Method for preparing carbon fiber surface densified sintering TiO2 coating

A carbon fiber and densification technology, applied in the field of materials, can solve the problems of high temperature anti-oxidation performance discount, and achieve the effect of improving high-temperature anti-oxidation performance and avoiding interface reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

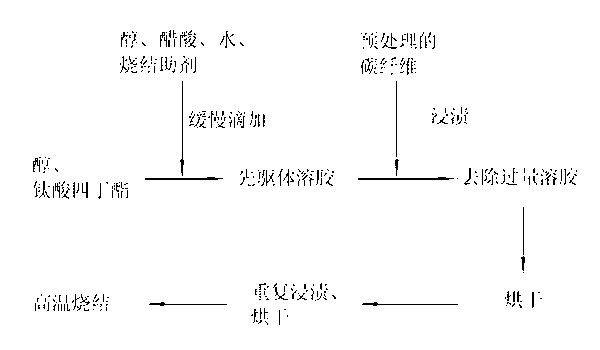

[0024] Example 1: figure 1 As shown, the carbon fiber surface densified and sintered TiO 2 The process steps of the coating method are described below.

[0025] (1) Soak carbon fibers (Lanzhou Carbon Plant, fiber diameter 10 μm) in acetone for 1 hour, rinse with deionized water, and dry at 80°C to obtain pretreated carbon fibers;

[0026] (2) Take 10mL of tetrabutyl titanate and 60mL of ethanol and mix them evenly to obtain a titanium source solution;

[0027] (3) Take 10mL of water, 60mL of ethanol and 0.5g of copper sulfate (5.18% of the mass of tetrabutyl titanate) and mix evenly, add acetic acid to adjust the pH of the solution to 2.5; then slowly drop it into the titanium source solution under stirring to obtain Precursor solution;

[0028] (4) Immerse the pretreated carbon fiber in the precursor solution for 0.5h under vacuum conditions, take out the carbon fiber, centrifuge to remove the excess precursor solution on the surface of the carbon fiber, and then dry it at...

Embodiment 2

[0031] Example 2: Densified and sintered TiO on the surface of the carbon fiber 2 The process steps of the coating method are described below.

[0032] (1) Take carbon fiber (Lanzhou Carbon Factory, fiber diameter 10μm,) and treat it with gas phase oxidation method to obtain pretreated carbon fiber;

[0033] (2) Take 10mL of tetraethyl titanate and 40mL of ethanol and mix evenly to obtain a titanium source solution;

[0034](3) Take 10mL of water, 30mL of butanol, 30mL of isopropanol and 0.2g of cobalt sulfate (1.8% of the mass of tetraethyl titanate) and mix evenly, add formic acid to adjust the pH of the solution to 2; then slowly drop it into In the titanium source solution, a precursor solution is obtained;

[0035] (4) Immerse the pretreated carbon fiber in the precursor solution for 60 minutes under vacuum conditions, take out the carbon fiber, centrifuge to remove the excess precursor solution on the surface of the carbon fiber, and then dry it at 100°C for 2 hours; r...

Embodiment 3

[0038] Example 3: Densified and sintered TiO on the surface of the carbon fiber 2 The process steps of the coating method are described below.

[0039] (1) Soak carbon fibers (TORAY, T-300B, Japan) in dilute nitric acid for 1 hour, rinse with deionized water, and dry at 80°C to obtain pretreated carbon fibers;

[0040] (2) Mix 10 mL of tetrabutyl titanate and 40 mL of methanol evenly to obtain a titanium source solution;

[0041] (3) Take 8mL of water, 20mL of methanol and 1g of sodium sulfate (10.35% of the mass of tetrabutyl titanate) and mix evenly, add acetic acid to adjust the pH of the solution to 3; then slowly drop it into the titanium source solution under stirring to obtain the precursor body solution;

[0042] (4) Immerse the pretreated carbon fiber in the precursor solution for 0.5 h under ultrasonic oscillation, take out the carbon fiber, mechanically squeeze to remove the excess precursor solution on the surface of the carbon fiber, and then dry it at 100°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com