Wear-resisting flame-retardant polyvinyl chloride insulation and sheathing materials

A technology of flame retardant polyvinyl chloride and sheath material, which is applied in the direction of insulated conductors, insulated cables, organic insulators, etc., can solve the problems of low content of flame retardants and lubricants, poor comprehensive performance of products, and high production costs, and achieve good The effect of softness, excellent wear resistance and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

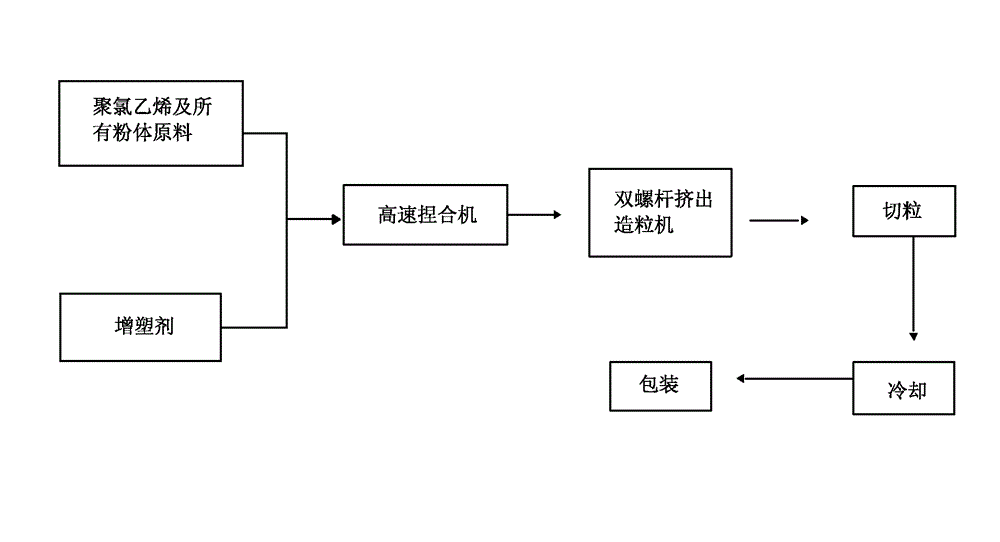

Method used

Image

Examples

Embodiment 1

[0051] Ingredient parts by weight

[0052] Polyvinyl chloride resin (polymerization degree 1000) 100

[0053] Diisononyl phthalate (DINP) 40

[0054] Chlorinated polyethylene (CPE135) 12.5

[0055] Calcium Zinc Composite Stabilizer 4.5

[0057] Magnesium hydroxide 12.5

[0058] Light calcium carbonate 10

[0059] Ground calcium carbonate 20

[0061] Polyethylene wax 0.5.

Embodiment 2

[0063] Ingredient parts by weight

[0064] Polyvinyl chloride resin (polymerization degree 1300) 75

[0065] Polyvinyl chloride resin (polymerization degree 1800) 25

[0066] Di(2-propylheptyl)phthalate (DPHP) 45

[0067] Nitrile rubber P83 7.5

[0068] Barium Zinc Composite Stabilizer 5

[0071] Aluminum hydroxide 7.5

[0072] Light calcium carbonate 12.5

[0073] Ground calcium carbonate 22.5

[0075] Polyethylene wax 0.6.

Embodiment 3

[0077] Ingredient parts by weight

[0078] Polyvinyl chloride resin (polymerization degree 1800) 100

[0079] Trioctyl trimellitate (TOTM) 52

[0080] Chlorinated polyethylene (CPE135) 5

[0081] Silica 25

[0082] Calcium zinc compound stabilizer 7.5

[0084] Magnesium hydroxide 5

[0085] Aluminum hydroxide 7.5

[0086] Ground calcium carbonate 25

[0087] Butyl stearate 1

[0088] Stearic acid 0.4

[0089] Polyethylene wax 0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com