Method for forming heteronitrogen nano TiO2 light catalytic activity coating on substrate

A nano-titanium dioxide, activator technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of non-photocatalytic materials, secondary pollution, and susceptible to photocorrosion environment, etc. High photocatalytic activity, firm material coating, simple and convenient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

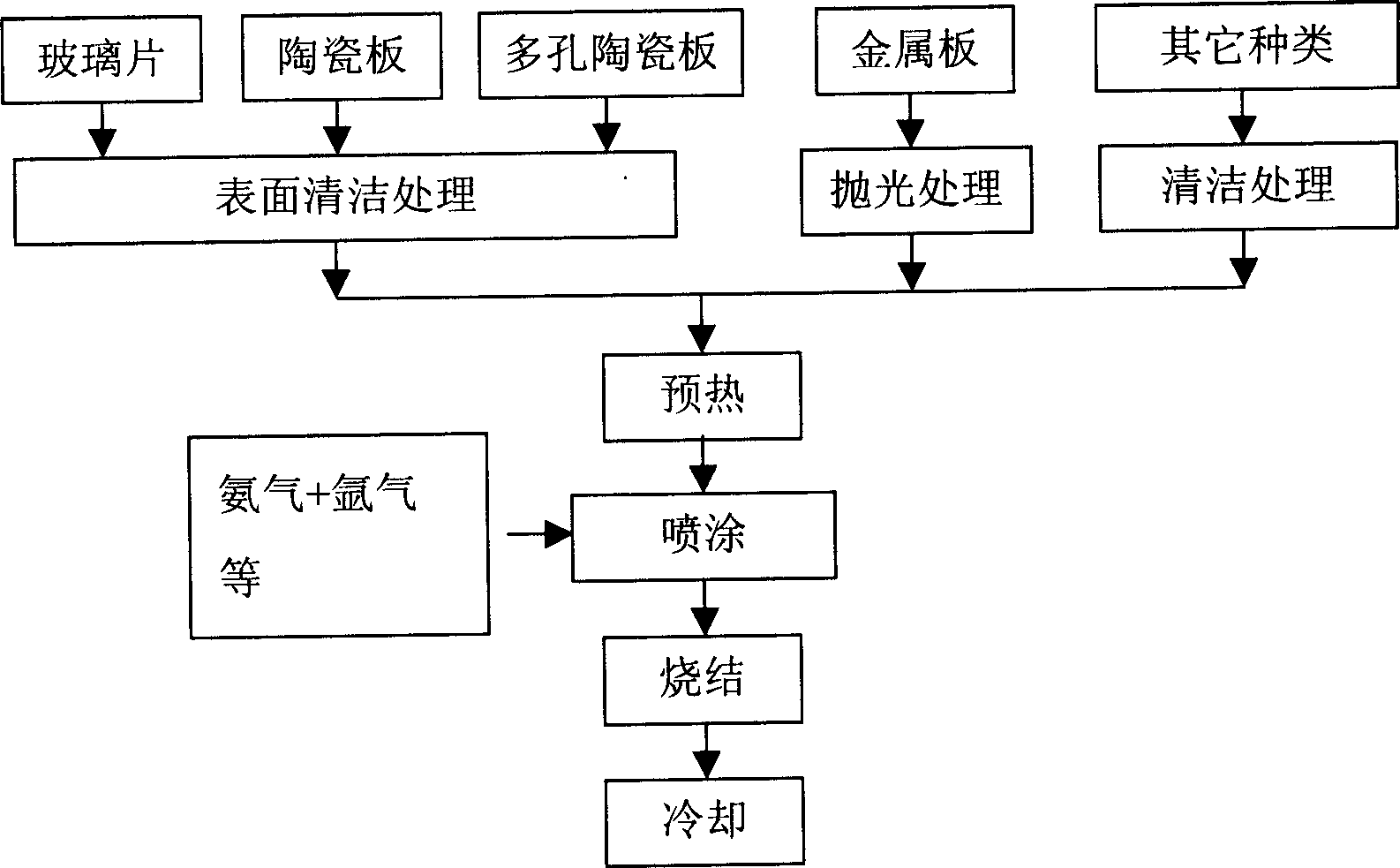

Method used

Image

Examples

Embodiment 1

[0033] First polish the side of the metal aluminum plate to be coated, then heat it to 500°C, keep the temperature for 3 hours, and use plasma spraying equipment to spray anatase phase nano-titanium dioxide powder with an average particle size of 52.0nm on the polished side , while doping with nitrogen, the doping ratio is about 1wt% (N / TiO 2 wt%). Among them, the spray gun is an internal powder-feeding spray gun, and the discharge form is DC discharge. The working gas used in spraying is a mixed gas of ammonia and argon, and the gas volume ratio is NH 3 / Ar=2:1, the pressure of the working gas is 0.5Mpa, the total gas flow is 40.0M 3 / h. Other parameters are: the power is 27.5kW, the powder feeding flow rate is 60g / min, the spray distance is 200mm, and the coating thickness is controlled at about 1.0μm. After spraying, keep the aluminum plate at a constant temperature of 300° C. for 2 hours, and cool it down to room temperature naturally to obtain a nitrogen-titanium diox...

Embodiment 2

[0035] Clean the glass sheet first, then heat it to 200°C, keep the temperature for 4 hours, use plasma spraying equipment to spray rutile phase nano-titanium dioxide powder with an average particle size of 80.0nm on the clean surface, and do nitrogen doping at the same time , the doping ratio is about 8wt% (N / TiO 2 wt%). Among them, the spray gun is an internal powder-feeding spray gun, and the discharge form is DC discharge. The working gas used in spraying is a mixed gas of ammonia and argon, and the gas volume ratio is NH 3 / Ar=1.5:1, the pressure of the working gas is 0.5Mpa, the total gas flow is 40.0M 3 / h. The powder feeding gas is argon. Other parameters are: spray distance 250mm, powder feeding flow rate 50g / min, power 25.0kW, control coating thickness about 0.8μm. After spraying, the glass sheet was kept at a temperature of 300°C for 3 hours, and then naturally cooled to room temperature. A coating coated with nitrogen nano-titanium dioxide can be obtained on ...

Embodiment 3

[0037] Clean the porous ceramic plate first, then heat it to 400° C., and after constant temperature for 2 hours, use plasma spraying equipment to spray it with anatase phase and rutile phase nano-titanium dioxide powder with an average particle size of 62.0 nm ( A / R=3 / 7), nitrogen doping is performed at the same time. The doping ratio is about 15wt% (N / TiO 2 wt%). Nitrogen (N 2 ) and argon (Ar) is the working gas, and the volume ratio of nitrogen to argon in the mixed gas is N 2 / Ar=1:1, the pressure of the working gas is 0.7Mpa, the total gas flow is 45.0M 3 / h, using argon as the powder feeding gas. Other parameters are: spray distance 200mm, powder feeding flow rate 30g / min, power 40.5kW, control coating thickness at about 1.0μm. After spraying, the porous ceramic plate was kept at a temperature of 400° C. for 2 hours, and then naturally cooled to room temperature. Under the operating frequency of the ultrasonic instrument at 20 Hz, the porous ceramic plate loaded wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com