Preparation and application of dendriform TiO2-coating CdS hollow double-shell material

A technology of titanium dioxide and cadmium sulfide, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unstable catalyst performance and insufficient catalyst efficiency, so as to enhance photocatalytic performance and improve photocatalytic performance. Catalytic efficiency, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

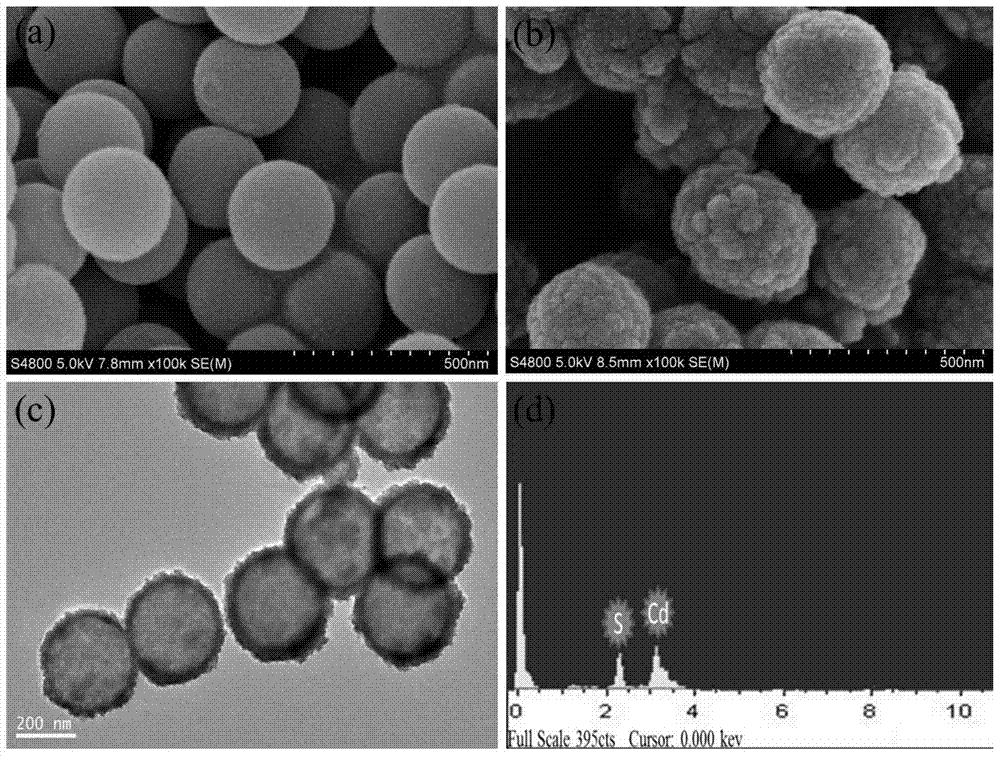

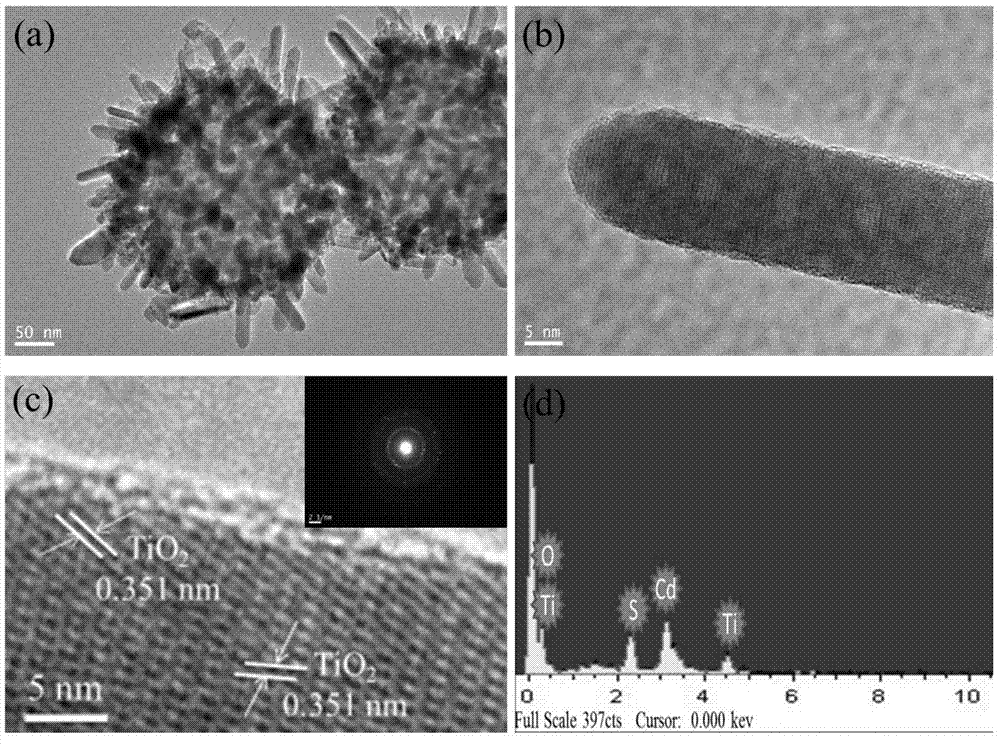

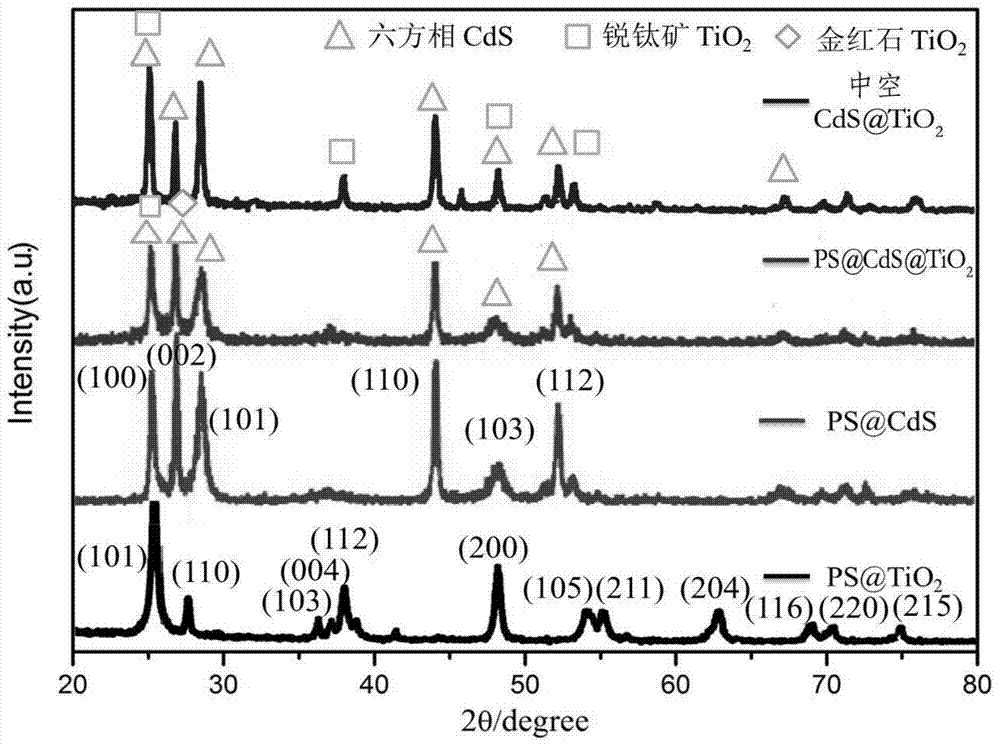

[0047] The preparation method of dendritic titanium dioxide coated cadmium sulfide hollow double-shell material is as follows:

[0048] (1) Polystyrene template (PS) was prepared, and a 500mL round-bottomed flask was heated in a 70°C water bath. Add deionized water 200mL, sodium bicarbonate (NaHCO 3 ) 0.0412g, sodium p-styrene sulfonate (SSS) 0.0412g and styrene (St) 19.59g. Nitrogen gas was introduced to remove the air in the reactor, and 0.288 g of potassium persulfate (KPS) was added, and the stirring rate was 200 r / min. After reacting for 15 hours, the reaction product was collected by cooling.

[0049] (2) Preparation of cadmium sulfide-coated polystyrene core-shell material. Take 1.2 mL of the prepared PS emulsion and dissolve it in 20 mL of ethanol, take it out after ultrasonication for 10 min, and add 0.2 g of polyvinylpyrrolidone PVP. Get 2.66g cadmium acetate (Cd(Ac) 2 2H 2 O) and 1.06 g of thioacetamide (TAA) were dissolved in 100 mL of deionized water and added...

Embodiment 2

[0056] The dendritic titania coated cadmium sulfide hollow double-shell material (dendritic CdSTiO 2 HDNPs) and dendritic titania-coated cadmium sulfide-coated polystyrene core-shell-shell materials (PSCdSTiO 2 ), cadmium sulfide-coated polystyrene core-shell material (PSCdS) and titanium