High temperature resistance anti-ultraviolet hydrophobic coating material and preparation method thereof

A hydrophobic coating and anti-ultraviolet technology, which is applied in the direction of coating, etc., can solve the problems of nano-titanium dioxide that do not take into account the degradation of coatings, and achieve good anti-ultraviolet performance, simple equipment and processes, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 10 parts of nano-titanium dioxide and 0.5 part of BYK180 to 100 parts of absolute ethanol, add 5mm zirconium beads, and disperse at a high speed in a sand mill disperser for 2 hours to obtain a dispersion of nano-titanium dioxide;

[0021] Mix the above dispersion with 100 parts of silicone, add 0.8 parts of curing agent at the same time, and continue to disperse into a uniform coating;

[0022] Coat the silicone / titanium dioxide coating on the glass sheet by spin coating, dry at 70°C for 1 min, cool to room temperature naturally, then spin coat a layer of titanium dioxide dispersion, and then place it in an oven at 70°C for drying.

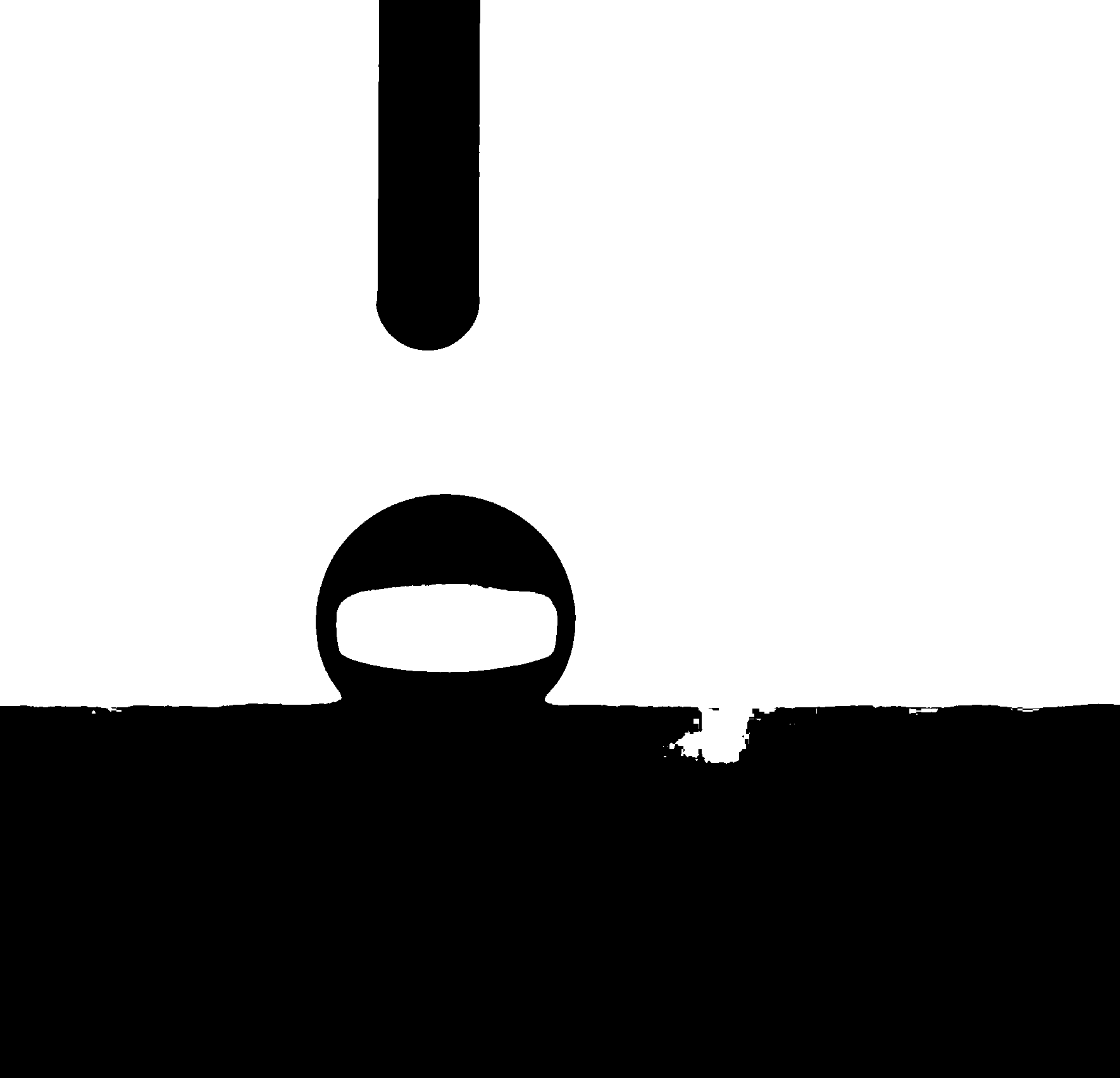

[0023] The prepared coating has good water-repellent performance. After continuous irradiation under ultraviolet light for 24 hours, and placed in a muffle furnace at 450°C for 3 hours, the surface does not change, and the performance remains unchanged.

Embodiment 2

[0025] Add 15 parts of nano-titanium dioxide and 0.8 parts of BYK180 to 100 parts of absolute ethanol, add 5mm zirconium beads, and disperse at a high speed in a sand mill disperser for 2.5 hours to obtain a dispersion of nano-titanium dioxide;

[0026] Mix the above dispersion with 100 parts of silicone, add 0.8 parts of curing agent at the same time, and continue to disperse into a uniform coating;

[0027] Apply the silicone / titanium dioxide coating on the glass sheet by spin coating, dry at 70°C for 1min, cool to room temperature naturally, then spin coat the titanium dioxide dispersion, repeat the coating of the titanium dioxide dispersion twice, and then place it in an oven at 70°C Dry in medium.

