Liquid-phase deposition-impregnation preparation method of micro/nano low-surface hydrophobic composite anti-scaling coating

An anti-fouling coating and liquid deposition technology, which is applied to the device, coating, special surface and other directions of coating liquid on the surface, which can solve the complex preparation method of the coating, the difficulty of coating with glass, and the high temperature sintering resistance of red copper. and other problems, to achieve the effect of improving heat transfer and anti-fouling performance, dense and uniform coating without cracking, and dense and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

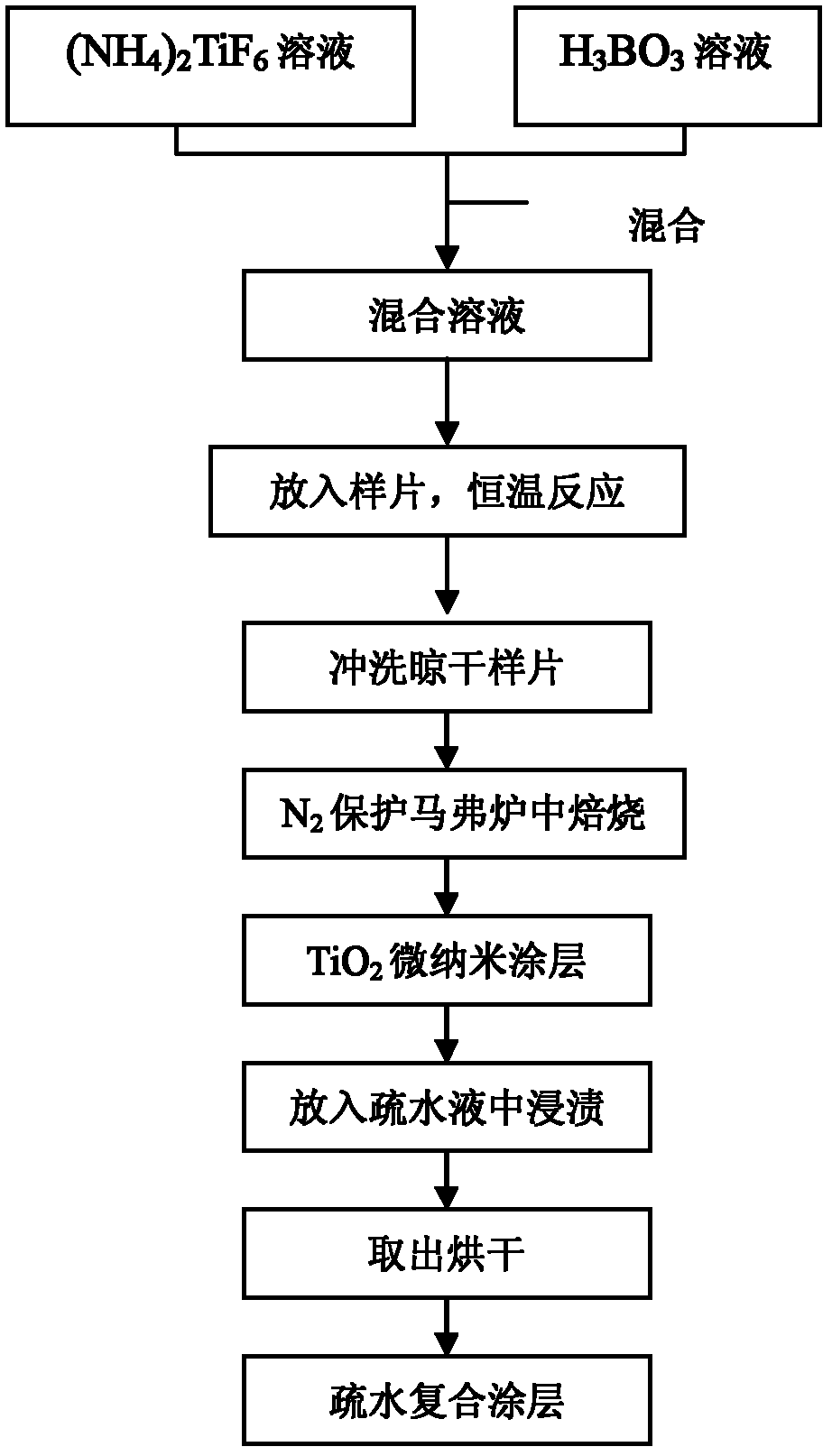

[0023] see figure 1A method for preparing a micro-nano hydrophobic liquid phase deposition-dipping composite antifouling coating of the present invention comprises the following steps: (a) grinding, polishing and cleaning the stainless steel substrate to be deposited to obtain a clean and bright surface; ( b) Ultrasonic treatment of the stainless steel substrate with a mass percentage of 1%-3% dilute acid to form a rough structure layer on the surface of the stainless steel substrate, rinsed with distilled water, and dried at room temperature. The preferred dilute acid is hydrochloric acid or nitric acid; (c) The stainless steel substrate with a rough structure layer on the surface is placed in a mixed solution in a constant temperature water bath at 20-80°C to deposit and prepare a substrate (lower than the temperature range of this constant temperature water bath, the deposition time required to prepare a coating with a required thickness is longer; Higher than this temperat...

