Waterborne polyurethane-MXene electromagnetic shielding bionic nanocomposite material film and preparation method

A water-based polyurethane and composite film technology, applied in the field of electromagnetic shielding materials, can solve problems such as poor mechanical properties and flexibility, and cannot be applied, and achieve the effects of broad application, diverse preparation methods, and controllable thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1. Synthesis of WPU: Dry PTMEG (Mn=1000) in a vacuum oven at 100° C. for 10 h, take 0.020 mol of dried PTMEG and add it to a dry there-necked flask equipped with a mechanical stirring device, and set the stirrer speed to 100 rpm. Then 0.046mol of HDI was added dropwise, and the temperature was raised to 80°C for 3.5h; 0.0234mol of DMBA was dissolved in 5mL of anhydrous DMF, then added to the reaction system, and reacted at 80°C for 2.5h; the temperature of the system was lowered to 40°C, followed by Add 0.0234 mol of triethylamine, react for 15 minutes, adjust the stirring speed to 3000 rpm, add 75 mL of deionized water, emulsify and disperse for 20 minutes, and obtain WPU emulsion.

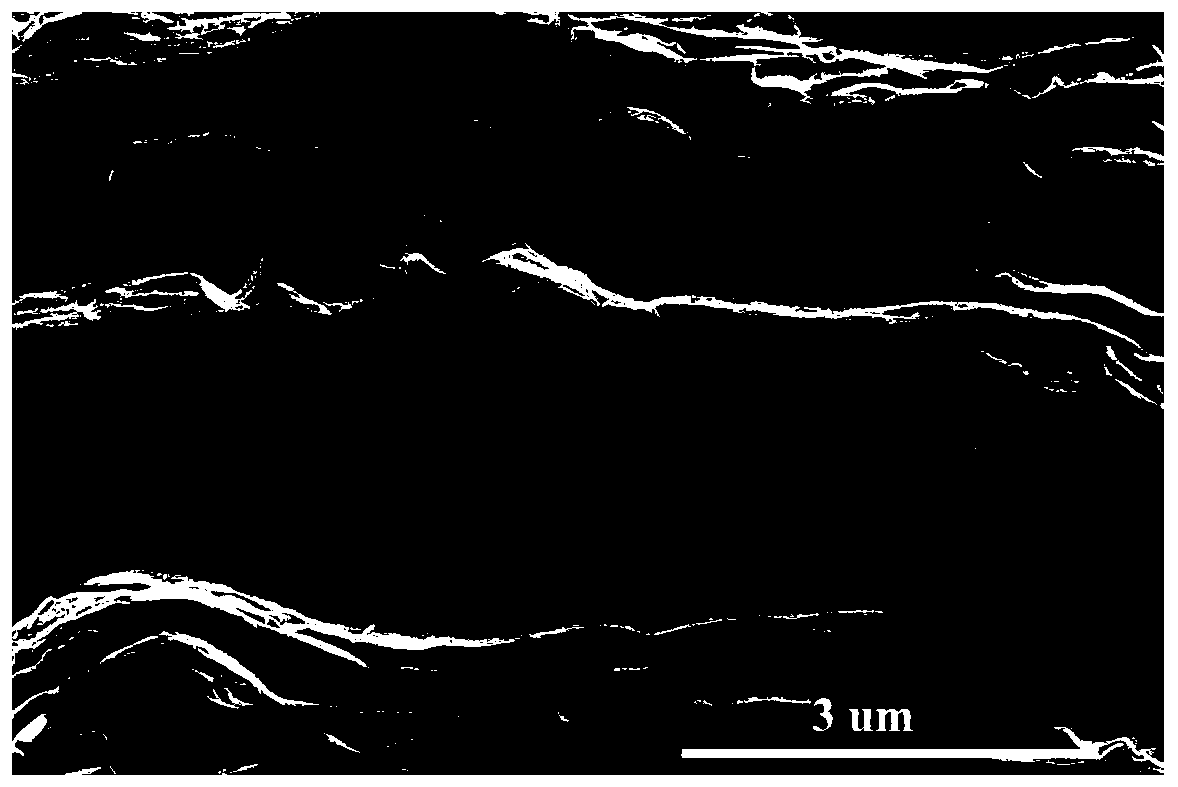

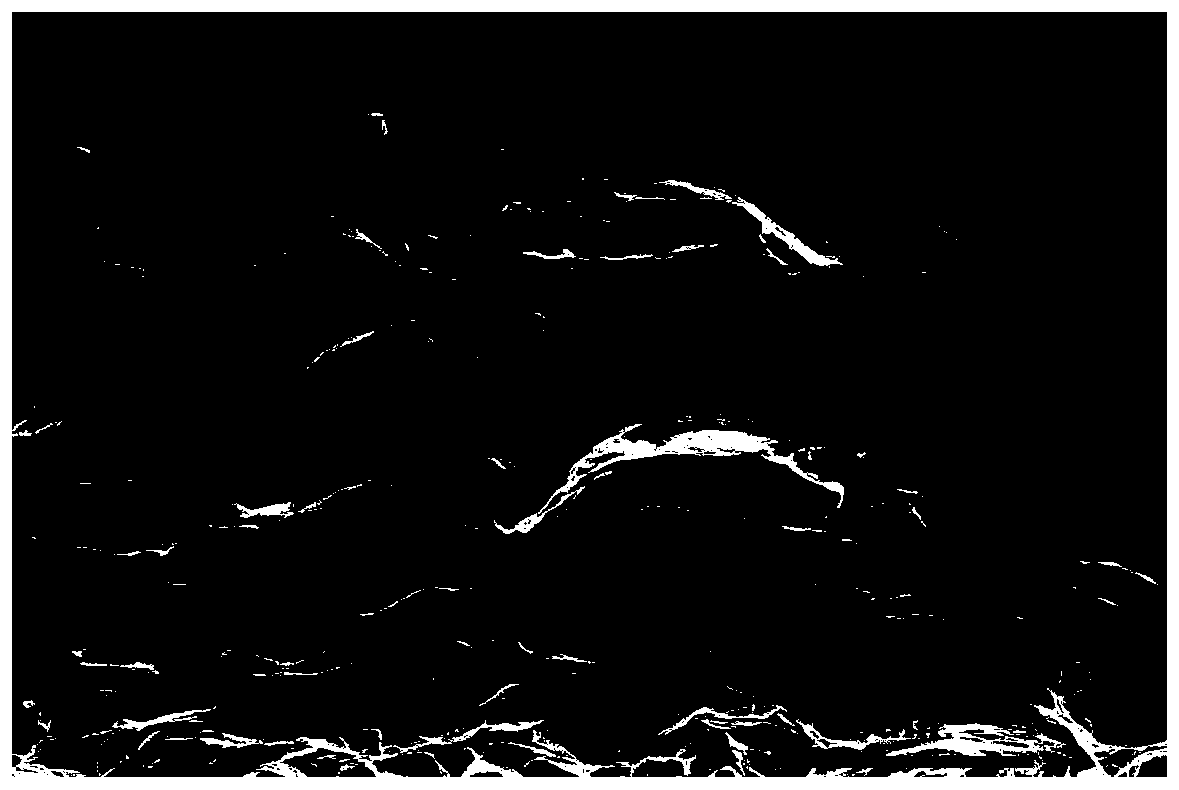

[0035] Step 2. Preparation of WPU-MXene composite dispersion: Dilute WPU with deionized water into an emulsion with a mass fraction of 0.3%; then add Ti 3 C 2 T x MXene was formulated into an aqueous dispersion with a mass fraction of 0.6%; the WPU and Ti 3 C 2 T x The mass rat...

Embodiment 2

