Micro-nanostructure composite coating and preparation method thereof

A technology of micro-nano structure and composite coating, which is applied in the direction of coating, metal material coating process, superimposed layer plating, etc. Functional limitations and other issues, to achieve the effect of high specific surface area, important application value, and good roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

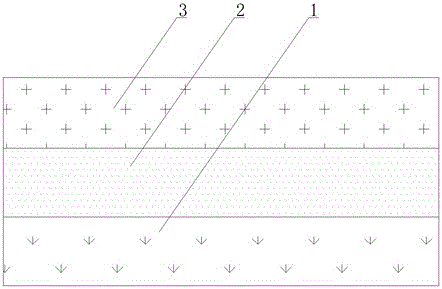

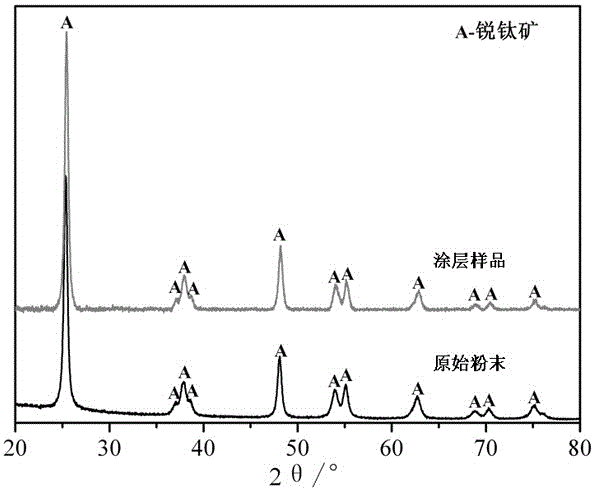

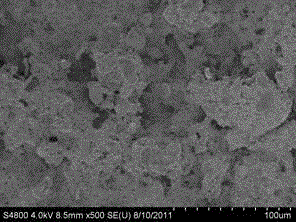

[0030] In this embodiment, the selected substrate is a 316L stainless steel sheet with a thickness of about 2 mm, and the TiO 2 The thickness of the composite coating is about 250 μm, of which the metal Al coating is 200 μm, and the micronano TiO 2 The coating is 50 microns, and the coating is a porous micro-nano structure, mainly nano-TiO 2 Particles are accumulated on the surface of the rough sprayed Al coating, and the TiO in the coating 2 The crystal forms are anatase phase and rutile phase, and the anatase phase has no obvious transformation, and the coating is well combined with the substrate. The concrete preparation method of this coating is as follows:

[0031](1) Mix deionized water and absolute ethanol at a volume ratio of 1:1 to make a solution, add commercially available P25 nano-powder with an average particle size of 25nm at 4.5 wt% to the above prepared solution, and magnetically stir to mix evenly. Add polyurethane (PU) and polyvinylpyrrolidone (PVP K30) at...

Embodiment 2

[0040] In this embodiment, the selected substrate is a 316L stainless steel sheet with a thickness of about 2 mm, and the TiO 2 The thickness of the composite coating is about 150 μm, of which the metal Al coating is 100 μm, and the micronano TiO 2 The coating is 50 microns, and the coating is a porous micro-nano structure, mainly nano-TiO 2 Particles are accumulated on the surface of the rough sprayed Al coating, and the TiO in the coating 2 The crystal forms are anatase phase and rutile phase, and the anatase phase has no obvious transformation, and the coating is well combined with the substrate. The concrete preparation method of this coating is as follows:

[0041] (1) Mix deionized water and absolute ethanol at a volume ratio of 3:1 to make a solution, add commercially available P25 nano-powder with an average particle size of 25nm at 5 wt% to the above prepared solution, and magnetically stir to mix evenly. Add polyurethane (PU) at 1.5 wt% to the above-mentioned mixe...

Embodiment 3

[0050] In this embodiment, the base material is selected as a low-carbon steel sheet with a thickness of about 2 mm, and the TiO 2 The thickness of the composite coating is about 150 μm, of which the metal nickel-chromium-titanium coating is 100 μm, and the micronano TiO 2 The coating is 50 microns, and the coating is a porous micro-nano structure, mainly nano-TiO 2 The particles are accumulated on the surface of the rough sprayed nickel-chromium-titanium coating, and the TiO in the coating 2 The crystal forms are anatase phase and rutile phase, and the anatase phase has no obvious transformation, and the coating is well combined with the substrate. The concrete preparation method of this coating is as follows:

[0051] (1) Mix deionized water and absolute ethanol at a volume ratio of 5:1 to make a solution, add commercially available P25 nano-powder with an average particle size of 25nm at 5wt% to the above prepared solution, and magnetically stir to mix evenly. Polyuretha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com