Preparation and application of novel wastewater treatment agent, ZnFe2O4/TiO2 compound

A wastewater treatment agent, znfe2o4 technology, applied in textile industry wastewater treatment, light water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve the problems of small adsorption capacity, high density, limitations, etc., and achieve simple process, The effect of continuous separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

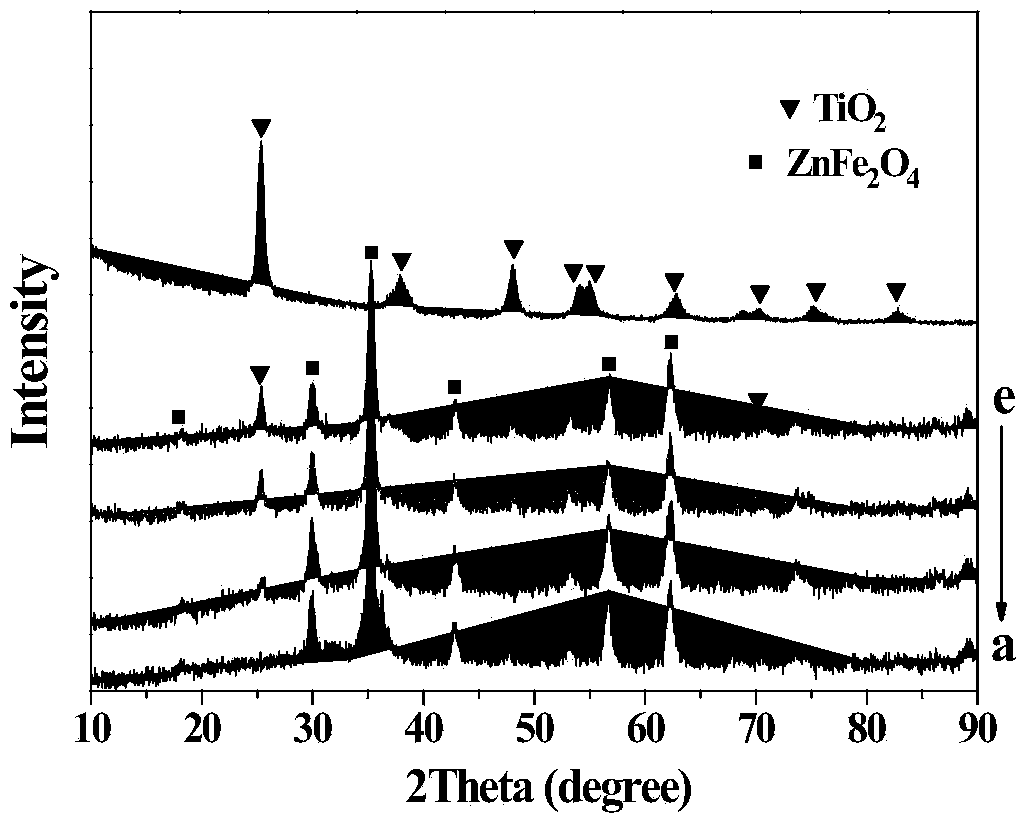

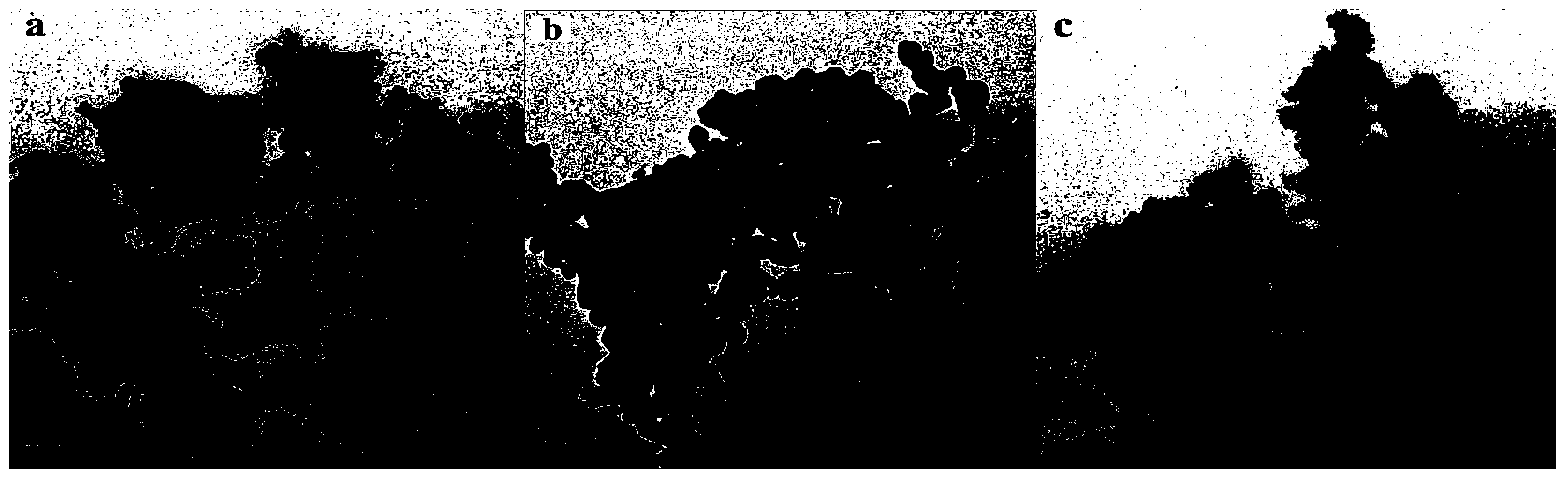

[0028] Example 1: omega TiO2 9.09% ZnFe 2 o 4 / TiO 2 Compound (treatment agent)

[0029] A. Preparation of treatment agent

[0030] (1) Weigh a certain amount of glucose and dissolve it in an appropriate amount of distilled water to obtain carbon microspheres according to step (1).

[0031] (2) Accurately weigh 0.8077~2.4231gFe(NO 3 ) 3 9H 2 O and 0.2974~0.8922gZn(NO 3 ) 2 ·6H 2 O, dissolve with 25-75mL ethanol-water solution (volume ratio of ethanol and water is 2:1), add 0.3-1.0g urea and 0.1-0.4g carbon microspheres to it, and process according to step (2) to obtain hollow ZnFe 2 o 4 powder.

[0032] (3) Accurately weigh 1.4465g hollow ZnFe 2 o 4 Powder, join in the microemulsion system that is made up of 2.4gCTAB, 25mL cyclohexane, 3.0mL amyl alcohol, process by step (3) to obtain mixed solution A; Weigh and ω TiO2 =9.09% equivalent Ti(OBu) 4 Dissolve 0.6153g in 50mL alcohol aqueous solution (volume ratio of alcohol to water is 2:1) to obtain solution B; slow...

Embodiment 2

[0039] Example 2: ω TiO2 16.67% ZnFe 2 o 4 / TiO 2 Compound preparation (treatment agent)

[0040] A. Preparation of treatment agent

[0041] (1) Prepare carbon microspheres according to step (1).

[0042] (2) prepare hollow ZnFe according to step (2) 2 o 4 powder.

