Flexible platinum formaldehyde room-temperature oxidation catalyst and preparation method thereof

An oxidation catalyst and formaldehyde technology, applied in the field of indoor air purification, can solve the problems of high equipment requirements, complex process, increased air resistance, etc., and achieve the effect of avoiding easy breaking, firm bonding and small air resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

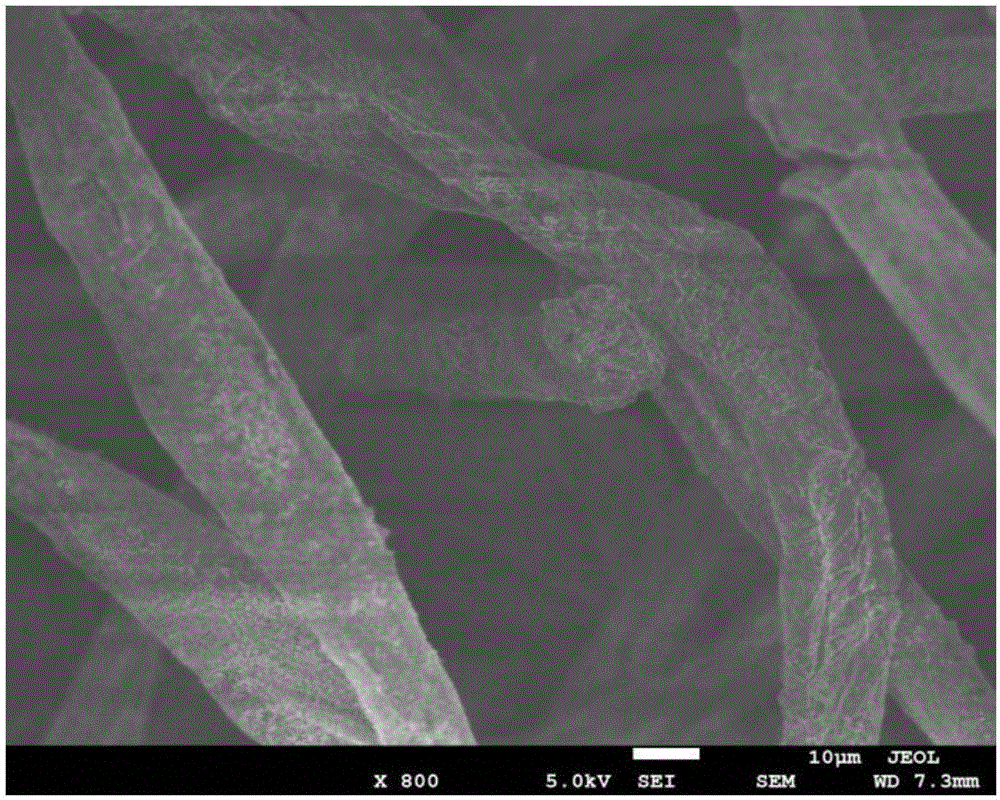

[0024] (1) First, dissolve butyl titanate in absolute ethanol, add acetylacetone, stir to form a transparent solution, then add dropwise to an acidic (pH = 2) aqueous solution containing 0.01% PVA, and stir for 6 days to obtain stability TiO 2 Sol, wherein the molar ratio of water, absolute ethanol, acetylacetone and butyl titanate is =100:2:0.5:0.5.

[0025] (2) Soak absorbent cotton in the TiO of step (1) 2 In the sol, soaking time is 5 min, in which absorbent cotton and TiO 2 The mass ratio is 1:2.0; o Dry at C for 5min, then at 115 o C for 30 min, then repeat the above process, but the drying temperature is 60 o C, with a drying time of 12 h, TiO 2 / Cotton fiber composite base material.

