Process for preparing nano structured titanium dioxide photocatalyst coating

A titanium dioxide and nanostructure technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of harsh process conditions, complex equipment, high cost, simplify the preparation process, promote application and reduce manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

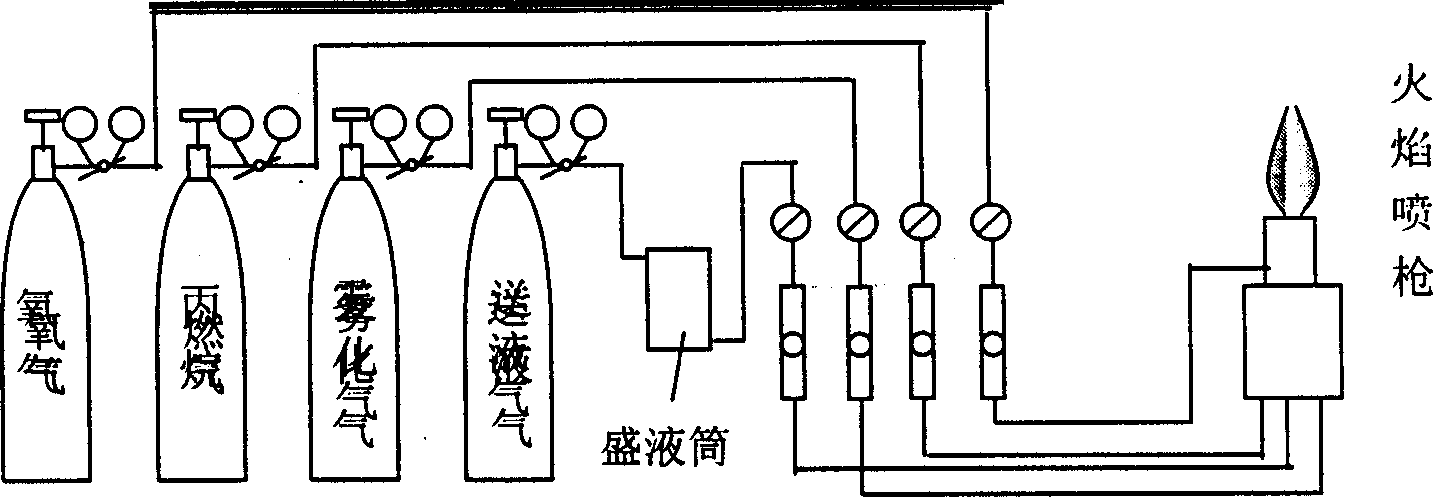

[0029] Embodiment 1: see figure 1 . figure 1 It is a schematic diagram of a liquid flame spraying system for implementing the present invention. The spray gun is an axial liquid-feeding flame spray gun. Propane is used as the gas, the pressure is 0.1MPa, and the flow rate is 7.34L / min; oxygen is used as the atomizing gas and supporting gas, the pressure is 0.5, 0.3MPa, and the flow rate is 42.9, 42.0L / min; the liquid uses butyl titanate Anhydrous ethanol solution with a concentration of 20%. When spraying the coating, the spraying distance is 150mm.

