Novel cable used in electromobile and preparation method of cable

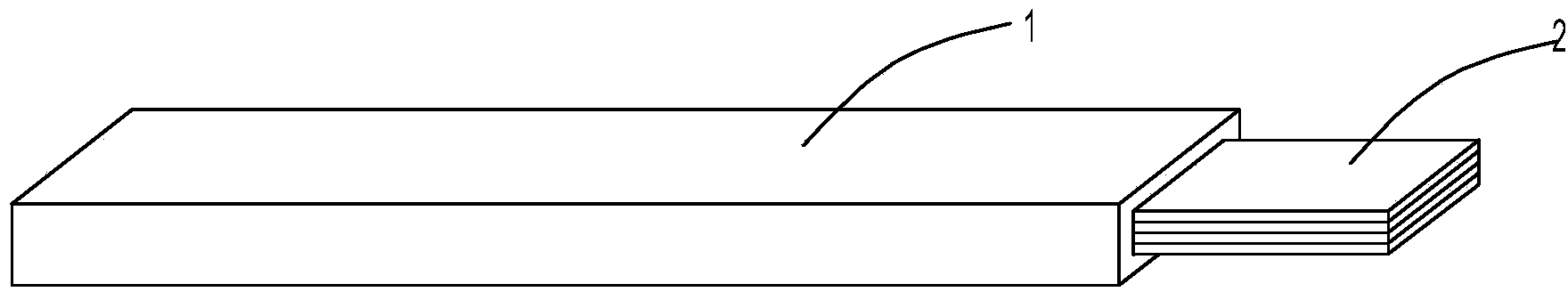

An electric vehicle, a new type of technology, used in power cables, cable/conductor manufacturing, insulated cables, etc., can solve the problems of large size, low longitudinal tear resistance, and large space occupation of circular cables, so as to improve the scope of use. , the production method is simple, the effect of large current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Its a kind of preparation method of electric vehicle internal cable comprises the following steps:

[0036] (1) Use copper material to process a single flat square copper strip conductor that meets the size requirements, and process it into a thickness: 0.1-1.0mm, and a width: 10-50mm.

