Antibiotic-mould proof textile fabric and method for preparing same

An antibacterial and mildew-proof, textile technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of poor washability and antibacterial effect durability, affecting the physical properties of textiles, and hidden health and safety hazards, so as to improve hydrophilicity and long-lasting Efficient antibacterial, anti-mildew and deodorant performance, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

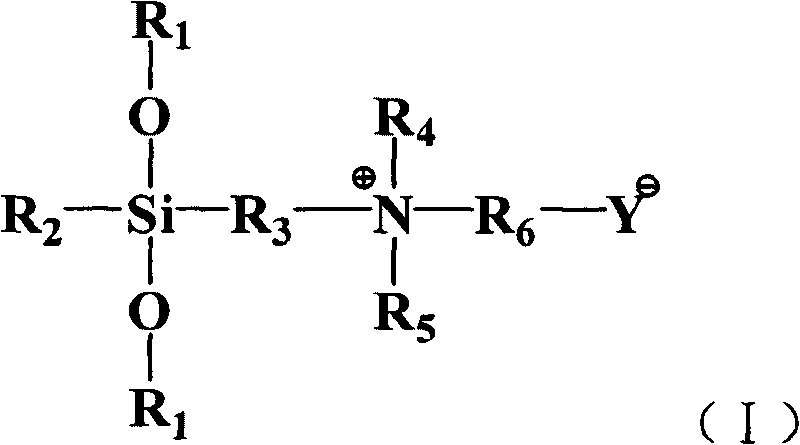

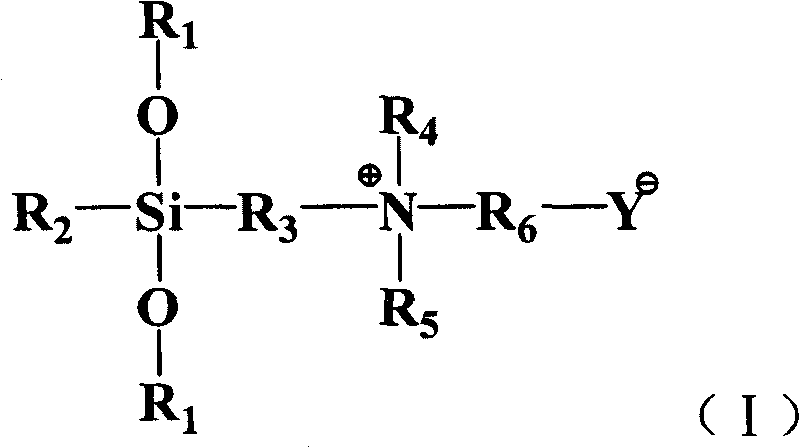

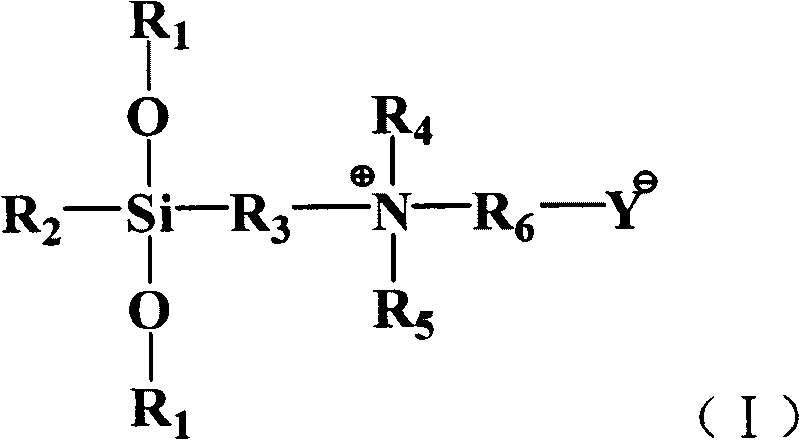

[0056] The preparation method of this organic silicon betaine is:

[0057] 1) Preparation of tertiary amine-containing organosiloxane, and reacting the tertiary amine-containing organosiloxane with reactant B for 1-48 hours under stirring in an environment at a temperature of 20-80°C to obtain a white Precipitation matter;

[0058] 2) filtering or centrifuging the above-mentioned white precipitated substance to obtain organosilicon betaine, that is, to obtain the target product;

[0059] Above-mentioned reactant B is selected from propane sultone, butane sultone, acrylic acid, β-propionolactone, X(CH 2 ) v SO 3 - , or X(CH 2 ) v CO 2 - One of, wherein X is Br, Cl or I, and v is a positive integer greater than or equal to 1.

[0060] The typical synthetic route diagram of above-mentioned preparation method is:

[0061]

[0062] In the above-mentioned preparation steps, wherein the preparation method of the organosiloxane containing tertiary amine is: take (R 1 O) ...

Embodiment 1

[0086] (1) Configuration (mass ratio) of antibacterial finishing solution:

[0087] Silicone sulfonate betaine, 20.0%

[0088] The structural formula is as follows: (CH 3 CH 2 O) 3 Si(CH 2 ) 3 + N(CH 3 ) 2 (CH 2 ) 3 SO 3 -

[0089] Ethanol: 80.0%;

[0090] The bath ratio of the sample to the finishing solution is 1:30;

[0091] (2) Immerse the textile to be treated in the above-mentioned antibacterial finishing solution for 10 minutes;

[0092] (3) drying the textiles processed in step (2) at 120°C;

[0093] (4) After the sample obtained in step (3) is washed, shaped and dried, a durable antibacterial, mildew-proof and moisturizing textile is obtained.

[0094] Its antibacterial performance, hydrophilicity, water content and mechanical properties are shown in attached table 1 and table 2.

Embodiment 2

[0096] (1) Configuration (mass ratio) of antibacterial finishing solution:

[0097] Silicone sulfonate betaine, 5.0%

[0098] The structural formula is as follows: (CH 3 CH 2 O) 3 SiCH 2 + N(CH 2 CH 3 ) 2 (CH 2 ) 3 SO 3 -

[0099] Ethyl acetate: 95.0%;

[0100] The bath ratio of the sample to the finishing solution is 1:50;

[0101] (2) Immerse the textile to be treated in the above-mentioned antibacterial finishing solution for 20 seconds;

[0102] (3) naturally drying the textiles processed in step (2) at room temperature;

[0103] (4) Immerse the sample obtained in step (3) in the above-mentioned antibacterial finishing solution for 20 seconds again;

[0104] (5) After the sample obtained in step (4) is washed, shaped and dried, a durable antibacterial, mildew-proof and moisturizing textile is obtained.

[0105] Its antibacterial performance, hydrophilicity, water content, moisture permeability and mechanical properties are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com