Embodiment 1

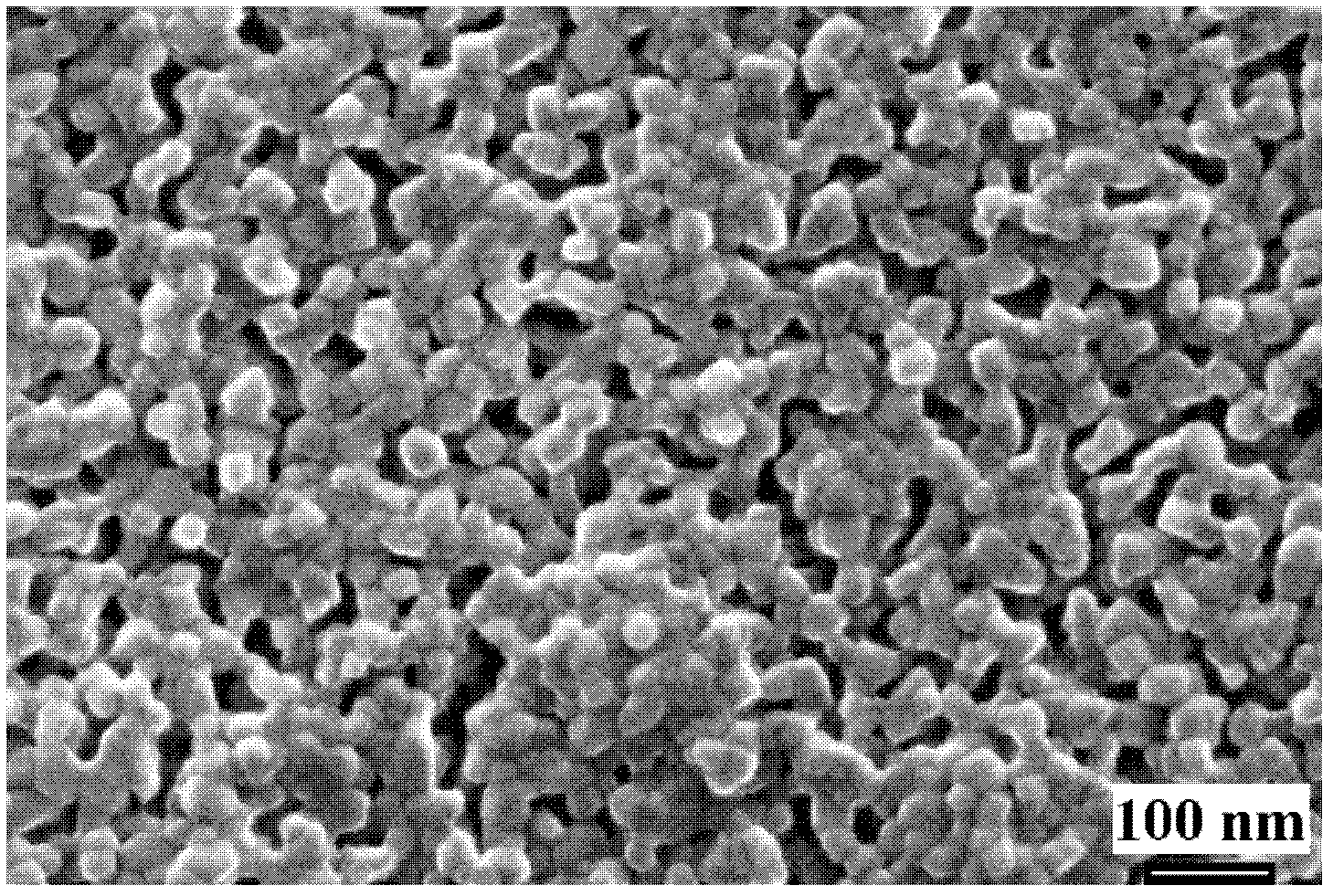

[0031] (a)) Roughly grind the outer surface of the stainless steel substrate until the stainless steel metal surface is exposed; carry out medium grinding to remove the deep and large texture wear marks left by the coarse grinding process; use a 600-mesh cylindrical louver emery cloth wheel to polish the stainless steel substrate until Sand away all coarser grain; finish grind the stainless steel substrate with a 1000 grit sandpaper sheet to remove fine streaks on the surface to be polished; polish the stainless steel substrate surface with a metal polisher coated with polishing soap on a wool buffing wheel , until the polished texture is no longer visible to the naked eye; then use 10% NaOH by mass percentage to ultrasonically soak and clean for 5 minutes to remove stubborn grease, and then rinse it with tap water; then put the stainless steel substrate in turn in acetone Ultrasonic cleaning with absolute ethanol with a mass ratio greater than 99.7% was performed for 8 minutes...

