, hydrochloric acid, methyltrichlorosilane, benzotriazole, silver nitrate and zirconium nitrate in sequence, and the addition amounts are 60%, 21%, 12.96%, 4%, 0.5%, 1.5%, 0.005%, 0.005%, 0.03%, stirring for 7 hours to prepare titanium oxide coating.

[0059] After immersing the metal of the medical device in the titanium oxide coating for 10 minutes, the metal is evenly lifted upward at a speed of 1-5cm / min, and blown by a fan for 1.5 hours. After drying, the metal was placed in a muffle furnace and calcined at 120°C for 8 hours. After being taken out, it is naturally cooled to room temperature to obtain a metal antibacterial coating for medical devices. The surface of the coating is smooth, still has the color of the underlying metal material, does not turn black, and has a good antibacterial effect.

Embodiment 3

[0061] Preparation of titanium oxide paint: under stirring, add methanol, butanol, butyl titanate, hydrochloric acid, ethyl silicate, methyl benzotriazole, silver nitrate and zirconium oxychloride in sequence, the addition amount is 80%, 13.454%, 3%, 1.5%, 2%, 0.003%, 0.003%, 0.04%, stirring for 5 hours to prepare titanium oxide coatings.

[0062] After immersing the metal of the medical device in the titanium oxide coating for 10 minutes, the metal is evenly lifted upward at a speed of 1-5 cm / min, and baked at 50°C for 3 hours. After drying, the metal was placed in a muffle furnace and calcined at 230° C. for 1 hour. After being taken out, it is naturally cooled to room temperature to obtain a metal antibacterial coating for medical devices. The surface of the coating is smooth, still has the color of the underlying metal material, does not turn black, and has a good antibacterial effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com