Micropore ceramic catalyst and preparation method thereof

A technology of microporous ceramics and catalysts, applied in the field of microporous ceramic catalysts and their preparation, can solve the problems of high proportion of PM2.5, difficult filtration, large gaps, etc., and achieve the effect of high SCR catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

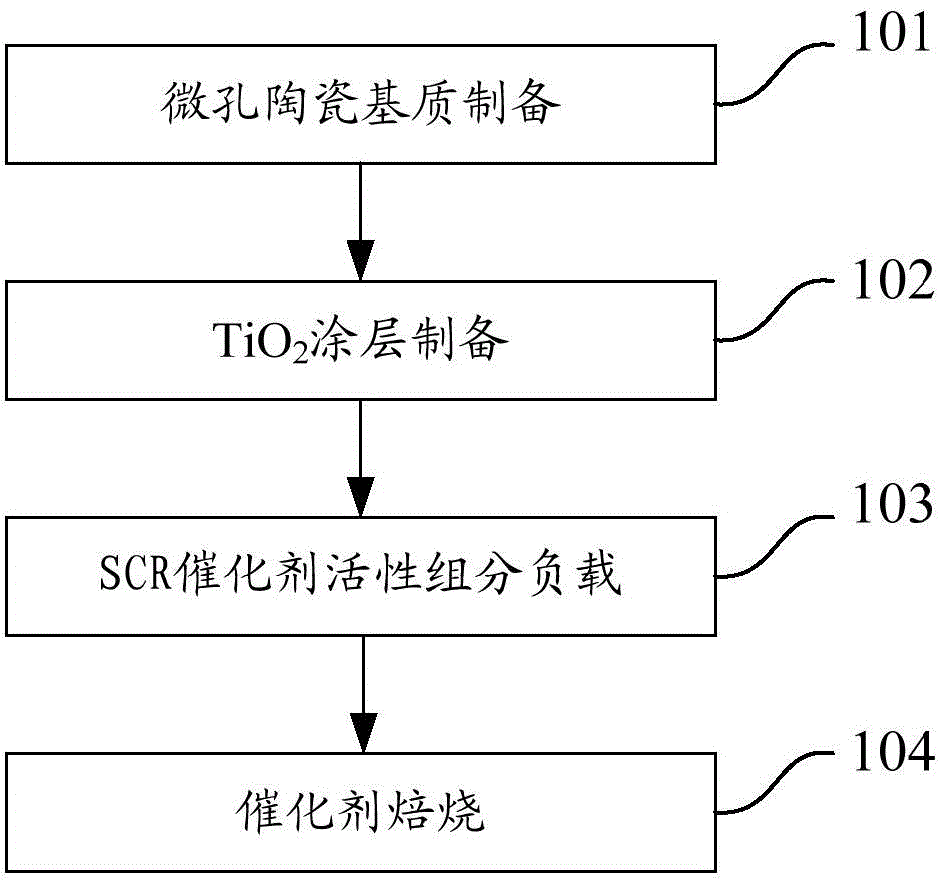

[0037] see figure 1 , a preparation method of microporous ceramic catalyst, comprising the following steps:

[0038] S101: Preparation of Microporous Ceramic Matrix

[0039] Select SiC, SiO 2 、Al 2 o 3 At least one of the materials is aggregate, then doped with a binder and a pore-forming agent, and prepared into a plate-type microporous ceramic through sintering to obtain a microporous ceramic matrix;

[0040] S102: TiO 2 coating preparation

[0041] Tetrabutyl titanate Ti(OC 4 o 9 ) 4 As raw material, ethanol as solvent, acetylacetone as complexing agent to prepare TiO 2 Sol, TiO prepared on microporous ceramic surfaces by the LBL (layer-by-layer self-assembly) method 2 Coating, drying and calcining to obtain a microporous SCR catalyst carrier;

[0042] S103: SCR catalyst active component loading

[0043] The catalyst active component is supported on the surface of the microporous SCR carrier by the solution impregnation method to obtain a microporous ceramic loa...