Embodiment 2

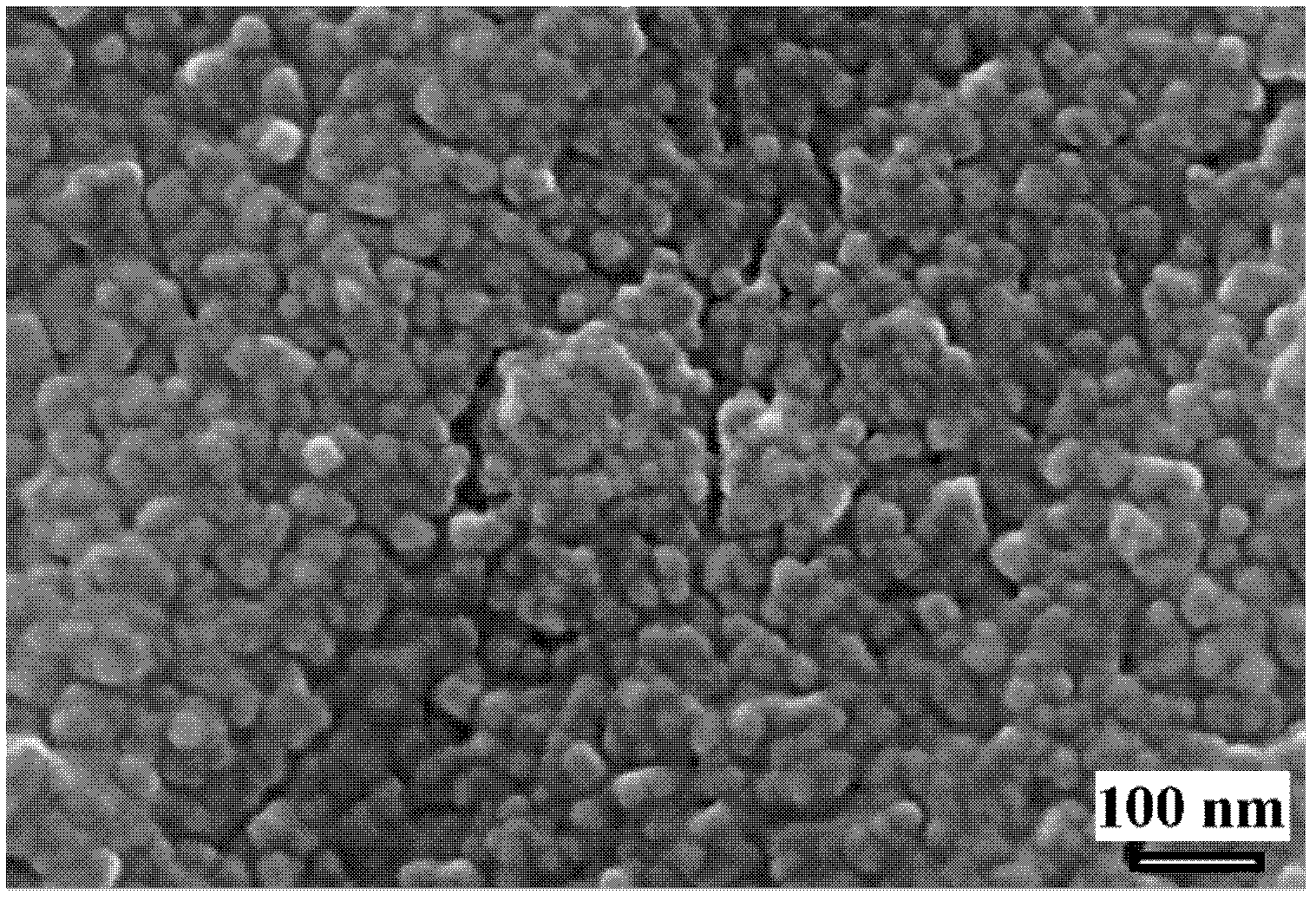

[0039] (a) Pre-treat the stainless steel substrate, use an angle grinder equipped with louver blades to roughly grind the outer surface of the cut stainless steel sample, remove surface dirt, scale and large-pore defects, and expose the stainless steel metal surface; then replace Use a nylon grinding disc for medium grinding to remove the deep and large textured grinding marks left by the rough grinding process, and select the substrate surface to be deposited on the coating; use the engraving handle of the metal polishing machine, and use a 600-mesh cylindrical louver abrasive cloth wheel Sand the base, making sure the surface is completely sanded to remove the coarser texture from the previous step. Then install a 90° angle machine or a gun-type reciprocating machine, and use 800-mesh sandpaper to finely grind the substrate to remove fine stripes on the surface to be polished; then use the die-cutting handle of the metal polishing machine combined with wool The polishing whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com