Embodiment 2

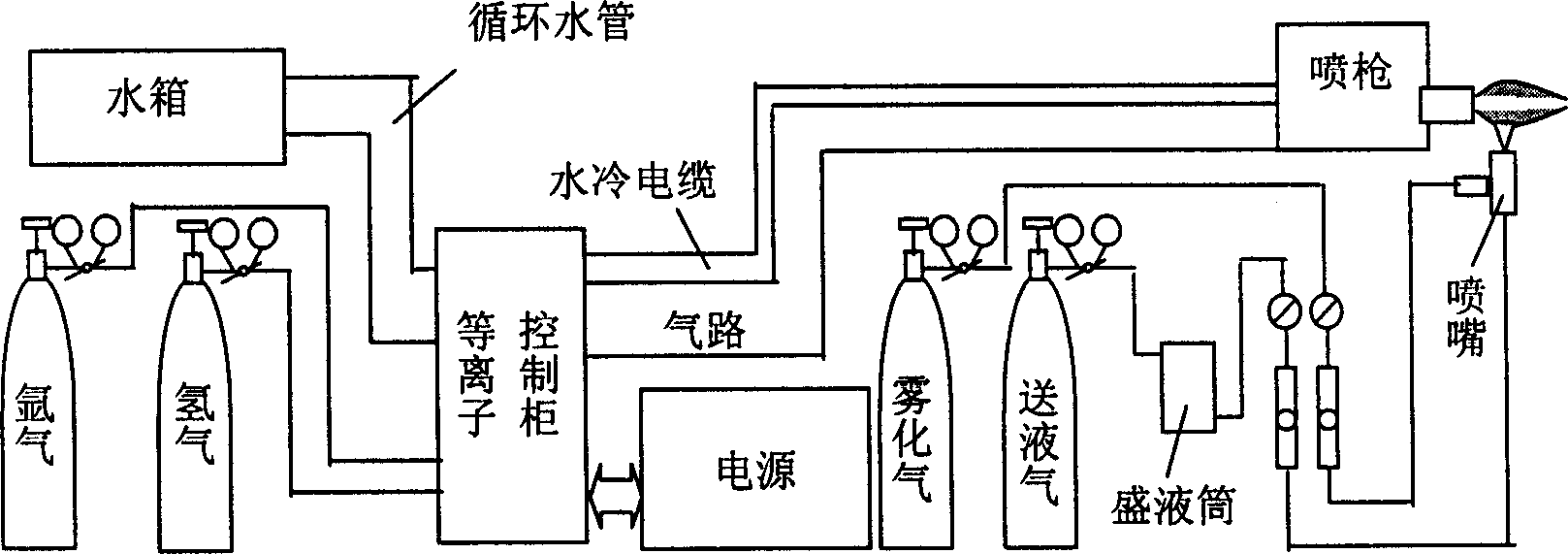

[0030] Example 2: see figure 2 . figure 2 It is a schematic diagram of a liquid plasma spraying system for implementing the present invention. The spray gun is a plasma spray gun, and the liquid atomizing nozzle atomizes the liquid into fine droplets. Argon pressure is 0.8MPa, flow rate is 77.5L / min; hydrogen pressure is 0.5MPa, flow rate is 4.23L / min; current is 400A, voltage is 50V. When spraying the coating, the spraying distance is 80mm. The liquid is an ethanol solution of butyl titanate with a concentration of 10%.

Embodiment 3

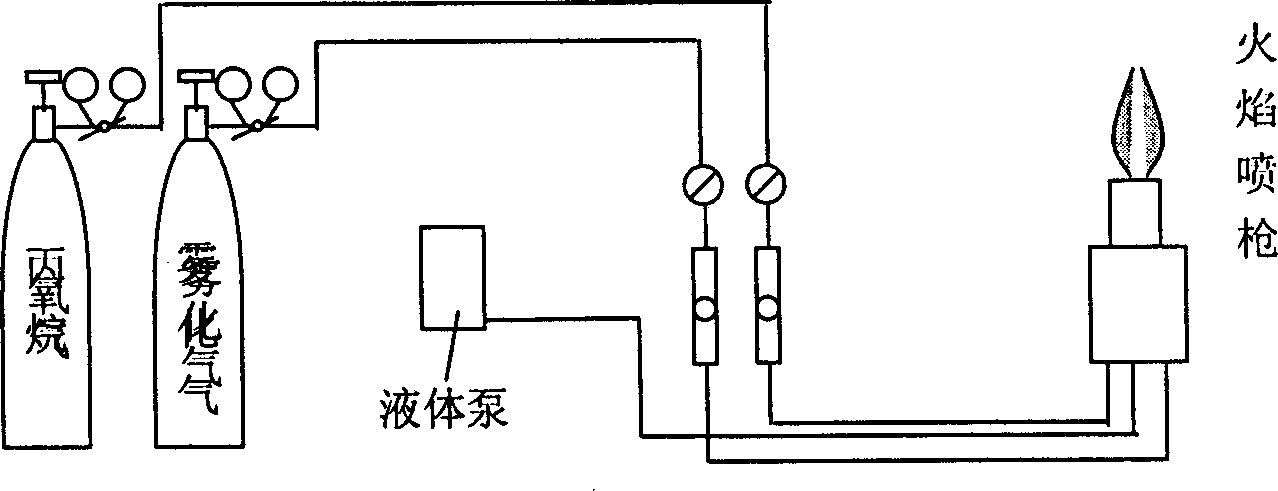

[0031] Embodiment 3: see image 3 . According to the traditional thinking, the heat source of the spraying system is a heat source in the form of flame, electric arc, plasma, etc., which is a specially applied heat source. Although the combustible components in the liquid raw material burn in the flame flow, they are not used as a heat source, but a an incidental phenomenon. image 3 In the liquid thermal spraying system shown, the raw material liquid is directly used as both the fuel and the spraying raw material, and this embodiment is simpler. The liquid is atomized into fine droplets through the atomizing nozzle, and the flammable components in the liquid are burned under the action of the gas-supporting oxygen to provide the energy necessary for spraying, and the solute in the liquid is heated, and the solute in the liquid is heated under the action of heat change, become titanium dioxide, and deposit on the substrate to form the nanostructure titanium dioxide photocata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com