Nanometer TiO2 coating structure, preparation method and uses thereof

A nano-coating technology, applied in the direction of catalyst activation/preparation, coating, chemical instruments and methods, etc., can solve the problems of easy dry cracking, low quantum efficiency, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In the preparation of nanometer TiO of the present invention 2 In the coating structure method, the linear titanyl polymer described in step 1) is a linear titanyl polymer with repeated Ti-O bonds as the main chain and organic groups connected to the side groups, which includes the following Structural units:

[0050]

[0051] where R 1 are independently selected from -C 2 h 5 ,-C 3 h 7 ,-C 4 h 9 ,-C 5 h 11 ; 2 stands for OR 1 Or represent selected from CH 3 COCHCOCH 3 and CH 3 COCHCOOC 2 h 5 The complexing group; the condition is based on R 2 total amount of groups, at least 50% of R 2 The group represents the complexing group; the number-average molecular weight Mn of the titanium oxide polymer measured by the vapor pressure osmosis method is 2000 to 3000; the pure titanium oxide polymer without solvent has a softening point, and the softening point measured by the ring and ball method is The point range is 90-127°C.

[0052] Preferably, the line...

Embodiment 1

[0085] Embodiment 1: the preparation of linear titanium oxide polymer

[0086]1) Add 1 mol of tetraisobutyl titanate into the reaction vessel, adjust the temperature to 50°C, add 0.8mol of acetylacetone, heat and stir at 50°C for 1 hour;

[0087] 2) Adjust the temperature to 80°C, add dropwise a mixed solution of 0.8mol water and 2.5mol isobutanol, continue heating and stirring at 80°C for 2 hours after dropping, and remove the solvent under reduced pressure after dropping the temperature to obtain a yellow titanyl polymer.

[0088] The softening point measured by the ring and ball method was 92° C., and the number average molecular weight Mn=2750 was measured by the vapor pressure osmosis method.