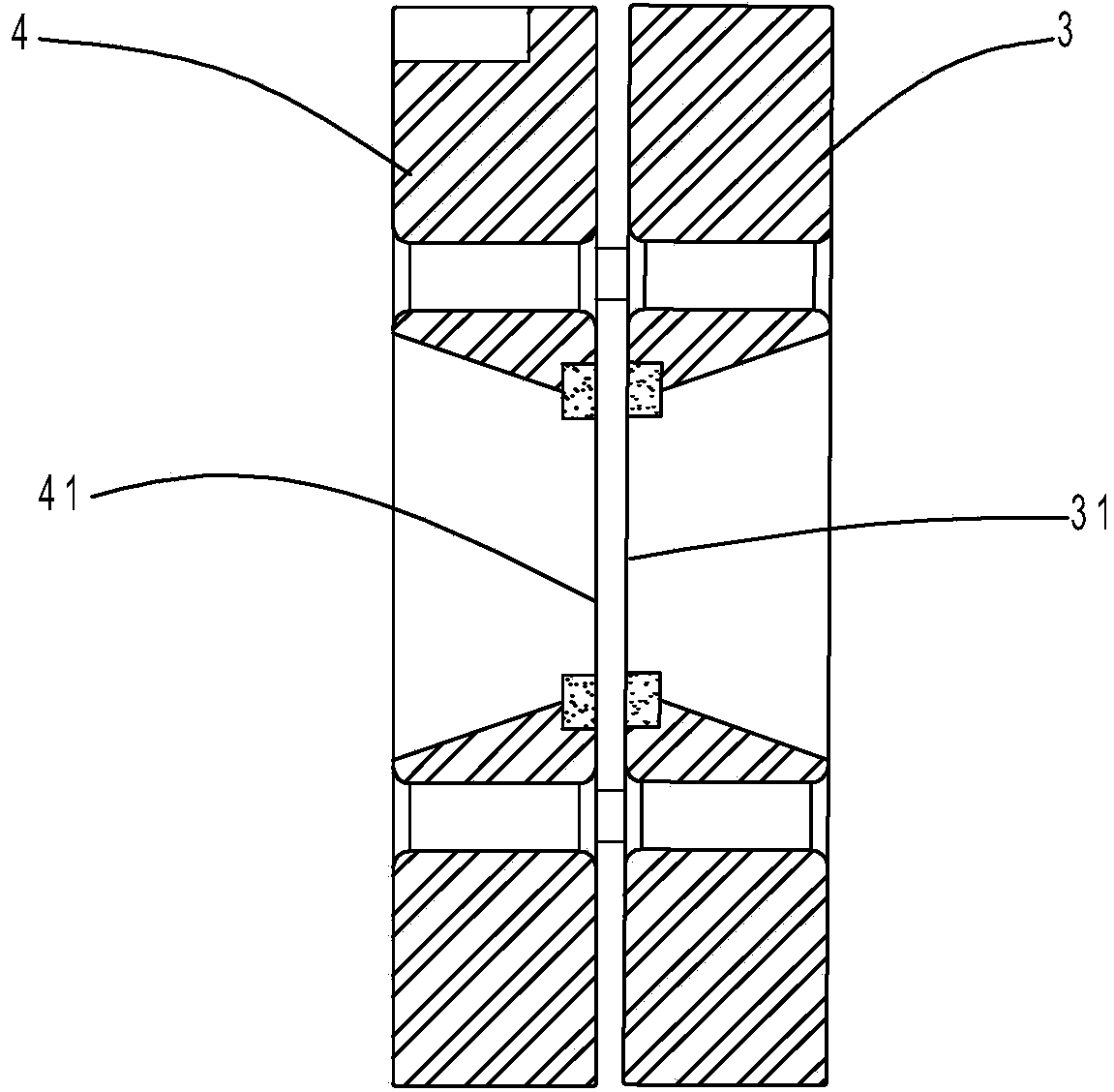

[0037] (2) Pull out the required number of flat square copper strip conductors through a tension-controlled pay-off frame and overlap them neatly together. To ensure that the stacks are neat, they are extruded through a special inner mold and outer mold. The extruder out of the mold is extruded at a temperature of 135-165 degrees and a speed of 30-80 m / min. At the same time, the crawler tractor is used to draw out the extruded wire body.

[0038] (3) The 150° C. crosslinked polyolefin insulation of the insulating layer is irradiated and crosslinked by using a crosslinking dose of 12 to 18 MRD and using an electron beam physical crosslinking method.

Embodiment 1

[0040] Now take three flat square copper strips, the size of a single copper strip is 0.8mm thick and 30mm wide as an example:

[0041] (1) Use copper material to process a single flat square copper strip conductor that meets the size requirements, and process it into a thickness of 0.8mm and a width of 30mm.

[0042] (2) Pull out three flat square copper strip conductors through a tension-controlled pay-off frame and overlap them neatly together. To ensure that the stacks are neat, they are extruded through an extrusion die that is equipped with a special inner mold and an outer mold. The extruder is extruded at a temperature of 135-165 degrees and a speed of 30-80 m / min. At the same time, the crawler tractor is used to draw out the extruded wire body.

[0043] (3) The 150° C. crosslinked polyolefin insulation of the insulating layer is irradiated and crosslinked by using a crosslinking dose of 12 to 18 MRD and using an electron beam physical crosslinking method.

[0044] De...

Embodiment 2

[0049] Taking 20 flat square copper strips as an example, the size of a single copper strip is 0.1mm thick and 18mm wide:

[0050] (1) Use copper material to process a single flat square copper strip conductor that meets the size requirements, and process it into a thickness of 0.1mm and a width of 18mm.

[0051] (2) Pull out 20 flat square copper strip conductors through a tension-controlled pay-off stand and overlap them up and down neatly to ensure that the layers are neat, and then pass through the extruding mold with a special inner mold and outer mold. The extruder extrudes at a temperature of 135-165 degrees and a speed of 30-80 m / min, and at the same time uses a crawler tractor to draw out the extruded wire body.

[0052] (3) The 150° C. crosslinked polyolefin insulation of the insulating layer is irradiated and crosslinked by using a crosslinking dose of 12 to 18 MRD and using an electron beam physical crosslinking method.

[0053] During production, the height of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com