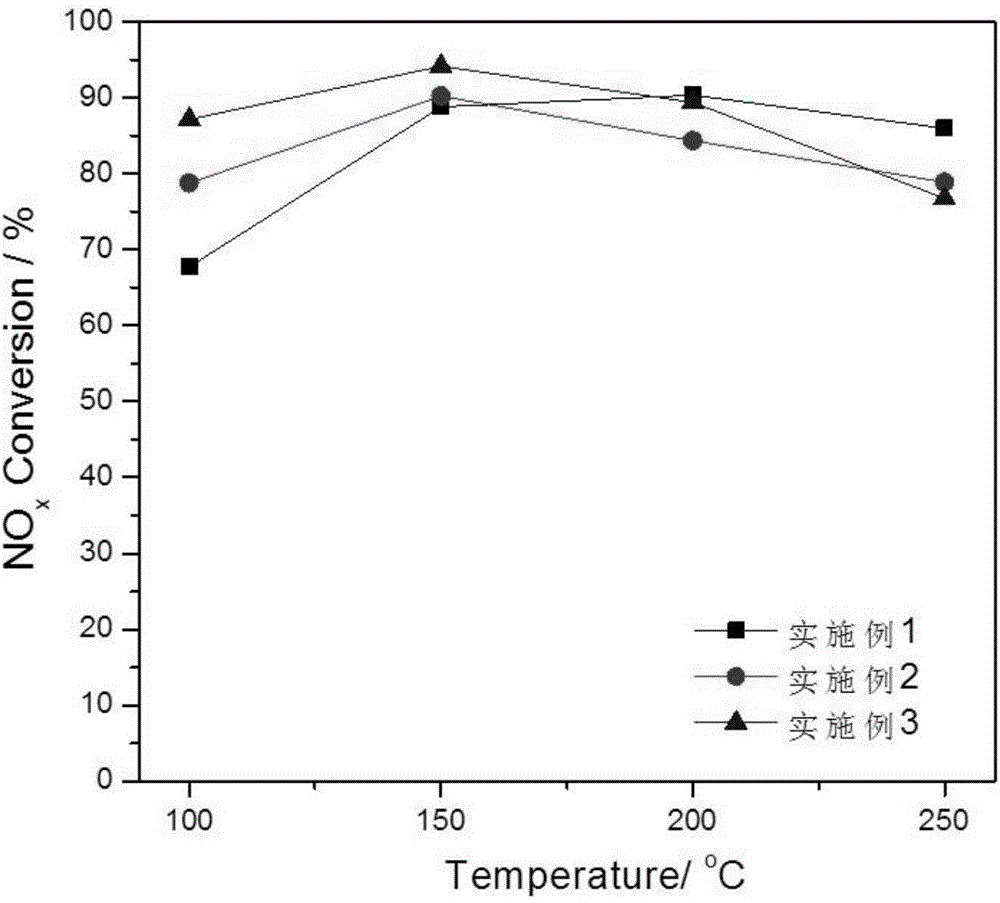

Embodiment 1

[0049] A preparation method of microporous ceramic catalyst: comprising the following steps:

[0050] (1) Preparation of microporous ceramic matrix

[0051] SiC:SiO with a mass ratio of 1:1:1 2 :Al 2 o 3 The mixture is aggregate, doped with sodium hydroxymethylcellulose (accounting for 1% of the total mass of the aggregate), oleic acid (accounting for 3% of the total mass of the aggregate), monoethanolamine (accounting for 1% of the total mass of the aggregate), Carbon black and methyl methacrylate-styrene copolymer (accounting for 8% of the total aggregate mass, carbon black: methyl methacrylate-styrene copolymer = 1:1) or sintered at 1150 ° C to prepare a plate Microporous ceramics, obtaining a microporous ceramic matrix;

[0052] (2)TiO 2 coating preparation

[0053] Weigh tetrabutyl titanate Ti(OC 4 o 9 ) 4 , ethanol as a solvent, the molar ratio of ethanol to tetrabutyl titanate is 9:1, add complexing agent acetylacetone (the molar ratio of acetylacetone: tetrabu...

Embodiment 2

[0059] (1) Preparation of microporous ceramic matrix

[0060] Select SiC as the aggregate, doped with silicone (accounting for 2% of the total mass of the aggregate), oleic acid (accounting for 3% of the total mass of the aggregate), carbon black and polystyrene microspheres (accounting for 5% of the total mass of the aggregate, Carbon black: polystyrene microsphere mass ratio = 3:1), after sintering at a high temperature of 1000 ° C, it is prepared into plate-type microporous ceramics, and a microporous ceramic matrix is obtained;

[0061] (2)TiO 2 coating preparation

[0062] Tetrabutyl titanate Ti(OC 4 o 9 ) 4 As a raw material, a mixture of ethanol and water is used as a solvent (solvent: tetrabutyl titanate molar ratio=6:1, and the volume ratio of ethanol and water is 8:1), and acetylacetone is used as a complexing agent (acetylacetone: titanic acid Tetrabutyl molar ratio=1:1), and inhibitor citric acid solution (citric acid: tetrabutyl titanate molar ratio=1:5), p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com