[0037] Embodiment 2: the synthesis of the WPU of step 1 is replaced with following:

[0038] Step 1. Synthesis of WPU: Dry PTMEG (Mn=2000) in a vacuum oven at 110° C. for 10 h, take 0.020 mol of dried PTMEG and add it to a dry three-necked flask equipped with a mechanical stirring device, and set the stirrer speed to 100 rpm. Then add 0.04mol of TDI dropwise, raise the temperature to 65°C for 2 hours; dissolve 0.02mol of DMPA in 5mL of anhydrous DMF, then add to the reaction system, react at 70°C for 2h; cool the system to 40°C, then add 0.018 mol of triethylamine, after reacting for 15 minutes, adjust the stirring speed to 2000 rpm, add 75 mL of deionized water to it, and emulsify and disperse for 30 minutes to obtain WPU emulsion.

Embodiment 3

[0039] Embodiment 3: the synthesis of the WPU of step 1 is replaced with following:

[0040] Dry PTMEG (Mn=650) in a vacuum oven at 90°C for 12 hours, take 0.020 mol of dried PTMEG and add it to a dry three-necked flask equipped with a mechanical stirring device, set the stirrer speed to 100 rpm, and then dropwise add 0.03 mol of IPDI , the temperature was raised to 80°C for 3 hours; 0.012mol of DMBA was dissolved in 5mL of anhydrous NMP, then added to the reaction system, and reacted for 3h at 85°C; the temperature of the system was lowered to 30°C, and then 0.013mol of triethanolamine was added to react After 30 minutes, the stirring speed was adjusted to 3000 rpm, 75 mL of deionized water was added thereto, emulsified and dispersed for 20 minutes, and WPU emulsion was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com