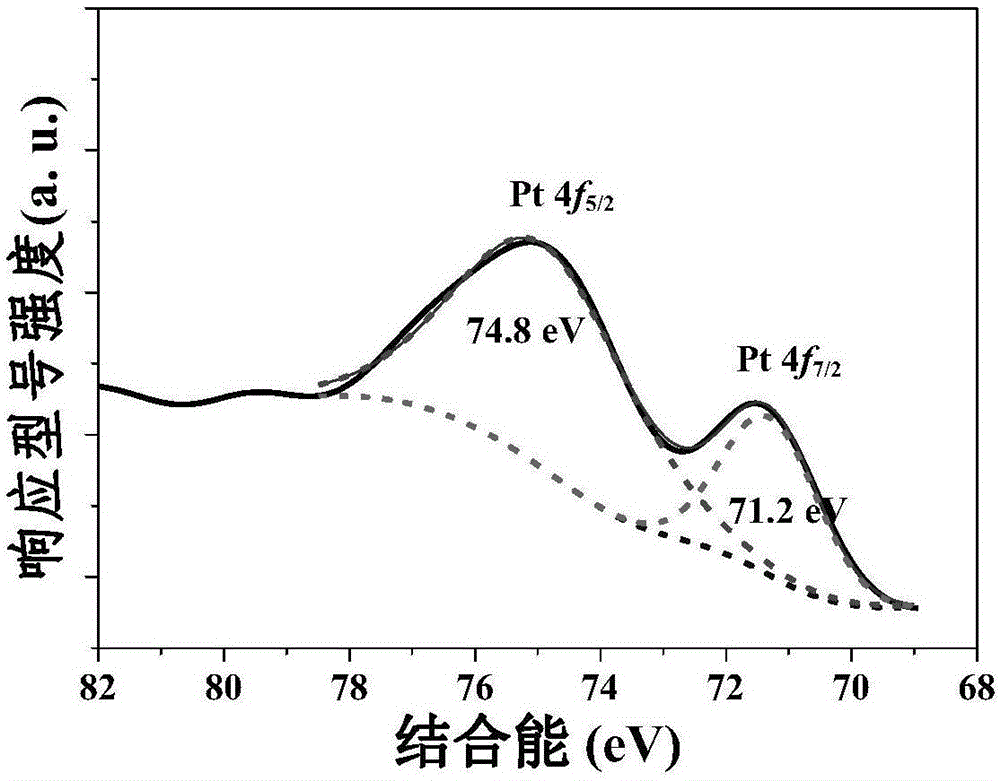

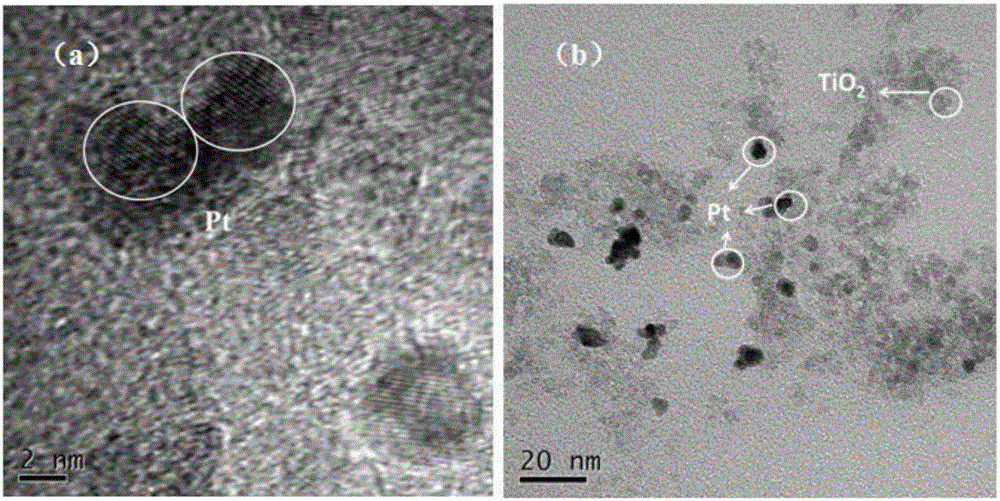

[0026] (3) Add the complexing agent trisodium citrate to the chloroplatinic acid solution, stir evenly, and mix the TiO obtained in step (2) 2 / Cotton fiber composite base material was dispersed in the above mixed solution and soaked for 5 min, wherein chloroplatinic acid was cal...

Embodiment 2

[0028] Preparation of embodiment 2 formaldehyde room temperature oxidation catalyst

[0029] (1) First, dissolve butyl titanate in absolute ethanol, add acetylacetone, stir to form a transparent solution, then add dropwise to an acidic (pH = 2.5) aqueous solution containing 0.05% PVA, and stir for 8 days to obtain a stable solution TiO 2 Sol, wherein the molar ratio of water, acid, absolute ethanol, acetylacetone and butyl titanate is =100:4:0.5:0.5.

[0030] (2) Soak absorbent cotton in the TiO of step (1) 2 In the sol, the soaking time is 5 min, in which cotton and TiO 2 The mass ratio is 1:2.5, after being separated by the filter screen, at 60 o Dry at C for 12 h to obtain TiO 2 / Cotton fiber composite base material.

[0031] (3) Add the complexing agent trisodium citrate to the chloroplatinic acid solution, stir evenly, and mix the TiO obtained in step (2) 2 / Cotton fiber composite base material was dispersed in the above mixed solution and soaked for 5 min, wherei...

Embodiment 3

[0032] Preparation of embodiment 3 formaldehyde room temperature oxidation catalyst

[0033] (1) First, dissolve butyl titanate in absolute ethanol, add acetylacetone, stir to form a transparent solution, then add dropwise to an acidic (pH = 3) aqueous solution containing 0.01% PVA, and stir for 4 days to obtain stability TiO 2 Sol, wherein the molar ratio of water, absolute ethanol, acetylacetone and butyl titanate is =100:2:0.1:0.1.

[0034] (2) Soak absorbent cotton in TiO 2 In the sol, the soaking time is 5 min, in which cotton and TiO 2 The mass ratio is 1:2, after being separated by the filter screen, at 80 o C, with a drying time of 10 h, TiO 2 / Cotton fiber composite base material.

[0035] (3) Add the complexing agent trisodium citrate to the chloroplatinic acid solution, stir evenly, and mix the TiO obtained in step (2) 2 / Cotton fiber composite base material was dispersed in the above mixed solution and soaked for 5 min, wherein chloroplatinic acid was calcu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com