Preparation method of TiO2 plated type PU (polyurethane) or TPU (thermoplastic polyurethane) film anti-drag micro groove for airship skin

A technology of micro-groove and thin film, which is applied in the field of airship skin material preparation, can solve the problems of poor heat insulation, poor weather resistance, large size, etc., and achieve the effect of dense coating, good protection effect and strong absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

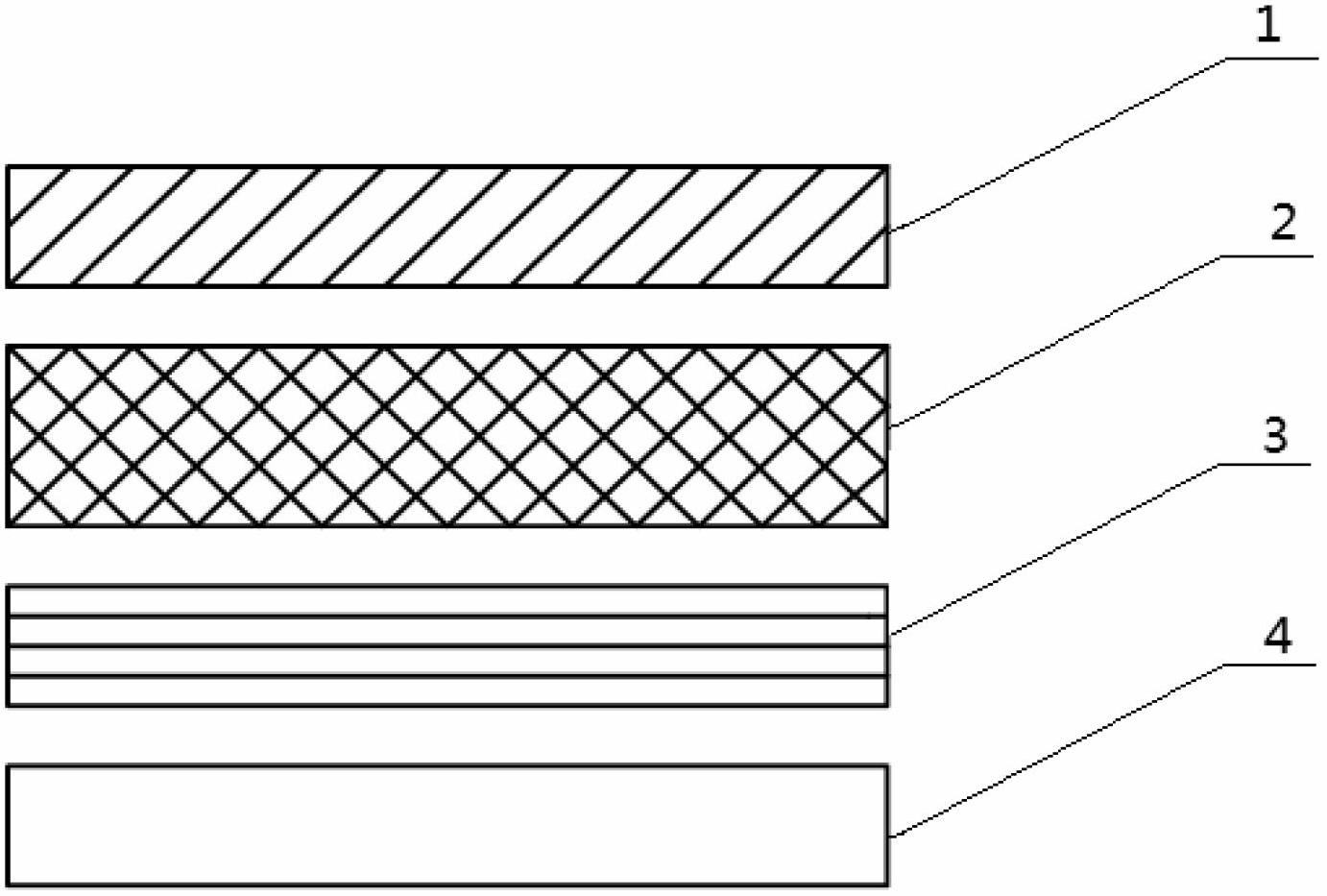

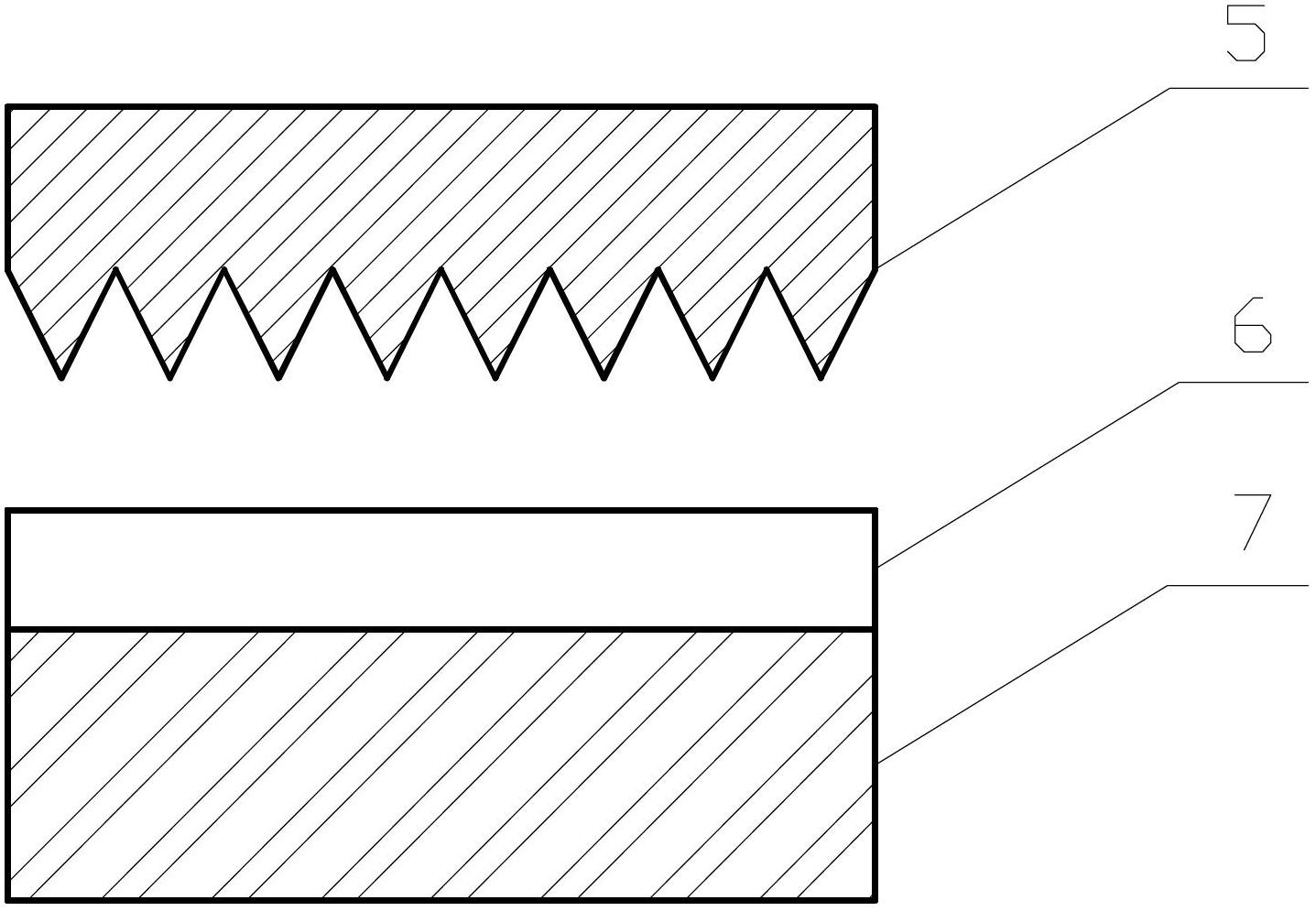

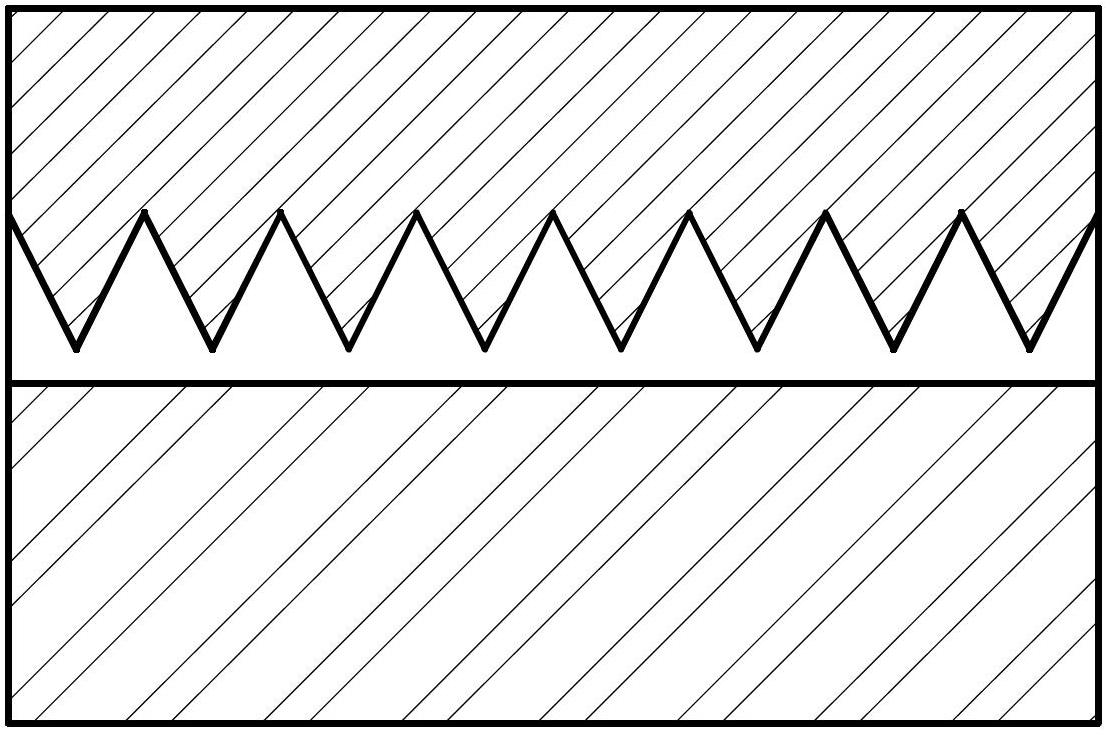

[0049] Specific embodiment 1: TiO plating for the skin of the airship in this embodiment 2 The preparation method of the drag-reducing micro-grooves of the PU or TPU film is carried out according to the following steps:

[0050] 1. Preparation of TiO 2 Sol precursor:

[0051] A, take by weighing tetrabutyl titanate, dehydrated alcohol, strong acid, deionized water and glacial acetic acid, wherein the ratio of the amount of material of tetrabutyl titanate, dehydrated alcohol, deionized water and glacial acetic acid is 1:10 : 3:1, the amount of tetrabutyl titanate and H in the strong acid + The ratio of the amount of the substance is 1: (0.6~1); the strong acid is concentrated hydrochloric acid, concentrated nitric acid or concentrated sulfuric acid;

[0052] b. Take two conical flasks, marked as A and B, divide the anhydrous ethanol measured in step a into 3 parts, 2 parts are placed in conical flask A, and 1 part is placed in conical flask B Then, the glacial acetic acid m...

specific Embodiment approach 2

[0064] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass fraction of concentrated hydrochloric acid in step a is 37.5%, the mass fraction of concentrated nitric acid is 65%, and the mass fraction of concentrated sulfuric acid is 70%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0065]Specific embodiment 3: This embodiment differs from specific embodiment 1 or 2 in that: the stirring in step b uses an electric stirrer, and the stirring speed is 150-180 r / min. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com