[0028] The prepared coating has good water-repellent performance. After continuous irradiation under ultraviolet light for 24 hours, and placed in a muffle furnace at 450°C for 3 hours, the surface does not change, and the performance remains unchanged.

Embodiment 3

[0030] Add 20 parts of nano-titanium dioxide, 1 part of BYK180 and 1 part of KH550 to 100 parts of absolute ethanol, add 5mm zirconium beads, and disperse at a high speed in a sand mill disperser for 2 hours to obtain a dispersion of nano-titanium dioxide;

[0031] Mix the above dispersion with 100 parts of silicone, add 0.8 parts of curing agent at the same time, and continue to disperse into a uniform coating;

[0032] Coat the silicone / titanium dioxide coating on the glass sheet by spin coating, dry at 70°C for 1 min, cool to room temperature naturally, then spin coat a layer of titanium dioxide dispersion, and then place it in an oven at 70°C for drying.

[0033] The prepared coating has good water-repellent performance. After continuous irradiation under ultraviolet light for 24 hours, and placed in a muffle furnace at 450°C for 3 hours, the surface does not change, and the performance remains unchanged.

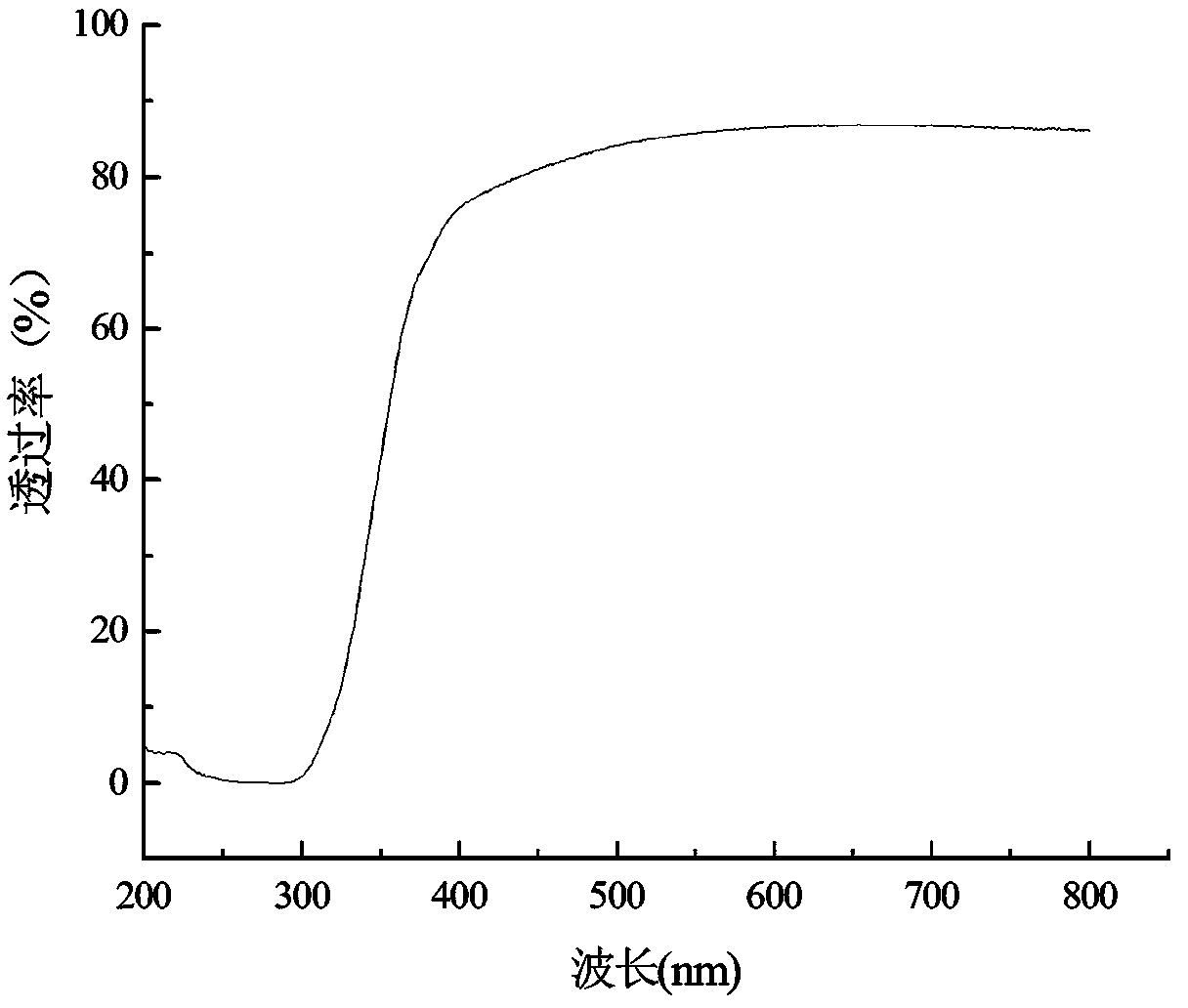

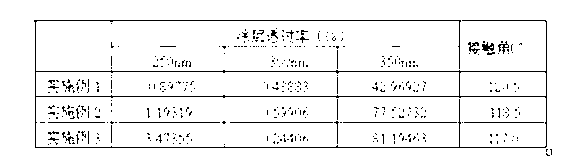

[0034] Table 1 UV transmittance and contact angle of the coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| UV shielding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com