[0043] (3) Accurately weigh 1.4465g hollow ZnFe 2 o 4 Powder, join in the microemulsion system that is made up of 2.4gCTAB, 25mL cyclohexane, 3.0mL amyl alcohol, process by step (3) to obtain mixed solution A; Weigh and ω TiO2 =16.67% equivalent Ti(OBu) 4 1. Dissolve 1.0259g in 50mL alcohol aqueous solution (volume ratio of alcohol to water is 2:1) to obtain solution B; slowly add solution B to mixed solution A, and process according to step (3) to obtain ω TiO2 = 16.67% ZnFe 2 o 4 / TiO 2 Complex.

[0044] B. Application of treatment agent

[0045] (1) Add 50mgω TiO2 = 16.67% ZnFe 2 o 4 / TiO 2 Add the complex to 50mL methyl orange solution with a concentration of 50mg / L, control the pH to about ...

Embodiment 3

[0050] Example 3: ω TiO2 25% ZnFe 2 o 4 / TiO 2 Compound preparation (treatment agent)

[0051] A. Preparation of treatment agent

[0052] (1) Prepare carbon microspheres according to step (1).

[0053] (2) prepare hollow ZnFe according to step (2) 2 o 4 powder.

[0054] (3) Accurately weigh 1.4465g hollow ZnFe 2 o 4 Powder, join in the microemulsion system that is made up of 2.4gCTAB, 25mL cyclohexane, 3.0mL amyl alcohol, process by step (3) to obtain mixed solution A; Weigh and ω TiO2 = 25% equivalent Ti(OBu) 4 1.5387g was dissolved in 50mL alcohol aqueous solution (volume ratio of alcohol to water: 2:1) to obtain solution B; slowly add solution B to mixed solution A, and process according to step (3) to obtain ω TiO2 = 25% ZnFe 2 o 4 / TiO 2 Complex.

[0055] B. Application of treatment agent

[0056] (1) Add 50mgω TiO2 = 25% ZnFe 2 o 4 / TiO 2 Add the complex to 50mL methyl orange solution with a concentration of 50mg / L, control the pH to about 4.0, ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com