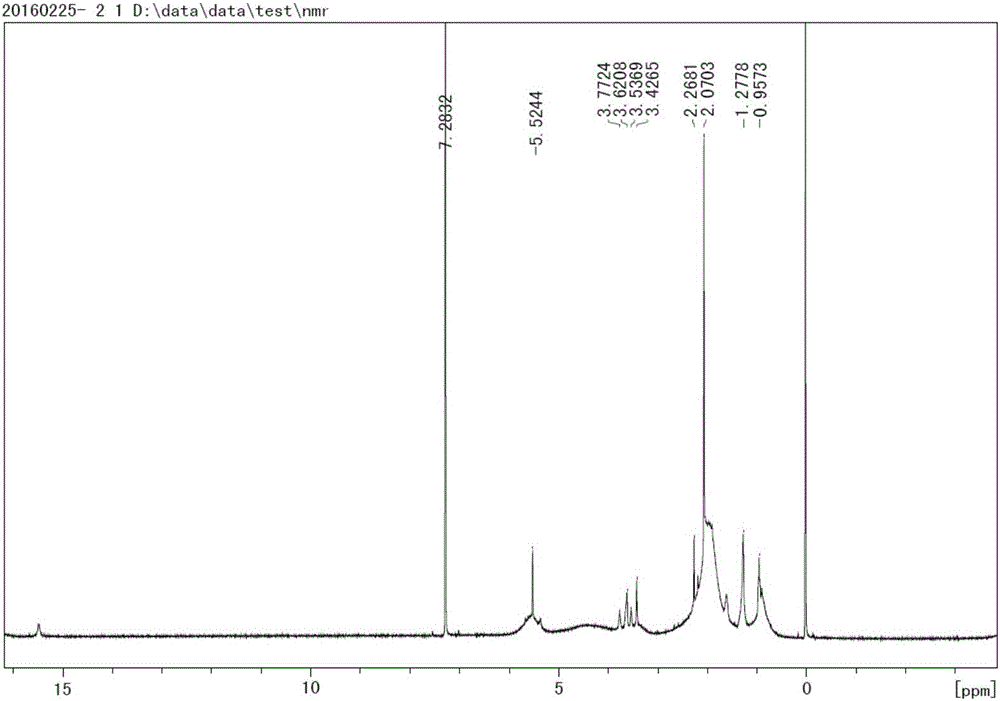

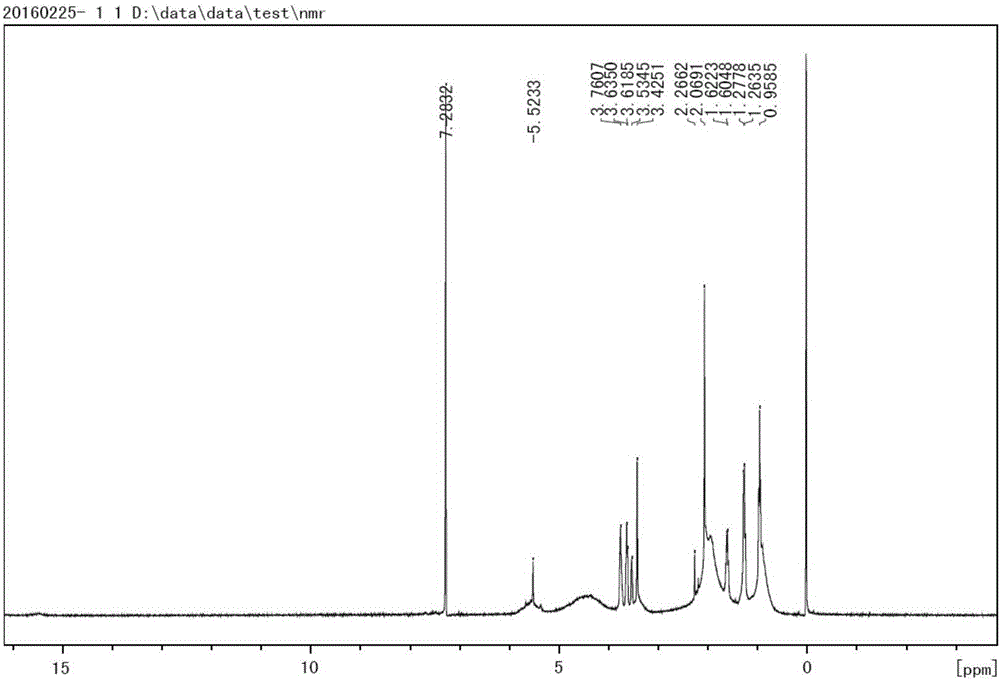

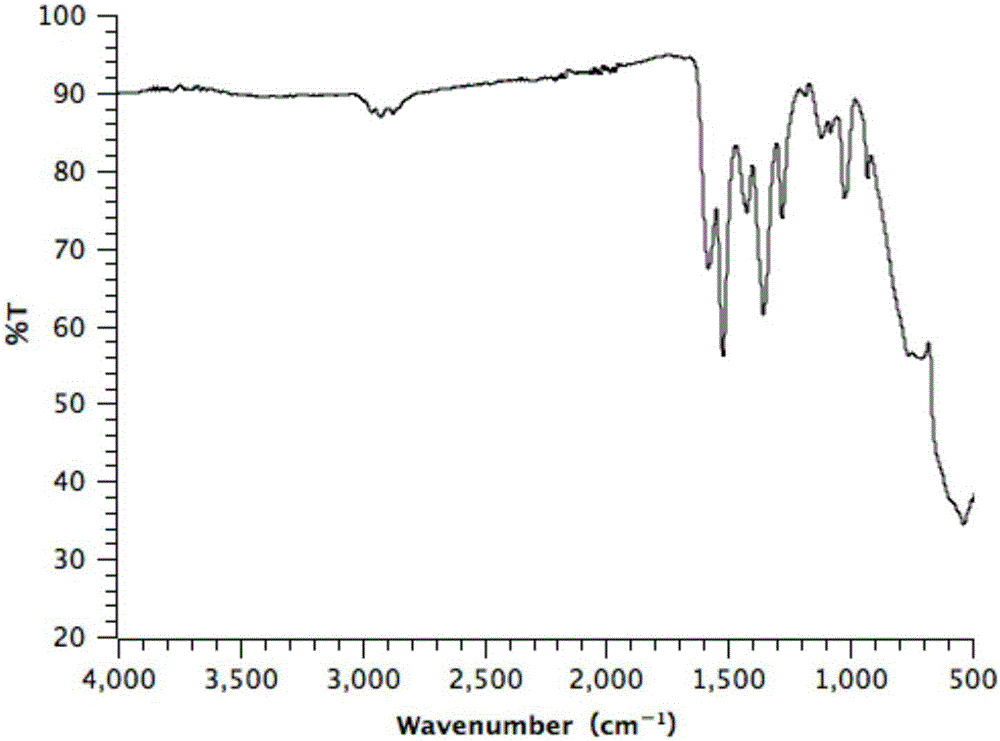

[0089] Grind 1-2 mg of the obtained yellow titanyl oxide polymer and 200 mg of pure KBr evenly, place it in a mold, and press it into a transparent sheet on a tablet machine for IR spectrum characterization, see Picture 1-1 ;exist Picture 1-1 Medium, 2959cm -1 、2922cm -1 、2872c...

Embodiment 2

[0091] Embodiment 2: the preparation of linear titanium oxide polymer

[0092] 1) Add 1 mol of tetrabutyl titanate into the reaction vessel, add 0.5 mol of acetylacetone, and heat and stir at 90° C. for 1.5 h;

[0093] 2) Adjust the temperature to 70° C., drop in a mixture of 1.2 mol of water and 6 mol of n-butanol, stir at 100° C. for 2.5 hours after dropping, and remove the solvent under reduced pressure after cooling down to obtain the titanium oxide polymer.

[0094] The softening point measured by the ring and ball method is 98° C., and the number average molecular weight Mn=2930 is measured by the vapor pressure osmosis method.

[0095] Grind 1-2 mg of the obtained titanyl polymer and 200 mg of pure KBr evenly, place it in a mold, and press it into a transparent sheet on a tablet machine for IR spectrum characterization, see diagram 2-1 ;

[0096] The resulting titanyl polymer was dissolved in deuterated chloroform for NMR characterization, the results are shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com