dioxide-coated polystyrene core-shell material (PSTiO 2) to conduct 5mg / LRhB simulated printing and dyeing wastewater degradation experiments, using a 500W xenon lamp as a visible light source, fixed in a cylindrical glass reactor, cooled with circulating water and kept at 20-30°C. Use a cut-off filter to ensure that it is fully illuminated by visible light sources (>450nm). The average intensity of irradiation measured by a digital illuminance meter is 6.5×10 4 lux. Add 0.2 g of the prepared catalyst to 200 mL of 5 mg / L Sudan Red B (RhB) solution, and stir for 30 min in a dark place before light exposure to ensure that the adsorption-degradation equilibrium is reached. Start to illuminat...

Embodiment 3

[0059] The dendritic titania-coated cadmium sulfide hollow double-shell material prepared in the present invention was subjected to degradation experiments at different RhB concentrations of 5-15 mg / L. The specific steps were the same as in Example 2, and 5, 10, and 15 mg / L RhB simulated printing and dyeing wastewater were respectively configured for experimentation. The experimental results take C as the instant RhB concentration, Co as the initial RhB concentration, and C / C o Indicates the degree of degradation, and the experimental results are drawn as Image 6 shown.

[0060] It can be seen from the figure that the prepared dendritic titania-coated cadmium sulfide hollow double-shell material has treatment effects in the case of different concentrations of pollutants, and has better catalytic performance in the case of low concentration (5mg / L). This coincides with the fact that the photocatalytic method is suitable for treating low-concentration wastewater, and at the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| photodegradation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com